2/53 IMET - M550 ALL1-EN

CONTENTS

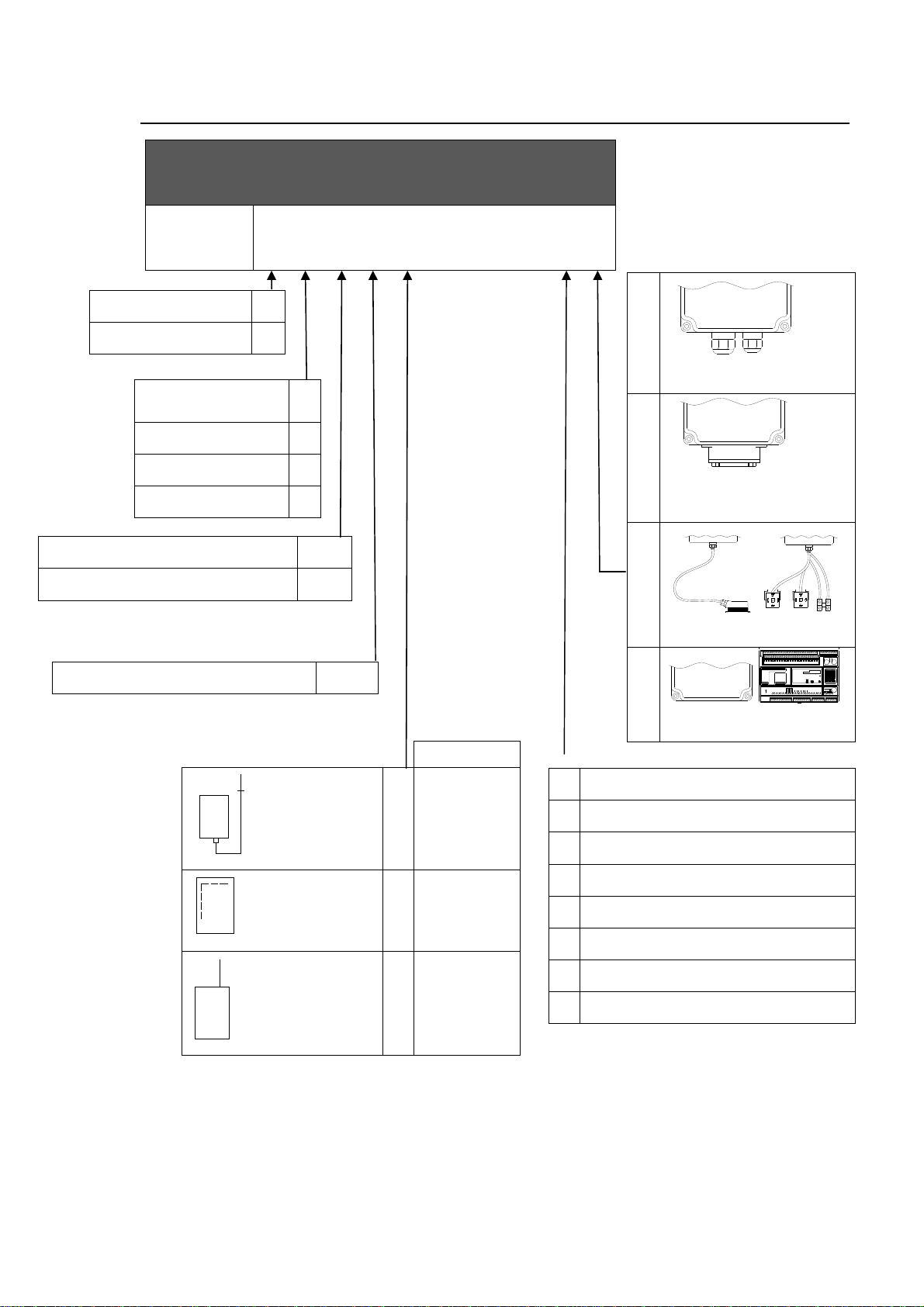

CONTENTS............................................................................................................................................................2

