IMT Diamond air DA440HU User manual

DA440HU: 99900782: ii

PRECAUTIONS

Read before operating your compressor!

19980224

71393886

DANGER

EXPLODINGTANK WILL CAUSE

DEATH, SERIOUS INJURY

OR PROPERTY DAMAGE

●

Drain air tank after each use to prevent

moisture build-up and corrosion which

leads to tank failure.

Assure that tank and compressor relief

valves work properly, and are at correct

pressure settings.

DO NOT modify or repair air tank.

NEVER drive vehicle with pressure in air

tank.

●

●

●

DA440HU: 99900782: iii19980224 TABLE OF CONTENTS

PARA TITLE PAGE

Section 1. GENERAL INFORMATION

1-1. INTRODUCTION ....................................................................................................1-1

1-2. ORDERING INFORMATION ..................................................................................1-2

Section 2. INSTALLATION

2-1. GENERAL ..............................................................................................................2-1

2-2. PTO AND PUMP INSTALLATION...........................................................................2-1

2-2-1. PTO INSTALLATION ..............................................................................................2-1

2-2-2. DRIVELINE AND PUMP INSTALLATION ............................................................... 2-2

2-3. UNDERDECK COMPRESSOR INSTALLATION....................................................2-3

2-4. OIL COOLER (OPTIONAL) ....................................................................................2-4

Section 3. OPERATION

3-1. INTRODUCTION ....................................................................................................3-1

3-2. OPERATION...........................................................................................................3-1

3-3. SYSTEM SHUTDOWN...........................................................................................3-1

Section 4. PREVENTIVE MAINTENANCE

4-1. INTRODUCTION ....................................................................................................4-1

4-2. LUBRICATION........................................................................................................4-1

4-3. HYDRAULIC SYSTEM ...........................................................................................4-1

4-3-1. HYDRAULIC FLUID SELECTION ..........................................................................4-1

4-3-2. HYDRAULIC FLUID SPECIFICATIONS.................................................................4-1

4-3-3. HYDRAULIC FLUID DETERIORATION .................................................................4-1

4-3-4. HYDRAULIC SYSTEM PURGING .........................................................................4-2

4-3-5. FILTER ELEMENT REPLACEMENT......................................................................4-2

4-4. PREVENTIVE MAINTENANCE CHECKLIST ........................................................4-3

Section 5. REPAIR

5-1. INTRODUCTION ....................................................................................................5-1

5-2. HYDRAULIC SYSTEM COMPONENTS ................................................................5-1

5-3. DRIVE BELT ...........................................................................................................5-1

Section 6. PARTS

6-1. GENERAL ..............................................................................................................6-1

Section 7. REFERENCE

LIST OF ILLUSTRATIONS

FIG TITLE PAGE

B-1. PTO INSTALLATION ..............................................................................................2-2

B-2. DRIVELINE AND PUMP INSTALLATION ............................................................... 2-2

B-3. KILL SWITCH WIRING DIAGRAM .........................................................................2-3

B-4. OIL COOLER-GENERAL HYDRAULICS DIAGRAM..............................................2-4

D-1. HYDRAULIC FLUID SPECIFICATIONS.................................................................4-1

D-2. PREVENTIVE MAINTENANCE CHECKLIST ........................................................4-3

E-1. DRIVE BELT ADJUSTMENT ..................................................................................5-1

E-2. HYDRAULIC SYSTEM TROUBLESHOOTING CHART.........................................5-2

F-1. DA440HU HYDRAULIC UNDERDECK COMPRESSOR (23000081-1) ................6-1

F-1A. DA440HU HYDRAULIC UNDERDECK COMPRESSOR (23000081-2) ................6-2

G-1. TORQUE DATA CHART .........................................................................................7-1

G-2. TIRE LOAD AND INFLATION PRESSURES..........................................................7-2

DA440HU: 99900782: iv19980224

RECOMMENDED SPARE PARTS LIST

1 Year Supply

DA440HU HYDRAULIC DRIVEN TOPDECK COMPRESSOR

For Manual: 99900782

This spare parts list does not necessarily indicate that the items can be expected to fail in the course of a year. It is intended to

provide the user with a stock of parts sufficient to keep the unit operating with minimal down-time waiting for parts. There

may be parts failures not covered by this list. Parts not listed are considered as not being Critical or Normal Wear items

during the first year of operations and you need to contact the distributor or manufacturer for availability.

