IMT Diamond Air DA435ELW User manual

DA435ELW: 99900917: iii

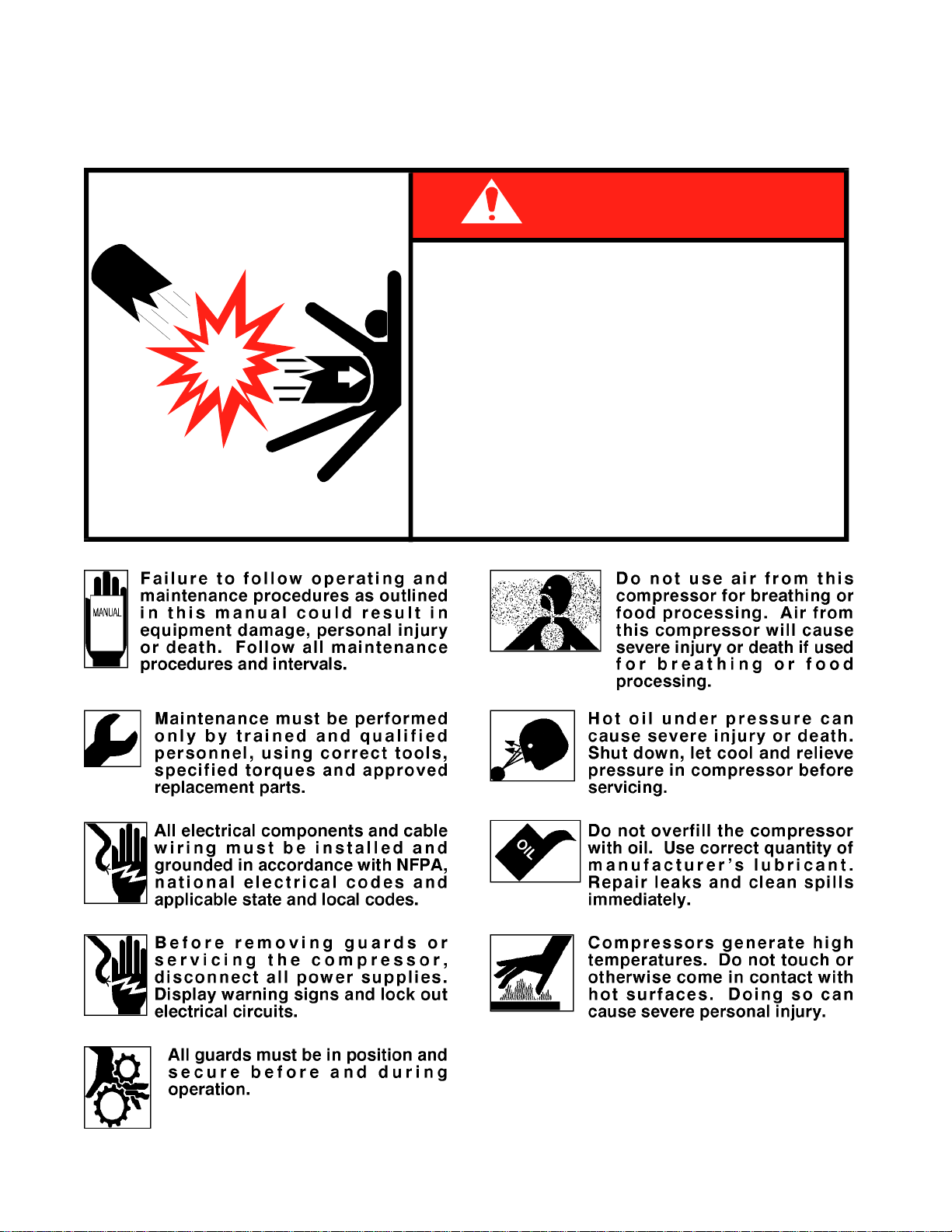

PRECAUTIONS

Read before operating your compressor!

19980223

71393886

DANGER

EXPLODINGTANK WILL CAUSE

DEATH, SERIOUS INJURY

OR PROPERTY DAMAGE

●

Drain air tank after each use to prevent

moisture build-up and corrosion which

leads to tank failure.

Assure that tank and compressor relief

valves work properly, and are at correct

pressure settings.

DO NOT modify or repair air tank.

NEVER drive vehicle with pressure in air

tank.

