impro technologies ISC960-1-0-GB-XX User manual

MODEL NUMBER:

ISC960-1-0-GB-XX ISC962-1-0-GB-XX

IPS960-1-0-GB-XX IPS961-1-0-GB-XX

IPS962-1-0-GB-XX IPS963-1-0-GB-XX

GSM900-0-6-GB-XX

XEA901-1-0-GB-XX

XEA902-1-0-GB-XX

xea

IXP220 CONTROLLER

ImproX IXP220 Controller

INSTALLATION MANUAL

SPECIFICATIONS

Working Environment

Open Frame Construction ..........

(ISC96X)

Designed to work in an indoor (dry)

environment. The Controller is NOT sealed

against water.

Power Supply Combo (IPS96X)..

Designed to work in an indoor (dry)

environment similar to IP20. The Power

Supply Combo is NOT sealed against water.

Power

Open Frame Construction (ISC96X)

Power Input

Main Power Input Port............

18 V DC to 32 V DC or 16 V AC to 24 V AC.

Battery Input Port...................

12 V DC to 14 V DC.

Typical Current Distribution

Controller

Current (mA)

Power (W)

12 V DC with no

peripherals connected

and relays off..................

90

1.08

24 V DC with no

peripherals connected

and relays off..................

60

1.4

16 V AC with no

peripherals connected

and relays off..................

70

1.1

Battery Charging....................

350 mA Trickle charge at 13.7 V DC

maximum.

External Readers ...................

200 mA continuous at 5 V DC and 12 V DC

maximum per port.

Power Output Port..................

1 A continuous at 12 V DC to 14 V DC.

ISC300-0-0-GB-03

November 2009

Page 2

Power Input Protection ...............

Over-voltage and over-current protection are

provided on the Main Power Input.

NOTE: EMC emissions only apply when using the main Power Input Port.

NOTE: As an alternative to a battery, power the IXP220 using a 12 V DC

uninterrupted power supply connected using the Battery Input.

NOTE: The Power Output Port provides a nominal 12 to 14 V DC at 1 A continuous

current. When using the 12 V Backup Battery, the output provides up to 3 A

briefly to cater for in rush currents into locks and other equipment. When

using the Controller without the 12 V Backup Battery, then any load that

demands more than 3 A from the Power Output Port can cause the IXP220

to protect against overload. The Controller achieves this by indefinitely

entering Total Shutdown Mode. Once the overload is removed, the IXP220

resumes normal operation after a maximum of 3 seconds.

Power Supply Combo (IPS96X)

NOTE: An integrated transformer supplies power to this model IXP220 Controller.

The Typical Current Distribution (page 1) for the Open Frame Construction

applies.

Transformer

Input Voltage..........................

230 V AC (nominal) at 50 Hz to 60 Hz.

Output Voltage.......................

16 V AC.

Output Current .......................

2 A maximum.

The following specifications are common to both the Open Frame Construction and the

Power Supply Combo options.

Battery

Type.......................................

12 V Sealed Lead Acid, 7 Ahr (Max).

Approximate Length...............

151 mm (6 in) (Max).

Approximate Width.................

65 mm (3 in) (Max).

Approximate Height................

99 mm (4 in) (Including the Terminals) (Max).

Charge Voltage......................

13.8 V DC at 350 mA (Max).

Real Time Clock (RTC) Backup

Battery

Battery Type...........................

1 x 3 V, CR2032, Lithium cell Battery.

Battery Life.............................

2 Years with power OFF,

5 years with Power ON,

5 Years Storage with Battery Tab in place.

Controller Communication

USB Port.......................................

USB Device, Type-B, female connector,

12 Mbps, USB V2.0.

Ethernet Port................................

Standard Ethernet RJ45 connector.

10/100 Base T, half or full duplex.

ISC300-0-0-GB-03

November 2009

Page 3

RS232 Port ...................................

9-Way, D-type, female connector or terminal

block connection.

Default Baud Rate..................

38 400.

NOTE: To achieve RS232 connection, use

either the 9-way, D-type, female

connector or the terminal block

connection.

RS485 Controller Port

Electrical Interface..................

RS485.

Default Baud Rate..................

38 400.

Data Format...........................

8 data bits, no parity, 1 stop bit.

Communications Protocol ......

ImproX Secure Communications Protocol.

Line Termination (RS485)......

Provision is made for line termination.

GSM Module

Frequency..............................