INTRODUCTION ..................................................................................................................................................4

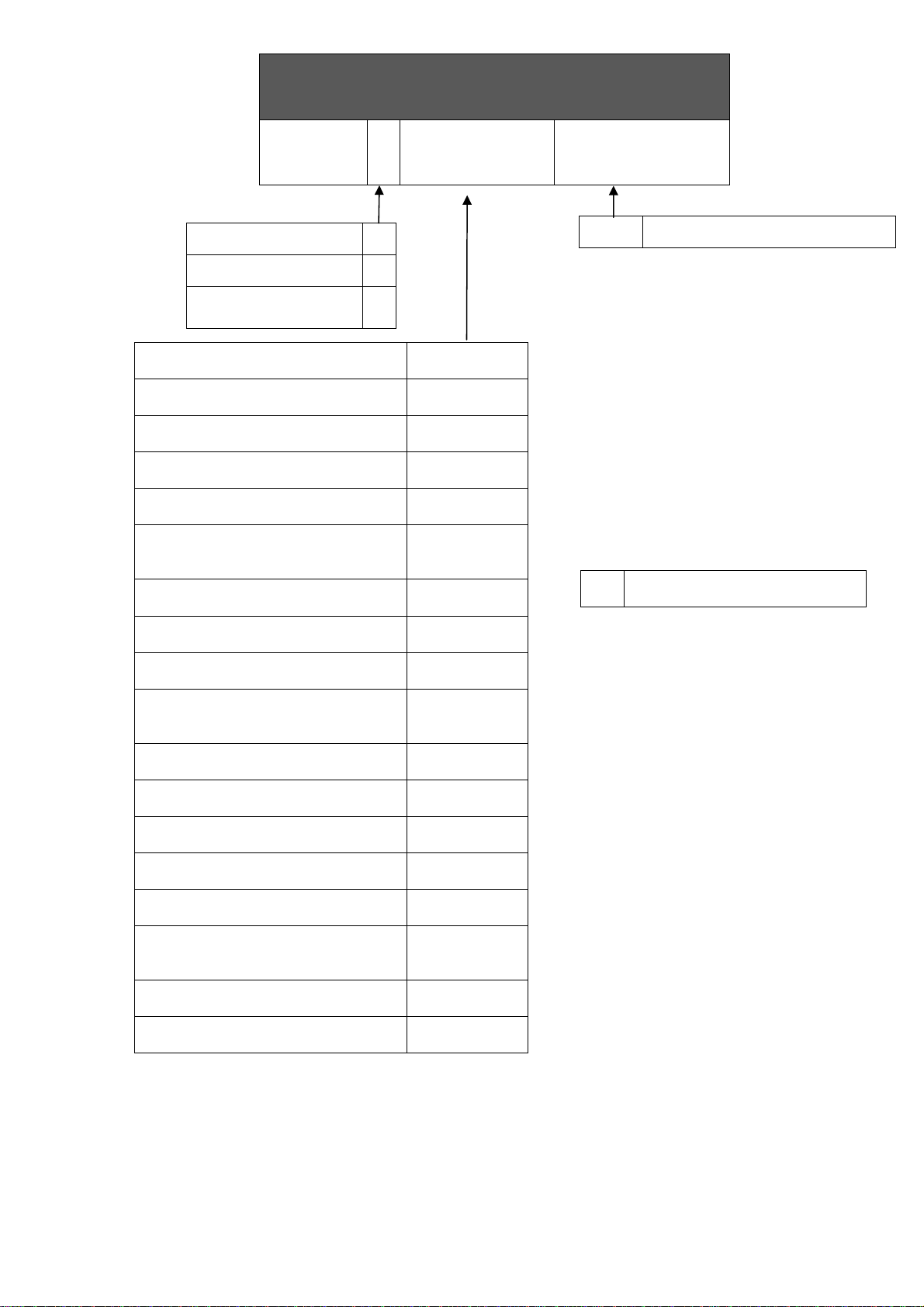

1. IDENTIFICATION DATA.........................................................................................................................5

