3

Lowes.com

PREPARATION

WARNING

CAUTION: Installation should be performed in temperatures ranging from 208F to 1008F

Please read and understand this entire manual before attempting to assemble, operate or install

the product.

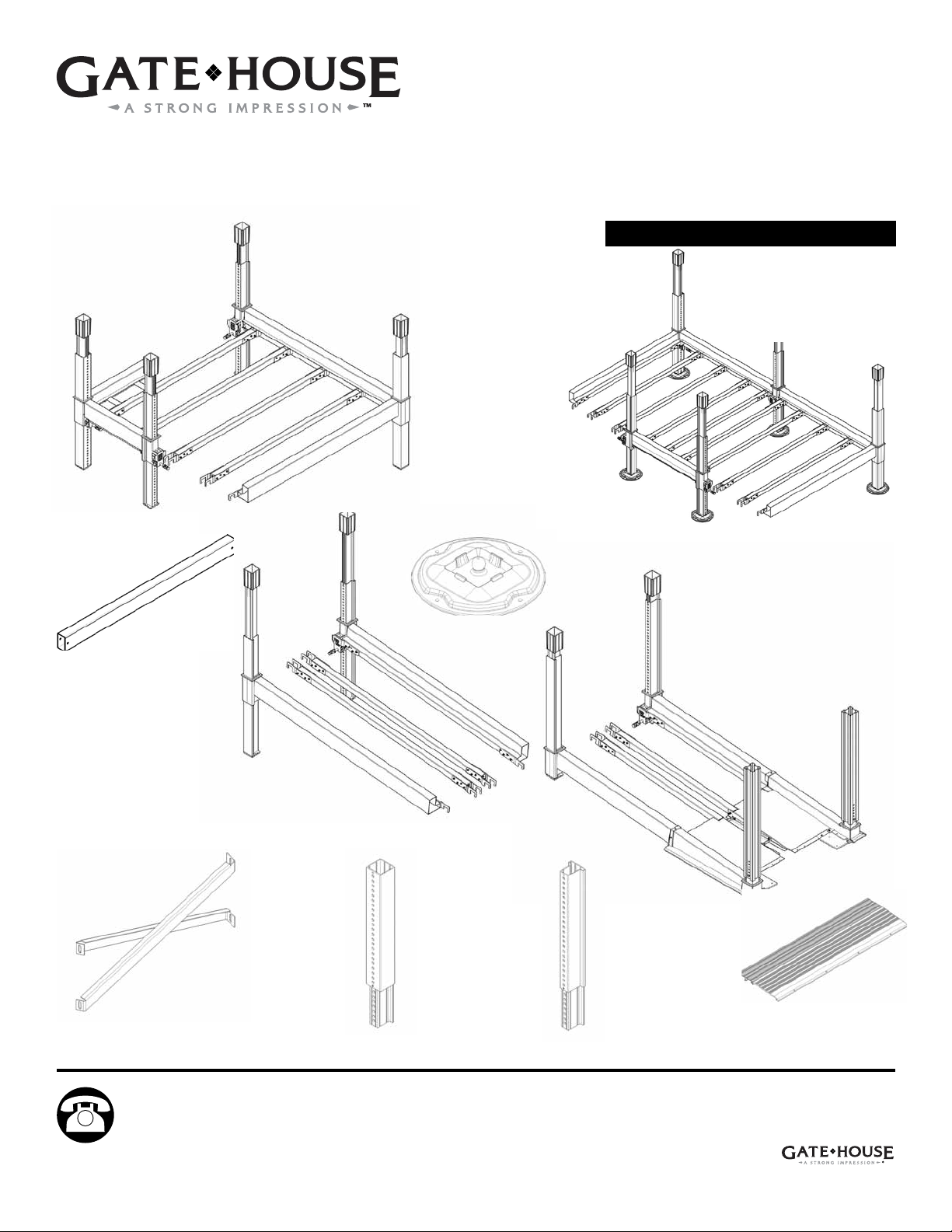

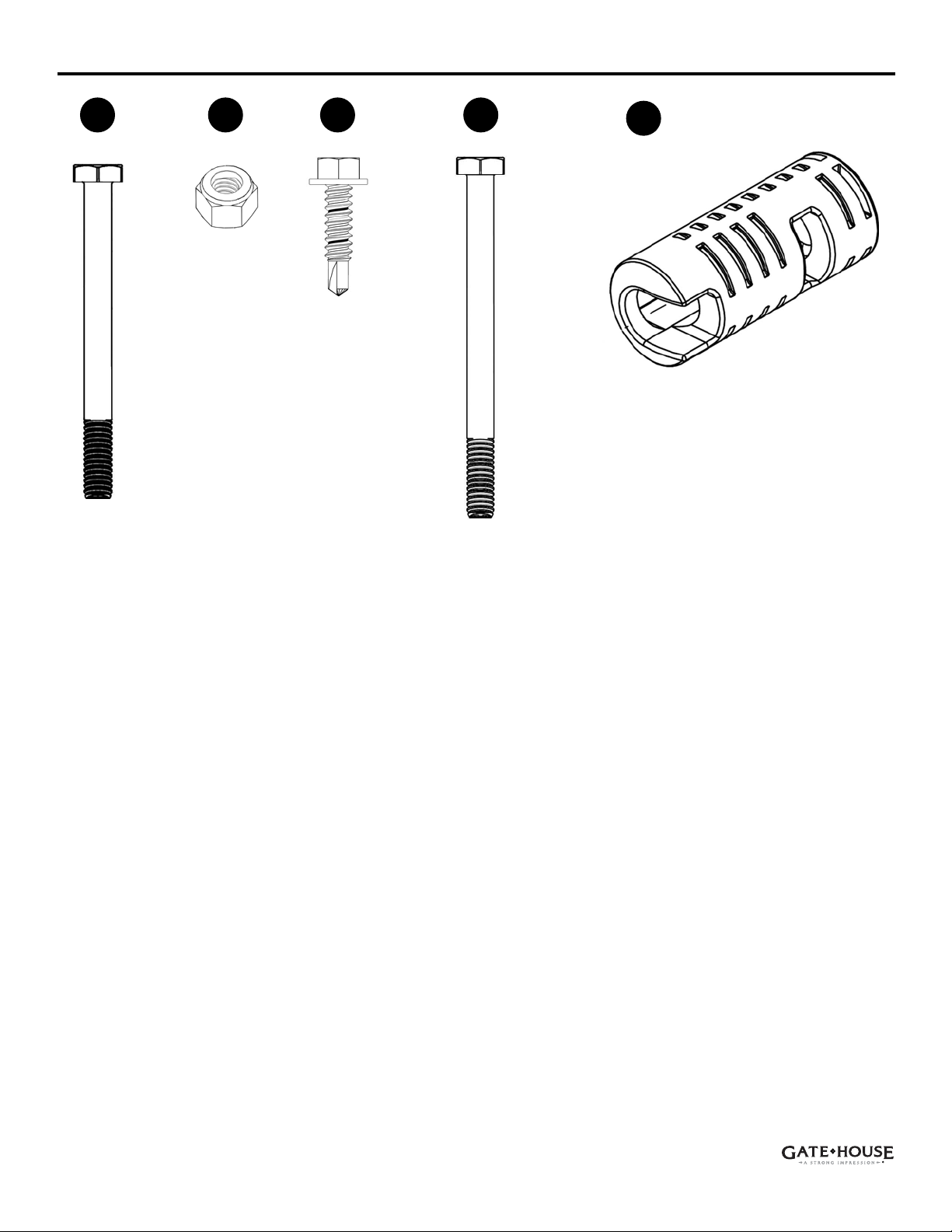

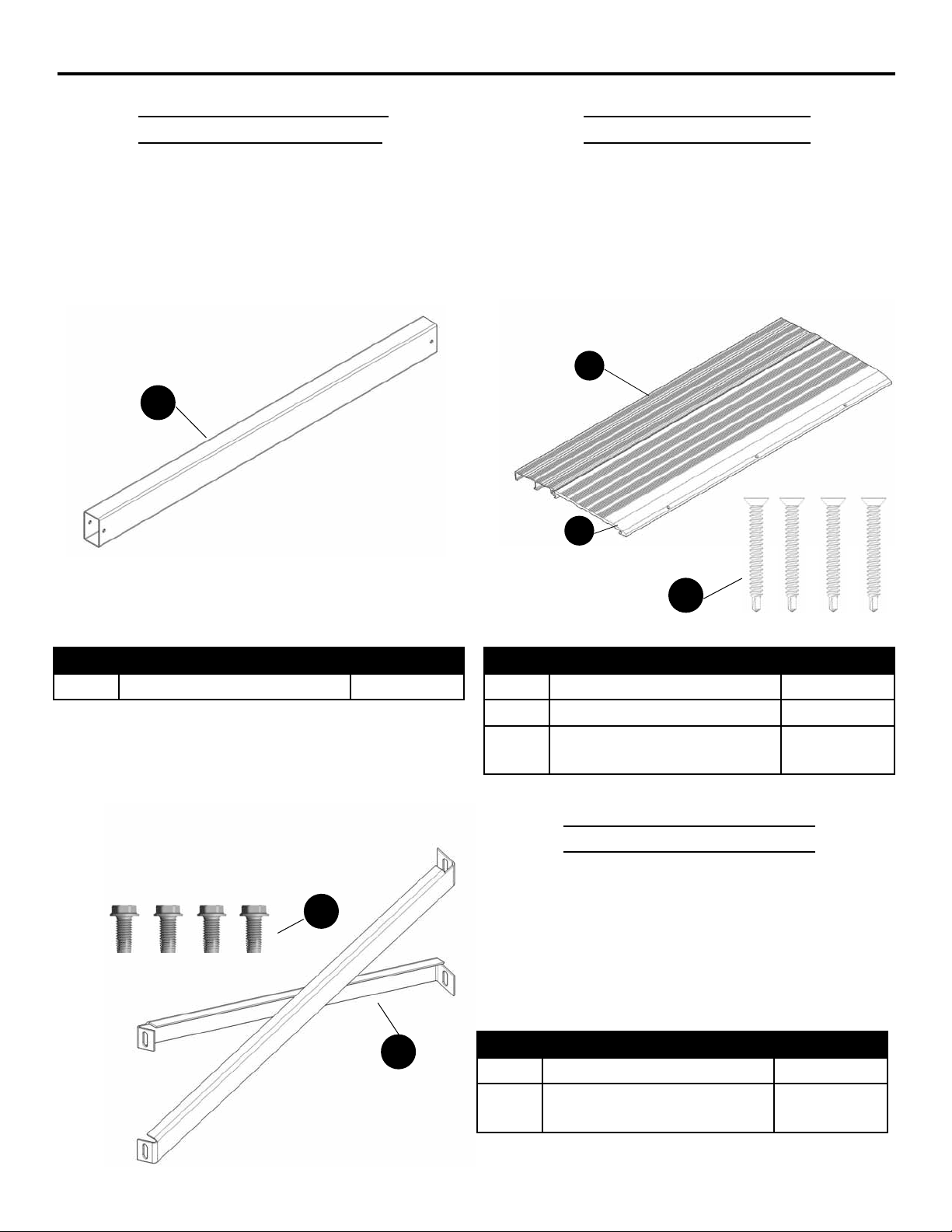

Before beginning assembly of product, make sure all parts are present. Compare parts with package

contents list and hardware contents list. If any part is missing or damaged, do not attempt to

assemble the product; call 1-888-442-2923.

Tools Required for Assembly: Safety Glasses, Gloves, Tape Measure, Level, Carpenter’s Square,

Drill with Phillips #3 bit and 3/8 in. hex nut driver, Hex Key, Utility Knife or Scissors, Combination

Wrenches or Ratchet Wrench with socket sizes 7/16 in., 1/2 in., 3/4 in. Adjustable Wrench optional.

Please consult anchor manufacturer for any additional tools required for securing chosen anchors

(sold separately). Electric impact driver and angle meter recommended but not required.

Additional tools may be required for installation of decking and railing.

• Based on the International Building Code (IBC) 2012, American Society of Civil Engineers

(ASCE) 7-10 design code and National 2010 ADA Standards for Accessible Design, the Custom

Access Ramp System (CARS) has been designed to 100 lbs. per square foot vertical load and

the greater of 50 lb. per foot on top rail or 200 lb. horizontal load. Consult chosen railing for load

specications. Local building codes should be veried before construction. Consult a qualied

designer for footing details to extend max. rise.

• Can be congured to meet National 2010 ADA Standards for Accessible Design.

• Design of the ramp does not take into account impact from weight of snow accumulations

falling from adjacent surfaces or snow loads in excess off 100 lbs.

