CAUTIONS FOR SAFE OPERATION

• Read Owner's Manual completely before operating this sprayer.

• Always wear safety goggles, gloves and protective clothing while using this sprayer.

• Do not leave sprayer in the sun, when not in use.

• Never use ammable liquids in this tank.

• Never store spray material in this tank.

• Always release pressure when sprayer is not in use and befor removing pump from tank.

• Read and follow all instructions and cautions on label of chemical spray material to be used.

• Clean and rinse sprayer thoroughly aer each use.

• Never attempt to alter sprayer from original condition.

• Always use replacement parts from original manufacturer.

WARNING

IMPROPER USE OR FAILURE TO FOLLOW INSTRUCTIONS CAN RESULT IN EXPLOSIVE

FAILURE WITH MAJOR INJURIES. FOR SAFE USE OF THIS PRODUCT, YOU MUST READ

AND FOLLOW ALL INSTRUCTIONS BEFORE USE.

PRE-USE SPRAYER SAFETY INSPECTION:

1. Check tightness of hose clamp with screwdriver to be sure hose is securely attached to the tank

outlet nipple.

2. Inspect hose for deterioration, cracks, soness or brittleness. If any of these conditions are

found, replace hose before using. Replace with original manufacturer's parts only.

3. Remove pump (SEE PRESSURE RELEASE INSTRUCTIONS.)

4. Inspect interior and exterior of tank for signs of deterioration (i.e. rust, cracks, bubbling and/

or pitting) of body and bottom. Any sign of deterioration indicates possible tank weakening

and could result in explosive bursting under pressure. If any of these signs are found, DISCARD

TANK IMMEDIATELY AND REPLACE.

CAUTION: DO NOT ATTEMPT TO PATCH LEAKS, ETC. AS THIS COULD RESULT IN

SERIOUS INJURY.

5. For pressure testing and sprayer use familiarization. FOLLOW FILLING INSTRUCTIONS

EXCEPT: Use water only.

6. FOLLOW PRESSURIZATION INSTRUCTIONS EXCEPT, pump plunger only 8-10 strokes and

inspect for leaks.

7. Aer inspection is completed, pump plunger until it works hard and lock handle.

8. (FOLLOW SPRAYING INSTRUCTIONS) Verify desired spraying patterns and practice

spraying.

9. If unit passes this test, release pressure (SEE PRESSURE RELEASE INSTRUCTIONS.)

10.Empty tank.

11.PROCEED WITH FILLING, PRESSURIZING AND SPRAYING INSTRUCTIONS WITH

DESIRED CHEMICAL SOLUTION.

WARNING

NEVER SPRAY FLAMMABLE MATERIALS; ALWAYS READ CHEMICAL LABEL BEFORE

FILLING SPRAYER, AS SOME CHEMICALS MAY BE HAZARDOUS WHEN USED WITH THIS

SPRAYER.

