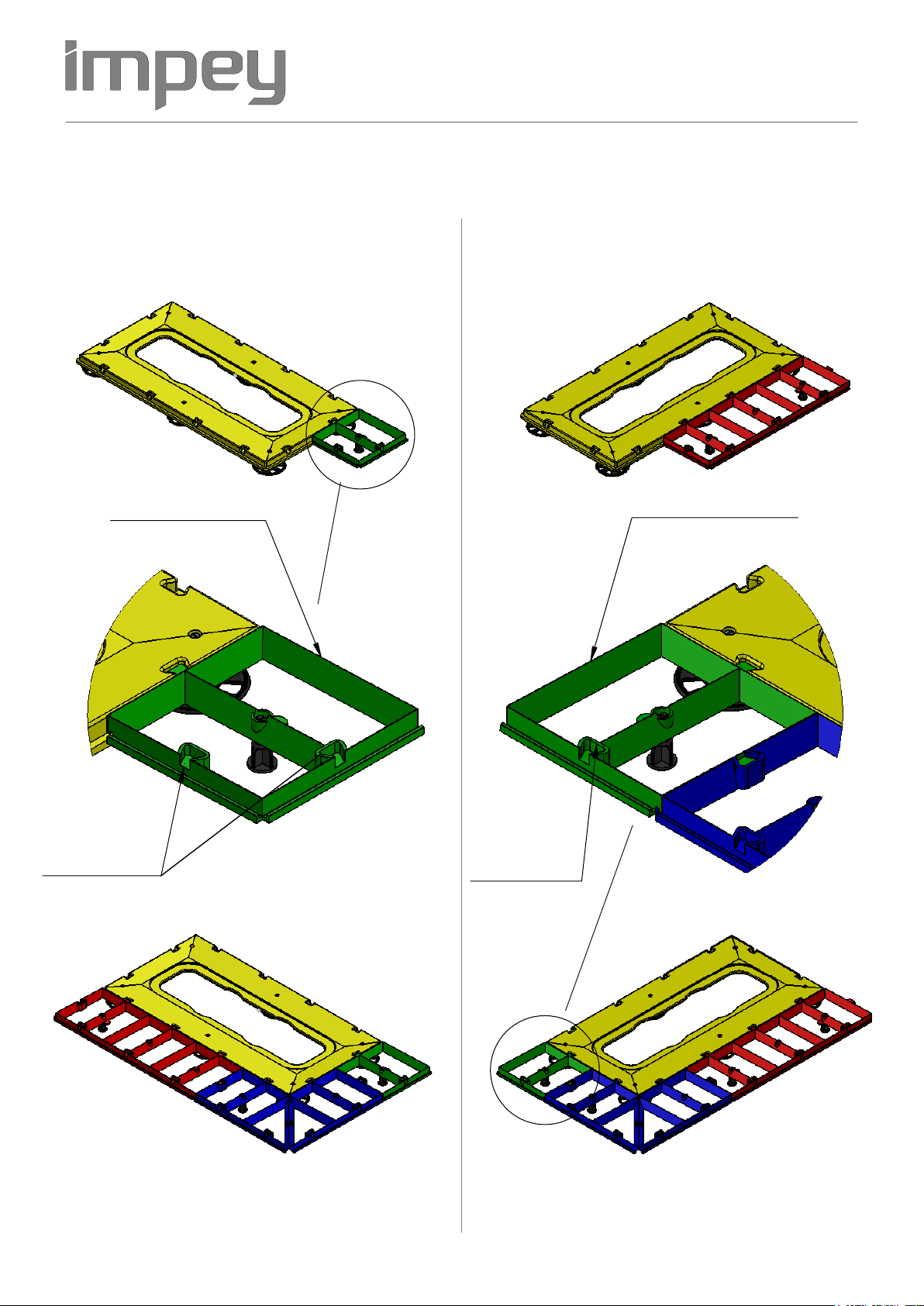

7

Remove the mounting plates from the feet, drill and

fix them to the sub floor to secure them in position.

9

Using a screwdriver and spirit level adjust the levelling

feet until all outside edges are level.

Ensure the height is set correctly at this stage also.