23000081.01.19971112 HYDRAULIC UNDERDECK COMPRESSOR

2 70058486 BELT-POWER V 2B80 1 P

15 89086120 OIL-30W NON-DETERGENT 1 P

30 73051614 PUMP 1 W

40 73054995 RELIEF VALVE 1 W

44 70048069 MOISTURE REGULATOR 1 P

COMPRESSOR (R30)-70073051

REF 70073727 LP INTAKE VALVE 1 W

REF 70073726 LP EXHAUST VALVE 1 W

REF 70732447 HP INTAKE VALVE 1 W

REF 73054340 HP EXHAUST VALVE 1 W

REF 70073766 RING SET 1 W

REF 70143298 RELEASE VALVE KIT 1 W

REF 70732429 INTERCOOLER TUBE LH 1 W

REF 70732430 INTERCOOLER TUBE RH 1 W

REF 70732448 AIR FILTERS 1 P

REF 76391490 SHAFT SEAL 1 W

REF 73054339 POP OFF 70PSI 1 W

REF 73054031 PILOT VALVE 1 C

SHELF

LIFE

(MO) ORDER

QTYCODEQTYDESCRIPTIONPART NO.ITEM NO.

ASSEMBLY

DESIGNATION

DA440HU: 99900782: 1-119941223

SECTION 1. GENERAL INFORMATION

TO BE COMPLETED BY DEALER

CHASSIS INFORMATION

TRANSMISSION MAKE:

PTO NUMBER:

COMPRESSOR MODEL:

PUMP MAKE:

RESERVOIR CAPACITY:

MODEL:

PTO %:

SERIAL NUMBER:

MODEL:

ENGINE RPM:

COMPRESSOR AND HYDRAULIC PUMP INFORMATION

1-1. INTRODUCTION

This manual provides information on the

installation, operation and repair of the IMT

DA440HU Hydraulic Under Deck Compressor.

Three means are used throughout this manual to gain

the attention of operating and service personnel.

They are NOTES, CAUTIONS and WARNINGS

and are defined as follows:

NOTE

A NOTE IS USED TO EITHER CONVEY ADDITIONAL

INFORMATIONORTOPROVIDEFURTHEREMPHASIS

FOR A PREVIOUS POINT.

CAUTION

A CAUTION IS USED WHEN THERE IS THE STRONG

POSSIBILITY OF DAMAGE TO THE EQUIPMENT OR

PREMATURE EQUIPMENT FAILURE.

WARNING

AWARNINGISUSED WHENTHEREIS THEPOTENTIAL

FOR PERSONAL INJURY OR DEATH.

Operate this equipment with respect and service it

regularly. These two things can add up to a safer

working environment and longer equipment life.

1-2. ORDERING INFORMATION

When placing orders or requesting assistance, refer

to the information below:

DA440HU: 99900782: 2-119941223SECTION 2. INSTALLATION

2-1. GENERAL

This section deals with the installation of the PTO

and pump and the IMT hydraulic compressor. The

instructions are intended as a guide to assist you

with your particular installation. We can not cover

every make, model and year of truck manufactured

world-wide, so these instructions will provide only

general information. Use this section as a guide

only.

2-2. PTO AND PUMP INSTALLATION

The pump may either be installed directly on the

PTO or, as an optional method, it may be driven by a

driveline.

2-2-1. PTO INSTALLATION

Power take-off manufacturers provide specific

installation instructions for their products. Those

instructions should be followed when installing a

PTO. Some trucks may require modification of the

transmission cross-member to provide clearance and

the exhaust pipe may need modification. Check

with the PTO manufacturers representative for

specific instructions regarding your particular make,

model and year of vehicle. The following

instructions are a guide in this application.

1. If the vehicle is new, drain the transmission oil

into a clean container for reuse. If the vehicle is

used, drain and dispose of the transmission oil.

2. Temporarily install the PTO with the proper

gaskets and only two studs. Snug the PTO down

and check the backlash for maximum allowance of

1/32" to 1/16". If the backlash is excessive, remove

gaskets and check backlash again until it is

corrected.

3. Remove the PTO and apply Permatex® to the

gaskets. If the holes for the studs are tapped through

the transmission housing, apply Permatex to the

studs and tighten them down. Make certain that the

studs do not interfere with the transmission gears.

CAUTION

AVOID CONTACT OF PERMATEX WITH AUTOMATIC

TRANSMISSION FLUID.

