Incite Fire Sigma CP AFP-2516 User manual

Man-AIM-AUS Issue 01 October 2011

Conventional Fire Control Panel AFP-2516

Australian Interface Module

Sigma_CP_Australian Interface Module.doc Page 2 of 9

Index

Section Page

1 Introduction ................................................................................................ 3

2 Safety and mounting .................................................................................... 4

2.1 Safety ..................................................................................................................... 4

2.2 Mounting ................................................................................................................. 4

3 Technical specification .................................................................................. 5

4 Connecting to the circuit board ...................................................................... 5

5 24V Input ...................................................................................................

Connection to main panel and other boards.....................................................

7 Operation ................................................................................................... 8

7.1 Normal condition ...................................................................................................... 8

7.2 ACF – Ancillary Control Facility .................................................................................. 8

7.2.1 Outputs.............................................................................................................................8

7.2.2 Configuration:..................................................................................................................8

7.2.3 Controls – only available at Access Level 2....................................................................8

7.3 Door older Output .................................................................................................. 8

7.4 ASE Outputs (Alarm Signalling Equipment) ................................................................. 9

7.5 Fuse fail .................................................................................................................. 9

7.6 COMMS ................................................................................................................... 9

7.7 Microprocessor Reset link .......................................................................................... 9

7.8 Module Address ........................................................................................................ 9

8 Power requirements ..................................................................................... 9

Sigma_CP_Australian Interface Module.doc Page 3 of 9

1Introduction

The Sigma CP Australian Interface Module is optional on the Sigma range of panels and can be

utilised to provide a means of connecting to an Ancillary Control Facility (ACF), magnetic door

holders, and Alarm Signalling Interface (ASE) from the control panel via a 2 core data bus.

The Australian Interface Module is compatible with all Sigma CP control panels.

Only one AIM is permitted on each control panel and has a fixed addressed at “o7”, output unit 7.

NOTE: The Australian Interface Module, if fitted, is fixed at address 7, and in this instance only 6

Ancillary boards can be fitted at addresses 1 to 6.

The total length of the data cable from the main panel must not exceed 1200 metres.

Australian Interface Module Overview

Sigma_CP_Australian Interface Module.doc Page 4 of 9

2Safety and mounting

2.1 Safety

Suppliers of articles for use at work are required to ensure as reasonably as is practical that the

article will be safe and without risk to health when properly used.

An article is not regarded as properly used if it is used ‘without regard to any relevant information

or advice’ relating to its use made available by the supplier.

This product should be installed, commissioned and maintained by trained service personnel in

accordance with the following:

(i) Local regulations for electrical equipment in buildings

(ii) Codes of practice

(iii) Statutory requirements

(iv) Any instructions specifically advised by the manufacturer

You are therefore requested to take such steps as are necessary to ensure that you make any

appropriate information about this product available to anyone concerned with its use.

This Ancillary board is designed for indoor use only and at temperatures between -50C and +400C

and with a maximum relative humidity of 95%.

The IP rating for the enclosure is IP30.

Operation outside of these limits may render the equipment unreliable and unsafe.

2.2 Mounting

If not fitted inside a Sigma CP panel, the board should be mounted in a suitable enclosure such

that it is protected from ingress of water, dust or foreign bodies.

It should be positioned in an accessible place as agreed with the end user.

Suitable fixings should be used at all fixing points such that the board and enclosure are securely

mounted and not liable to move once fixed.

The enclosure should not be mounted near sources of excessive heat.

Cables should be connected using suitable, metal, shielded cable glands. All swarf and debris

caused by drilling of additional cable entries must be cleared before power is applied.

Sigma_CP_Australian Interface Module.doc Page 5 of 9

3Technical specification

Table 1 – Electrical Specifications

Power supply 21 to 30 V DC Nominal 24V DC

Maximum ripple current 200 millivolts

Maximum current draw 0.25 Amps In full alarm

Mains failed current consumption 20 milliamps In standby mode

Zonal relay contact rating 30VDC 1A Amp maximum for each Maximum ratings not to be exceeded

Fault relay contact rating 30VDC 1A Amp maximum for each Maximum ratings not to be exceeded

Fire relay contact rating 30VDC 1A Amp maximum for each Maximum ratings not to be exceeded

Coincidence relay contact rating 30VDC 1A Amp maximum for each Maximum ratings not to be exceeded

Terminal capacity 0.5mm

2

to 2.5mm

2

solid or stranded wire

Cabling - power FP200 or equivalent Metal cable glands should be used

Cabling - communication RS485 data cable or FP200 Maximum total cable distance 1200

metres. Metal cable glands should be

used

Size 155 X 135 X 30 Millimetres

Fixing Four 4mm holes One in each corner of the board

4Connecting to the circuit board

All connections for field wiring are to rows of terminals along the top and bottom of the circuit

board.

Cabling must comply with the relevant Australian Standards. Shielded fire alarm cable for power

and RS485 data cable for comms and metal cable glands should be used for all connections to the

board. The resistance of any core of any cable must not exceed 25 ohms. The shields of the

cables should be bonded securely to the enclosure via metal glands.