●

●

●

DA435ELW: 99900917: v

TABLE OF CONTENTS

PARA TITLE PAGE

Section 1. SPECIFICATIONS

GENERAL 1-1

SPECIFICATIONS 1-1

OUTSIDE DIMENSIONS 1-1

Section 2. NOT USED

Section 3. OPERATION

GENERAL 3-1

OPERATION 3-1

Section 4. MAINTENANCE & PARTS

GENERAL 4-1

ROUTINE MAINTENANCE CHECKLIST 4-1

AIR COMPRESSOR DA435ELW-PARTS (51713976) 4-2

AIR COMPRESSOR DA435ELW-DRAWING (51713976) 4-3

AIR COMPRESSOR DA435ELW-DRAWING (51713976) 4-4

REPAIR KITS 4-5

PRESSURE SWITCH KIT (51713977) 4-5

Section 5. REPAIR

5-1. GENERAL 5-1

5-2. PISTON RING REPLACEMENT 5-1

5-3. OIL PUMP REPLACEMENT 5-2

5-4. CRANKSHAFT AND BEARING REPLACEMENT 5-4

5-5. COMPRESSOR DRIVE BELT REPLACEMENT 5-5

5-6. CLUTCH REPLACEMENT 5-5

5-7. TROUBLESHOOTING 5-6

19980223

DA435ELW: 99900917: 1-119970808

SPECIFICATIONS

Bore 2-5/8"

Stroke 2-1/2"

Cylinder Configuration V4

Displacement 44 CFM*

Delivery 35 CFM*

Lubrication Oil Pump

Oil Capacity 1-1/3 qts

Cooling Water

Height 13-1/2”

Width 15”

Length 13-7/8”

Material Aluminum Alloy

Weight 87 lbs.

* @ 1400 RPM - 100 PSI

SECTION 1. SPECIFICATIONS

OUTSIDE DIMENSIONS

GENERAL

The IMT DA435ELW air compressor is a single

stage, liquid cooled, 4-cylinder, pressure lubricated

unit, with a delivery rate of 35 CFM at 1400 RPM.

The compressor is belt driven from the engine

crankshaft, through a magnetic clutch. It is engaged

and disengaged by use of an air pressure sensing,

electric switch. This pressure switch is preset at

approximately 90 PSI to engage, and 130 PSI to

disengage.

CAUTION

OPERATING THE COMPRESSOR AT 35 CFM WITH

PRESSURESGREATERTHAN130 PSIWILLSHORTEN

THE SERVICE LIFEAND VOID THE WARRANTY.

The compressor must not operate more than 6

minutes out of a 10 minute period. This will include

operating continuously for 6 minutes out of 10

minutes or operation in segments for a total of 6

minutes out of 10 minutes.

DA435ELW: 99900917: 3-119970508 SECTION 3. OPERATION

GENERAL

Each compressor is bench tested under load at the

factory to ensure proper break-in and operation.

While it is not necessary to follow any break-in

procedure, the following checks should be made

before putting the unit into service, as well as,

periodically during use.

Before start-up:

1. Check the oil level in the compressor

crankcase with the dipstick on the unit. If oil is

needed, use only IMT’s synthetic compressor oil.

2. Check the air intake filter pads on each head

to make certain that they are clean and

unobstructed. Dirty filters are a possible cause of

reduced air output. Bi-weekly checks of air

filters is recommended.

OPERATION

The system will function automatically. It will

engage the compressor clutch when the air receiver

tank pressure is below 90 psi, and disengage the

clutch when the air pressure reaches 130 psi.

CAUTION

OPERATING THIS UNIT IN EXCESS OF 1400 RPM,

WILLVOIDTHEWARRANTY,ANDWILLSHORTENTHE

NORMAL SERVICE LIFE OF THE COMPRESSOR.

