IMT CAS40PL User manual

Iowa Mold Tooling Co., Inc.

500 Highway 18 West

Garner, Iowa 50438

Phone: 641.923.3711

Fax: 641.923.2424

www.imt.com

©2020 Iowa Mold Tooling Co., Inc.

All rights reserved

KEEP THE MANUAL

WITH THE VEHICLE

P/N 99906549 rev 00

Effective Date:

FEBRUARY - 2020

CAS40PL, CAS40PL-CW,

CAS40PLE, CAS40PLE-CW

40 CFM/100 PSIG HYDRAULIC ALL WEATHER

CLOSED OR OPEN CIRCULATION RECIPROCATING COMPRESSOR

OPERATION MANUAL AND PARTS LIST

Read this manual before install-

ing, operating or servicing this

equipment. Failure to comply with

the operation and maintenance in-

structions in this manual will VOID

THE EQUIPMENT WARRANTY.

NOTE

This publication contains the

latest information available at

the time of preparation. Every

effort has been made to ensure

accuracy.

Iowa Mold Tooling Co., Inc.

reserves the right to make

design change modifications

or improvements without prior

notification.

NOTE

Use only IMT Reciprocating

Compressor Oil and Genuine

IMT Parts. Inspect and replace

damaged components before

operation. Substituting non-IMT

oil or non-genuine IMT filter

components WILL VOID THE

COMPRESSOR WARRANTY!

NOTE

Making unauthorized modifica-

tions to the system components

WILL VOID THE WARRANTY!

Always inform IMT before

beginning any changes to the

CAS40PL systems.

BLANK PAGE

TABLE OF

CONTENTS

99906549 rev 00 (JANUARY-2020) TOC - I

TABLE OF CONTENTS

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

TABLE OF CONTENTS ................................................................ TOC - I

Section 1: SAFETY .................................................................... 1 - 1

1.1 GENERAL INFORMATION ..................................................................................... 1 - 1

1.2 INTERNATIONAL SAFETY SYMBOL ..................................................................... 1 - 1

1.3 DANGERS, WARNINGS, CAUTIONS, AND NOTES.............................................. 1 - 1

1.3.1 DANGERS........................................................................................................ 1 - 1

1.3.2 WARNINGS...................................................................................................... 1 - 1

1.3.3 CAUTIONS ....................................................................................................... 1 - 2

1.3.4 NOTES ............................................................................................................. 1 - 3

1.4 SAFETY DECALS ................................................................................................... 1 - 3

1.5 DISPOSING OF MACHINE FLUIDS ....................................................................... 1 - 3

SECTION 2: SPECIFICATIONS ....................................................... 2 - 2

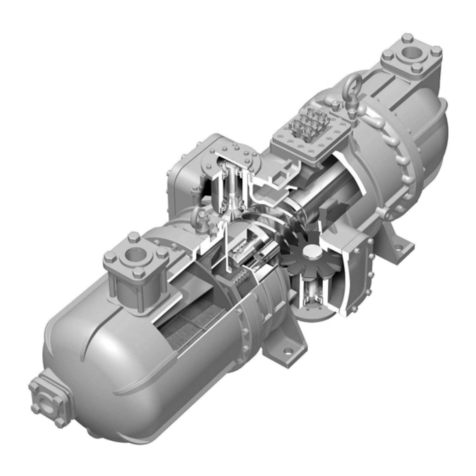

Figure 2-1: Machine Main Component Locations........................................................... 2 - 1

2.1 GENERAL INTRODUCTION ........................................................................................ 2 - 2

TABLE 2A: SPECIFICATIONS .............................................................................................. 2 - 2

TABLE 2B: CAPSCREW TIGHTENING TORQUE VALUES................................................. 2 - 3

TABLE 2C: COMPRESSOR TORQUE VALUES................................................................... 2 - 3

SECTION 3: INSTALLATION ........................................................... 3 - 1

3.1 MACHINE PACKAGE RECEIPT/INSPECTION ......................................................... 3 - 1

3.2 GENERAL INSTRUCTIONS....................................................................................... 3 - 1

3.3 DETERMINING THE CAS40PL UNIT MOUNTING LOCATION................................... 3 - 2

3.4 HYDRAULIC SYSTEM OVERVIEW............................................................................. 3 - 2

3.4.1 HYDRAULIC SYSTEM FILTRATION................................................................... 3 - 2

Figure 3-1: Installation and Dimensions Diagram - Open Center 12VDC ...................... 3 - 3

Continued on next page...

TOC - II 99906549 rev 00 (JANUARY-2020)

TABLE OF CONTENTS

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

SECTION 3: INSTALLATION (CONTINUED)

Figure 3-2: Installation and Dimensions Diagram - Open Center 12V,

No Thermal Valve .................................................................................................... 3 - 4

Figure 3-3: Installation and Dimensions Diagram - Open Center 12V,

With Thermal Valve & Gauges................................................................................ 3 - 5

3.4.2 HYDRAULIC OIL RESERVOIR ........................................................................... 3 - 6

3.4.2.1 DETERMINING RESERVOIR SIZE........................................................... 3 - 6

3.4.2.2 DETERMINING RESERVOIR SHAPE....................................................... 3 - 6

3.4.2.3 MANDATORY RESERVOIR FEATURES................................................... 3 - 6

3.4.2.4 RECOMMENDED RESERVOIR OPTIONS............................................... 3 - 7

3.4.2.5 RESERVOIR FEATURES TO AVOID......................................................... 3 - 8

3.4.2.6 RECOMMENDED HYDRAULIC SYSTEM SPECIFICATIONS .................. 3 - 8

3.4.3 STANDARDS GUIDELINES ................................................................................ 3 - 8

3.5 INSTALLATION............................................................................................................. 3 - 8