1.1. DOCUMENTATION...........................................................................................................................................6

2. CONVENTIONS USED IN THIS MANUAL............................................................................................7

3. CAUTION....................................................................................................................................................7

3.1. RISK ANALYSIS................................................................................................................................................7

3.2. APPLICATIONS................................................................................................................................................7

4. PREVENTIVE MAINTENANCE..............................................................................................................8

4.1. ROUTINE MAINTENANCE TO BE CARRIED OUT BY OPERATOR..............................................................................8

4.2. MAINTENANCE AND INTERNAL CHECKS............................................................................................................8

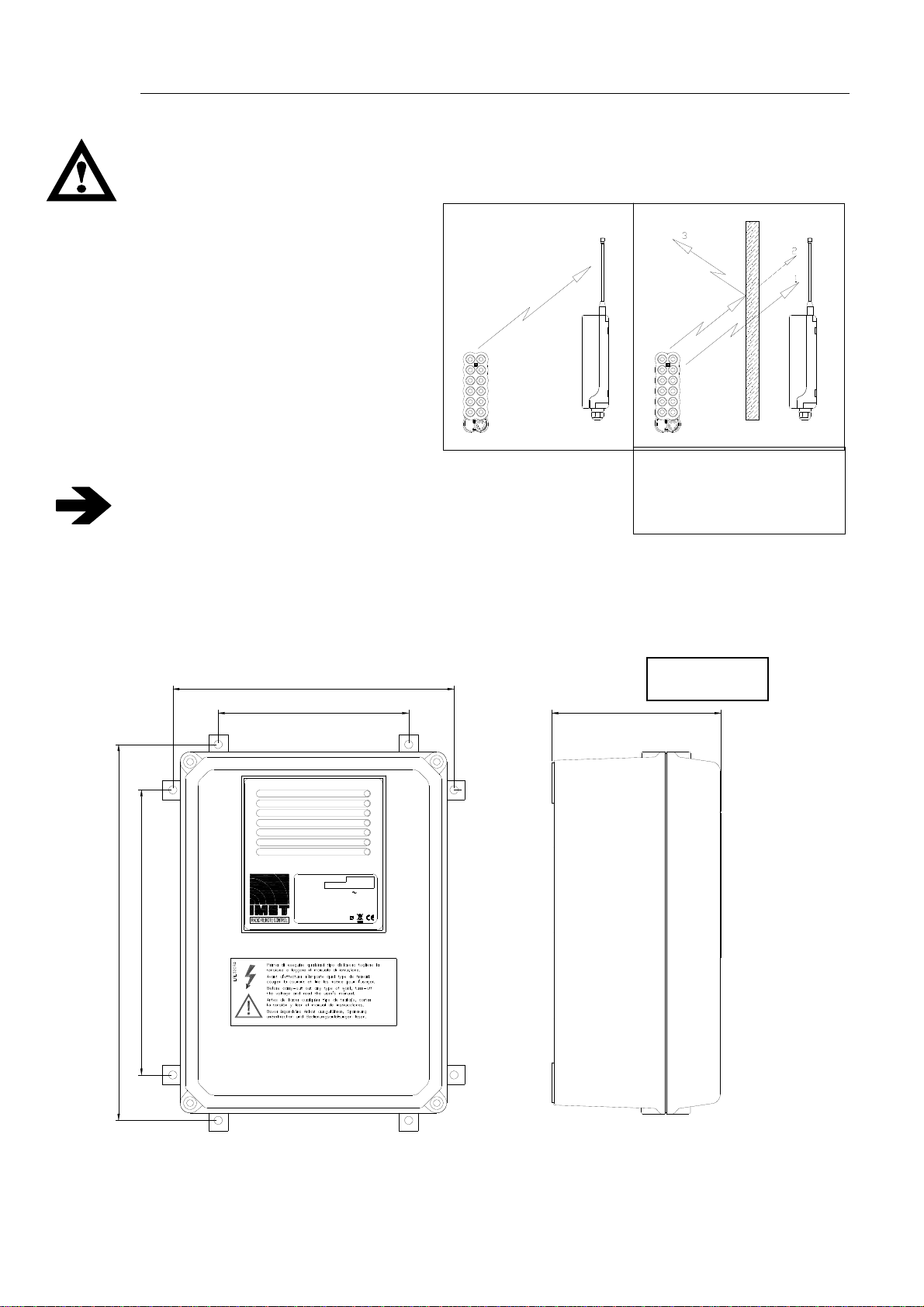

5. INSTALLING THE RADIO REMOTE CONTROL .................................................................................9

