1IM483 Operating Instructions Revision R032306

Table of Contents

Introduction............................................................................................... 5

The IM483 ..................................................................................................................... 5

Features and Benets ................................................................................................... 5

The Product Manual ...................................................................................................... 6

The Product Manual ...................................................................................................... 6

Notes and Warnings...................................................................................................... 7

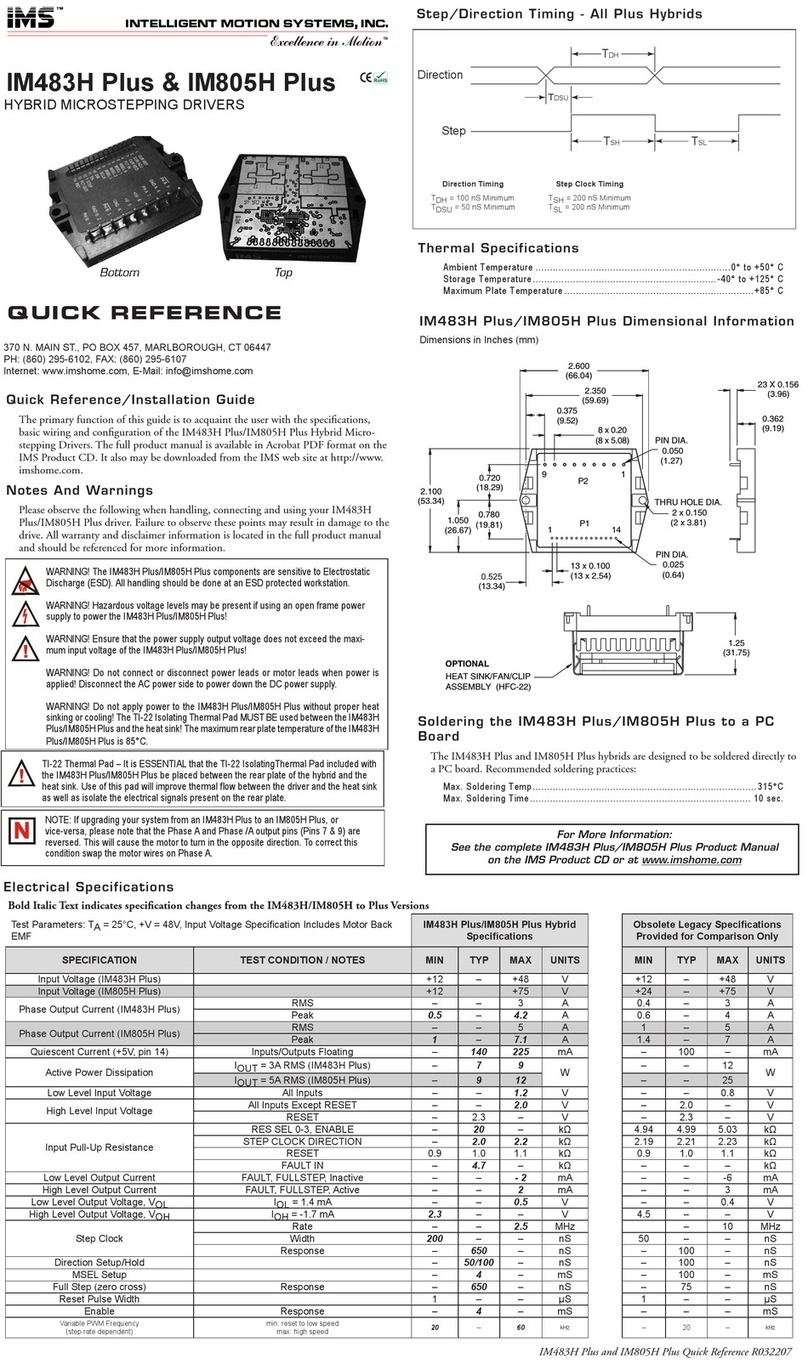

Hardware Specications........................................................................... 8

Section Overview .......................................................................................................... 8

Mechanical Specications ............................................................................................. 8

Electrical Specications................................................................................................. 9

Thermal Specications ................................................................................................ 10

Pin Assignment and Description ................................................................................. 10

Mounting The IM483 .............................................................................. 13

Theory of Operation ............................................................................... 14

Section Overview ........................................................................................................ 14

Circuit Operation ......................................................................................................... 14

Microstep Select (MSEL) Inputs.................................................................................. 15

Stepping ...................................................................................................................... 15

Dual PWM Circuit ........................................................................................................ 16

Fullstep Output Signal ................................................................................................. 17

Timing.......................................................................................................................... 17

Power Supply Requirements.................................................................. 18

Section Overview ........................................................................................................ 18

Selecting a Power Supply ........................................................................................... 18

Selecting an Opto Supply............................................................................................ 20

Recommended Wiring................................................................................................. 21

AC Line Filtering.......................................................................................................... 22

Motor Requirements............................................................................... 23

Section Overview ........................................................................................................ 23

Selecting a Motor ........................................................................................................ 23

Motor Wiring ................................................................................................................ 28

Connecting the Motor .................................................................................................. 28

Interfacing and Controlling the IM483 .................................................... 32

Section Overview ........................................................................................................ 32

Layout and Interface Guidelines.................................................................................. 32

Motor Power Connection (+V)..................................................................................... 33

Conguring and Controlling the Output Current .......................................................... 34

Controlling the Output Resolution ............................................................................... 39

Interfacing and Using the Isolated Logic Inputs .......................................................... 41

Connecting and Using the Fault Output ...................................................................... 47

Full Step Output .......................................................................................................... 48

Minimum Connections................................................................................................. 49

Troubleshooting...................................................................................... 50

Section Overview ........................................................................................................ 50

Basic Troubleshooting................................................................................................. 50

Problem Symptoms and Possible Causes .................................................................. 50

Contacting Technical Support ..................................................................................... 53

The IMS Web Site ....................................................................................................... 53

Returning Your Product to IMS ................................................................................... 53