4. Install the PTO and gaskets. Torque the nuts to

30 - 35 ft-lbs (4.14 - 4.84 kg-m) for a 6-bolt PTO

and 45 - 50 ft-lbs (6.22 - 6.91 kg-m) for 8-bolt

PTOs. Recheck the backlash.

5. Install the shifter cable to suit conditions.

Always allow for a slight overshift on lever or knob

to ensure the PTO is fully disengaged.

CAUTION

ITISIMPORTANTTHATROOMBEALLOWEDFOR FULL

ENGAGEMENT OF THE PTO. MODIFYTHE EXHAUST

OR OTHER OBSTRUCTIONS AS NEEDED.

CAUTION

AVOID SHARP BENDS IN THE SHIFTER CABLE. ALL

BENDS SHOULD HAVE AT LEAST A 6" RADIUS.

TIGHTERBENDS WILLCAUSE DIFFICULTOPERATION

OF THE SHIFTER KNOB.

6. Replace the transmission oil. If the PTO is

located below the transmission oil level, an

additional quantity of oil will be required.

7. Start the engine, engage the PTO and allow it to

run for 5-10 minutes. Check for leaks, unusual noise

and proper operation.

8. Retorque the mounting bolts.

DA440HU: 99900782: 2-2 WARNING

THE INSTALLER OF THE DRIVELINE MUST INSPECT

THE FINAL POSITION OF THE DRIVELINE TO

DETERMINE WHETHER ITS LOCATION PROVIDES

SUFFICIENT PROTECTION TO AN OPERATOR, OR

OTHER PERSONNEL, FROM HAZARDS ASSOCIATED

WITH A ROTATING DRIVELINE. IF PROTECTION IS

INSUFFICIENT, THE INSTALLATION OF A GUARD IS

REQUIRED. IF YOU ARE UNSURE OF METHODS TO

GUARD A ROTATING DRIVELINE, CALL IOWA MOLD

TOOLING CO., INC. FOR INSTRUCTIONS. FAILURE

TO DO SO MAY RESULT IN SERIOUS INJURY OR

DEATH.

19990120

FIGURE B-2. DRIVELINE & PUMP INSTALLATION

FIGURE B-1. PTO INSTALLATION

2-2-2. DRIVELINE AND PUMP

INSTALLATION

The pump may be driven as shown in Figure B-2 as

an optional method to the one shown in Figure B-1.

The following steps are a guide in this application.

1. Install the PTO (refer to Paragraph 2-2-1).

2. Loosely bolt the pump mounting bracket (A) to

the adjustable bracket (B).

3. Bolt the adjustable bracket to the frame at a

point that will not exceed 48" (122 cm) from the

PTO and will not cause a joint angle greater than 8°.

4. Check pump rotation and install pump, pump

end yoke and PTO end yoke.

5. Size, cut and weld the driveline to the necessary

length. Ensure driveline balance. Allow 1" (2.54

cm) extra for PTO end yoke.

6. Install driveline, lock set screws and lubricate U-

joints.

7. Ensure all mounting bolts are tight.

DA440HU: 99900782: 2-319941223

2-3. UNDERDECK COMPRESSOR

INSTALLATION

Due to variations, the instructions should be used as

a guide only.

1. Position the compressor below the compressor

compartment with the belt side to the rear of the

compartment.

2. Lift the compressor base into position, so the

base is flush with the bottom of the compartment.

Be certain there is clearance within the compartment

and no interference is present. Support the

compressor in this position.

3. Using the base as a template, drill eight holes

17/32" diameter through the compartment.

4. Bolt the compressor base to the walls of the

compartment using 1/2" grade 5 cap screws, flat

washers and lock nuts.

5. Connect the hydraulic hose from the pump to the

relief valve connected to the hydraulic drive motor

on the compressor. See compressor assembly

drawing.

6. Connect the return line to the reservoir. See

compressor assembly drawing.

7. Torque all mounting bolts per Torque Data Chart

if the compressor is positioned properly.

FIGURE B-3. KILL SWITCH WIRING DIAGRAM

8. Connect the air hoses per the compressor

assembly drawing.

9. Install the engine speed control as shown and

connect hoses from compressor to speed control.

