IMV SD Logger4 User manual

IMV CORPORATION

SD Logger4 instruction manual[X51 00 -3]

1/28 <2020/03/03> (3rd edition)

SD Logger4 Instruction Manual

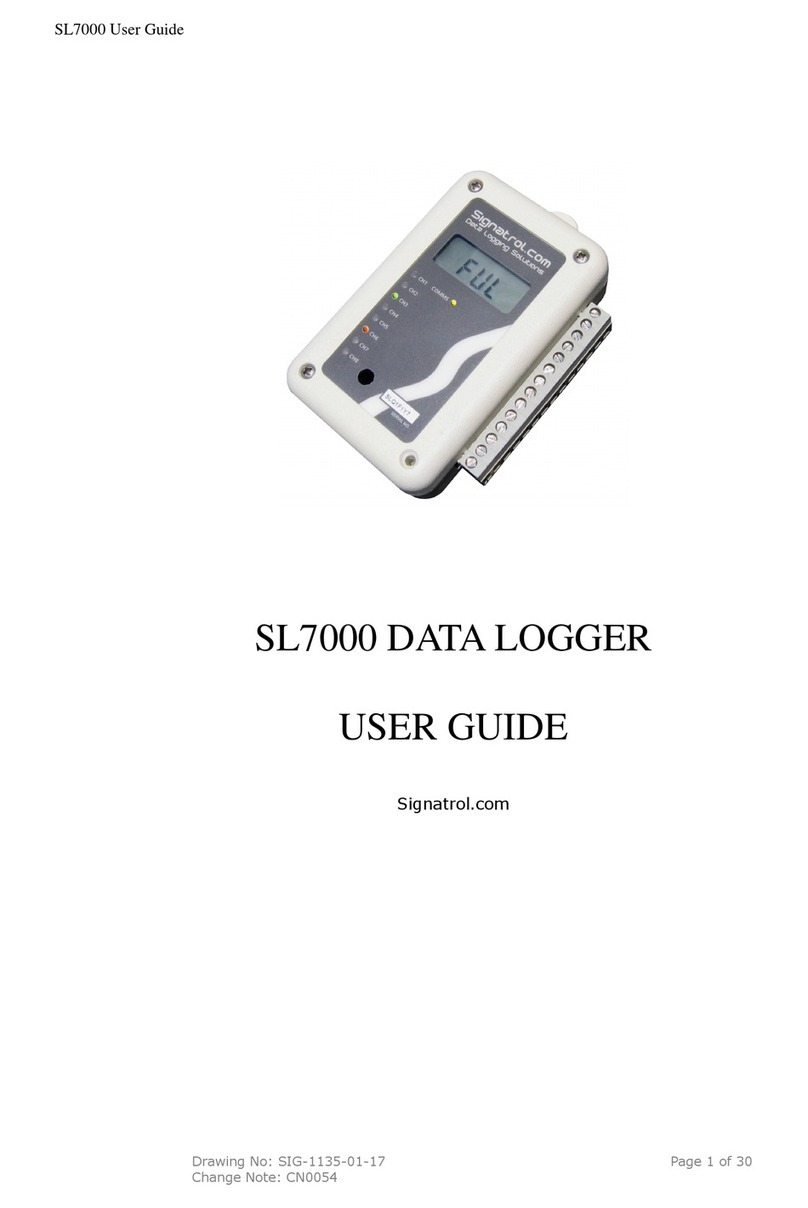

ESD-CS4A

ESD-CC4A

ESD-BS4A

ESD-BC4A

【Cased (Case Type)】

【PCB(PCB Type)】

・The contents of this instruction manual are subject to change without notice for improvement.

・Please check our website for the latest information.

SD Logger4 instruction manual[X51 00 -3]

2/28 <2020/03/03> (3rd edition)

Contents

I Overview・Specification .......................................................................................... 4

1. Overview .............................................................................................................. 4

2. Variation .............................................................................................................. 5

3. Setting change by configuration mode ............................................................... 5

4. Specification ........................................................................................................ 6

5. Name of each part ............................................................................................... 7

II Setting ....................................................................................................................