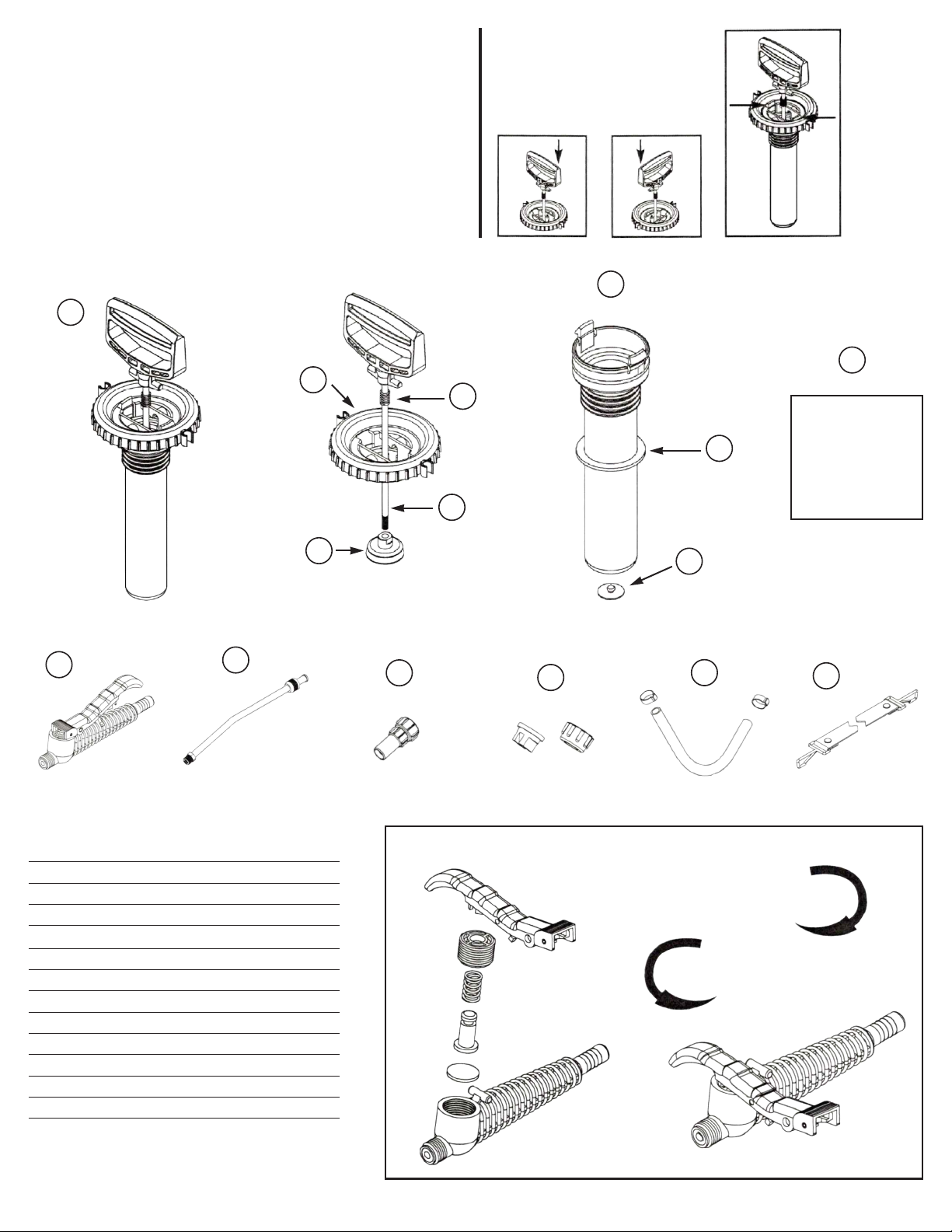

FILLING INSTRUCTIONS:

1. To engage handle in lock position: Push handle down to completely compress spring and rotate

handle 1/4 turn clockwise, then allow handle to raise into lock position.

2. To remove pump engage handle in locked position and turn pump handle down to completely

compress spring and rotate handle 1/4 turn clockwise, then allow handle to raise into lock

position.

3. Prepare spray solution following directions on chemical container label.

4. Strain solution to remove foreign particles, which can clog sprayer nozzle.

5. Fill tank to indicated or desired useable capacity, leaving remaining space for compressed air

(SEE FRONT PAGE OF MANUAL FOR THE MAXIMUM USABLE CAPACITY).

6. Check pump barrel to be sure no dirt or grass is stuck to barrel.

7. Place pump into tank opening and rotate clockwise until tightly locked and sealed into tank

opening.

PRESSURING INSTRUCTIONS:

1. Disengage handle from locked position by pushing down and turning 1/4 turn counter-

clockwise to release handle.

CAUTION: TO PREVENT EJECTED PUMP ASSEMBLY AND/OR SOLUTION FROM STRIKING

AND INJURING YOU, NEVER STAND WITH FACE OR BODY OVER TOP OF

TANK WHEN PUMPING OR LOOSENING PUMP.

CAUTION: NEVER PRESSURIZE SPRAYER BY AND MEANS OTHER THAN THE ORIGINAL

PUMP

2. TO PRESSURIZE TANK: Pump plunger up and down until it works hard.

3. Engage handle in lock position.

WARNING

THIS SPRAYER IS NOW UNDER PRESSURE AND DANGEROUS.

SPRAYING INSTRUCTIONS:

1. Always wear protective goggles, gloves, long sleeve shirt, long pants and sturdy foot protection.

2. Point nozzle away from you.

3. Squeeze shut-o handle to open and adjust nozzle to desired spray pattern by rotating nozzle

cap (not complete nozzle) clockwise from ne spray to solid stream (maximum 2 turns).