3.5.1 MACHINE LOCATION ......................................................................................... 3 - 8

3.5.2 CLEARANCES..................................................................................................... 3 - 8

3.5.3 MACHINE STABILIZATION AND GROUNDING ................................................. 3 - 8

3.5.4 SERVICE CONNECTIONS.................................................................................. 3 - 8

3.5.5 ELECTRICAL CONNECTIONS ........................................................................... 3 - 8

3.5.6 HYDRAULIC SUPPLY CIRCUIT.......................................................................... 3 - 9

3.5.7 ROUTING ............................................................................................................ 3 - 9

3.5.8 HYDRAULIC SYSTEM REQUIREMENTS .......................................................... 3 - 9

3.6 CONNECTING THE HYDRAULIC SUPPLY AND RETURN.................................. 3 - 9

3.7 CONNECTING THE AIR SUPPLY ......................................................................... 3 - 9

3.7.1 AIR RESERVOIR TANK INSTALLATION .......................................................... 3 - 10

SECTION 4: OPERATION ................................................................ 4 - 1

4.1 GENERAL INFORMATION......................................................................................... 4 - 1

4.2 OPERATING CONDITIONS ....................................................................................... 4 - 1

4.3 INITIAL (FIRST-TIME) START-UP................................................................................ 4 - 1

Continued on next page...

99906549 rev 00 (JANUARY-2020) TOC - III

TABLE OF CONTENTS

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

SECTION 4: OPERATION (CONTINUED)

Figure 4-1: Instrumentation............................................................................................. 4 - 2

4.3.1 ROUTINE START-UP FROM MACHINE ............................................................. 4 - 2

4.3.2 ROUTINE SHUTDOWN PROCEDURE (FIRST AND ROUTINE) ....................... 4 - 2

Figure 4-2: Controller Screen Identification and Navigation ........................................... 4 - 3

4.4 EXTREME CONDITION OPERATION ....................................................................... 4 - 4

SECTION 5: MAINTENANCE........................................................... 5 - 1

5.1 GENERAL INFORMATION......................................................................................... 5 - 1

5.2 MACHINE MAINTENANCE SCHEDULE ................................................................... 5 - 1

5.3 REPLACEMENT PARTS .............................................................................................. 5 - 2

TABLE 5A: ROUTINE MAINTENANCE SCHEDULE............................................................ 5 - 3

TABLE 5B: ROUTINE REPLACEMENT KITS....................................................................... 5 - 3

5.4 PARTS REPLACEMENT AND ADJUSTMENT PROCEDURES ................................ 5 - 5

5.4.1 REMOVING PANELS FOR MACHINE MAINTENANCE ACCESS ..................... 5 - 5

5.4.1.1 REMOVING LONG-SIDE PANELS FOR MAINTENANCE ACCESS......... 5 - 5

5.4.1.2 REPLACING LONG-SIDE PANELS........................................................... 5 - 6

5.4.2 CHECKING PRESSURE READING.................................................................... 5 - 6

5.4.3 COMPRESSOR SYSTEM LUBRICATION .......................................................... 5 - 6

5.4.3.1 CHECKING THE OIL LEVEL ..................................................................... 5 - 6

5.4.3.2 CHANGING THE COMPRESSOR OIL...................................................... 5 - 6

5.4.4 AIR FILTER MAINTENANCE............................................................................... 5 - 7

5.4.4.1 INSPECTING THE AIR FILTER ................................................................. 5 - 7

5.4.4.2 REPLACING THE AIR FILTER ELEMENT................................................. 5 - 8

5.4.5 COOLER CORE MAINTENANCE ........................................................................ 5 -8

5.4.6 COUPLING ALIGNMENT .................................................................................... 5 - 9

5.4.7 REPLACING THE DRIVE COUPLING ................................................................ 5 - 9

5.4.7.1 REPLACING THE DRIVE COUPLING ELEMENT................................... 5 - 10

5.4.7.2 COUPLING ASSEMBLY........................................................................... 5 - 10

5.4.7.3 HUB ALIGNMENT CHECK ...................................................................... 5 - 11

5.4.7.4 COUPLING MAINTENANCE ................................................................... 5 - 11

Continued on next page...

TOC - IV 99906549 rev 00 (JANUARY-2020)

TABLE OF CONTENTS

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

SECTION 5: MAINTENANCE (CONTINUED)