Wiring should enter the enclosure and be formed tidily to the appropriate terminals which are

capable of accepting wires of up to 2.5mm2.

Wiring must not go across the front of the circuit board. If cable entries need to be in positions

other than at the knockouts provided, wiring must be fed well away from the surface of the circuit

board.

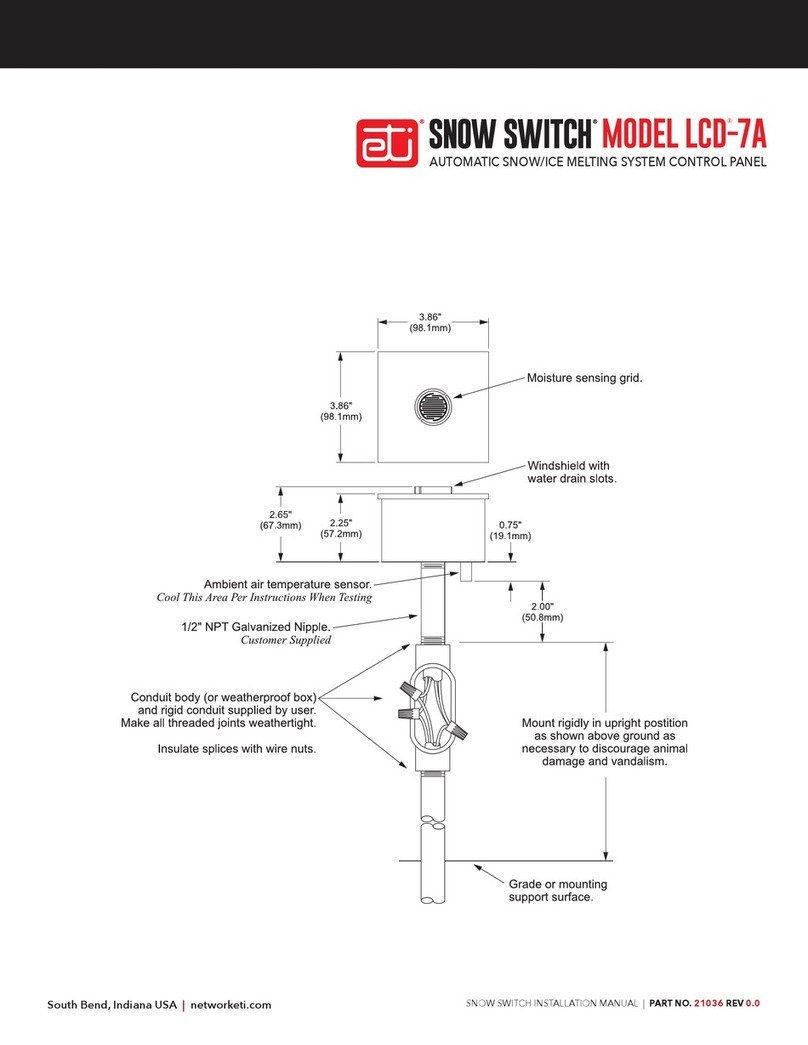

Figure 1- Wiring to the circuit board

CORRECT

INCORRECT INCORRECT

Sigma_CP_Australian Interface Module.doc Page 6 of 9

Figure 2-Power connection

524V Input

The Australian Interface Module requires a nominal

24V DC power supply to operate. This can be taken

from the AUX 24V output of the panel to which the

ancillary board is connected or another 24V DC source

if this is more convenient.

Four power terminals are provided so that 24V DC

wiring can be taken into the module and then out again

on to other ancillary boards or other equipment.

6Connection to main panel and other boards

If power is supplied locally to the Australian Interface Module board only two wires are required

from the main panel.

Wiring can be standard fire alarm cable or shielded data cable. The shield of the cable must be

securely bonded to the enclosure case at both ends, and must comply with the relevant Australian

Standards.

Sigma_CP_Australian Interface Module.doc Page 7 of 9

To terminate the data cable correctly,

the last board on the comms line must

have jumper J2 fitted as shown.

For the position of J2 on other panels or

boards refer to the relevant manual.

After the AIM has been connected to

the main panel, the main panel has to

“learn” that it exists. This is necessary

so that the main panel can announce a

fault condition if the AIM becomes

disconnected.

To “teach” the main panel that an AIM is

connected, ensure that all other boards

have the data cable connected with the

correct polarity. Check that all boards

are supplied with power and that the

green, OK LED is lit at each one.

Press the processor reset switch on the

main panel PCB. The main panel will

display the address of the first board it

finds on the seven segment LED display

such as.

o1

This indicates ancillary board 1 (o1). To accept this, the enter button on the main panel should be

pressed whereupon, if more boards are found, their addresses will be displayed and must be

accepted by pressing the enter button once again. This is repeated until all of the boards are

recognised by the main panel. The AIM is fixed at ancillary board address 7 and will appear on the

display as

o7

If any board becomes disconnected after it has been “learnt” by the main panel, the main panel will

display a comms fault and the number of the board will be shown on the seven segment LED

display.