850 MHz, 900 MHz, 1800 MHz and 1900 MHz.

Power Consumption

Minimum.........................

0.05 W.

Operating........................

1.5 W.

Peak...............................

7.5 W.

Terminal Communication

RS485 Terminal Port

Electrical Interface..................

RS485.

Baud Rate..............................

38 400.

Data Format...........................

8 data bits, no parity, 1 stop bit.

Communications Protocol ......

ImproX Secure Communications Protocol.

Line Termination (RS485)......

Provision is made for line termination.

Reader Options

Wiegand Ports .............................

2 Fully functional Wiegand Reader Ports.

Power Output.........................

12 V DC and 5 V DC (selectable) at maximum

200 mA.

Modes Supported...................

Tag, Tag + PIN-code, Personal Access Code

or Reason Code Mode except when the

Reader Port is set to Wiegand Open Mode.

Antenna Reader Ports.................

2 Fully functional Antenna Reader Ports.

Relays

Relay Output ................................

2 x Relays, Form C, each with NO, COM and

NC contacts.

ISC300-0-0-GB-03

November 2009

Page 4

Contact Ratings...........................

10 A at 28 V DC,

5 A at 220 V AC,

12 A at 120 V AC.

Operations....................................

100 000 Minimum.

Digital Inputs

Input Types ..................................

4 x Dry Contact Digital Inputs.

Detection Resistance Range ......

< 2 kOhm.

Protection Range.........................

+ 20 V continuous.

Figure 1: End of Line (EOL) Sensing Circuit

NOTE: End of Line (EOL) Sensing enables the Controller to raise an alarm when

somebody tampers with the circuit (that is, cutting or shorting the wires)

between Reader 1 or Reader 2 Input (of DOS [1] or DOS [2]) and GROUND

(GND). In other words the Controller distinguishes between tampering on

the circuit, and the door being in an actual ‘Normally Open’ or ‘Normally

Closed’ state. By placing Resistors into the circuit between the Reader 1

or Reader 2 Input (of DOS [1] or DOS [2]) and GROUND (GND), the

Controller’s Digital Input monitors a constant resistance through the circuit.

When the circuit is tampered with, the Resistors are bypassed; the

Controller detects the resistance change raising an alarm.

NOTE: When using the End-of-Line Sensing function, LEDs 6 and 14 will not

indicate the true status of the Input.

Alarm

Alarm Relay

Relay Output..........................

1 x Relay, Form C, with NO, COM and NC

contacts.

Contact Ratings......................

10 A at 28 V DC,

5 A at 220 V AC,

12 A at 120 V AC.

ISC300-0-0-GB-03

November 2009

Page 5

Alarm Signal.................................

IN: Dry Contact Digital Input.

GND: Ground reference.

OUT: Open Collector Digital Output.

General

SD Card Adapter..........................

Reserved for future use.

Connection.............................

Standard 9-Pin SD Mode Interface, 2 GB max.

Controller Diagnostic Interfaces

Liquid Crystal Display (LCD)..

Reserved for future use.

Characters......................

16 Characters by 4 lines.

Character Sets................

English, Katakana.

Contrast..........................

Adjustable using the Trimpot (see Figure 4 for

location).

Back-lighting...................

Turned on and off via the Communications

Protocol.

Keypad...................................

Reserved for future use.

Buttons...........................

12 Alphanumeric and function keys.

Back-lighting...................

Yes.

NOTE: The LCD and Keypad back-lighting

operate independently of each other.

LED Indicators

Controller Status LED.....

Steady Red LED (internally visible).

Incoming RS485 Data ....

Flashing Green LED (internally visible).

Outgoing RS485 Data ....

Flashing Red LED (internally visible).

Incoming RS232 Data ....

Flashing Green LED (internally visible).

Outgoing RS232 Data ....

Flashing Red LED (internally visible).

Speed LED (Ethernet)....

Steady Red LED (internally visible).

Link LED (Ethernet)........

Steady Red LED (internally visible).

Active LED (Ethernet).....

Flashing Red LED (internally visible).

Relay LED ......................

Steady Red LED (internally visible).

SD/MMC Active..............

Steady Red LED (internally visible).

USB Active .....................

Steady Red LED (internally visible).

Digital Inputs...................

Steady Green LED (internally visible).

GSM Status LED............

Flashing Red LED (internally visible, only on

installed GSM Module).

Antenna Reader Interfaces .........

2 Individual standard interfaces.

Wiegand Reader Interfaces.........