5.4.8 CHECKING HOSES AND WIRING ................................................................... 5 - 11

5.5 SERVICING THE SYSTEM FUSE ............................................................................. 5 - 12

5.6 PRESSURE (SAFETY) RELIEF VALVES .................................................................. 5 - 12

5.7 LONG TERM STORAGE............................................................................................ 5 - 13

SECTION 6: TROUBLESHOOTING................................................. 6 - 1

6.1 GENERAL INFORMATION......................................................................................... 6 - 1

6.2 TROUBLESHOOTING GUIDE ................................................................................... 6 - 2

SECTION 7: ILLUSTRATED PARTS LIST....................................... 7 - 1

7.1 PARTS ORDERING INFORMATION.......................................................................... 7 - 1

TABLE 7A: RECOMMENDED SPARE PARTS LIST............................................................. 7 - 2

7.2 COMPRESSOR AND PARTS..................................................................................... 7 - 4

7.3 COMPRESSOR PARTS............................................................................................. 7 - 6

7.4 DISPLAY AND CONTROLLER................................................................................... 7 - 8

7.5 DISPLAY AND GAUGE ASSEMBLY (MECHANICAL CONTROL) ............................. 7 - 8

7.6 MOTOR AND DRIVE PARTS ..................................................................................... 7 - 9

7.7 HYDRAULIC COOLER & PARTS - 12V WITH THRML / GAUGES ......................... 7 - 10

7.8 HYDRAULIC COOLER & PARTS - 24V WITH THRML / GAUGES ......................... 7 - 12

7.9 FRAME AND CANOPY - 1 OF 3 (ASSEMBLY PART A) .......................................... 7 - 14

7.9 FRAME AND CANOPY - 2 OF 3 (ASSEMBLY PARTS B - C) .................................. 7 - 16

7.9 FRAME AND CANOPY - 3 OF 3 (ASSEMBLY PARTS D - F) .................................. 7 - 17

7.10 HYDRAULIC MANIFOLD ASSEMBLY - 12VDC OPEN CENTER

(STANDARD & COLD WEATHER)........................................................................... 7 - 18

7.11 HYDRAULIC MANIFOLD ASSEMBLY - CLOSED CENTER (24V)

(STANDARD & COLD WEATHER)........................................................................... 7 - 20

7.12 DECAL IDENTIFICATION/LOCATIONS - 1 OF 2..................................................... 7 - 22

7.12 DECAL IDENTIFICATION/LOCATIONS - 2 OF 2..................................................... 7 - 23

7.13 HOSE AND TUBE ROUTING - OPEN CENTER 12V, NO THERMAL ..................... 7 - 24

7.14 HOSE AND TUBE ROUTING - OPEN CENTER 12V, WITH THERMAL ................. 7 - 25

7.15 HOSE AND TUBE ROUTING - OPEN CENTER 12V, NO THERMAL,

WITH GAUGES ........................................................................................................ 7 - 26

7.16 HOSE AND TUBE ROUTING - OPEN CENTER 12V, THERMAL & GAUGES........ 7 - 27

Continued on next page...

99906549 rev 00 (JANUARY-2020) TOC - V

TABLE OF CONTENTS

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

SECTION 7: ILLUSTRATED PARTS LIST (CONTINUED)

7.17 HYDRAULIC THERMAL VALVE ASSEMBLY........................................................... 7 - 28

7.18 ELECTRICAL SCHEMATIC...................................................................................... 7 - 29

7.19 WIRING DIAGRAM .................................................................................................. 7 - 30

7.20 HYDRAULIC OIL FLOW SCHEMATIC DIAGRAM - OPEN CENTER,

WITH THERMAL VALVE .......................................................................................... 7 - 31

7.21 HYDRAULIC OIL FLOW SCHEMATIC DIAGRAM - OPEN CENTER...................... 7 - 32

7.22 HOSE INSTALLATION GUIDE ................................................................................. 7 - 33

TABLE 7B: MAINTENANCE TRACKING LOG.................................................................... 7 - 34

TOC - VI 99906549 rev 00 (JANUARY-2020)

TABLE OF CONTENTS

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

BLANK PAGE

SECTION 1:

SAFETY

99906549 rev 00 (JANUARY-2020) 1 - 1

SECTION 1: SAFETY

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

1.1 GENERAL INFORMATION

The products provided by IMT®Mfg., Inc. are de-

signed and manufactured for safe operation and

maintenance. But it is ultimately the responsibility

of the users and maintainers for safe use of this

equipment. Part of this responsibility is to read

and be familiar with the contents of this manual

before operation or performing maintenance ac-

tions.

1.2 INTERNATIONAL

WARNING SYMBOL

The international warning symbol (shown above)

is used on all decals, labels and signs that con-

cern information pertaining to bodily harm. When

you see the international warning symbol, pay

extremely careful attention, and follow the given

instructions or indications to avoid any possible

hazard.

1.3 DANGERS, WARNINGS,

CAUTIONS AND NOTES

These boxes are labeled clearly with the title

block listing either Danger, Warning, Caution, or

other non-safety issue. They draw attention to

specific issues that are pertinent to the safe and

correct operation of the machine.

The symbols shown and defined in Section 1:

Safety are used throughout this manual and on

the machine to call attention to, and identify, pos-

sible hazards.

1.3.1 DANGERS

DANGER

Identifies actions or conditions which will cause

death, severe injury, or equipment damage or

destructive malfunctions.

• Keep tools or other conductive objects away

from live electrical parts.

• Never touch electrical wires or components

while the machine is operating. They can be

sources of electrical shock.

1.3.2 WARNINGS

WARNING

Identifies actions or conditions which may

cause death, severe injury, or equipment dam-

age or destructive malfunctions.

• DO NOT EVER use this compressor as a

breathing air source. IMT disclaims any and all

liabilities for damage or loss due to fatalities,

personal injuries resulting from the use of a

IMT compressor to supply breathing air.

• DO NOT perform any modifications to this

equipment without prior factory approval.

• DO NOT operate the compressor or any of its

systems if there is a known unsafe condition.

Disable the equipment by disconnecting it

from its power source. Install a lock-out tag to

identify the equipment as inoperable to other

personnel.

• DO NOT operate the compressor with any by-

pass or other safety systems disconnected or

rendered inoperative.

• DO NOT operate the equipment while you are

under the influence of alcohol or drugs.

• DO NOT operate the equipment while you are

feeling ill.

• DO NOT attempt to service the equipment

while it is operating.