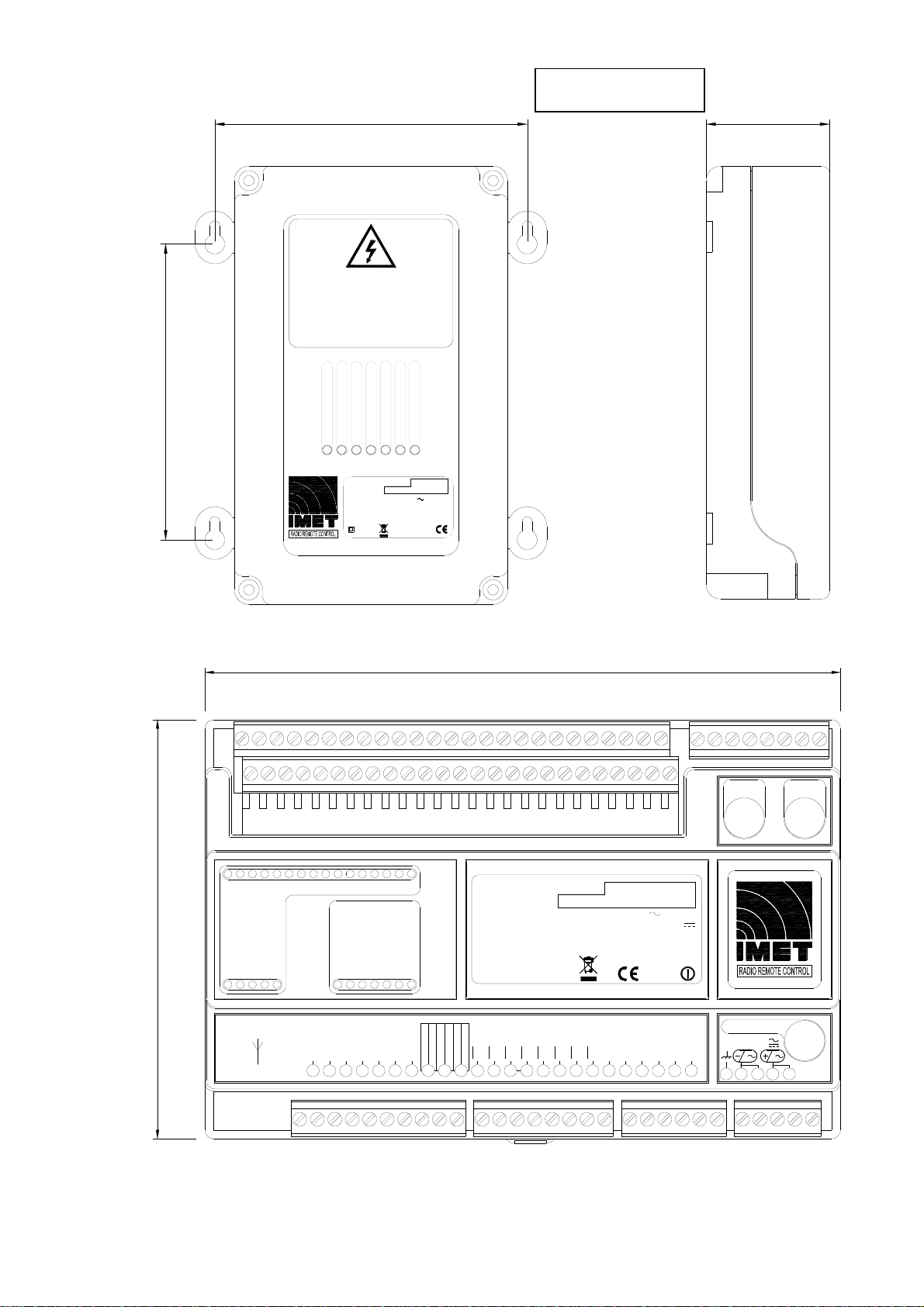

5.1. RECEIVING UNIT DIMENSIONS AND DRILLING DIAGRAM ....................................................................................9

5.2. CONNECTING THE RECEIVER.........................................................................................................................11

5.2.1. INSTALLING THE EXTERNAL ANTENNA ............................................................................................................11

5.2.2. STOP (E-STOP) .........................................................................................................................................12

5.2.3. SAFETY STOP (S-STOP)..............................................................................................................................12

5.3. BASIC FUNCTIONS.........................................................................................................................................13

5.4. CONNECTION DIAGRAMS OF HRECEIVERS.....................................................................................................13

5.4.1. HRECEIVER WITH ANALOG OUTPUT CARD AND DATA FEEDBACK CARD............................................................14

5.4.2. POWER SUPPLY CONNECTIONS OF H-DC AND H-AC RECEIVERS ....................................................................15

5.4.3. ANALOG COMMAND CARD.............................................................................................................................16

5.4.4. LOGIC BOARD...............................................................................................................................................17

5.4.5. DATA FEEDBACK CARD .................................................................................................................................17

5.4.6. RELAY CONTROL CARDS ................................................................................................................................18

5.4.7. POTENTIOMETER CARD.................................................................................................................................18

5.5. CONNECTION DIAGRAMS FOR LAND KRECEIVERS .........................................................................................19

5.5.1. L-AC VERSION ............................................................................................................................................19

5.5.2. L-DC VERSION.............................................................................................................................................20

5.5.3. KVERSION ...................................................................................................................................................21

5.5.4. RELAY CONTROL CARDS FOR LAND KRECEIVERS...........................................................................................22