2 Standard interfaces, including 12 V DC and

5 V DC Power Outputs, 0 and 1 Data Streams,

LED Control, Buzzer Control and Scanner

Inhibit.

ISC300-0-0-GB-03

November 2009

Page 6

INSTALLATION INFORMATION

Accessories

Find the following when unpacking the ImproX IXP220 Controller:

An ImproX IXP220 Controller with an open frame construction. The construction

consists of a Trivalent Passivated Mild Steel Mounting Plate and a Biaxially-

oriented Polypropylene Cover Plate.

Or an ImproX IXP220 Controller housed in a Black Mild Steel, powder-coated

Cabinet. The Cabinet consists of a hinged Lid and a Base.

One copy of IXP220 Software on CD.

CAUTION: DO NOT use the Metal-oxide Varistors (25 Vrms, 500 A, 77 V max

clamping) with mains power applications.

Three Metal-oxide Varistors, 25 Vrms, 500 A, 77 V max clamping.

A 3 V, CR2032, Lithium cell Battery.

NOTE: This Battery is partially installed all models of the IXP220 Controller.

Four Combi Screws (No. 4 x 10 mm) (IPS96X model only).

Four Brass Wood Screws (3.5 mm x 25 mm).

Four Wall Plugs (7 mm).

A MAC Address Label.

An extra Fixed Address Label.

You will find the following when unpacking the optional extra ImproX GSM Module

(GSM900-0-6-GB-XX):

An ImproX GSM Module.

NOTE: The ImproX GSM Module does NOT include a SIM Card. Please obtain one

from your preferred GPRS (Cellular) service provider.

One GSM Quad Band Antenna with a 1 m (3 ft) cable.

An Alcohol Prep Pad.

General

Remember the following when installing your IXP220 Controller:

Communications Distance

The RS485 communications distance between the IXP220 Controller and the

LAST Controller or Terminal in a cable run, MUST NOT exceed 1 km (1 090 yd).

Achieve this using good quality screened twisted 2-pair cable, earthed on one

side.

If using Ethernet, plug the Controller into an Ethernet Switch or Hub (or other

network device); cable runs must conform to Ethernet cabling specifications.

The RS232 communications distance between the Controller and the connected

Host PC MUST NOT exceed 25 m (82 ft). Achieve this by using good quality

screened twisted 4-core cable.

The USB communications distance between the Host PC and the Controller MUST

NOT exceed 5 m (16 ft).

ISC300-0-0-GB-03

November 2009

Page 7

GPRS has no minimum communications distance.

Termination Resistors for RS485 Bus Communications

Long transmission lines or multiple “star” connections, may cause communication

problems. Placing the Termination Resistor Jumper Link (see Figure 4) in the LAST

IXP220 CONTROLLER AT THE END OF THE CABLE RUN should solve the problem

(depending on the bus).

Reader Connections

NOTE: The IXP220 Controller has three Fixed Addresses. One Fixed Address is

reserved for the Controller. The other two Fixed Addresses (Terminal

Addresses) allow connection of either two Antenna Readers or two Wiegand

Readers.

Antenna Reader

The specified cable distance between the IXP220 Controller and its Antenna

Reader ranges between 2 m to 16 m (7 ft to 53 ft). Optimal performance is not

guaranteed outside of this range. Achieve optimal performance using a good

quality shielded multi-strand 3-pair twisted cable. The cable individual conductor

cross-sectional area should not be less than 0.2 mm2(0.0003 in2).

Ensure that your cable specifications are similar to the following:

Conductor Resistance: < 2 ohms.

Capacitance, Core to Earth: < 160 pF/m.

Capacitance, Core to Core: < 100 pF/m.

To avoid mutual interference Install dual Antenna Readers from the SAME

Controller no closer than 150 mm (6 in) apart.

To avoid mutual interference Install dual Antenna Readers from DIFFERENT

Controllers no closer than 500 mm (20 in) apart.

Wiegand Reader

CAUTION: When implementing the 150 m (164 yd) cable distances with Impro

Wiegand Readers use the 12 V power output option.

For maximum, data communications distance, install the Wiegand Readers no

further than 150 m (164 yd) from the Host unit. The cable individual conductor

cross-sectional area should not be less than 0.2 mm2(0.0003 in2).

To avoid mutual interference, install Wiegand Readers no closer than 500 mm

(20 in) apart.