10. Fill the oil reservoir and open the suction gate

valve. Disconnect the pressure hose at the hydraulic

pump. Engage the PTO and turn the vehicle engine

with the starter until oil flows through the pressure

side of the pump. Reconnect the pressure hose. Pull

out the compressor switch and open the gate valve to

the air receiver. Disengage the PTO and start the

truck. Depress clutch and engage PTO. Release the

clutch slowly. It may be necessary to warm the truck

engine so that it will pull at idle RPM. Push in the

compressor switch. This will close the control valve

and start the compressor. Allow for warm-up time.

Close the gate valve on the air receiver. This will

activate the speed control. Adjust the engine speed

control for proper operating RPM. Check for system

leaks and proper operation.

11. Install compressor kill switch. See Figure B-1.

DA440HU: 99900782: 2-419941223

FIGURE B-4. OIL COOLER-GENERAL HYDRAULICS DIAGRAM

2-4. OIL COOLER (OPTIONAL)

Oil coolers vary in their installation dependent on

available space and other considerations. Install the

oil cooler either in front of the carrier vehicle’s

radiator or, as an alternative, in a protective structure

which is cooled by an electric fan. Refer to Figure

B-4 for general location within the hydraulic system.

DA440HU: 99900782: 3-119950719 SECTION 3. OPERATION

3-1. INTRODUCTION

This section deals with the proper methods of

system operation and shutdown. These procedures

should be followed to prevent damage and ensure

efficient operation.

3-2. OPERATION

The compressor has an operating time limit of

approximately 3-hours depending upon ambient air

temperature (outside air temperature), weather

conditions and whether an oil cooler has been

installed.

CAUTION

THE HYDRAULIC OIL TEMPERATURE MUST NOT BE

ALLOWED TO EXCEED 190°F (88°C). IF THE OIL

TEMPERATURE REACHES THIS LIMIT, THE SYSTEM

MUST BE SHUT DOWN AND ALLOWED TO COOL.

Oil coolers will extend the 3-hour limit.

To start the compressor:

1. Ensure the PTO is disengaged, control valve is

open (pull the compressor switch out) and the

receiver drain cock is open.

2. Start the truck engine and allow it to idle until it

reaches the proper operating temperature (refer to

the Owners Manual).

3. Depress the clutch, engage the PTO and

carefully release the clutch pedal. Allow the system

to warm up for the time period specified in below.

COMPRESSOR WARM-UP TIME

AMBIENTAIR IDLING TIME

TEMPERATURE (°F) (WARM-UP)

+40 OR ABOVE NONE

+20 TO +40 2 - 5 MINUTES

0 TO +20 5 - 10 MINUTES

-20 TO 0 10-15 MINUTES

-40 TO -20 15-20 MINUTES

BELOW -40 20 MINUTES MIN.

4. When starting the compressor, the RPMs will

automatically increase due to low volume of air in

the system.

CAUTION

1000 RPM MAX.

Operating this unit in excess of 1000 RPM, measured at

the compressor flywheel, will void your warranty. Engine

RPM may be different.

3-3. SYSTEM SHUTDOWN.

System shutdown is accomplished as follows:

1. Allow the compressor to build to maximum

pressure and the truck engine will automatically idle

down.

2. Place the compressor control valve in the open

(off) position.

3. Depress the clutch pedal and disengage the PTO.

4. Open the receiver drain cock and discharge the

air in the receiver.

WARNING

FEDERAL LAW PROHIBITS DRIVING THE CARRIER

VEHICLE ON PUBLIC ROADS WITH THE RECEIVER

FILLEDWITH COMPRESSEDAIR. ALWAYS DRAINTHE

RECEIVER BEFORE MOVING THE VEHICLE.

DA440HU: 4-199900782: 19941223

Section 4. PREVENTIVE MAINTENANCE

FIGURE D-1. HYDRAULIC FLUID SPECIFICATIONS

4-1. INTRODUCTION

Proper maintenance on a regular schedule is

essential to keep your unit operating efficiently.

Proper maintenance procedures and required service

intervals are outlined in this section. Personnel

responsible for unit upkeep should become familiar

with frequency and type of maintenance required

and perform these tasks at recommended intervals.

4-2. LUBRICATION

The only lubrication required is on the carrier vehicle

and the compressor itself. Refer to the appropriate

Owners Manual for information on the truck and

compressor for the type and frequency of lubrication

required.