DA435ELW: 4-251713976.01: 19970620

ITEM PARTNO. DESCRIPTION QTY

1. 60025012 CRANKCASE (PART OF 94) 1REF

2. 60025194 CYLINDER BLOCK 2

3. 60250270 CYLINDER HEAD 2

4. 60025193 PULSATION TANK 1

5. 70733069 REED VALVEASM 2

6. 73073030 DIPSTICK 1

7. 70014613 DIPSTICK TUBE 1

8. 60120238 OIL SCREEN TUBE (PART OF 94) 1REF

9. 60120289 OIL SCREEN (PART OF 94) 1REF

10. 72066008 OIL SCREEN CLAMP (PART OF 94) 1REF

11. 72053090 PIPE NIPPLE 1/2NPT X CLOSE 1

12. 51705310 BREATHER CAP ASM(INCL:95,96) 1

13. 72063050 WASHER 5/16 LOCK (PART OF 94) 5REF

14. 72053403 PLUG 3/8NPT SH (PART OF 94) 1REF

15. 72053413 PLUG 3/8NPT SQHD (PART OF 94) 1REF

16. 70039300 IDENTIFICATION PLATE 1

17. 72063001 WASHER 1/4 FLAT 12

18. 70014626 AIR INTAKE RETAINER 8

19. 76393803 AIR INTAKE FILTER 8

20. 72062001 NUT 5/16-18 HEX 12

21. 72060063 CAP SCR 7/16-14X1-1/4 HHGR5 4

22. 72062036 NUT 5/16-24 HEX 12

23. 76039111 GASKET 2

24. 72053403 PIPE PLUG 3/8NPT SH 6

25. 70024122 WASHER 5/16 FLAT COPPER 12

26. 72063052 WASHER 7/16 LOCK 4

27. 72063050 WASHER 5/16 LOCK 1

28. 72063001 WASHER 1/4 WRT 2

29. 72060005 CAP SCR 1/4-20X1-1/4 HHGR5 2

30. 72053404 PLUG 1/2NPT SH 1

31. 7Q072212 O-RING 8

32. 76392642 HEAD GASKET 2

33. 76392641 GASKET-CYL/VALVEPLATE 2

34. 76392119 GASKET-CYL/SPACER 2

35. 70029293 SPACER-CYL BLOCK 2

36. 60106933 CAP 2

37. 72063049 WASHER 1/4 LOCK 2

38. 72066537 CABLE CLAMP 2

39. 70394571 PLUG 2

40. 72661487 DRIVE PIN 3

41. 76393107 O-RING 2

42. 72066426 BALL (PART OF 97) 2REF

43. 70029593 INSERT (PART OF 97) 2REF

44. 7Q073017 O-RING (PART OF 97) 2REF

45. 72601708 STUD 5/16-18X3-1/2 12

53. 76392550 FOAM FILTER 4

54. 70732444 CLUTCH HARDWARE 1

55. 70056437 PULLEY-1 GROOVE .63" REF

70056304 PULLEY-2 GROOVE .50" REF

70056441 PULLEY-6 GROOVE SERPENTINE REF

70056442 PULLEY-7 GROOVE SERPENTINE REF

CONTINUED

DA435ELW AIR COMPRESSOR

(51713976-1)

ITEM PARTNO. DESCRIPTION QTY

56. 77044419 COIL 1

57. 76039119 SEAL (PART OF 91) 1REF

58. 60025007 FRT BRG HSG (PART OF 91) 1REF

59. 70055011 FRT BRG CUP (PART OF 91) 1REF

60. 70055012 FRT BRG CONE PART OF 93) 1REF

61. 60108748 CRANKSHAFT (PART OF 93) 1REF

62. 72066267 WOODRUFF KEY #6 1

63. 70055009 REAR BRG CONE (PART OF 93) 1REF

64. 60101269 OIL PUMP COLLAR (PART OF 93) 1REF

65. 72066307 DRIVE PIN (PART OF 93) 1REF

66. 70055010 REAR BRG CUP (PART OF 92) 1REF

67. 60025005 REAR BRG HSG (PART OF 92) 1REF

68. 70014583 COIL SPRING 1

69. 60101505 SLEEVE 1

70. 70051006 OIL PUMP 1

71. 60250501 PUMP COVER 1

73. 72053411 PIPE PLUG 1/8NPT SQHD 2

74. 72060731 CAP SCR 5/16-18X3/4 SH

(PART OF 94) 5REF

75. 72060731 CAP SCR 5/16-18X3/4 SH 4

76. 51029283 CONNECTING ROD 4

77. 51029285 PISTON ASM (INCL:78,79,100) 4

78. 70014627 WRIST PIN (PART OF 77) 4REF

79. 72066018 RETAINING RING (PART OF 77) 8REF

80. 70014600 OIL RING (PART OF 88) 4REF

81. 70014599 COMPRESSION RING(PART OF 88) 8REF

82. 76039092 GASKET-REAR BRG .006 2AR

76039094 GASHET-REAR BRG .010 2AR

76039144 GASKET-REAR BRG .020 2AR

76039143 GASKET-REAR BRG .015 2AR

83. 76039093 PUMP COVER GASKET 1

84. 76039112 FRT BRG HSG GASKET 2REF

87. 72060025 CAP SCR 5/16-18X1HHGR5

(PART OF 94) 5REF

88. 51014947 RING SET (INCL:80,81) 1

91. 51705709 FRT BRG HSG (INCL:57-59)

