PAGE 04

Your safety is of the utmost importance to. Please

make sure that you read this instruction booklet

before attempting to install or use the appliance. If

you are unsure of any of the information contained

in this booklet, please contact the Retailer where you

purchased your unit from.

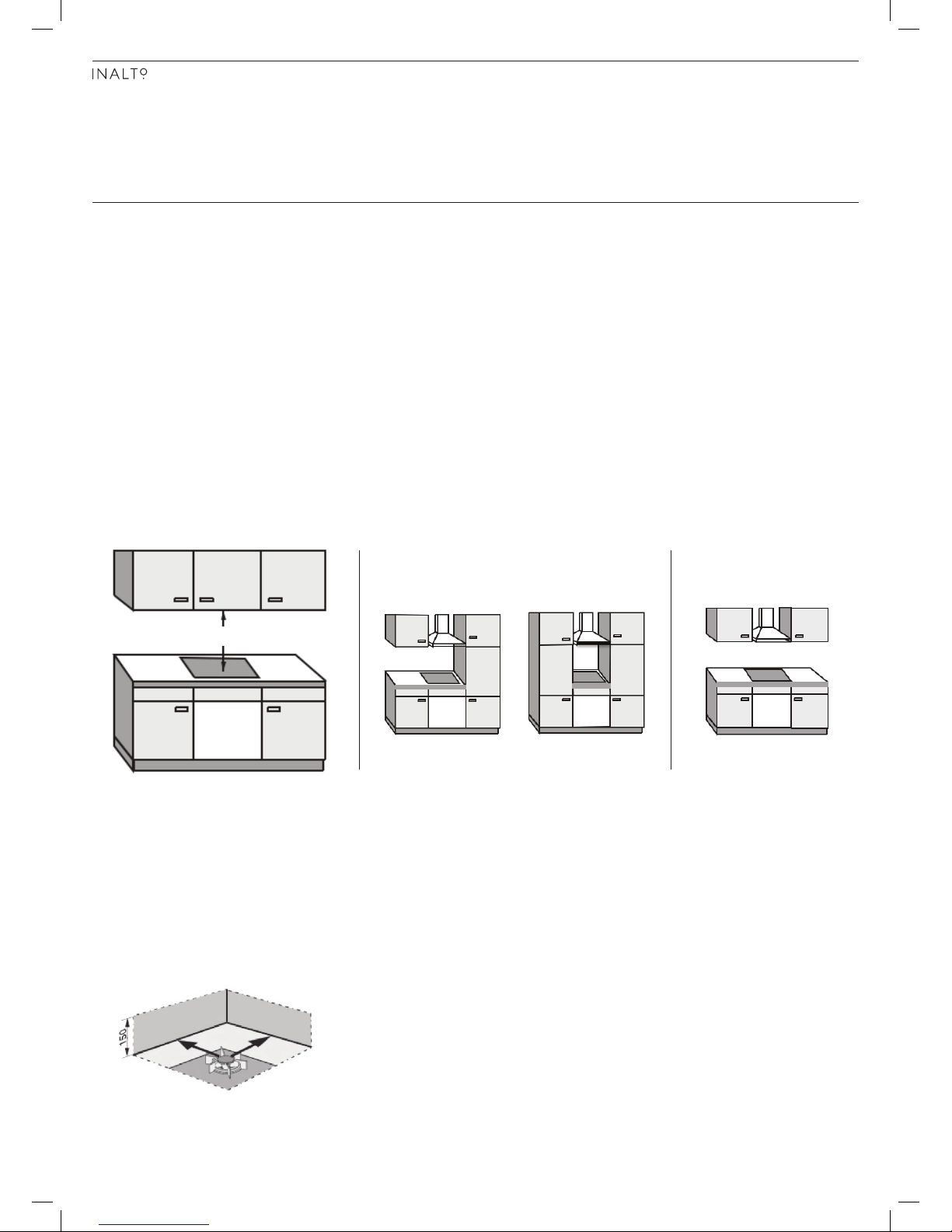

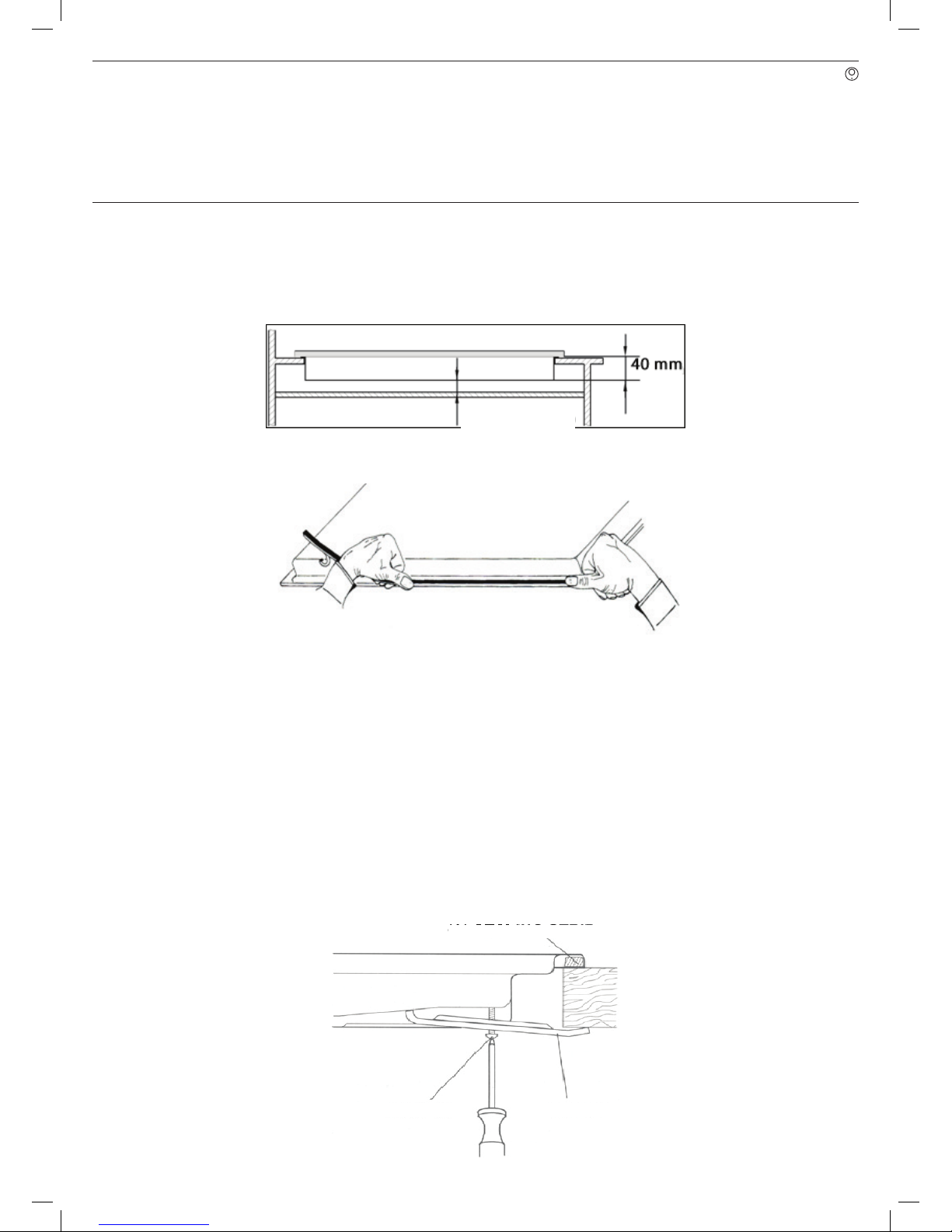

The appliance should only be installed and connected

by a suitably qualified and authorised person, strictly in

accordance with the manufacturer's instructions. Please

see the specific section of this user manual that refers to

installation.

IMPORTANT!

The gas supply to the cooktop must be cut off before any

adjustments or maintenance work is undertaken.

WARNING

When using this product, basic precautions should always

be taken including the following:

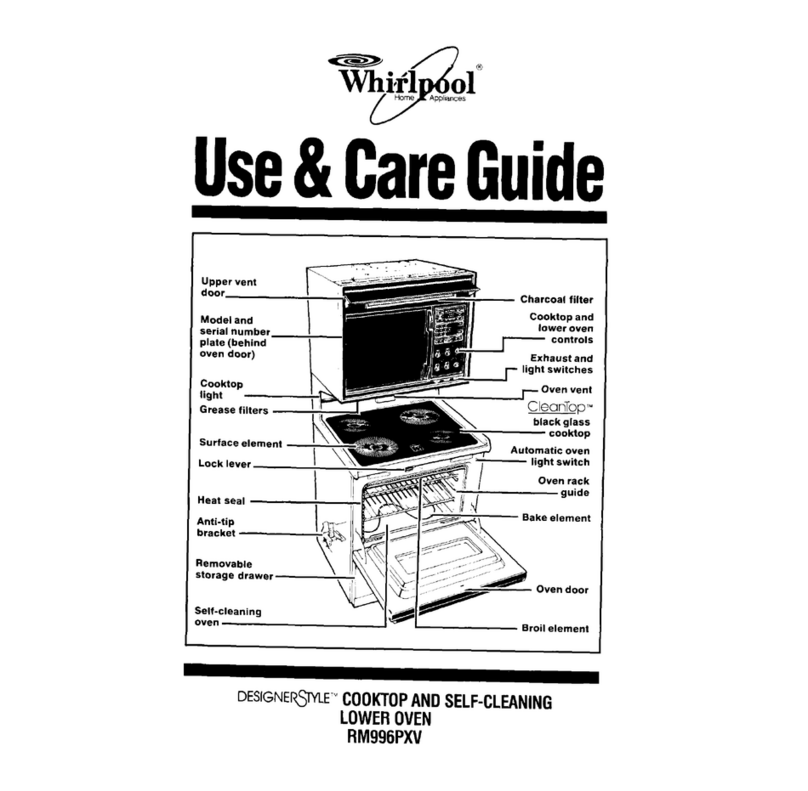

► The appliance is designed for domestic household use

and for the cooking and frying of domestic foodstuffs.

► Care should be taken to ensure that the units and work

surfaces that you build the appliance into, meet with

the relevant standards.

► Not for use in Marine craft, caravans or mobile homes.

IMPORTANT!

The adjacent furniture and all materials used in the

installation must be able to withstand a minimum

temperature of 65°C above the ambient temperature

of the room it is located in, whilst in use.

► Certain types of vinyl or laminate kitchen cabinetry

are particularly prone to heat damage or discolouration

at temperatures above the guidelines given.

► Any damage caused by the cooktop being installed in

contravention of this temperature limit, will be the

liability of the owner.

► Your new cooktop is guaranteed against electrical or

mechanical defects, subject to certain exclusions that

are noted in the Warranty Terms and Conditions (at the

rear of this user manual). The foregoing does not affect

your statutory rights.

► The use of this cooktop for any other purpose or in any

other environment, without the express agreement

of Residentia Group, will invalidate any warranty or

liability claim.

► You should not use this appliance to store items on or

as a work surface.

► No modifications to the appliance are permitted by

Residentia Group.

► You should not store or place flammable or highly

flammable liquids/materials on top of or near the

appliance. Items made from aluminium, plastic

or plastic film should also be kept away from the

appliance, as they may fuse to the surface.

► Repairs may only be carried out by authorised service

agents.

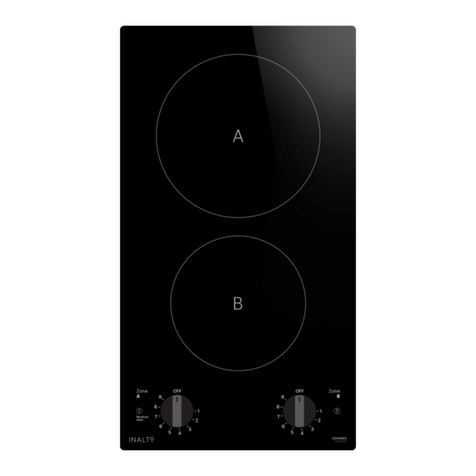

► Your Inalto cooktop is not to be used by children or

persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction.

► Any film or stickers that are present on the cooktop

when it is delivered should be removed before use.

► Care should be used when utilising the cooktop,

otherwise there is a risk of burns being caused.

► You should not allow the electrical connection cables to

come into contact with the cooktop surface when it is

hot or any hot cookware.

► If fat and oil overheats, then it can ignite extremely

quickly. For this reason, when cooking with fat and oil

the appliance should not be left unattended.

► Make sure that all of the cooking zones are switched off

after use.

► Cleaning of the cooktop should be carried out on a

regular basis, once the cooktop has cooled down.

► Great care should be taken whilst using this appliance

and when following the cleaning procedure.

► You should not use a steam jet or any other high

pressure cleaning equipment to clean the appliance.

SAFETY INSTRUCTIONS