4-3. HYDRAULIC SYSTEM

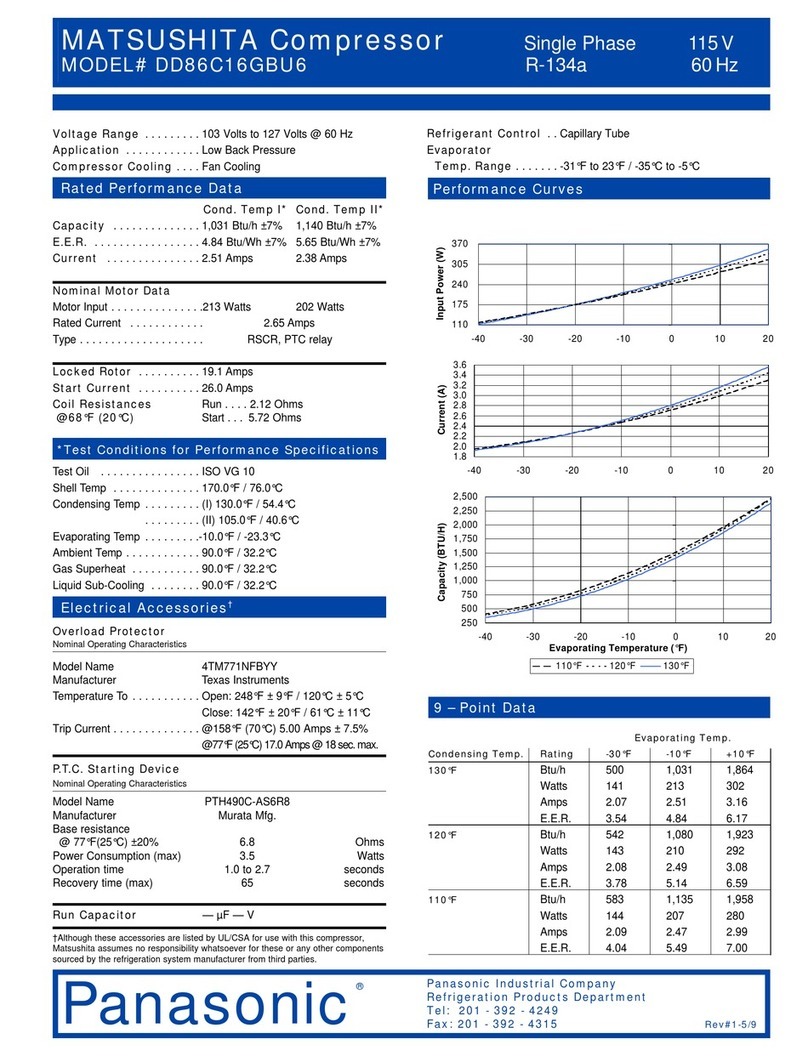

4-3-1. HYDRAULIC FLUID SELECTION

Minimum viscosity specifications for hydraulic oil to

be used in the hydraulic system are given in Figure

D-1. Any major oil company can supply products

which meet these requirements.

Oils selected for use with this class of equipment, in

addition to meeting viscosity requirements, should

have the following additives:

1. Antifoam Inhibitors

2. Antioxidant Inhibitors

3. Rust Resistant Additives

4. Antiwear Additives

4-3-2. HYDRAULIC FLUID

SPECIFICATIONS

Figure D-1 states oil specifications for a full range of

operating temperatures encountered in the temperate

zones. Arctic conditions present special

requirements which are not in the scope of the table

and must be analyzed individually. Consult your oil

supplier for the proper hydraulic fluids for working

under these severe conditions. Electric reservoir

heaters are available to improve conditions at

extremely low temperatures.

4-3-3. HYDRAULIC FLUID

DETERIORATION

Contamination of the hydraulic fluid by solvents,

water, dust or other abrasives will cause deterioration

of the fluid. Sustained presence of the impurities will

result in premature breakdown of antifoam,

lubrication, anti-rust and viscosity properties.

Introduction of water to the system and operation at

high temperatures (above 180°F) will result in an

increase in the oil oxidation rate. Oxidation produces

varnish forming materials and sludge in the oil.

Operating the system on a sustained basis with

contaminated or broken down oil will increase wear

and can significantly shorten the efficient service life

of the unit.

DA440HU: 4-299900782: 19941223

Periodically, draw off a sample of the oil and check

the oil for breakdown. To check oil quality:

1. Place the oil in a clean glass.

2. Smell the oil to detect a burnt or rancid odor.

3. Visually examine the oil for a dark or cloudy

appearance.

4. Allow the sample to stand for several minutes.

Inspect the sample for water which will settle to the

bottom of the glass if present. Water can result from

a system leak or condensation due to temperature

extremes.