(PART OF 94) 1REF

92. 51705710 REAR BRG HSG (INCL:66,67)

(PART OF 94) 1REF

93. 51705661 CRANKSHAFT ASM(INCL:60,61,63-65)

(PART OF 94) 1REF

94. 51714001 CRANKSHAFT/CASE ASM 1

95. 60107276 CAP-MODIFIED (PART OF 12) 1REF

96. 70048080 BREATHER (PART OF 12) 1REF

97. 51714023 INSERT ASM (INCL:42-44,98,102) REF

98. 70029468 SHIM (PART OF 97) 2REF

99. 70039124 DECAL-OIL FILL 1

100. 70029062 PISTON (PART OF 77) 4REF

101. 72601060 STUD 5/16-24X2 NC GR5 12

102. 76393085 O-RING (PART OF 97) 2REF

DA435ELW: 4-551713977.01: 19971022

REPAIR KITS

GASKET KIT - 51393640

7Q072212 O-RING - CYL HEAD 8

76039092 GASKET-REAR BRG HSG .006 2

76039093 GASKET-PUMP COVER 1

76039094 GASKET-REAR BRG HSG .010 2

76039111 GASKET-CYL BLOCK BOTTOM 2

76039112 GASKET-FRT BRG HSG 2

76039119 SEAL 1

76039143 GASKET-REAR BRG HSG .015 2

76039144 GASKET-REAR BRG HSG .020 2

76392119 GASKET-CYL BLOCK 2

76392642 GASKET-REED VALVE/HEAD 2

76392641 GASKET-REEDVALVE/CLY 2

CRANKSHAFT KIT - 51705743

51705742 CRANKSHAFT ASM 1

51705661 CRANKSHAFT MACH 1REF

72066297 WOODRUFF KEY 1REF

70055010 BEARING-REAR CUP 1

70055011 BEARING-FRT CUP 1

70055012 BEARING-FRT CONE 1REF

70055009 BEARING-REAR CONE 1REF

72066307 DRIVE PIN 1REF

60101269 OIL PUMP COLLAR 1REF

PISTON RING SET - 51014947

70014599 COMPRESSION RING 8

70014600 OIL RING 4

ITEM PARTNO. DESCRIPTION QTY

1. 77041532 PRESSURE SWITCH 1

2. 72532952 BRASS INSERT 4

3. 89034176 AIR LINE 1/4" (10 FT) 1

4. 72531827 REDUCER BUSHING 3/8-1/2NPT 2

5. 72531042 ELBOW 1/8-1/4NPT 90° 3

PRESSURE SWITCH KIT (51713977)