WARNING

TURNING NOZZLE CAP TOO FAR WILL RESULT IN CAP FLYING OFF ALLOWING SPRAY

MATERIAL TO SPRAY BACK ON YOU. Re-pump unit as required to maintain spray force.

CAUTION: Do not leave a pressurized sprayer in the hot sun. Heat can cause pressure build-up.

PRESSURE RELEASE INSTRUCTIONS:

WARNING

To safely release pressure in tank and avoid possibility of injury follow steps 1 through 4

COMPLETELY LISTED BELOW.

1. Place unit on its side with top directed away from you and with hose outlet on top.

2. Direct nozzle away from you and open shut-o allowing spray solution in discharge assemble

and remaining air pressure to be completely exhausted.

3. Turn sprayer up right.

4. Remove pump (FOLLOW STEPS 1 AND 2 OF FILLING INSTRUCTION) while maintaining

position of top sprayer directed away from you.

CLEANING SPRAYER AFTER USE:

1. Rinse tank thoroughly with clear water.

2. Empty tank.

3. Rell tank with clear water.

4. Check pump into tank opening and rotate clockwise until tightly locked and sealed in tank

opening.

5. Place pump into tank opening and rotate clockwise until tightly locked and sealed in tank

opening.

6. Disengage handle from locked position by pushing down and turning 1/4 turn counter-

clockwise to release handle.

7. Pump plunger up and down 8-10 strokes.

8. Open shut-o and allow water to run throughout to clean discharge assembly.

9. Release pressure (FOLLOW PRESSURE RELEASE INSTRUCTIONS).

10.Remove pump.

11.Empty sprayer.

12.REPEAT STEPS 1-11 IF NECESSARY.

SPRAYER MAINTENANCE:

1. Periodically remove nozzle and extension tube from shut-o.

2. With shut-o discharge hole pointing upward, place 6-8 drops of light oil into discharge hole

then depress lever.

3. Piston cup should be periodically greased.

4. If nozzle clogs:

A. Remove complete nozzle assembly.

B. Disassemble nozzle.

C. Clean openings of any obstructions

5. Never use any tool to remove pump if there is pressure in sprayer.

SPRAYER STORAGE:

1. Sprayer tank should be hung upside down with pump removed in a warm dry location.

2. Do not store or leave any solution in tank aer use.

CAUTION: DO NOT ATTEMPT TO MODIFY OR REPAIR THIS PRODUCT EXCEPT WITH

ORIGINAL MANUFACTURER'S PARTS.

TROUBLESHOOTING

Spraying leaks at closure

LOOK FOR: 1. Sediment or foreign particles on surface of pump gasket or closure surface.

2. Chipped, torn swollen defective pump gasket.

REMEDY: 1. Clean all foreign particles from pump gasket and closure surface.

2. Remove old gasket and replace with new.

Spray material overows through pump barrel or pump handle rises when handle is unlocked.

LOOK FOR: Sediment or foreign particles under check valve or chipped, torn, or swollen pump

check valve.

REMEDY: Remove pump, clean check valve and pump valve seat if necessary.

Hose leaks at tank.

LOOK FOR: 1. Loose hose clamp.

2. Cracked hose.

REMEDY: 1. Tighten hose clamp.

2. Replace hose.

Poor spray pattern, partial spray or complete stoppage.

LOOK FOR: 1. Spray extension, nozzle, or shut-o plugged.

REMEDY: 2. Remove nozzle and clean.

3. Depressurize tank, remove lever and unscrew retainer from shut-o. Remove

diaphragm and clean inside of shut-o. Se assembly and disassembly.

Hose leaks at shut-o.

LOOK FOR: Swollen, split or faulty hose.

REMEDY: Replace hose.

Sprayer pumps hard.

LOOK FOR: Plunger cup dry.

REMEDY: Grease plunger cup.

Sprayer pump does not compress air.

LOOK FOR: Damaged plunger cup.

REMEDY: Replace with new pump or rod assembly.

PARTS LIST & MAINTENANCE MANUAL

#7512 AND #7513

ALL-PURPOSE SPRAYER INSTRUCTIONS

impact-products.com

419.841.2891

800.833.1541

Impact Products LLC.

2840 Centennial Road

Toledo, OH 43617

7512_7513_Instructions (REV 01/21)