Electrical Specifications

HYBRID MICROSTEPPING DRIVERS

WARNING! The IM483H Plus/IM805H Plus components are sensitive to Electrostatic

Discharge (ESD). All handling should be done at an ESD protected workstation.

WARNING! Hazardous voltage levels may be present if using an open frame power

supply to power the IM483H Plus/IM805H Plus!

WARNING! Ensure that the power supply output voltage does not exceed the maxi-

mum input voltage of the IM483H Plus/IM805H Plus!

WARNING! Do not connect or disconnect power leads or motor leads when power is

applied! Disconnect the AC power side to power down the DC power supply.

WARNING! Do not apply power to the IM483H Plus/IM805H Plus without proper heat

sinking or cooling! The TI-22 Isolating Thermal Pad MUST BE used between the IM483H

Plus/IM805H Plus and the heat sink! The maximum rear plate temperature of the IM483H

Plus/IM805H Plus is 85°C.

IM483H Plus & IM805H Plus

Quick Reference/Installation Guide

The primary function of this guide is to acquaint the user with the specifications,

basic wiring and configuration of the IM483H Plus/IM805H Plus Hybrid Micro-

stepping Drivers. The full product manual is available in Acrobat PDF format on the

IMS Product CD. It also may be downloaded from the IMS web site at http://www.

imshome.com.

Notes And Warnings

Please observe the following when handling, connecting and using your IM483H

Plus/IM805H Plus driver. Failure to observe these points may result in damage to the

drive. All warranty and disclaimer information is located in the full product manual

and should be referenced for more information.

Thermal Specifications

Ambient Temperature ....................................................................0° to +50° C

Storage Temperature ................................................................-40° to +125° C

Maximum Plate Temperature ..................................................................+85° C

Soldering the IM483H Plus/IM805H Plus to a PC

Board

The IM483H Plus and IM805H Plus hybrids are designed to be soldered directly to

a PC board. Recommended soldering practices:

Max. Soldering Temp..............................................................................315°C

Max. Soldering Time............................................................................. 10 sec.

TI-22 Thermal Pad – It is ESSENTIAL that the TI-22 IsolatingThermal Pad included with

the IM483H Plus/IM805H Plus be placed between the rear plate of the hybrid and the

heat sink. Use of this pad will improve thermal ow between the driver and the heat sink

as well as isolate the electrical signals present on the rear plate.

For More Information:

See the complete IM483H Plus/IM805H Plus Product Manual

on the IMS Product CD or at www.imshome.com

NOTE: If upgrading your system from an IM483H Plus to an IM805H Plus, or

vice-versa, please note that the Phase A and Phase /A output pins (Pins 7 & 9) are

reversed. This will cause the motor to turn in the opposite direction. To correct this

condition swap the motor wires on Phase A.