DA435ELW: 99900917: 5-1

SECTION 5. REPAIR

19970313

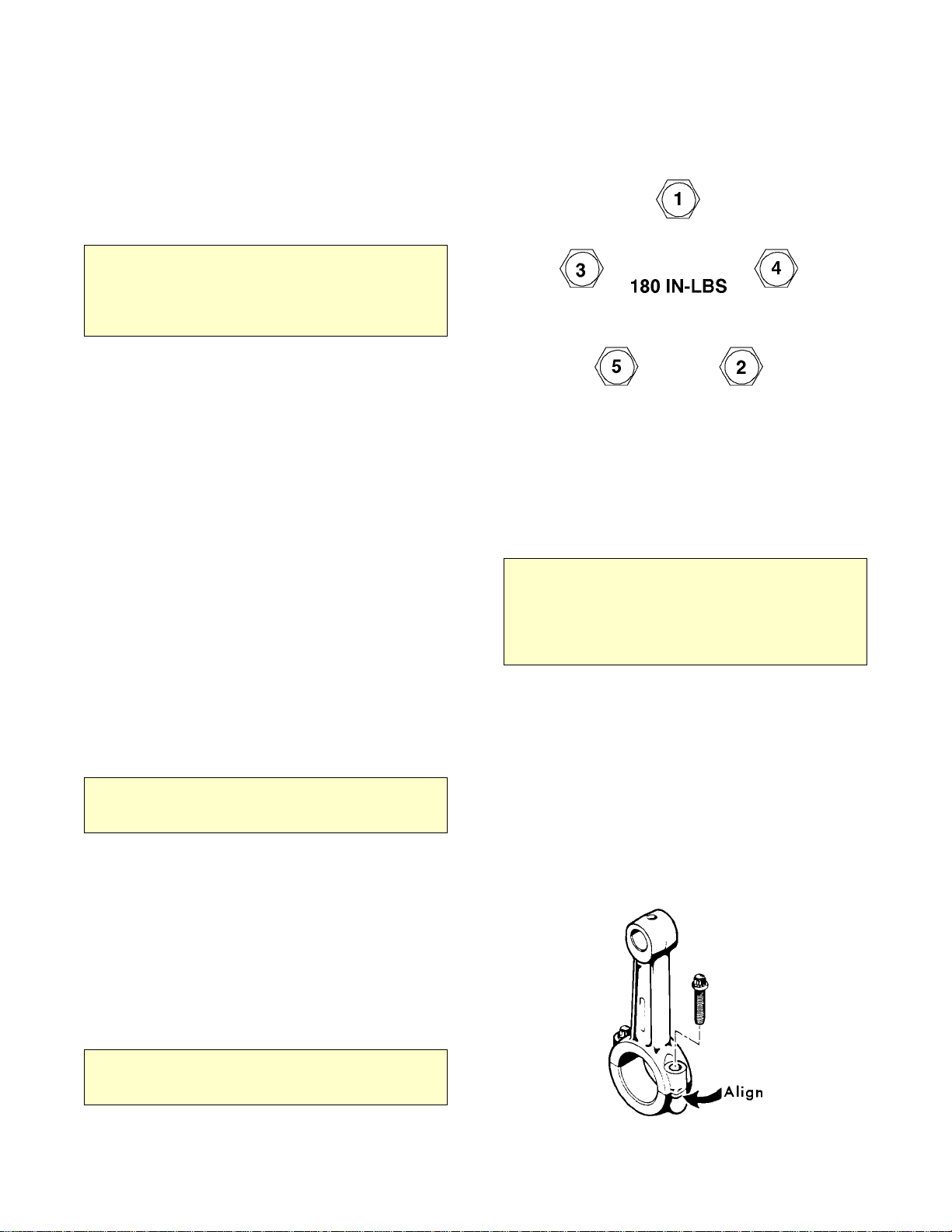

FIGURE E-2. CYLINDER HEAD TORQUE

SEQUENCE

FIGURE E-1. PISTON RING

ORIENTATION

5-1. GENERAL

This section describes the disassembly and assembly

procedures for the air compressor. In all cases,

remove the compressor from the welder before

proceeding with disassembly. Refer to the parts

drawing in section 4 of this manual for parts

locations.

5-2. PISTON RING REPLACEMENT

1. Remove the pulsation tank.

2. Unscrew the head bolts and remove the heads.

NOTE

A RUBBER FACED MALLET WILL HELP WHEN

REMOVING THE HEAD. TAP THE SIDES OF THE

HEAD CAREFULLY UNTIL THE HEAD IS LOOSE.

LIFT OFF THE HEADS.

3. Remove the cylinder bolts. Tap the sides of the

cylinder several times to break it loose from the

gasket. Rock the cylinder back and forth and lift

until it is free. Lift it off the pistons.

4. Use a single edged razor blade, or sharp putty

knife, to remove the old gasket material.

CAUTION

DO NOTALLOW THE GASKET MATERIAL TO FALL

INTO THE CRANKCASE. DO NOT NICK THE HEAD,

CYLINDER, OR CRANKCASE MATING FACES

WHILE REMOVING THE OLD GASKET. REMOVE

ALL OF THE OLD GASKET MATERIAL TO PROVIDE

A SMOOTH, CLEAN SURFACE FOR THE NEW

GASKET. FAILURE TO FOLLOW THIS PROCEDURE

MAY RESULT IN THE NEED TO RESEAL THE UNIT

LATER.

5. Hone the cylinder to break the glaze and to

remove the buildup at the top of the cylinders.

6. Measure the inside diameter of the cylinder for

roundness and excessive wear. The bore should be

2.625" (0.0025" tolerance). If the bore is oversized,

the cylinder must be replaced.

7. With a ring expander, remove the compression

and oil rings.