• Before performing maintenance, or replacing

parts, relieve the entire system pressure, af-

ter the system has blown down, by opening a

service valve which will vent all pressure to the

atmosphere. After that, remove any remaining

residual pressure by slowly opening the fill

cap. Remove all electrical power.

1 - 2 99906549 rev 00 (JANUARY-2020)

SECTION 1: SAFETY

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

NOTE

Slowly remove fill cap to vent compressor

sump pressure.

• DO NOT use the compressor for purposes oth-

er than for which it is intended. High pressure

air can cause serious and even fatal injuries.

• DO NOT operate the compressor outside of its

specified pressure and speed ratings. (See

Section 2: Specifications or refer to the equip-

ment data plate.).

• DO NOT use flammable solvents or cleaners

for cleaning the compressor or its parts.

• DO NOT operate the compressor in areas

where flammable, toxic, corrosive fumes, or

other damaging substance can be ingested by

the compressor intake.

• Keep arms, hands, hair and all other body parts,

and clothing away from fans, drive shafts, and

other moving parts.

• DO NOT wear jewelry, unbuttoned cuffs, ties,

or loose-fitting clothing when you are working

near moving/rotating parts.

• ALWAYS confine long hair when working near

moving/rotating parts.

• NEVER operate the equipment while wearing a

headset to listen to music or the radio.

• Wear personal protective equipment such as

gloves, work shoes, and eye and hearing pro-

tection as required for the task at hand.

• DO NOT operate the compressor with any

guards removed or damaged, or other safety

devices inoperative.

• DO NOT operate the compressor in enclosed

or confined spaces where ventilation is re-

stricted or closed-off.

• Ensure that hoses connected to service valves

are fitted with correctly sized and rated flow

limiting devices which comply with applicable

codes. Pressurized broken or disconnected

hoses can whip, causing injuries or damage.

• DO NOT use tools, hoses, or equipment that

have maximum ratings below that of this com-

pressor.

• Keep metal tools, and other conductive objects

away from live electrical components.

• Before performing maintenance or repair oper-

ations on the compressor, ensure that all pow-

er has been removed and been locked out to

prevent accidental application.

• DO NOT assume that because the compressor

is in a STOPPED condition that hydraulic pow-

er has been removed.

• Use this compressor only to compress atmo-

spheric air. Use of this equipment as a booster

pump and/or to compress any other gaseous

or aerosol substance constitutes improper

use. It can also cause damage or injuries.

Such misuse will also void the warranty.

• Install, operate, and maintain this equipment in

full compliance with all applicable OSHA, oth-

er Federal, state, local codes, standards, and

regulations.

• When lifting objects, be aware of proper lifting

techniques to avoid injury.

• ALWAYS read and follow safety related pre-

cautions found on containers of hazardous

substances.

1.3.3 CAUTIONS

CAUTION

Identifies actions or conditions which will or

can cause injuries, equipment damage or mal-

functions.

• Check all safety devices for proper operation

on a routine basis.

• Ensure that no tools, rags, or other objects are

left on compressor drive systems or near in-

takes.

• Keep the equipment clean when performing

maintenance or service actions. Cover open-

ings to prevent contamination.

• DO NOT operate the compressor if cooling air

is not available (fan/cooler not operating) or if

lubricant levels are below their specified min-

imum levels.

• Ensure all plugs, hoses, connectors, covers,

and other parts removed for maintenance ac-

99906549 rev 00 (JANUARY-2020) 1 - 3

SECTION 1: SAFETY

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

tions are replaced before applying power to

the compressor.

• Avoid touching hot surfaces and components.

• Ensure that electrical wiring, terminals; hoses

and fittings are kept in serviceable condition

through routine inspections and maintenance.

Replace any damaged or worn components.

1.3.4 NOTES

NOTE

Additional information (or existing information)

which should be brought to the attention of op-

erators/maintainers affecting operation, mainte-

nance, or warranty requirements.

Note boxes are usually listed to convey and give

focus to a distinct piece of information, which is

not directly related to a safety issue, but is nec-

essary to understand machine function and op-

eration. Special note referrals in the manual may

be contained in a box titled with an IMPORTANT

banner, as shown below, and may also contain

the WARNING symbol, should the information be

linked to a safety issue:

IMPORTANT

Additional, CRUCIAL information (or existing

information) which should be brought to the

attention of operators/maintainers affecting op-

eration, maintenance, or warranty requirements.

1.4 SAFETY DECALS

Safety decals are placed onto, or located near,

system components that can present a hazard to

operators or service personnel. All pertinent de-

cals listed in Section 7.12, Decal Identification/

Locations, are located near a component which

is subject to respect in terms of safety precau-

tions. Always heed the information noted on the

safety decals.

WARNING

DO NOT REMOVE OR COVER ANY SAFETY

DECAL. Replace any safety decal that becomes

damaged or illegible.

1.5 DISPOSING OF MACHINE

FLUIDS

Always dispose of machine fluids under the guid-

ance of all applicable local, regional and/or fed-

eral law.

IMT®encourages recycling when allowed. For

additional information, consult the container label

of the fluid in question.