1. DIP switch setting and configuration setting ....................................................

2. DIP switch ......................................................................................................... 11

III Connection ............................................................................................................ 13

1. RS-232C cable connection ................................................................................. 13

2. Power supply ..................................................................................................... 14

IV Usage procedure ................................................................................................... 15

1. Usage procedure ................................................................................................ 15

2. LED display and buzzer sound ......................................................................... 16

V File ........................................................................................................................ 17

1. File control system ............................................................................................ 17

2. Logging file [script version] .............................................................................. 17

3. Subdirectory ...................................................................................................... 17

4. Maximum number of files ................................................................................. 18

5. Command version file specification [Command version] ................................ 18

6. Script file [script version] ................................................................................. 18

7. Writing speed .................................................................................................... 1

VI Response to power shutdown .............................................................................. 20

1. Auto sync function ............................................................................................ 20

2. Capacitor backup .............................................................................................. 20

VII Other function ...................................................................................................... 21

1. Date / time setting ............................................................................................ 21

2. Jumper switch ................................................................................................... 21

3. Flow control ....................................................................................................... 23

4. Maintenance information ................................................................................. 23

VIII Enhanced functions and differences with Logger 3 .......................................... 24

1. Added high bit rate ........................................................................................... 24

2. Status file .......................................................................................................... 24

3. Update from card .............................................................................................. 25

4. Synchronize script and received data .............................................................. 25

5. Automatic clear of communication error ......................................................... 25

SD Logger4 instruction manual[X51 00 -3]

3/28 <2020/03/03> (3rd edition)

6. Strengthen short-term power-off response ...................................................... 25

7. Other enhancements ......................................................................................... 26

8. Main differences from Logger 3 ........................................................................ 26

IX Functions enhanced after V3 4X ........................................................................ 26

1. Script log start / stop function

X External dimensions ............................................................................................ 27

XI Notes・Other ......................................................................................................... 28

SD Logger4 instruction manual[X51 00 -3]

4/28 <2020/03/03> (3rd edition)

Ⅰ Overview・Specification

1. Overview

【Script version】

The SD logger “script version” is a device whose basic function is to save data

received from serial communication (RS-232C) to an SD card.

Data stored on the card can be read out on a PC using a commercially available

card reader.

In addition to basic functions, functions can be expanded by writing scripts in

their own scripting language.

It is possible to send a specific command at regular intervals, or send specific data

in response to some reception. A simple communication protocol can be realized.

It also has a date / time function. The script can write the date and time to the log

file.

Part of the written script can be simulated on a personal computer using the free

software "CMLogger" provided by our company.

After confirming the operation on the personal computer, it can be implemented

in the SD logger “script version”.

Please refer to the following documents for the script language specifications.

「SD logger script language reference format (X507018)」

「SD logger script language tutorial format (X50701 )」

【Command version】

The SD logger “Command Version” is a device that can read and write SD card file

data by exchanging commands via serial communication (RS-232C).

Card data can be read and written by a personal computer using a commercially

available card reader.

Refer to the following document for command specifications.

「SD logger (command version) Command communication specification (X507016)」

「SD logger (command version) command reference (X507017)」

「Date / Time Command Reference (X51 005)」

※The SD logger can be switched between “script version” and “command version”

by changing the setting in “configuration mode”.

※Free software provided by our company can be downloaded from our website.

SD Logger4 instruction manual[X51 00 -3]

5/28 <2020/03/03> (3rd edition)

2. Variation

This instruction manual explains the following models of the SD logger.

Model

Name

Factory function

Exterior

(Basic version)

ESD

-

CS4A

SD

logger

4

Script version

Case

ESD

-

CC4A

SD

logger

4

Command version

Case

ESD

-

BS4A

SD

logger

4

Script version

PCB

ESD

-

BC4A

SD

logger

4

Command version

PCB

※The “script version” includes the functions of the original “normal version”.

3. Setting change by configuration mode

In the logger, the setting can be changed in "Configuration Mode". The items that

can be changed are as follows.