When any of these conditions is observed, the

system should be purged and filled with new oil. In

addition, the oil should be changed in the reservoir

and complete system:

1. After every 800 hours of operation or every six

months, whichever occurs first.

2. After pump or other major hydraulic component

failure, drain the hoses.

4-3-4. HYDRAULIC SYSTEM PURGING

Purging the hydraulic system requires a new oil

supply sufficient to completely fill the reservoir,

hoses, filters, valves, etc., and an extra allowance for

loss during this procedure. To reduce oil loss,

operate the engine at a low speed (idle).

When purging, new oil is supplied to the pump

suction line via the reservoir, and the old oil is

discharged through the reservoir return line.

Two operators will be required; one to operate the

compressor and the other to regulate pump flow

(engine speed).

Purging is accomplished as follows:

1. Drain the hydraulic reservoir and disconnect the

suction hose to the pump. Drain the hose and

reassemble. Change the suction filter cartridge

(Paragraph 4-3-5).

NOTE

THE METHOD OF WASTE DISPOSAL IS LEFT TO THE

DISCRETION OF SERVICE PERSONNEL.

2. Disconnect the reservoir return line at the

reservoir and direct the discharge into a sump or

waste container. Plug the return line port on the

reservoir and fill the reservoir with clean oil (refer to

Paragraph 4-3-1).

NOTE

BE THOROUGHLY FAMILIAR WITH THE FOLLOWING

STEPS AND PREPARED TO PERFORM THEM IN AN

UNINTERRUPTEDSEQUENCE. IFTHIS IS NOTDONE,

EXCESSIVE OIL WASTE WILL OCCUR.

CAUTION

DO NOT ALLOW THE RESERVOIR LEVEL TO DROP

BELOW 1/3 CAPACITY DURINGTHIS OPERATION.

3. Start the engine and engage the PTO. Slowly

release the clutch. Activate the control valve so that

the fluid passes through the motor. Allow fluid to

discharge for about 15 seconds. Kill the engine.

4. Reconnect the return line to the reservoir port

and change the return line filter. All components of

the system are now purged.

5. Check the reservoir oil level and add oil as

necessary.

4-3-5. FILTER ELEMENT

REPLACEMENT

To avoid residue accumulation in the reservoir and to

protect the hydraulic components (valves,

pumps,motors, etc.), the filters must be serviced on a

regular basis.

They must be changed after the initial 50-hours of

new unit operation and every 200-hours thereafter.To

change filter elements:

1. Shut the gate valve and remove the filter

element.

2. Install the new filter ensuring proper rubber seal

seating and tighten as much as possible using both

hands.

3. Open the gate valve and check for leaks.

CAUTION

PUMPFAILURECANRESULTIFTHESHUTOFFVALVE

ISLEFTCLOSED.

DA440HU: 4-399900782: 19941223

4-4. PREVENTIVE MAINTENANCE

CHECKLIST

The checklist (Figure D-2) is designed to assist you

in keeping your unit in efficient operating condition.

Items in this section apply to the unit only. The

carrier vehicle should also be inspected regularly

(refer to the carrier vehicles service manual).

FIGURE D-2. PREVENTIVE MAINTENANCE CHECKLIST

DA440HU: 99900782: 5-1

SECTION 5. REPAIR

19941223

5-1. INTRODUCTION

This section deals with the disassembly and repair of

the components as well as troubleshooting

information.

5-2. HYDRAULIC SYSTEM

COMPONENTS

Disassembly and repair of components in the

hydraulic system requires special consideration for

proper functioning and service life of the unit.

These steps are to be followed whenever a hydraulic

component is removed from the system.

1. ALWAYS relieve internal hydraulic pressure

before proceeding with a repair, carefully loosen a

fitting and allow the pressure to bleed off.

2. NEVER allow foreign matter (dirt, water, metal

particles, etc.) to enter the system through the open

connections. Cap or plug any openings. If dirt does

get in, a filter change is required after 50 hours of

operation.

3. ALWAYS check for high pressure leaks after

completing a repair. A high pressure leak is

hazardous and must be repaired.

5-3. DRIVE BELT

To adjust the drive belt tension and alignment:

1. Loosen the four bolts securing the motor

mounting bracket to the base plate.

2. Turn the drawbolt in a clockwise direction to

tighten the belt until there is 1/4" - 1/2" play at the

center of the belt between the pulleys.