OPEN

CENTER

MANIFOLD

W2

AA

T

Z

G

L

E

F

H

D

A

J

C

K

BB1

EE

C

FF GG

E

W

1

CLOSED - CENTER CONFIGURATION

M1

Y

X

CLOSED

CENTER

MANIFOLD

CC DD

OPEN - CENTER CONFIGURATION

M2

BB2

R

NPQ

T

V

U

SR

N

QU

V

T

P

B1

B2

KEY DESCRIPTION KEY DESCRIPTION

ARELAY ISLOAD SENSE #4 MJIC 37° (1/4-12 UNF)

B1PRESSURE SWITCH (24V MACHINES) THYDRAULIC SUPPLY #12 MJIC 37° (1-1/16-12 UNF)

B2PRESSURE TRANSDUCER (12V MACHINES) UHYDRAULIC RETURN #16 MJIC 37° (1-5/16-12 UNF)

CCOMPRESSOR AIR FILTER HOUSING VCASE DRAIN #6 MJIC (9/16-18 UNF)

DCOMPRESSOR UNIT W1CLOSED CENTER MANIFOLD ASSEMBLY

ELOW PRESSURE RELIEF VALVE W2OPEN CENTER MANIFOLD ASSEMBLY

FHIGH PRESSURE RELIEF VALVE XSOLENOID VALVE

GCOMPRESSOR OIL FILL PORT YFLOW REGULATOR

HCOMPRESSOR OIL DRAIN HOSE ZRELIEF VALVE

JCOOLER FAN & FAN MOTOR AA SOLENOID

KCONTROLLER BB1INSTRUMENT PANEL - DIGITAL DISPLAY

LHYDRAULIC MOTOR BB2INSTRUMENT PANEL - GAUGE DISPLAY

M1CLOSED CENTER: functional piping & access locations CC PRESSURE GAUGE (gauge panel only)

M2OPEN CENTER: functional piping & access locations DD HOUR METER (gauge panel only)

NSERVICE AIR DISCHARGE / CONNECTION MOUNT EE HYDRAULIC OIL COOLER

PDEUTSCH 6-PIN ELECTRICAL CONNECTION FF MANIFOLD CHECK VALVE

QCOMPRESSOR OIL DRAIN (refer to Item H) GG SPIDER COUPLING ELEMENT

RCOMPRESSOR OIL SIGHT GLASS

I Relay size depends upon machine build order. Refer to Figure 5-7, Electrical Schematic (Section 7.18), and Wiring Diagram (Section 7.19), to

determine correct relay size.

Figure 2-1: Machine Main Component Locations

2 - 1 99906549 rev 00 (JANUARY-2020)

SECTION 2: SPECIFICATIONS

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

SECTION 2:

SPECIFICATIONS

SECTION 2: SPECIFICATIONS

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

2.1 GENERAL INTRODUCTION

The tables and figures in this section list the

specifications (including operational, output and

dimensional) of the overall machine. Contact the

IMT®Service Department if additional specifi-

cations are needed that cannot be found in this

manual.

Refer to Figure 2-1 for general machine compo-

nent locations. For additional information, includ-

ing measurement specifications, refer to Figure

3-1 (machine and identification and dimensions)

in Section 3, Installation.

TABLE 2A: SPECIFICATIONS

GENERAL SYSTEM INFORMATION SPECIFICATION

CFM Rating @ 100 psi: 30 I40 II

Air Pressure (psi): 100 125 150 175 100 125 150 175

Hydraulic flow (gpm): 8.25 8.25 8.25 9.0 10 10 10 10

Hydraulic pressure (psig): 2300 2450 2575 2600 2300 2470 2550 2600

NOTE: Compressor adjustment should be set in accordance with rated RPMs.

I30 CFM = 690 COMPRESSOR RPM

II 40 CFM = 1100 COMPRESSOR RPM

COMPRESSOR

GENERAL SYSTEM INFORMATION SPECIFICATION

Type: Two-stage, two cylinder, reciprocating

Compressor oil reservoir capacity: 3 quarts

Air inlet system: Dry-type, single stage

Drive coupling: Direct drive, coupled

Hydraulic motor: Gear type

PACKAGE

Main frame: Formed powder-coated steel with a bolt-down provision

Electrical supply: 12V Standard; 24V Optional

Electrical connections: Weatherpack

Enclosure: Aluminum, powder-coated

Cooler: Hydraulic oil cooler/radiator core — electric fan

Package connections:

(Refer to Figures 3-1 and 3-2 in Section 3)

Discharge air — 3/4” JIC male

Hydraulic supply — 3/4” 37° JIC male

Hydraulic return — 1” 37° JIC male

Load sense line (closed center only) — 1/4” 37° JIC male

+12VDC or +24VDC (PTO activated)

Motor case drain 3/8" 37° JIC male

Continued on next page

99906549 rev 00 (JANUARY-2020) 2 - 2

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

SECTION 2: SPECIFICATIONS CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

2 - 3 99906549 rev 00 (JANUARY-2020) IOWA MOLD TOOLING CO., INC.

(641) 923-3711

TABLE 2A: SPECIFICATIONS

GENERAL SYSTEM INFORMATION SPECIFICATION

PACKAGE (continued)

Dimensions: Length — 33.70”

Width — 21.00”

Height — 24.30”

Weight: 245 lbs.(dry; add 10-12 lbs for full wet machine weight)

CONTROLS

Hydraulic pressure relief: 3000 PSIG

Hydraulic solenoid valve (for automatic load

control):

12 or 24V

Air pressure switch (for automatic load control): Pre-set at factory

TABLE 2B: CAPSCREW TIGHTENING TORQUE VALUES

SIZE GRADE LUBRICATED

1/4 - 20 UNC 5 6 ft-bs

5/16 - 18 UNC 5 13 ft-lbs

3/8 - 16 UNC 5 23 ft-lbs

1/2 - 13 UNC 5 55 ft-lbs

3/4 - 10 UNC 5 200 ft-lbs

TABLE 2C: COMPRESSOR TORQUE VALUES

BOLTS SIZE GRADE TORQUE (ft.-lb.) POSITION

1/4-20 5 8 Side Plate Bolts

1/4-28 8 11.76 HP Valve Nut

3/8-16 5 26 Cylinder to Base Bolts

3/8-24 8 33.8 Connecting Rod Bolts

5/16-18 5 17 Head to Cylinder

5 10 LP & HP Valve Hold Down Covers

5 17 End Cover/Discharge Manifold Bolts

5/16-24 8 21.3 LP Valve Nut

SECTION 3:

INSTALLATION

99906549 rev 00 (JANUARY-2020) 3 - 1

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

3.1 MACHINE PACKAGE

RECEIPT/INSPECTION

Upon receipt of the machine package, inspect the

exterior of the shipping crate for signs of shipping/

transit damage. Any damage should be reported

immediately to the shipping company.