Item Contents

Function Script version

Command version

Data bit

※1

8〔Bit〕

7〔Bit〕

Stop bit

※1

1〔Bit〕

2〔Bit〕

Bit rate

※2

300〔bps〕

1,200〔bps〕

2,400〔bps〕

4,800〔bps〕

,600〔bps〕

1 ,200〔bps〕

38,400〔bps〕

57,600〔bps〕

115,200〔bps〕

Flow control

No flow control by RTS(DISABLE)。

Perform flow control by RTS(ENABLE)。

Auto clear Do not automatically clear communication errors.

Automatically clears communication errors.

※1:When DIP switch 6 is ON

※2:When DIP switches 1 to 3 are all ON

Please refer to the following documents for how to change the settings.

「How to use ESDHost (X51 006)」

SD Logger4 instruction manual[X51 00 -3]

6/28 <2020/03/03> (3rd edition)

4. Specification

Item Contents Remarks

Baud rate(bps) 300,1200,2400,4800,

600,1 200,38400,57600

115200

Data bit 7bit / 8bit ※1

Step bit 1bit / 2bit Refer to Chapter IV-4

Parity None/Odd/ Even number

File system FAT16、FAT32 Refer to ChapterV-1

Card SD card(Compatible with

SDHC)

※2

RS-232C D-SUB 9pin male connector Fixed screw:

Inch(#4-40UNC)

Power supply DC 8V~12V

Current consumption

Standard 100mA, maximum

150mA

Operating

temperature range

0℃~60℃

Time accuracy ±0.01% Script WAIT TIME

Built-in clock accuracy

Within ± 60 seconds per month

@25℃

Built-in clock battery

CR2032 Standard battery life

7 years ※3

(注)Memory card and connection cable are not included.

※1 Only 8 bit can be used in configuration mode and update mode.

※2 SDXC cards are not supported.

※3 Batteries installed at the time of product shipment do not guarantee a

battery life of 7 years from the time of purchase.

SD Logger4 instruction manual[X51 00 -3]

7/28 <2020/03/03> (3rd edition)

5. Name of each part

【PCB type】

No.

Symbol

Contents

① SW2 Power switch

② CN3 Connector for memory card

③ LED3

Red LED(Error)

④ LED2

Yellow LED(Access)

⑤ LED1

Green LED(Pilot)

⑥ CN2 DC Power connector(DC jack)

⑦ CN1 RS-232C Connector(D-Sub pin male)

Fixed screw:Inch (#4-40UNC)

⑧ SW1 Dip switch for baud rate and other settings

SD Logger4 instruction manual[X51 00 -3]

8/28 <2020/03/03> (3rd edition)

【Case type】

No.

Symbol Contents

① POWER

Power switch

② Connector for memory card

③ ERR Red LED(Error)

④ ACC Yellow LED(Access)

⑤ PL Green LED(Pirot)

⑥ DC8~12V

DC power connector(DC jack)

⑦ RS-232C

RS-232C Connector(D-Sub 9pin male)

Fixed screw:Inch(#4-40UNC)

⑧ DIPSW Dip switch for baud rate and other settings

SD Logger4 instruction manual[X51 00 -3]

/28 <2020/03/03> (3rd edition)

Ⅱ Setting

1. DIP switch setting and configuration setting

SD Logger 4 has a function that can be switched by DIP switch setting and a

function that can be switched by configuration setting.

Configuration settings are made by connecting to a PC.

For configuration settings, refer to “Chapter I-3”. For details, refer to 「the way of

using ESDHost (X51 006)」.

Item Dip

Switch Configuration

Remark

Bit rate

300〔bps〕 × 〇

1,200〔bps〕 × 〇

2,400〔bps〕 ◎ 〇

4,800〔bps〕 ◎ 〇

,600〔bps〕 ◎ 〇

1 ,200〔bps〕 ◎ 〇

38,400〔bps〕 ◎ 〇

57,600〔bps〕 ◎ 〇

115,200〔bps〕 ◎ 〇

Parity

None 〇 ×

Odd number 〇 ×

Even number 〇 ×

Data bit

8bit ◎ 〇

7bit × 〇

Stop bit

1bit ◎ 〇

2bit × 〇 ※1

Flow control

Not performed △ 〇

Do × 〇

(Continued on next page)

SD Logger4 instruction manual[X51 00 -3]

10/28 <2020/03/03> (3rd edition)

(Continued)

Item Dip

Switch Configuration

Remark

Automatic clear of communication

error

Don't do × 〇

Do

△

〇

Function

Script version × 〇

Command version × 〇

◎

Can be set. Dip switch settings can be prioritized.