8. With the ring expander, install the new ring kit.

Make certain that the oil ring is on the bottom and

the beveled inside edge of the compression ring is

toward the top of the piston.

9. Position the cylinder base gasket on the crankcase.

Use a few drops of oil to hold it in position. Install

the cylinder block spacer and gasket on the

crankcase.

10. Rotate the rings so that the gaps of the three

rings are 120° apart. Lightly lubricate the inside of

the cylinder. Rotate the crankshaft so that a piston is

at the top of the stroke. Compress the rings with a

ring compressor, and slide the cylinder over the

piston. Repeat for the other piston.

CAUTION

DO NOT LUBRICATE THE RINGS. USE A LIGHT

LUBRICANT, SUCH AS WD-40 ONLY, ON THE

CYLINDER WALLS. OILING THE RINGS WILL

PREVENT THEM FROM SEATING AND CAUSE

EXCESSIVE OIL CONSUMPTION.

DA435ELW: 99900917: 5-219970508

11. Slide the cylinder down until it mates with the

crankcase. Start all cylinder mounting bolts, until

they are snug. Torque the bolts to 180 in-lbs in the

sequence shown. Do not torque to the full 180 in-

lbs all at once. Torque in 25-50 in-lb increments.

NOTE

NO GASKET SEALER IS TO BE USED ON IMT REED

VALVE COMPRESSOR GASKETS.

12. Position the gaskets and valve plate on top of the

cylinder. Position the head on thecylinder and turn

studs finger tight.

NOTE

INSTALL THE REED VALVE PLATE WITH THE IMT

LOGO UP AND WORD “EXHAUST” TOWARD THE

PULSATION TANK.

NOTE

TO THIS POINT, STUDS SHOULD STILL BE FINGER

TIGHTAND NUTS INSTALLED ON STUDS.

13. Push the heads up toward each other and tighten

center two nuts on each head to 140 in-lbs (12 ft-

lbs).

14. Torque the remaining nuts to 140 in-lbs (15 ft-

lbs) per Figure E-2.

15. Install new O rings between heads and

pulsation tank.

16. Set pulsation tank into place and finger tighten

bolts.

17. Cross tighten the pulsation tank to 180 in-lbs (15

ft-lbs).

18. Torque per Figure E-2, all head nuts to 240 in-

lbs (15 ft-lbs) plus or minus 10 in-lbs, in 25-40 lb

increments.

19. Re-torque after 15 or 20 minutes have passed,

per Figure E-2, all head nuts to rating above.

NOTE

YOU MUST DOUBLE CHECK THE TORQUE OF

EVERY NUTAND BOLT.

20. Install the compressor, connect the wiring and

the air lines.

21. Be sure all tools, welder parts, or anything else

loose are removed from compressor before startup.

Follow startup procedures listed in owners manual.

Test the unit.

CAUTION

REMOVE FINGERS FROM FAN AREA.

22. After 10 hours of operation, wait for unit to

cool and re-torque all head bolts to

recommended torque shown in Figure E-2.

NOTE

IF PRESSURE FAILS TO BUILD AND THE

COMPRESSOR IS EXCESSIVELY NOISY, CHECK

THE VALVE PLATE. IT MAY HAVE BEEN INSTALLED

UPSIDE DOWN.

5-3. OIL PUMP REPLACEMENT

1. Remove the existing oil pump cover by

removing four 5/16" machine head cap screws. A

spring behind the oil pump will push the pump

partially out as these screws are loosened.

NOTE

BE CERTAIN TO NOTE THE LOCATION OF THE OIL

PORT HOLE IN BOTH THE GASKET AND THE

COVER. IT IS IMPORTANT THEYARE ALIGNED

WITH THE PORT ON THE CRANKCASE (BOTTOM)

FOR RE-ASSEMBLY.

2. With a single edged razor blade, or sharp putty

knife, remove the old gasket material. Take care

not to damage the machined surfaces.

3. Remove the oil pump so you are able to see

inside the rear bearing housing to locate the drive

pin. The drive pin should be protruding from the

drive collar approximately 1/8".

NOTE

THE NOTCH IN THE OUTSIDE (ROTOR) OF THE

PUMP MUST FIT AROUND THIS PIN DURING

ASSEMBLY. IF NOT, THE PIN AND/OR PUMP WILL

BE DAMAGED WHEN THE CAP SCREWSARE

TIGHTENED.