EARTH Connection

Connect the IXP220 Controller to a good EARTH point. Connect the EARTH Lead to

the “ETH” Terminal on the Power Input Port. Mains EARTH can be used, but electrical

noise may exist.

Blank Space

ISC300-0-0-GB-03

November 2009

Page 8

Arc Suppression

Snubber devices are recommended for EMF Flyback and Arc Suppression when

driving an inductive load with the Relay, see Figure 2.

Figure 2: EMF Flyback

Installing the Real Time Clock (RTC) Backup Battery

CAUTION: Insert the supplied 3 V Lithium Battery for the Real Time Clock into

the Battery Holder BEFORE powering up the IXP220 Controller.

Refer to Figure 4 for the location of the Real Time Clock Backup Battery Holder.

First Time Use

Open Frame Construction (ISC96X)

1. Ensure that power is NOT applied to the Controller.

2. Position the Controller with the Cover Plate facing upwards and the Impro logo on

the right-hand side.

3. Locate the removable Battery Tab underneath the Controller’s Cover Plate, in line

with the Impro logo on the right-hand side.

4. Pull the removable Battery Tab out of the Battery Holder.

5. Apply power to the Controller.

Power Supply Combo (IPS96X)

1. Ensure that power is NOT applied to the Power Supply Combo.

2. Open the Cabinet.

3. Locate the removable Battery Tab in the Real Time Clock Battery Holder.

4. Pull the removable Battery Tab out of the Battery Holder.

5. Close the Cabinet.

6. Apply power to the Power Supply Combo.

Replacement

1. Access the IXP220 Controller’s Printed Circuit Board (PCB):

For ICS96X, remove the Controller’s Cover Plate.

For IPS96X, open the Lid of the Cabinet.

2. Remove the old 3 V, CR2032, Lithium cell Battery from the Battery Holder by

pulling the plastic retaining clip AWAY from the Battery Holder. The Battery Holder

is spring-loaded and will raise the Battery out of the Holder.

ISC300-0-0-GB-03

November 2009

Page 9

3. Slide the NEW 3 V, CR2032, Lithium cell Battery under the metal clip of the Battery

Holder, with the "+" Terminal facing UP.

4. Pull the plastic clip away from the Battery Holder and press the Battery firmly into

the Battery Holder.

5. Complete replacement by:

For ICS96X, replace the Controller’s Cover Plate.

For IPS96X, close the Lid of the Cabinet.

Installing the 12 V Sealed Lead Acid Battery

Power Supply Combo

1. Open the Lid of the Cabinet.

2. Slide the Lid in an upwards direction and unhinge.

3. Place the Battery into the Cabinet with the Battery Terminals in an upwards

position.

4. Connect the Red Battery Terminal Lead to the Positive Battery Terminal.

5. Connect the Black Battery Terminal Lead to the Negative Battery Terminal.

6. Re-hinge the Lid and slide it in a downwards direction.

7. Close the Lid of the Cabinet.

Installing the ImproX GSM Module (Optional Extra)

CAUTION: Connect the ImproX GSM Module BEFORE powering up the IXP220

Controller. Power down the IXP220 Controller BEFORE removing

the GSM Module.

1. Insert the SIM Card as shown on the Module.

2. Access the IXP220 Controller’s Printed Circuit Board (PCB):

For ICS96X, remove the Controller’s Cover Plate.

For IPS96X, open the Lid of the Cabinet.

3. Locate the GSM Module Connectors (See Figure 4).

4. Plug in the GSM Module with the SIM Card Slot positioned on the right-hand side.

5. Plug the GSM Quad Band Antenna into the base of the Module.

6. Select a suitable position for the GSM Quad Band Antenna, considering

accessibility and routing of wires for optimal signal strength.

CAUTION: Ensure that you locate the GSM Quad Band Antenna outside of the

Power Supply Combo (IPS96X) as the metal housing interferes with

the Antenna’s reception.

7. Use the Alcohol Prep Pad (provided) to clean the selected area.

8. Remove the backing paper from the back of the GSM Quad Band Antenna.

9. Affix the GSM Quad Band Antenna in position.

10. Complete installation by:

For ICS96X, replace the Controller’s Cover Plate.

For IPS96X, close the Lid of the Cabinet.

ISC300-0-0-GB-03

November 2009

Page 10

Mounting the Controller

CAUTION: Make certain that you mount the Controller on a vibration-free

surface.