〇 Can be set.

× Cannot be set.

△

Default setting. What has been changed in the configuration settings

cannot be changed with the DIP switch.

※1 It can also be set with a script.

SD Logger4 instruction manual[X51 00 -3]

11/28 <2020/03/03> (3rd edition)

2. Dip switch

Dip switch[DIPSW(SW1)]

1 2 3 4 5 6 7 8 ON

The switches are [1] to [8] from the left. The switch is OFF at the top and ON at the

bottom.

(Setting Example)

Contens

600bps、Data 8 bits, 1 stop bit, no parity (all OFF)

No. [1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

Setting

OFF OFF OFF OFF OFF OFF OFF OFF

1-1)Bit rate setting

The bit rate is set by operating dip switches [1] to [3].

The correspondence between switch ON / OFF and bit rate is shown in the table

below.

No. Bit rate〔bps〕

[1] [2] [3] [4]

[5]

[6]

[7]

[8]

OFF

OFF

OFF

-

-

-

-

-

,600

ON

OFF

OFF

-

-

-

-

-

1 ,200

OFF

ON

OFF

-

-

-

-

-

38,400

ON

ON

OFF

-

-

-

-

-

57,600

OFF

OFF

ON

-

-

-

-

-

115,200

ON

OFF

ON

-

-

-

-

-

2,400

OFF

ON

ON

-

-

-

-

-

4,800

ON

ON

ON

-

-

-

-

-

Follow configuration settings.

1-2)Parity

The parity is set by operating the DIP switches [4] and [5].

The correspondence between switch ON / OFF and parity is shown in the

table below.

No. Parity

[1]

[2]

[3]

[4] [5] [6]

[7]

[8]

-

-

-

OFF

OFF

-

-

-

None

-

-

-

ON

OFF

-

-

-

Odd number

-

-

-

OFF

ON

-

-

-

Even number

-

-

-

ON

ON

-

-

-

None (for future expansion)

SD Logger4 instruction manual[X51 00 -3]

12/28 <2020/03/03> (3rd edition)

1-3)Data bit / stop bit

Data bits and stop bits are set by operating DIP switch [6].

The correspondence between switch ON / OFF and data bit / stop bit is shown

in the table below.

No. Data bit / stop bit

[1]

[2]

[3]

[4]

[5]

[6] [7]

[8]

-

-

-

-

-

OFF

-

-

8 data bits and 1 stop bit

-

-

-

-

-

ON

-

-

Follow configuration settings.

※In configuration mode and update mode, even if data bit 7 is set

in configuration settings, data bit 8 operates.

1-4)Mode

The mode is set by operating DIP switches [7] and [8].

The correspondence between the switch ON and OFF and the mode is as shown

in the table below.

No. Mode

[1]

[2]

[3]

[4]

[5]

[6]

[7] [8]

-

-

-

-

-

-

OFF

OFF

Normal

-

-

-

-

-

-

ON

OFF

Configuration mode

-

-

-

-

-

-

OFF

ON

Status display (maintenance) mode

-

-

-

-

-

-

ON

ON

Update (programming) mode

※The maintenance mode is for checking maintenance information and

for maintenance. Normally, use it in non-maintenance mode.

※If a card is installed, it will not be in configuration mode or update mode.

Remove the card to use in configuration mode or update mode.

※Do not use a mechanical pencil for dip switch operation.

Mixing the core powder into the inside may cause malfunction.

SD Logger4 instruction manual[X51 00 -3]

13/28 <2020/03/03> (3rd edition)

Ⅲ Connection

1. RS-232C cable connection

Check each signal so that there is no mistake in the connection of the RS-232C

connector. The connector pin assignments are as follows.