4. Using a marker, mark the location of the pin on

outside of bearing housing. Doing so will assist in

alignment of parts at re-assembly. Make certain the

crankshaft is not turned after this step.

DA435ELW: 99900917: 5-319970508

Re-assemble as follows:

5. To hold the parts in alignment at assembly,

screw two 5/16" studs into two diagonal holes in the

rear of the bearing housing. Slide the gasket into

position, making certain the oil port hole is on the

bottom.

6. Hold the pump cover in the vertical position

with flat side on top, behind the compressor.

7. Locate the step machined at the front of the oil

pump port plate. The pump cover has 2 stop pins and

a third pin to prevent incorrect installation. Position

these three pins into the machined area.

8. While keeping the port plate in place against the

cover, rotate the outside (rotor) of pump to align the

notch with the mark for the drive pin, which was

applied previously.

9. Slide the pump into the housing and the cover

onto the studs up against the pump. Pressure from

the spring behind the pump will be noticed.

10. Using even pressure on the cover, attempt to

push the cover to make contact with bearing

housing. This process may require several attempts

with minor adjustments to align all parts.

13. Once it is possible to make contact with the

bearing housing, using hand pressure only, and there

remains spring pressure in return, hold the cover

tight against the bearing housing using one hand,

and screw in two cap screws using the other hand.

14. Do not tighten these two screws until after

removing the studs and inserting the other two cap

screws.

15. Tighten the cap screws in a criss-cross pattern

and torque to 180 in-lbs.

16. Install the air compressor in the welder. Connect

the air lines and wiring.

CAUTION

DO NOT RUN COMPRESSOR UNTIL CERTAIN

THERE IS OIL PRESSURE. DOING SO WILL

SERIOUSLY DAMAGE THE COMPRESSOR

17. Check for oil pressure by removing the 1/4" pipe

plug on the side of the pump cover. Very briefly,

start the compressor and stop immediately. If oil

does not squirt out of this hole in 1 or 2 quick tries,

the oil pump may be pinched or misaligned. If so,

repeat steps 1-9. If oil pressure is present, replace the

pipe plug as the compressor is ready to be run.

Check the compressor oil pressure gauge located on

the welder’s lower control panel. It should move

from zero to approximately 50 psi on initial start-up.

MACHINED STEP LOCATION STOP LOCATIONS

DA435ELW: 99900917: 5-4

5-4. CRANKSHAFT AND BEARING

REPLACEMENT

If it is necessary to replace the crankshaft, related

components must also be replaced. Replace both

bearings, both races, the key, pump collar and pump

drive pin.

NOTE

DEPENDING ON THE CONDITION OF THE

CRANKSHAFT, BEARING MAY BE REPLACED

WITHOUT REPLACING THE CRANKSHAFT.

REPLACE THE BEARING RACES WHENEVER THE

BEARINGS ARE REPLACED.

1. Remove the pulsation tank, both heads,

cylinders, and pistons. Refer to the instructions in

section 5, paragraph 2.

2. Remove the bolts on the connecting rods, and

lift them out. Reassemble the connecting rods to be

certain that the matched parts remain together on the

same crankshaft journals.

3. Remove the pump cover, oil pump, sleeve,

spring, and rear bearing housing.

4. Remove the clutch and pulley assembly, and the

front bearing housing.

5. Pull the crankshaft from he crankcase.

6. Remove all gasket material with a single edged

razor blade, or sharp putty knife.

CAUTION

DO NOT GOUGE THE MACHINED SURFACES

WHEN REMOVING THE GASKETS. THIS MAY

CAUSE LEAKS.

7. Press the bearing races out of the bearing

housing.

8. Press the tapered roller bearings off of the

crankshaft if only the bearings are being replaced. If

the crankshaft is to be replaced, discard the entire

assembly.

9. Press the new bearings into position.

NOTE

THE CRANKSHAFT SHOULD HAVE NEW

BEARINGS INSTALLED. IF NOT, PRESS THE NEW

BEARINGS INTO POSITION ON THE CRANKSHAFT.

19970429 10. Generously oil the front bearing race and install

the front bearing housing with gasket. Torque the

bolts to 180 in-lbs. Torque the bolts as shown in the

pattern below.

