The IM2000S is a high per for -

mance microstepping controller

that in cor po rates a sine/cosine

sig nal gen er a tor, anti-res o nance

cir cuit ry, PWM cur rent control

and much more in one mono lith ic

IC. The IM2000S com bines hard-

ware in tense func tions to geth er

with in no va tive fea tures to provide

de sign ers with a powerful yet sim ple

solution for their high vol ume OEM

Never before has any motion prod-

uct integrated all the digital control

into one mono lith ic IC. This high

de gree of in te gra tion can signi -

cantly reduce design time as well

Beyond the integration of a com-

plete microstepping control sys tem,

the IM2000S has unique features

that give designers un prec e dent ed

con trol over motor move ment.

These fea tures in clude 14 se lect -

able res o lu tions (in both decimal

and binary) that can be changed at

any time with out motor move ment

in ter rup tion. There is no need to

reset the con trol ler. This al lows the

user to rapidly move long dis tanc es,

yet pre cise ly position the mo tor at

the end of trav el without the need or

expense of a com plex controller.

Another valuable feature is an “On

Full Step” output which in di cates

when the mo tor is at an electrical

full step. This output can be used

to reduce the over head needed to

track position when making long

The development of pro pri etary cir-

cuits has minimized ripple cur rent,

while main tain ing a 20 KHz chop-

ping rate. This prevents additional

motor heat ing that is common with

drivers re quir ing high er chop ping

rates. Now low inductance step per

motors can be used to im prove

high speed per for mance and peak

The IM2000S needs only clock

and di rec tion inputs to control the

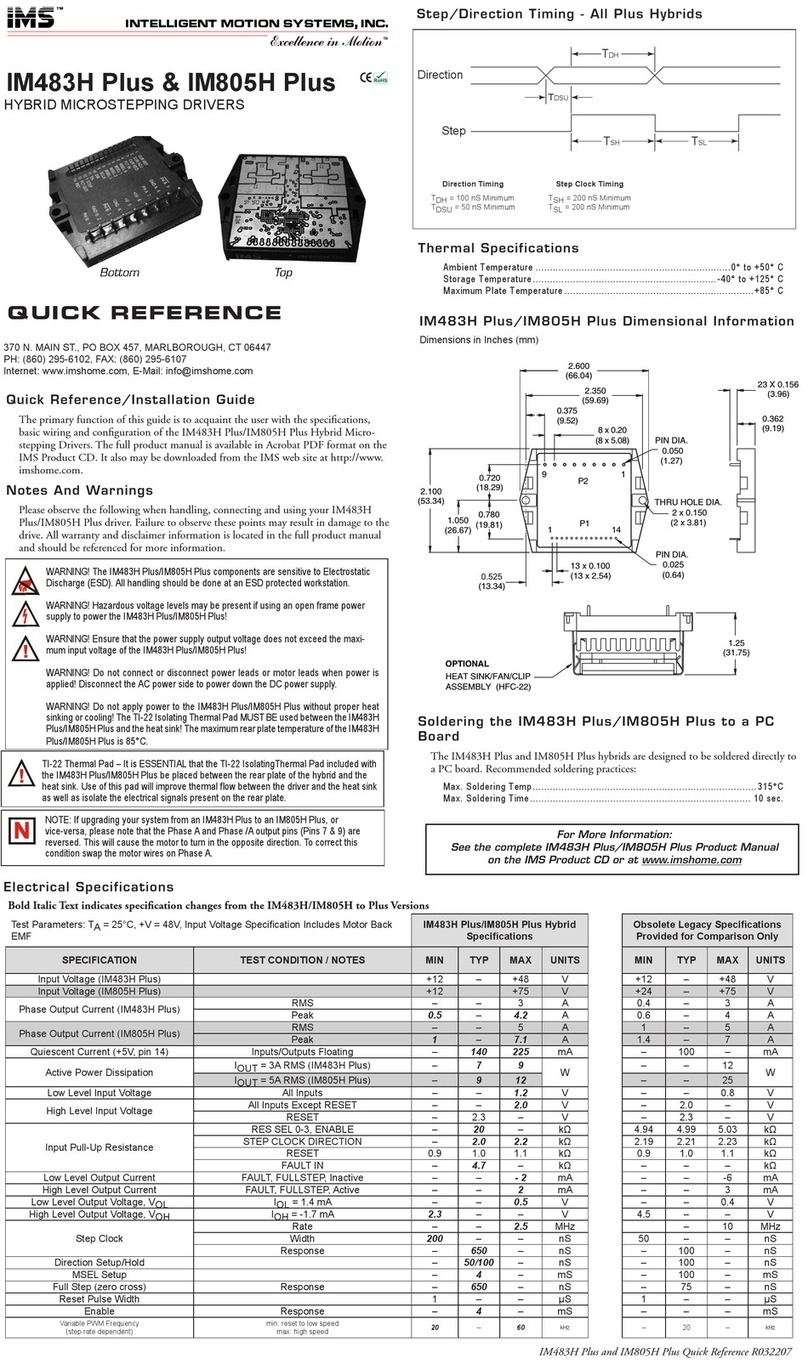

Dimensions in Inches (mm)

mo tor and will in ter face directly to

dis crete bridg es or com mon mono-

Designers can now place drivers

di rect ly on their PC boards with all

the nec es sary con trol in an ultra

small 64 pin QFP package.

Size, price and time-to-market are

three crucial aspects in today’s

com pet i tive mar kets and the

IM2000S of fers the ability to re-

IM2000S Offers a Com plete

Microstepping Control Sys tem

Up to 10MHz Step Clock Rate

Internal Sine/Cosine Generator

PWM Phase Current Control

Minimal External Components

Automatic Current Reduction

14 Selectable Resolutions, in

Both Dec i mal and Binary

On-The-Fly With out Motor

Single +5 VDC Power Supply

Temperature Protection Inputs