Select the mounting position of the Controller, considering accessibility, routing of wires

and visibility of the externally visible LED. Secure the Controller to the mounting

surface, using four suitable screws and wall plugs (supplied), nuts and bolts or rivets.

Mounting the Power Supply Combo (IPS96X)

1. Fix the Base to the wall using two of the supplied screws in the Mounting Key

Holes.

2. Fix the third screw in the Mounting Slot, adjusting the position of the Base if

necessary.

DIP-switch Settings

NOTE: Once the DIP-switch settings are modified reset the IXP220 Controller to

acknowledge the new settings.

Figure 3: Binary Details for DIP-switch

Reader DIP-switch Settings

Each of the Reader Ports has a 4-way DIP-switch to select the function of that Port.

DIP-switch Position

Connections

0

Antenna.

1

Reader unused. Does not report a Fixed Address.

2

ImproX (IR) Infrared Receiver.

3

Magstripe.

4

Barcode (code 3 of 9) with Checksum.

5

Barcode (code 3 of 9) without Checksum.

ISC300-0-0-GB-03

November 2009

Page 11

DIP-switch Position

Connections

6

Wiegand 26-bit, 44-bit, 40-bit, 37-bit and Tag + PIN-

code or Reason Code Mode.

(Sagem MA100, MA200 or MA300).

7

Wiegand Open Format.

8

If the ImproX RF is connected, then Button 1 of the

ImproX (QT) Quad Transmitter reports.

9

If the ImproX RF is connected, then Button 2 of the

ImproX (QT) Quad Transmitter reports

10

If the ImproX RF is connected, then Button 3 of the

ImproX (QT) Quad Transmitter reports.

11

If the ImproX RF is connected, then Button 4 of the

ImproX (QT) Quad Transmitter reports.

Table 1: Reader DIP-switch Settings

Door Lock Select DIP-switch Settings

DIP-switch Position

Connections

0

No special lock control.

1

Motor Lock.

2

Pulse or Repeating Lock.

3

Fail Safe or Fail Secure with Locked or Unlocked

Status (Solenoid Lock).

4

Normal Lock, no Lock or Unlock Sensors, only

Emergency Mode support.

5

Returns Controller to Factory Default Settings.

NOTE: Return Switch 1 to the OFF position to

resume normal operation.

Table 2: Door Lock Select DIP-switch Settings

ISC300-0-0-GB-03

November 2009

Page 12

ELECTRICAL CONNECTIONS

IXP220 Controller

Key Component Positions

Figure 4: Key Component Positions

ISC300-0-0-GB-03

November 2009

Page 13

Power Supply Combo (IPS96X) Key Component Positions

Figure 5: Power Supply Combo Layout

ISC300-0-0-GB-03

November 2009

Page 14

Electrical Connections

Figure 6: IXP220 Controller Left-hand Side Connection Details

ISC300-0-0-GB-03

November 2009

Page 15

Figure 7: IXP220 Controller Right-hand Side Connection Details

ISC300-0-0-GB-03

November 2009

Page 16

Figure 8: IXP220 Controller Connected to MIWA AL3M Motor Lock

ISC300-0-0-GB-03

November 2009

Page 17

Figure 9: IXP220 Controller Connected to a Pulse or Solenoid Lock

ISC300-0-0-GB-03

November 2009

Page 18

Modes of Operation

The IXP220 System provides five “Modes of Operation”. These Modes are selected via

the PC Software.

Power Control Mode

CAUTION: Refer to the Alarm Relays maximum current and voltage ratings

listed under Alarm (page 4).

Figure 10: Power Control Mode

Power Control (Emergency) Mode

This Mode allows you to unlock all Doors (Locations) on a single Controller. That is,

the “Emergency Open” input unlocks all doors in the System.

Where you have 2 Controllers with inter-controller communications, and both

Controllers set to Power Control (Emergency) Mode, the unlock instruction passes from

Controller 1 to Controller 2. That is, all Doors (Locations) connected to these

Controllers unlock.

Power Control (Lockdown) Mode

This Mode allows you to lockdown all Doors (Locations) on a single Controller. That is,

essentially denying Tagholder entry.

Where you have 2 Controllers with inter-controller communications, and both

Controllers set to Power Control (Lockdown) Mode, the lockdown instruction passes

from Controller 1 to Controller 2. That is, all Doors (Locations) connected to these

Controllers enter lockdown.

Alarm Arming Mode

In this Mode, the Controller interfaces with an Alarm Panel to either, arm or disarm, or

trigger the Alarm Panel.