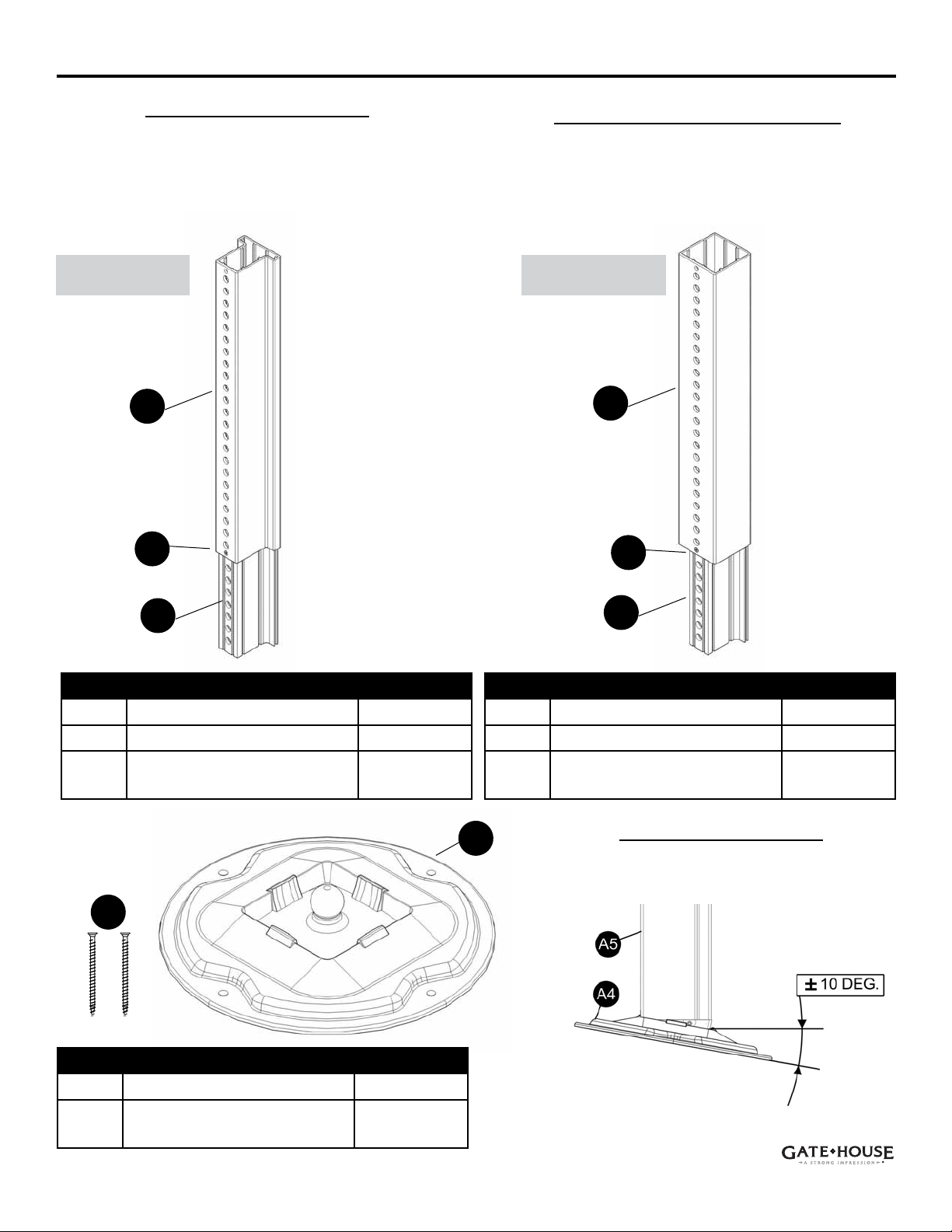

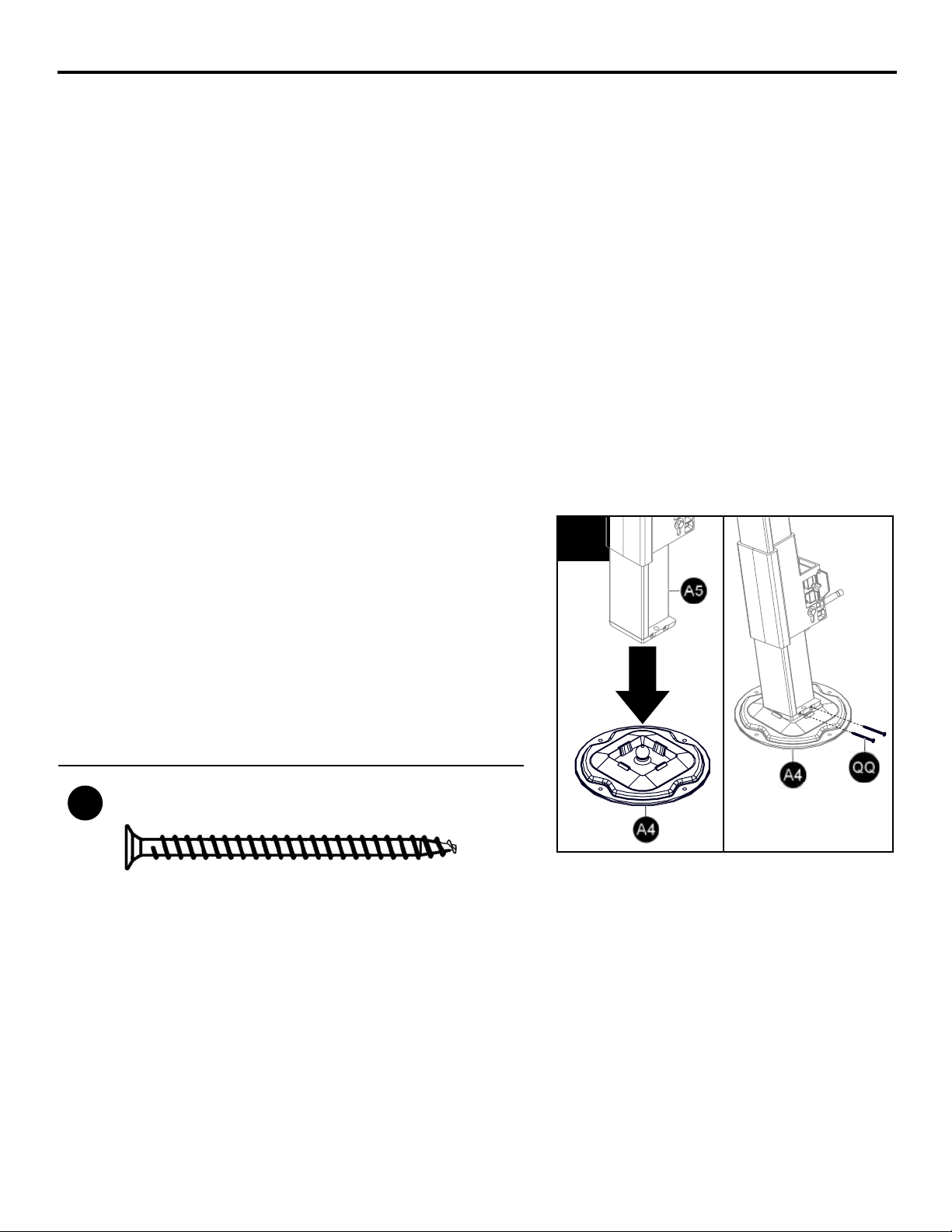

• Posts require a minimum foundation and anchorage sufcient to support 1600 lbs vertical

load. The landing area must be a solid, level surface. It is recommended that the adjustable post

support brackets of the item# 0254049 bottom run shall be connected to a single concrete footing

on which they both sit. It is the responsibility of the owner or qualied installer to verify soil condi-

tions and requirements for compliance with local codes.

• Actual soil conditions at ramp location shall be veried and the specic footing requirements

shall be designed by a qualied designer. For site specic conditions contact a qualied designer

(i.e. poor soil conditions, steep hill sides, and special loading conditions.)

• The top of the ramp assembly shall be connected to a supporting structure that is capable of

supporting all longitudinal and lateral ramp loads as required by the 2012 IBC and local building

codes.

• The design of the ramp assembly as set forth herein pertains only to the ramp components

and assembly as manufactured by Americana Building Products. The design of and attachment

to supporting structural elements are outside of the scope of this guide. It shall be the Owner and

Installer’s responsibility to provide sound supporting structure and attachment and to consult with

qualied individuals where the design or verication of such components is required.

• It shall be the Owner and Installer’s responsibility to verify that local building code require-

ments are met and that proper permits are obtained prior to the installation. Professional engi-

neering services may be required. Contact a Lowe’s representative for professional engineering

options if required. Hurricane tie downs are available for instances where local code requires

them. Please call 1-888-442-2923 for more information.

SAFETY INFORMATION