(see diagram 5 on page 4 for further guidance)

10

At this stage we recommend that the waste pipe is buried

and the the starter section is bedded. This can be done by

pushing sand/cement under the section. It may be preferred

to temporarily remove the linear channel to do this.

11

Begin adding the first section, ensure it is fully located

and levelled correctly. (this illustration shows a corner

section but this is dependant on the configuration type)

12

When making levelling adjustments it is important that

the feet are only just in contact with the sub floor, being

careful not to over or under adjust.

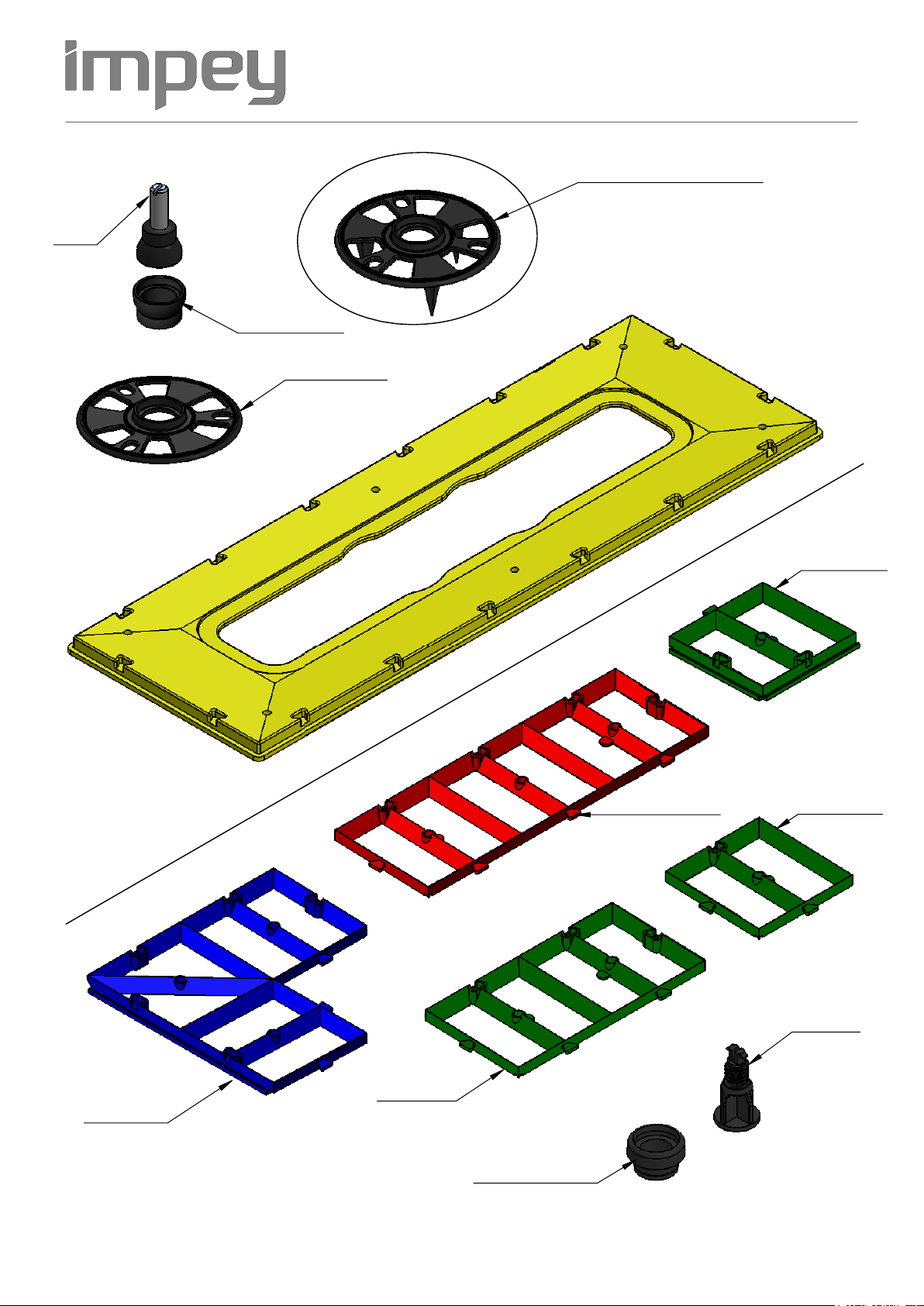

8

Reposition the starter section and clip into the mounting

plates. Place the Linear channel into the starter section,

drill and fix in place. (also see drain assembly guide)

Ensure screw is fitted to

connect gully to Linear channel.