FIGURE E-3. BEARING HOUSING

TORQUE SEQUENCE

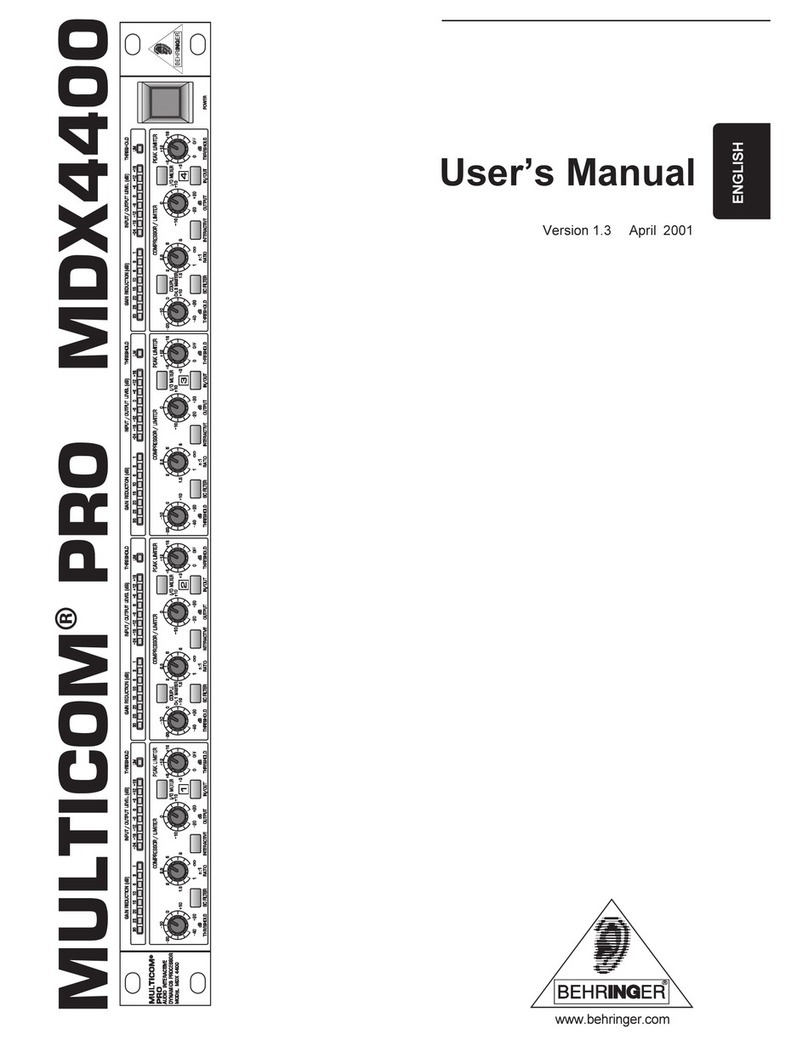

FIGURE E-4. ROD ALIGNMENT

11. Slide the crankshaft into the crankcase.

Generously lubricate the bearing race and install the

rear bearing housing and gaskets.

NOTE

GASKET KITS ARE SUPPLIED WITH TWO (2) EACH

OF .006, .010, .015, AND .020 GASKETS. USE

THESE REAR BEARING GASKETS IN ANY

COMBINATION AND QUANTITY TO LIMIT ALL PLAY

FRONT TO REAR, BUT STILL ALLOW THE

CRANKSHAFT TO TURN FREELY.

12. Install the oil pump as indicated in Section 5-3.

13. Install the connecting rods. Thoroughly oil the

crankshaft and rods before installing them. When

installing the rods, make certain that the tabs are

aligned on the same side of the rod as shown below.

14. Install the pistons, rings, heads and pulsation

tank.

Table of contents

Other IMT Air Compressor manuals

Popular Air Compressor manuals by other brands

Behringer

Behringer Multicom Pro MDX4400 user manual

Briggs & Stratton

Briggs & Stratton 74000 Operator's manual

CVS

CVS RKL 160 Mounting instructions

Full Boar

Full Boar V-TWIN FBACVT-5030U Original instructions

Air Techniques

Air Techniques AERO100 operating instructions

Craftsman

Craftsman evolv 921.167500 Operator's manual

ABAC

ABAC Air Compressor Instructions for use manual

Mars Air Systems

Mars Air Systems L-2254 Installation and operation

Neilsen

Neilsen CT1619 Original instructions

KUSSMAUL

KUSSMAUL AUTO-PUMP 091-9B-4-AD instruction manual

Quincy Compressor

Quincy Compressor Industrial Series instruction manual

Atlas Copco

Atlas Copco G 18 Instruction book