The board/s that have become disconnected from the main panel will also display a comms fault

on their COMMS LED.

Figure 4-Comms terminating jumper on the AIM

Sigma_CP_Australian Interface Module.doc Page of 9

Operation

7.1 Normal condition

Under normal conditions, ancillary boards will have only the green, OK LED lit.

7.2 ACF – Ancillary Control Facility

7.2.1 Outputs

The ACF has a 24V DC monitored output suitable for operating a remote, polarised and suppressed

relay. Monitoring is via an end of line resistor. This output is designated ACF O/P +/-

A clean contact relay rated at 30VDC 1Amp follows the monitored output.

The ACF outputs are activated by a non-silenceable fire signal from the Sigma control panel

section. A red LED indicator is lit when the output is active.

A fault on the ACF outputs is signalled at the Sigma panels as a General fault and on the AIM as

ACF fault.

7.2.2 Configuration:

The ACF can be configured as latching by setting the LATCH dipswitch to the ON position.

The ACF can be configured as failsafe (Normally Energised) by setting the FAIL S. dipswitch

to the ON position.

7.2.3 Controls – only available at Access Level 2

When the ACF is set to “latching” the Reset switch on the AIM module, in order to reset the ACF,

firstly, the Alarm must be reset, and then the ACF can be reset using the ACF Reset switch on the

AIM module.

When the ACF is set to “non-latching”, the ACF output is deactivated when the alarm is reset or

disabled.

The Isolate switch on the AIM module allows the ACF output to be disabled and not operate on an

alarm condition. A yellow ACF Isolated LED indicates when the ACF is isolated, and signals a

General Disablement to the Sigma control panel section.

7.3 Door Holder Out ut

The door holder circuit allows magnetic fire doors to be automatically closed in the event of a fire,

thus limiting smoke and fire egress in an emergency situation.

Four terminals are provided:

D 24V In A 24V supply to power the magnetic door holders.

Door olders The 24V from the “D 24V In” circuit appears at this output under

“Normal” condition. When an alarm occurs, power is disconnected from the “Door older” output.

The maximum output of the Door older circuit must be less than 1A.

The status of the door holder output follows that of the ACF output as described in section 7.1 and

is isolated via the ACF Isolate facility. The only exception is when the DOOR D. dipswitch is ON,

the Door older Output activates after a 30 seconds delay.

Sigma_CP_Australian Interface Module.doc Page 9 of 9

7.4 ASE Out uts (Alarm Signalling Equi ment)

Volt free relay outputs, rated at 30VDC 1Amp, are provided to facilitate connection of the Sigma

fire panel to a variety of ASE depending on the installation. These contacts are rated for switching

signalling circuits only and the maximum ratings listed in Error! Reference source not found. on

page 5 should not be exceeded under any circumstances. It is the responsibility of the installer to

ensure that the ASE being installed is compatible with the local fire station to which it is being

connected.

ALARM normally de-energised, activates on a non-disabled Alarm

FAULT normally de-energised, activates on a non-disabled Fault

ISOLATED normally de-energised, activates on a non-disabled Disable

POWER FLT normally energised, de-activates when there is an abnormality with the power

supply.

COINC. normally de-energised, activates on multiple alarms. This output will activate when

an alarm occurs any of the zones specified as being coincident zones. See options

51 to 58 in Sigma CP Fire Control Manual.

ENABLE normally de-energised, activates when the fire panel enters the Level 2 state.

ACF O/P this output follows the state of the ACF monitored output.

If voltages or currents exceeding those in Table 1 on Page 5 need to be switched then a suitable

relay or contactor device should be interposed between the ancillary board and the system to be

controlled.

7.5 Fuse fail

The AIM is fitted with a 1 Amp rated, self-resetting electronic fuse. This fuse protects the

electronics of the AIM and prevents any excessive loading of the power supply that is powering it.

If this fuse operates, the yellow Fuse LED will light.

7.6 COMMS

If the AIM loses communication with the control panel to which it is connected, the COMMS LED

will light.

7.7 Micro rocessor Reset link

Once started, the microprocessor controlling the panel should continue to run the AIM continuously

without interruption. If the microprocessor fails to run correctly it can be reset by momentarily

shorting J3 on the rear of the PCB.

This should not normally be necessary but should be done as a matter of course if the system is

behaving abnormally. The system should resume normal operation within a couple of seconds.

7.8 Module Address

NOTE: The AIM is fixed at ancillary board address 7 and in this instance only 6 Ancillary boards

can be fitted at addresses 1 to 6.

8Power requirements

The AIM requires a 24V DC power supply which connects to the terminal block labelled 24V DC.

The power supply should be capable of supplying a minimum of 250 milliamps to cater for a fully

loaded board with all outputs activated.

Sigma_CP_Australian Interface Module.doc Page 10 of 10

When supplied from the Sigma CP panel extra battery capacity of 0.6Ah should be allowed to give

24 Hour standby.

Table of contents

Other Incite Fire Control Panel manuals