(do not over tighten)

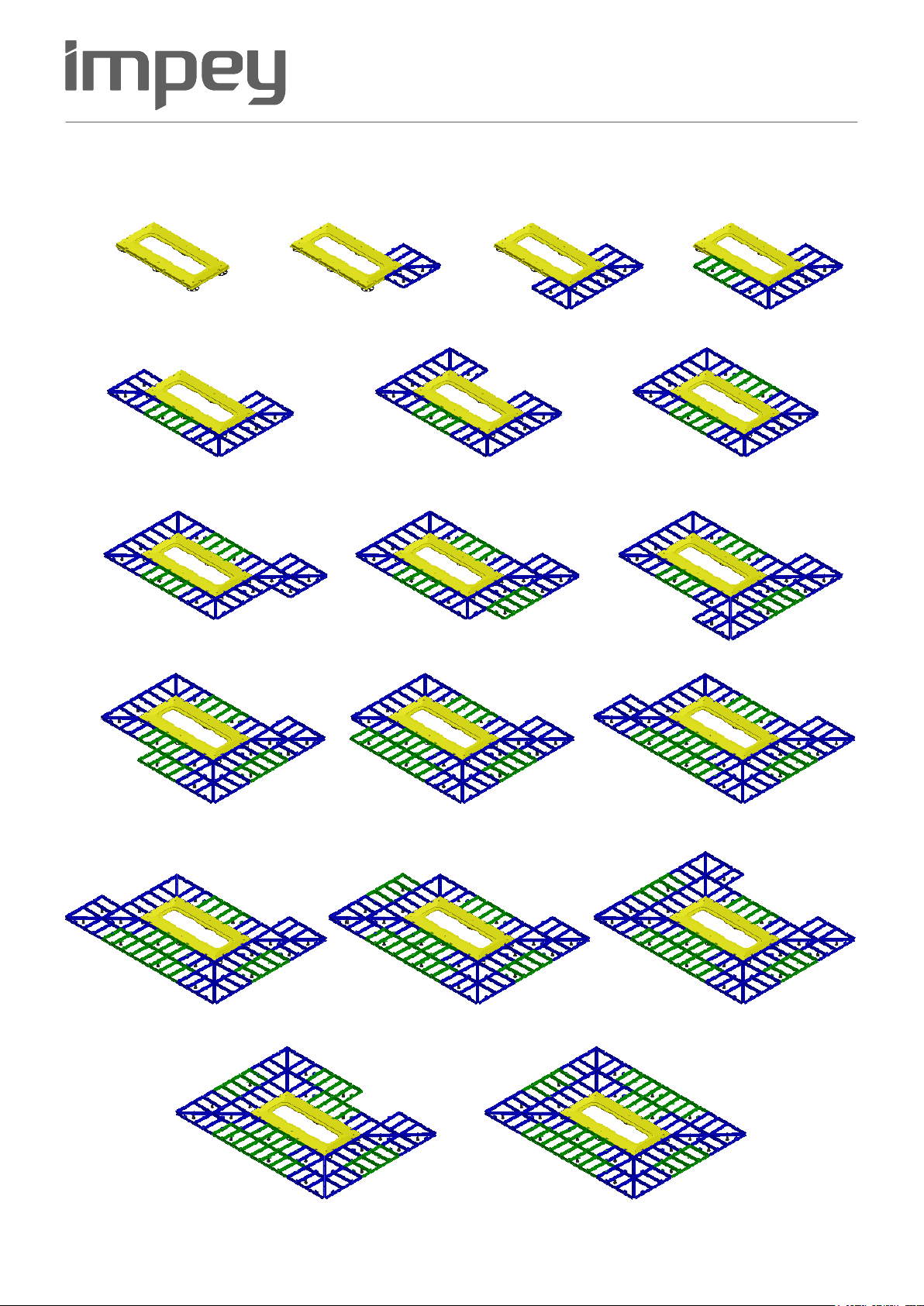

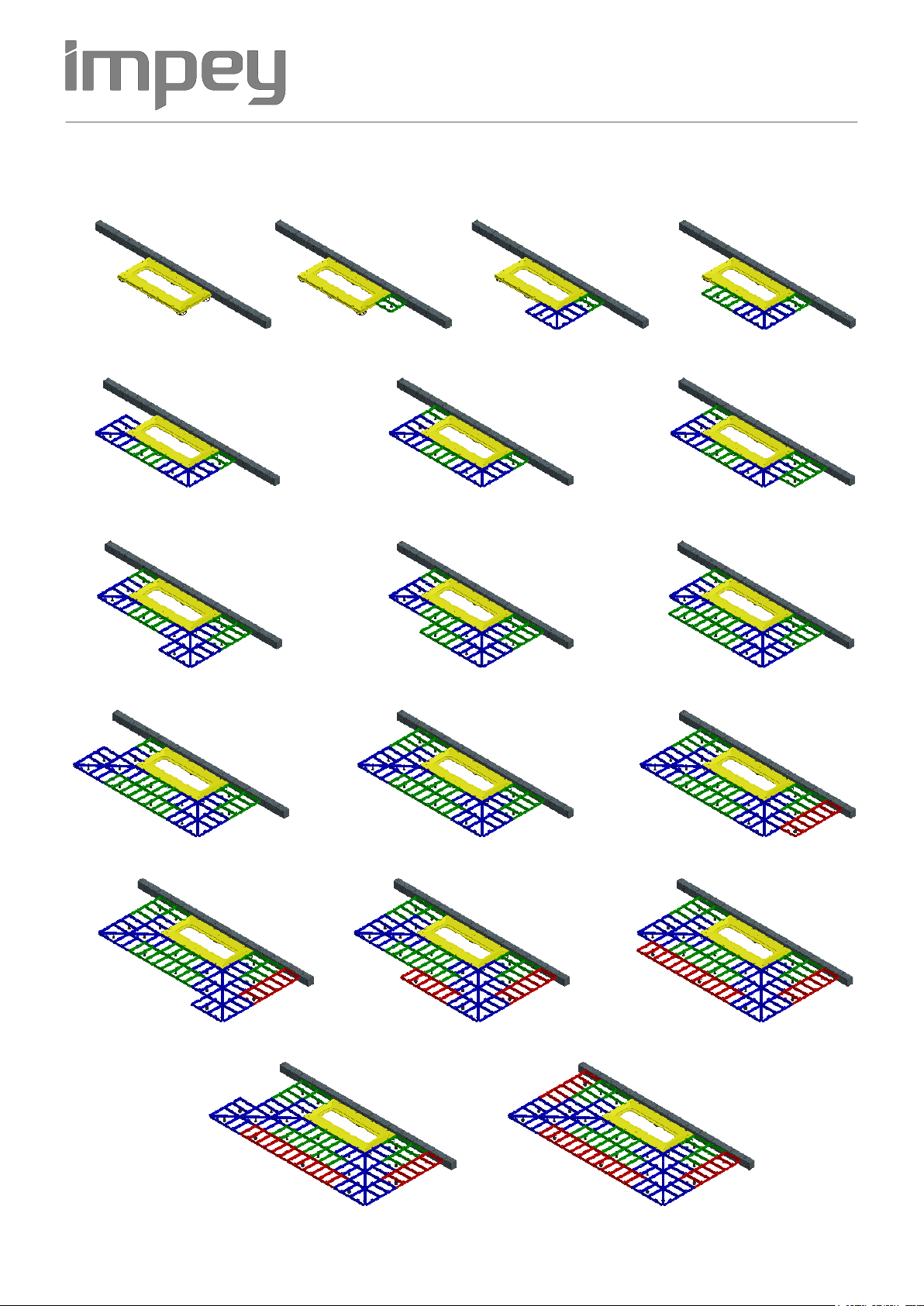

Section 4: General Installation guidance

for all configuration types

This section covers parts of the installation that are are common to all configuration types.

Please see section 5 and follow the relevant stages that are applicable to the type you are installing.

Page 6