3. Adjust the alignment drawbolt until the motor

pulley is square with the compressor. Use a

straightedge across the compressor pulley (Figure E-

3) and check the gap between the motor pulley and

the straight edge. The gap (1-3/4") on the

compressor side of the motor pulley should be the

same as on the far side of the pulley.

FIGURE E-1. DRIVE BELT ADJUSTMENT

DA440HU: 6-123000081.01.19971112 SECTION 6. PARTS

6-1. GENERAL

This section contains the exploded parts drawings

with accompanying parts lists for associated

assemblies. These drawings are intended to be used

in conjunction with the instructions found elsewhere

in this manual.

For information pertaining to the compressor, refer

to its specific manual.

See Section 7 for reference data which may be

useful in the repair and operation of your

compressor.

FIGURE F-1. DA440HU HYDRAULIC UNDERDECK COMPRESSOR (23000081-1)

ITEM PART NO. DESCRIPTION QTY

1. 52702376 BASE 1

2. 70058486 BELT-POWER V 2B80 1

3. 70073051 COMPRESSOR (R30) 1

4. 72053013 PIPE NIPPLE 1/4NPT X CLOSE 1

5. 72053049 PIPE NIPPLE 3/8NPT X CLOSE 1

6. 72053283 STREET ELBOW 3/8NPT 90° 1

7. 72053533 STREET ELBOW 1/4NPT 45° 1

8. 77041008 PRESSURE SWITCH 1

9. 72060094 CAP SCR 1/2-13X1-3/4 HHGR5 4

10. 72062080 NUT 1/2-13 LOCK 4

11. 72532013 STREET TEE 1/4NPT 1

13. 72532552 HOSE FITTING 1/4-1/4 1

15. 89086120 OIL-30W NON-DETERGENT 1GAL

17. 52070869 BRACKET-HYD MTR 1

18. 52706302 TIGHTENER BOLT 8" 2

19. 60104598 TIGHTENER BAR 1

20. 60106708 BUSHING-SPLIT TAPER MOD 1

21. 70056043 PULLEY 1

22. 72053141 PIPE NIPPLE 3/4NPT X CLOSE 2

23. 72053285 STREET ELBOW 3/4NPT 90° 1

ITEM PART NO. DESCRIPTION QTY

24. 72053558 ADAPTER 3/4MPT 3/4MPT HEX 1

25. 72053604 TEE 3/4NPT 1

26. 72053713 ELBOW 3/4MPT 3/4FPT 90° SWVL 1

27. 72053750 ADAPTER #16MSTR 3/4FPT 1

28. 72060094 CAP SCR 1/2-13X1-3/4 HHGR5 4

29. 72063005 WASHER 1/2 WRT 4

30. 73051614 PUMP 1

31. 72062080 NUT 1/2-13 LOCK 6

32. 72060097 CAP SCR 1/2-13X3 HHGR5 2

33. 72053747 ADAPTER MSTR FPT 2

34. 51705296 HOSE ASM FF 3/4X20 1

35. 72053436 COUPLING 1" - 3/4"NPT 1

36. 72053676 ADAPTER 3/4MPT #12MJIC 1

37. 72531131 STREET ELBOW 1/4NPT 90° 1

38. 72532367 ADAPTER #16MSTR #12MJIC 2

39. 73054435 PRESSURE GAUGE 5000PSI 1

40. 73054995 RELIEF VALVE 1

41. 72053245 PIPE PLUG 1/4NPT SQHD 1

42. 72053411 PIPE PLUG 1/8NPT SQHD 1

44. 70048069 MOISTURE REGULATOR 1

Table of contents

Other IMT Air Compressor manuals

Popular Air Compressor manuals by other brands

NorthStar

NorthStar M36029L Installation, operation and maintenance manual

Becker

Becker KDT 3.100 operating instructions

Craftsman

Craftsman 919.724320 owner's manual

Sullair

Sullair TS32 Series Operator's manual and parts list

ring

ring RAC750 operating instructions

Airpress

Airpress L6-95SILENT Translation original manual

Campbell Hausfeld

Campbell Hausfeld FP2030 operating instructions

MIOL

MIOL 81-196 manual

WilTec

WilTec AS196A instruction manual

Dover

Dover PSG Mouvex Enterprise Series Installation operation & maintenance

Corken

Corken HG601 Series Installation, operation & maintenance manual

Craftsman

Craftsman 919.184192 owner's manual