RS-232C

1 2 345

67 8 9

D-Sub pin male

(View from connector mating surface)

Pin No. Name Contents Signal direction

1 NC Not connected (Note 1)

Logger Side

2 RXD Received data

3 TXD Send data

4 DTR Data terminal ready, connected to pin 6

5 GND Signal ground

6 DSR Data set ready, connected to pin 4 (Note

1)

7 RTS Transmission request (usually high

level, Note 3)

8 CTS Transmission permission (not used,

note 4)

Unused (Note 2)

(Use a cross cable when connecting to RS-232C on a PC.)

(For flow control using 7-pin RTS, refer to 「Ⅶ Other functions / 3. Flow

control」.)

(Note 1) Can be used as a terminal to turn the power on and off from the outside

by jumper settings. See 「Ⅶ Other functions 2. Jumper switches」.

(Note 2) It can be used as a terminal to supply power from outside by jumper

setting. See 「Ⅶ Other functions 2. Jumper switches」.

(Note 3) Can be controlled by script language.

(Note 4) Can be used to control the script language.

SD Logger4 instruction manual[X51 00 -3]

14/28 <2020/03/03> (3rd edition)

2. Power supply

Supply DC power (DC8V to 12V) from the DC power connector (DC jack, CN2

for board).

Use a compatible DC plug with an inner diameter of φ2.1 and an outer

diameter of φ5.5.

When using an AC adapter, select a suitable DC plug.

When using an AC adapter, the switching regulator type is recommended.

(Center is a plus)

SD Logger4 instruction manual[X51 00 -3]

15/28 <2020/03/03> (3rd edition)

Ⅳ Usage procedure

1. Usage procedure

Procedure 1.Insert memory card

Insert a memory card into the logger.

Procedure 2.Power switch(POWER/SW2)ON

Turn the power switch to the [ON] side to turn on the power.

Setting the power switch to the [ON] side is expressed as 「Turn the power

switch ON」.

If the green LED (PL / LED1) turns on and the yellow LED (ACC / LED2) turns

off, the preparation is complete.

Procedure 3.Power switch(POWER/SW2)OFF

To finish the work after receiving data and exchanging commands, set the power

switch to the [OFF] side.

Setting the power switch to the [OFF] side is expressed as 「Turning the power

switch off」. The power turns off automatically after closing the open file.

*It is possible to remove the memory card.

If the card is being accessed, it may take some time before the power is actually

turned off even if the power switch is turned off.

Check the card access with the yellow LED display.

Check that all LEDs are off before inserting or removing the card.

SD Logger4 instruction manual[X51 00 -3]

16/28 <2020/03/03> (3rd edition)

2. LED display / buzzer sound

The LED is displayed as follows.

Pilot lamp (Green)

PL/LED1

Lighting Power is on.

Access lamp (Yellow)

ACC/LED2

Lighting Accessing the memory card.

Holding data in the buffer.

Flashing In configuration mode.

Error lamp (red)

ERR/LED3

Flashes once The card is not installed.

Flashes twice

Error in card access.

Flashes 3

times Data communication error.

Flashing In update mode.

The buzzer sounds as follows.

Buzzer

When the access lamp(Yellow、 )starts to light,

it sounds briefly.

※Does not sound when the configuration mode

is blinking.

Sounds the same as the blinking error lamp (Red、 )

※Does not sound when flashing in update mode.

The buzzer can be stopped by removing the jumper switch, J3. See section 「Ⅶ.2」

for how to remove the jumper switch.

SD Logger4 instruction manual[X51 00 -3]

17/28 <2020/03/03> (3rd edition)

Ⅴ File

1. File control system

Logger uses the FatFs file system created by ChaN.I would like to thank and

thank Mr. ChaN for providing a competent file system.

Long file names are not supported.

2. Logging file

【Script version】

File name [4-digit hexadecimal number].LOG

(Example)

0000.LOG

0001.LOG

0002.LOG

The logging file has a name that does not overlap with an existing file.