Arming

1. In the IXP220 Software, designate a Reader as an “Alarm Arming Reader”, by

selecting the Alarm Arm checkbox.

2. Present an Administrator or Supervisor Tag to the “Alarm Arming Reader”.

3. Press the “#” key on the Keypad Reader, within 10 seconds of presenting the Tag.

The Reader beeps for 30 seconds, before activating the Alarm Relay, giving you

sufficient time to vacate the Alarm Zone.

ISC300-0-0-GB-03

November 2009

Page 19

The “Armed” Input is used to detect if the Alarm Panel is armed. This Input sets the

“Alarm Arming Readers” Status LED to blink, indicating that the Alarm is armed.

When the System is armed, the “Alarm Arming Reader” will deny Normal or Visitor

Tags access.

Disarming

Present an Administrator or Supervisor Tag to the “Alarm Arming Reader”. The Alarm

Relay will deactivate, signaling the Alarm Panel to disarm.

Alarm Events

The Controller has several Events that can trigger the Alarm Panel when it is armed.

These are:

Door Forced.

Anti-tamper.

Figure 11: Alarm Mode

Intrusion Mode

In this Mode, there is no installed Alarm Panel, and a simple Alarm Sensor is required.

You may connect Passive Infrared or other types of sensors to the IXP220 System’s

Digital Inputs (Inputs 1 and 2). If any of these sensors trigger, the IXP220 System

receives an input signal, activating Relay 3. Relay 3 then drives the siren.

Arming

1. In the IXP220 Software, designate a Reader as an “Intrusion Arming Reader”, by

selecting the Alarm Arm checkbox.

2. Present an Administrator or Supervisor Tag to the “Intrusion Arming Reader”.

3. Press the “#” key on the Keypad Reader, within 10 seconds of presenting the Tag.

The Reader beeps for 30 seconds, after which Intrusion Mode activates.

When the System is armed, the “Intrusion Arming Reader” will deny Normal or Visitor

Tags access.

Disarming

Present an Administrator or Supervisor Tag to the “Intrusion Arming Reader”.

Blank Space

ISC300-0-0-GB-03

November 2009

Page 20

Figure 12: Intrusion Mode

Bell Button

In this mode, the Bell Button on the ImproX (KMA) Mullion Keypad Antenna Reader,

when pushed, drives Relay 3 on the IXP220 Controller.

Action Mode

Use this Mode to drive Relay 3 when using the Building Management feature.

Figure 13: Bell Button and Action Mode

Blank Space

This manual suits for next models

6

Table of contents

Popular Controllers manuals by other brands

CHCNAV

CHCNAV LT800H user guide

EUCHIPS

EUCHIPS EULP50D-2HMC-0 quick start guide

Mitsubishi Electric

Mitsubishi Electric MELSERVO MR-J4-B-LL Series instruction manual

Addonics Technologies

Addonics Technologies AD2N1GPX4 user guide

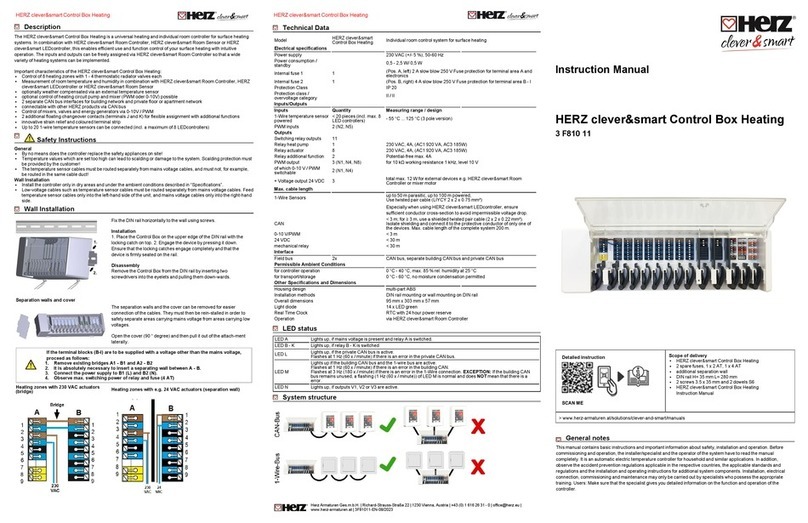

Herz

Herz clever&smart Control Box Heating instruction manual

RMG

RMG GSM1SPAT installation manual