NOTE

Before fully unpacking the unit, inspect the

component parts, supports and loose-packed

parts to ensure that there have been no inter-

nal movements of assemblies or components,

which may have been damaged during ship-

ment.

Should any damage be discovered during pack-

age inspection, contact the shipping company

immediately.

Iowa Mold Tooling Co., Inc.

500 Highway 18 West

Garner, Iowa 50438

Phone: 641.923.3711

Fax: 641.923.2424

www.imt.com

3.2 GENERAL INSTRUCTIONS

This section provides general guidance for lo-

cating and preparing the CAS40PL compressor

package for operation. Each installation is unique

and can be affected by location, ventilation, and

other factors such as electrical and hydraulic

power supply availability and location.

DISCLAIMER

DO NOT install in any enclosed space without

first contacting IMT.

WARNING

Install, operate, and maintain this equipment in

full compliance with all applicable OSHA, other

Federal, state, local codes, standards, and regu-

lations.

WARNING

Before performing maintenance or repair oper-

ations on the compressor, ensure that all power

has been removed and locked out to prevent

accidental start-up.

DO NOT assume that because the compressor

is in a STOPPED condition that power has been

removed.

WARNING

DO NOT perform any modifications to this

equipment without prior factory approval.

WARNING

DO NOT use plastic pipe, or incorrectly rated

piping or hose. Incorrectly rated connection

material can fail and cause injury or equipment

damage.

WARNING

DO NOT operate the compressor in enclosed or

confined spaces where ventilation is restricted

or closed off.

NOTE

Install electrical components (circuit breakers,

pressure switches, toggle switches, etc.) in

locations where exposure to water or moisture

will be most minimized.

NOTE

In order to prevent accidental damage to vehi-

cle components (fuel tanks, lines, brake lines,

wiring harnesses), note their location before

drilling any holes.

3 - 2 99906549 rev 00 (JANUARY-2020)

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

3.3 DETERMINING THE CAS40PL

UNIT MOUNTING LOCATION

When determining the location to mount the

CAS40PL unit, the following criteria must be tak-

en into consideration:

• The mounting surface must be level and able to

accommodate the four (4) mounting bolts and

isolators of the base frame. Refer to Figure

3-1 or Figure 3-2 for layout of mounting hole

slots’ locations.

IMPORTANT

Mounting surface must be able to bear the

weight of the machine (255-260 lbs, wet).

• Mount the machine with a minimum of four (4)

mounting locations.

• The location must allow for the machine dimen-

sions, and additional space requirements for

minimum cooling, maintenance and access.

Refer to Figure 3-3 to determine the additional

minimum space requirement measurements.

• The external gauges/display must be easily

visible to the operator.

It is recommended, for most installations, to

mount the compressor on the driver’s side of the

vehicle. The unit should be situated in such a

manner that the fan (rear) and hydraulic cooler

(front) are not obstructed. Do not place the com-

pressor in any location where it can ingest ex-

haust fumes, dust or debris.

NOTE

When considering external system layout hoses

refer to Section 7.22, Hose Guide for proper

routing and mounting practices.

3.4 HYDRAULIC SYSTEM

OVERVIEW

IMPORTANT

IMT®highly recommends consulting a hydraulic

supply expert for specifying the correct hydrau-

lic supply components for vehicle-side integra-

tion (including oil reservoir size, hydraulic pres-

sure relief, hose size, etc.) for your application.

IMPORTANT

Contaminated hydraulic fluid allowed to enter

the pump will cause malfunction of the pump

controls. Hydraulic system hoses must be

flushed and cleaned prior to being connected to

the unit.

Refer to Figure 3-1 or Figure 3-2 for hydraulic

pump system connections.

Please take into consideration the following:

• The hydraulic flow and pressure requirements

of the system.

• A continuous hydraulic load is necessary when

compressor is running.

• The duty cycle and ambient operating tempera-

tures.

• Other hydraulic equipment which may share

that same hydraulic supply system (IMT rec-

ommends a dedicated pump and hydraulic

circuit).

WARNING

Follow all applicable safety recommendations

as outlined in Section 1: Safety of this manual.

WARNING

Improperly, or non-connected lines may cause

harm, and will damage the equipment.

The hydraulic hoses must be run to the machine.

Verify that hoses are hooked up properly to en-

sure proper flow. Also, verify that the hoses are

laid out properly so that no chafing or kinking

of the hoses is possible. Refer to Section 7.22,

Hose Installation Guide, for assistance with

proper hose layout and connecting functions.

NOTE

The temperature of the hydraulic oil should not

exceed 160°F due to the rating of the IMT- sup-

plied hydraulic motor.