Search for the existence of the file from "0000.LOG" to "FFFF.LOG", and the

name of the first non-existent file found is used as the logging file name.

※The extension can be changed by script.

3. Subdirectory

In the case of "script version", the following subdirectory function works.

If a directory called 「LOGDATA」 exists in the root directory, a logging file will be

created under that directory.

If there is no "LOGDATA" directory, the logging file will be created in the root

directory.

The “command version” does not have a subdirectory function.

SD Logger4 instruction manual[X51 00 -3]

18/28 <2020/03/03> (3rd edition)

4. Maximum number of files

The maximum number of files that can be logged by the logger is 65536 [* 1].

However, in general, only 512 [* 2] files can be created in the FAT16 root directory,

so the logger also conforms to this restriction.

It seems that the maximum number of files that can be created in a subdirectory

is generally limited to 65534 [* 2], but the logger can create more than 65535 [* 2]

files.

And in our verification, the 65535th and 65536th files created by the logger can

also be read on a personal computer.

[*1] The maximum number of logging files created by the logger.

[*2] This is the maximum number including files other than logging files.

Start-up time

If there are many files on the card, it takes time to start up, which is not practical.

The following table gives an estimate of the startup time for the number of files

under certain conditions.

Number of

files

512pcs 1,024pcs 4,0 6pcs 10,000pcs

Start-up time

1.3seconds 2.1 seconds 16. seconds 1minutes

2 .6 seconds

※It is a reference value , not a guaranteed value.

5. Command version file specification

【Command version】

File name 8 single-byte alphanumeric characters + 3 character extension

(Long file names are not supported)

For details on the file names that can be handled by the command version,

See「Command Communication Specifications」.

The subdirectory function cannot be used in the command version.

6. Script file

【Script version】

In the case of “script version”, if there is a file named 「SCRIPT.TXT」 or

「SCRIPT.SCR」 on the installed memory card, it will be read as a script file.

The script file is read and executed when the power switch is turned on and the

power is turned on.

Script files are read from the root directory even if the directory “LOGDATA”

exists.

In the script file, LF (0x0A) is judged as the end of the line.

CR (0x0D) appearing in the script file is ignored.

SD Logger4 instruction manual[X51 00 -3]

1 /28 <2020/03/03> (3rd edition)

7. Writing speed

As the amount of data in the card increases, the writing speed decreases, which is

not practical.If writing speed is required, it is recommended that you use a card that

has just been formatted or has not recorded much data.

Consider using flow control for use with large amounts of data. In the command

version, check the response firmly (it takes longer time to get a response).

Notes

If it takes time to write 1 byte, the power will not be turned off immediately even

if the power switch is turned off.

Depending on the situation, the power may not be turned off for more than 1

minute even if the power switch is turned off.

In such a case, please wait for the card to be inserted or removed or the main

power supply to be shut off until all LEDs turn off even if the power switch is turned

off.

SD Logger4 instruction manual[X51 00 -3]

20/28 <2020/03/03> (3rd edition)

Ⅵ Response to power shutdown

1. Auto sync function

When data is lost for 3 seconds, the data remaining in the buffer is written to the

card and the consistency of the file structure is restored.

As a result, data received more than 3 seconds ago will not be lost even if the

power is suddenly shut down.

In addition, even if the power supply is cut off without receiving data for more

than 3 seconds, the file structure will not be damaged.

2. Capacitor backup

Even if the external power supply is cut off, the internal power supply is

secured by the capacitor.

Even if the power supply (main power supply) to the DC power connector is cut off

while the power switch is ON, the power is supplied from the backup capacitor and

the shutdown process is performed.

When the shutdown process is completed, the logger will cut off the power supply

to itself.

Power is supplied from the backup capacitor for a short time during the shutdown

process.

Even if the external power supply is suddenly cut off due to auto sync and

capacitor backup, the possibility of damaging the file structure is low.

Notes

The time required for the shutdown process varies depending on the usage

conditions of the card used.

On the other hand, the backup time with a capacitor is limited.

Please fully verify the effectiveness under the conditions of use.

This manual suits for next models

4

Table of contents