5.5.5. OTHER CONTROL CARDS FOR L-DC AND K-DC RECEIVERS............................................................................23

5.6. SERIAL DATA TRANSMISSION..........................................................................................................................24

5.6.1. USER SERIAL (RS232)...................................................................................................................................24

5.6.2. SERIAL CONNECTION CABLE..........................................................................................................................24

5.7. CONNECTION DIAGRAMS FOR M-AC RECEIVERS ............................................................................................25

5.7.1. M-AC RECEIVER ..........................................................................................................................................25

5.7.2. COMMON CONNECTIONS ON M-AC TRANSCEIVERS ........................................................................................26

5.7.3. M-AC TRANSCEIVERS:DATA ACQUISITION CONNECTIONS...............................................................................27

6. USING THE RADIO REMOTE CONTROL...........................................................................................28

6.1. SAFETY RULES..............................................................................................................................................28

6.2. POWERING AND STARTING THE RADIO REMOTE CONTROL ...............................................................................28

6.3. STOP..........................................................................................................................................................28

6.4. TURNING OFF THE REMOTE CONTROL............................................................................................................28

6.5. AUTO POWER-OFF........................................................................................................................................28

6.6. MEANING OF LEDS......................................................................................................................................29

6.7. TRANSMITTING UNIT POWER SUPPLY..............................................................................................................30

6.7.1. BATTERY STATE OF CHARGE ..........................................................................................................................30

6.7.2. CHANGING AND CHARGING THE BATTERY ......................................................................................................30

6.8. DIP-SWITCH PROGRAMMABLE OUTPUT CONFIGURATIONS...............................................................................31

7. RADIO REMOTE CONTROL OPTIONS ...............................................................................................32