3.4.1 HYDRAULIC SYSTEM

FILTRATION

IMT recommends using a 10 micron oil filter on

99906549 rev 00 (JANUARY-2020) 3 - 3

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

ALTERNATE

LID HINGE

DIRECTION

DEFAULT

LID HINGE

DIRECTION

28.68

DISPLAY CONTROLLER

26.15

15.45

32.50

23.94

AIR DISCHARGE

#12 MJIC 37°

(1 1/16 - 12UNF)

ELECTRICAL

CONNECTION

(6 - PIN DEUTSCH)

HYDRAULIC RETURN

#16 MJIC 37°(1 5/16 - 12 UNF)

HYDRAULIC SUPP LY

#12 MJIC 37°(1 1/16 - 12UNF)

CASE DRAIN

#6 MJIC 37°(9/16-18 UNF)

COMPRESSOR

OIL DRAIN

COMPRESSOR OI L

SIGHT GLASS

8.04

4.17

12.09

6.54

7.45

1/2 - 13 UNC NU T

8 - PLACES

3.51 23.48

21.25

1.00 30.50

1

8.44

NOTES:

1. DECAL AREA SHOWN IN DASHED [ ] LINES

Figure 3-1: Installation and Dimensions Diagram - Open Center 12VDC 051665ID_r0

DISCLAIMER

If machine package is to be mount-

ed within a confined space such as

beneath a canopy, the area must be

determined to allow for adequate air

flow to take place for cooling purpos-

es. Consult factory for assistance

in ensuring adequate air flow before

mounting the machine.

NOTE

The dimensions listed in this diagram

are the minimum required clearance

distances needed for properly cooling

the machine, and providing service

access. For additional clearances

needed, refer to Figure 3-4.

3 - 4 99906549 rev 00 (JANUARY-2020)

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

CLOSED CENTER FLOW

CONTROL ACCESS POINT

HYDRAULIC RETURN

#16 MJIC 37°

(1 5/16 - 12 UNF)

HYDRAULIC SUPPLY

#12 MJIC 37°(3/4 JIC)

CASE DRAIN

#6 MJIC (9/16 - 18 UNF)

COMPRESSOR OIL DRAIN

AIR DISCHARGE

3/4" JIC

ELECTRICAL CONNECTION

6-PIN DEUTSCH

ALTERNATE DISPLAY

POSITION

COMPRESSOR AIR INLET

ALTERNATE

LID HINGE

DIRECTION

DEFAULT

LID HINGE

DIRECTION

NOTES:

1. DECAL AREA SHOWN IN SINGLE LENGTH

DASHED LINES

PRESSURE GAUGE

& HOUR METER OR

CONTROLLER DISPLAY

1/2 - 13 UNC NUT

8 - PLACES

Figure 3-2: Installation and Dimensions Diagram - Open Center 12V, No Thermal Valve 051787_r2

DISCLAIMER

If machine package is to be mounted

within a confined space such as beneath

a canopy, the area must be determined to

allow for adequate air flow to take place

for cooling purposes. Consult factory for

assistance in ensuring adequate air flow

before mounting the machine.

NOTE

The dimensions listed in this diagram are

the minimum required clearance dis-

tances needed for properly cooling the

machine, and providing service access.

For additional clearances needed, refer to

Figure 3-4.

99906549 rev 00 (JANUARY-2020) 3 - 5

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

COMPRESSOR AIR INLET

ALTERNATE DISPLAY POSITION

7.45

28.68

23.94

26.15

15.45

32.50

PRESSURE GAUGE &

HOUR METER OR

CONTROL DISPLAY

AIR FLOW

CLOSED CENTER FLOW

CONTROL ACCESS POINT

6.54

12.09

ELECTRICAL CONNECTOR

6-PIN DEUTSCH

AIR DISCHARGE 3/4 JIC COMPRESSOR

OIL DRAIN

HYDRAULIC RETURN

#16 MJIC 37° (1 5/16-12 UNF)

HYDRAULIC SUPPLY #12 MJIC 37° (3/4 JIC)

CASE DRAIN #6 MJIC 37° (9/16-18 UNF)

DEFAULT LID

HINGE DIRECTION

ALTERNATE LID

HINGE DIRECTION

21.00

3.51 23.48

18.44

1.40

1.00

1/2-13 UNC NUT 8-PLACES

30.50

NOTES:

1. DECAL AREA SHOWN IN SINGLE LENGTH

DASHED LINES

Figure 3-3: Installation and Dimensions Diagram - Open Center 12V, With Thermal Valve & Gauges 051788_r2

DISCLAIMER

If machine package is to be mounted

within a confined space such as beneath

a canopy, the area must be determined to

allow for adequate air flow to take place

for cooling purposes. Consult factory for

assistance in ensuring adequate air flow

before mounting the machine.

NOTE

The dimensions listed in this diagram are

the minimum required clearance dis-

tances needed for properly cooling the

machine, and providing service access.

For additional clearances needed, refer to

Figure 3-4.

3 - 6 99906549 rev 00 (JANUARY-2020)

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

the hydraulic oil return line. Flow rating of the fil-

ter must be equal to, or greater than, the maxi-

mum GPM at which the system will be operated.

IMPORTANT

Use only a filter that is specifically intended for

hydraulic systems.

3.4.2 HYDRAULIC OIL RESERVOIR

3.4.2.1 DETERMINING RESERVOIR

SIZE

In a conventional hydraulic system, minimum

tank size, in gallons, should be equal to the max-

imum GPM flow rate, times two (x 2).

3.4.2.2 DETERMINING

RESERVOIR SHAPE

The reservoir structure should be tall and narrow

rather than shallow and broad (Figure 3-4). A tall,

narrow tank is recommended because:

1. The oil level is well above suction line open-

ing, avoiding the possibility of drawing air into

the pump due to a vortex or “whirlpool” effect

within the tank during operation flow.