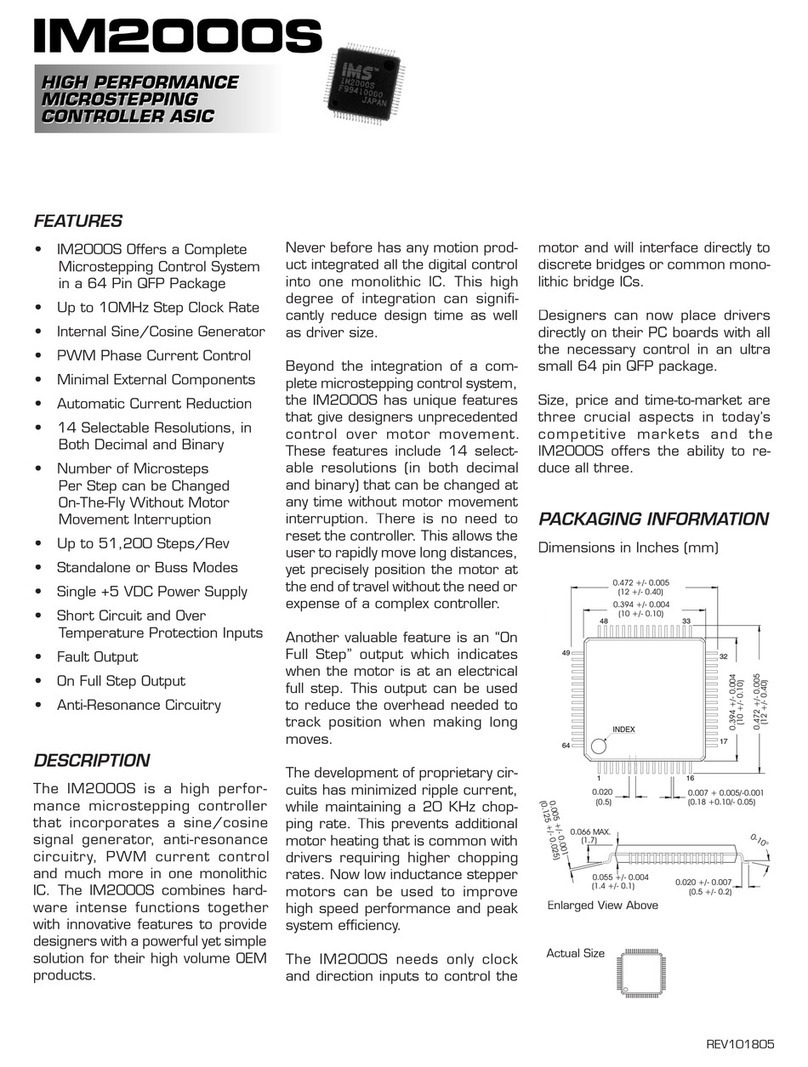

IM483H Plus/IM805H Plus Dimensional Information

Dimensions in Inches (mm)

HEAT SINK/FAN/CLIP

ASSEMBLY (HFC-22)

1.25

(31.75)

0.525

(13.34)

13 x 0.100

(13 x 2.54)

PIN DIA.

0.025

(0.64)

PIN DIA.

0.050

(1.27)

THRU HOLE DIA.

2 x 0.150

(2 x 3.81)

2.100

(53.34)

0.780

(19.81)

1.050

(26.67)

0.720

(18.29)

1

141

9P2

P1

0.375

(9.52)

8 x 0.20

(8 x 5.08)

2.350

(59.69)

2.600

(66.04)

23 X 0.156

(3.96)

0.362

(9.19)

OPTIONAL

Test Parameters: TA = 25°C, +V = 48V, Input Voltage Specication Includes Motor Back

EMF

IM483H Plus/IM805H Plus Hybrid

Specications

Obsolete Legacy Specications

Provided for Comparison Only

SPECIFICATION TEST CONDITION / NOTES MIN TYP MAX UNITS MIN TYP MAX UNITS

Input Voltage (IM483H Plus) +12 – +48 V +12 – +48 V

Input Voltage (IM805H Plus) +12 +75 V +24 – +75 V

Phase Output Current (IM483H Plus) RMS – – 3 A 0.4 – 3 A

Peak 0.5 –4.2 A 0.6 – 4 A

Phase Output Current (IM805H Plus) RMS – – 5 A 1 – 5 A

Peak 1–7.1 A 1.4 – 7 A

Quiescent Current (+5V, pin 14) Inputs/Outputs Floating – 140 225 mA – 100 – mA

Active Power Dissipation IOUT = 3A RMS (IM483H Plus) – 7 9 W– – 12 W

IOUT = 5A RMS (IM805H Plus) – 9 12 – – 25

Low Level Input Voltage All Inputs – – 1.2 V – – 0.8 V

High Level Input Voltage All Inputs Except RESET – – 2.0 V – 2.0 – V

RESET – 2.3 – V – 2.3 – V

Input Pull-Up Resistance

RES SEL 0-3, ENABLE – 20 –kΩ 4.94 4.99 5.03 kΩ

STEP CLOCK DIRECTION – 2.0 2.2 kΩ 2.19 2.21 2.23 kΩ

RESET 0.9 1.0 1.1 kΩ 0.9 1.0 1.1 kΩ

FAULT IN – 4.7 –kΩ – – – kΩ

Low Level Output Current FAULT, FULLSTEP, Inactive – – - 2 mA – – -6 mA

High Level Output Current FAULT, FULLSTEP, Active – – 2mA – – 3 mA

Low Level Output Voltage, VOL IOL = 1.4 mA – – 0.5 V – – 0.4 V

High Level Output Voltage, VOH IOH = -1.7 mA 2.3 – – V 4.5 – – V

Step Clock

Rate – – 2.5 MHz – 10 MHz

Width 200 – – nS 50 – – nS

Response – 650 – nS – 100 – nS

Direction Setup/Hold –50/100 – nS – 100 – nS

MSEL Setup – 4– mS – 100 – mS

Full Step (zero cross) Response – 650 – nS – 75 – nS

Reset Pulse Width 1 – – µS 1 – – µS

Enable Response – 4– mS – – – mS

Variable PWM Frequency

(step rate dependent)

min: reset to low speed

max: high speed 20 –60 kHz – 20 – kHz

T

DSU

T

DH

T

SH

T

SL

Direction

Step

TDH = 100 nS Minimum

TDSU = 50 nS Minimum

TSH = 200 nS Minimum

TSL = 200 nS Minimum

Direction Timing Step Clock Timing

Step/Direction Timing - All Plus Hybrids

Bold Italic Text indicates specification changes from the IM483H/IM805H to Plus Versions

intelligent motion systems, INC.

370 N. MAIN ST., PO BOX 457, MARLBOROUGH, CT 06447

PH: (860) 295-6102, FAX: (860) 295-6107

Q U I C K R E F E R E N C E

IM483H Plus and IM805H Plus Quick Reference R032207