2. Allows for better oil level tolerance level of

the system if vehicle operates at an unusual

(slightly offlevel) vehicle angle.

3. To keep return flow well below the surface so

it does not break the surface and cause aer-

ation (cavitation) of the oil.

3.4.2.3 MANDATORY RESERVOIR

FEATURES

• The reservoir should incorporate the following

design features:

• In terms of location of the reservoir tank within

the hydraulic system, note that the hydraulic

pump’s inlet line (suction line out from the res-

ervoir to the pump) should be located near the

bottom of the tank, well below the oil level. The

suction line should protrude a minimum of two

(2”) inches into the reservoir to keep it away

from potential contaminant surface buildup.

A

B

B

C

C

D

Figure 3-6: Minimum Clearnace Distances Needed for Machine Cooling and Access

KEY DESCRIPTION

AROOF ACCESS PANEL CLEARANCE: 24”

BMACHINE LATERAL CLEARANCES: 10”

CMACHINE FRONT/REAR CLEARANCES: 10”

DCOOLING AIR FLOW DIRECTION

NOTE: The dimensions listed above are the minimum required clearance

distances needed for properly cooling the machine. Additinal clearance

room may be desired for easier acess for control and/or maintenance

functions.

IMPORTANT

Additional allotted dimensions/surroundings

space of package must allow for continu-

ous circulation of air around and through

the machine for cooling purposes. DO NOT

install in an enclosed area.

This manual suits for next models

3

Table of contents

Other IMT Air Compressor manuals

Popular Air Compressor manuals by other brands

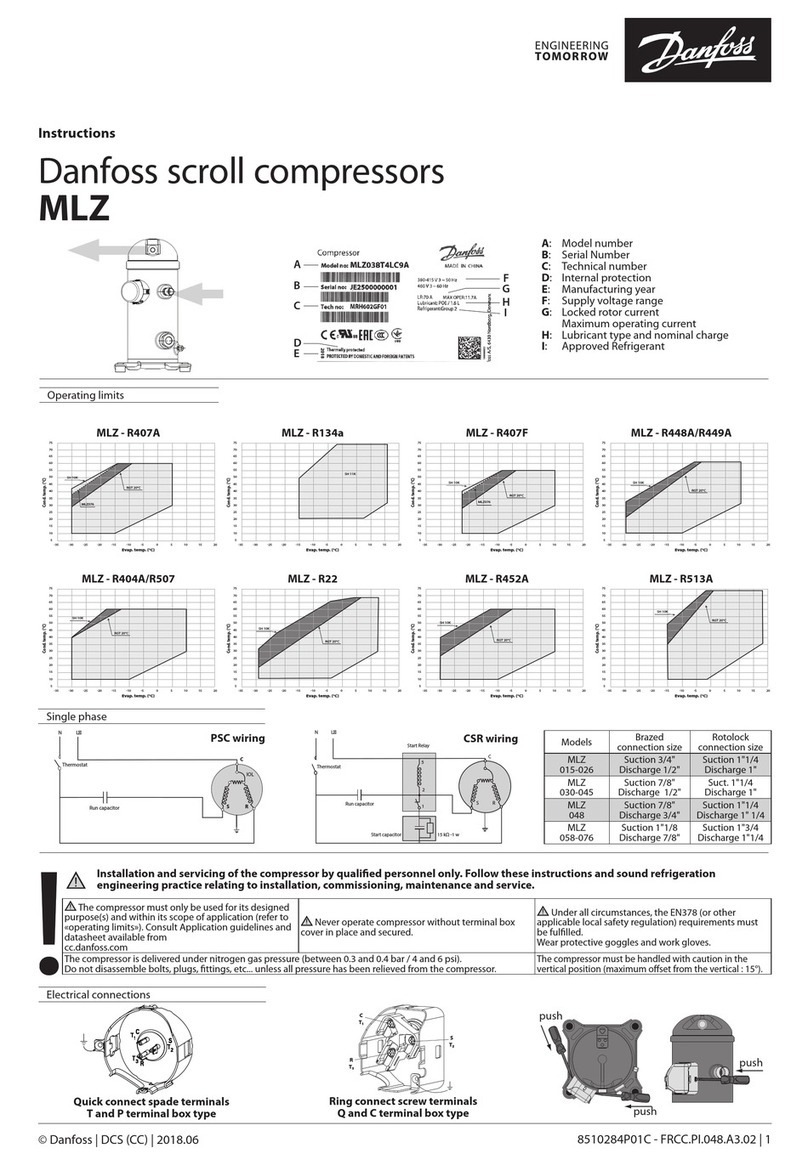

Danfoss

Danfoss MLZ Series instructions

Kellogg-American

Kellogg-American V8051-335 instruction manual

Clarke

Clarke CSS1 Operation & maintenance instructions

Ingersoll-Rand

Ingersoll-Rand P425AWIR Installation, operation and service manual

Craftsman

Craftsman 919.165380 owner's manual

Emerson

Emerson Vilter VSS Installation, operation & maintenance manual

Estwing

Estwing E10GCOMP manual

TOLSEN TOOLS

TOLSEN TOOLS 73134 instruction manual

Daikin

Daikin ZH(C)3LSF Service manual

Truper

Truper COMP-120LV manual

Harbor Freight Tools

Harbor Freight Tools Central Pneumatic 4077 Assembly and operating instructions

Clarke

Clarke Ranger 7/240 Operation & maintenance instructions