Indeeco 781 SERIES Assembly instructions

INSTALLATION, OPERATING &

MAINTENANCE INSTRUCTIONS FOR

781 SERIES STORAGE TANK HEATERS

GENERAL

INDEECO Storage Tank Heaters are designed to provide

years of trouble free operation if properly installed and

maintained. Please read and follow these instructions for

installing and maintaining the heater.

1

Storage Tank Heaters provide an effective way to heat large

storage tanks. The heating element design allows removal

and servicing of the heating element without draining the

tank.

HEATING ELEMENT CONSTRUCTION

The heating elements are open coil design and consist of

heavy gauge nickel-chromium alloy supported by ceramic

insulators. The ceramic insulators are fastened to a strip of

heavy sheet metal.

PIPE ASSEMBLY CONSTRUCTION

The heating elements are installed in 3” NPS pipes of

sufficient wall thickness to prevent the pipe from distorting

from the heat generated. The pipes are constructed so that

the heating elements may be removed without draining the

tank. Multiple pipes are provided as required. The heater is

mounted to the tank by one of three methods: ANSI flange

mount, INDEECO adapter box, or with a custom rectangular

flange.

A built-on terminal box is provided with pre-wired controls for

proper heater operation. When requested, controls may be

remote mounted. Refer to IOM 87-2000-83 for remote

Industrial Control Panels.

The heater watt density and design features must be closely

matched to the application. Life of the heating element is

directly related to its surface temperature.

Temperature regulating devices, temperature limiting

controls, and low liquid level controls are recommended for

use with Storage Tank Heaters, to control the heating

process and safeguard the heater from excessive

temperatures that can cause damage. Also, damage to fluid

could occur if the heater is allowed to exceed the maximum

film temperature recommended by the manufacturer.

INDEECO Storage Tank Heaters can be specially designed

for use in hazardous areas as specified in Article 500 through

516 of the National Electrical Code. Refer to the heater

nameplate or INDEECO Application Data for classification of

the heater provided. See section below labeled Hazardous

Areas for specific requirements.

It is the ultimate responsibility of the user to verify that

the construction materials provided by INDEECO are

suitable for use with the process fluid. Specifically,

corrosion issues must be reviewed. Refer to INDEECO

Application Data for heater construction materials and

design conditions.

For additional product offerings, refer to INDEECO catalog

literature on Process Heating such as Circulation Heaters,

Immersion Heaters, or Tubular Heating Elements.

INSTALLATION

Handling and Storage

Care must be taken to avoid damage to the heater during

storage and handling. The Pipe Insert Heater elements are

constructed of ceramics that can be damaged if not handled

carefully.

Protect the heater from weather damage during storage.

CAUTION

Failure to follow INDEECO recommendations could

result in premature failure and/or serious equipment

damage.

CAUTION

INDEECO recommends installation be performed by

qualified personnel familiar with the National Electrical

Code and all local codes and standards. It is the

responsibility of the installer to verify the safety and

suitability of the installation

WARNING

DO NOT mount heaters in an atmosphere containing

combustible gases, vapors, dusts, or fibers unless properly

marked as suitable for the condition. Refer to section

below for special instructions for Hazardous Areas.

It is recommended to store the heater in a cool dry area to

help prevent the heating element ceramic spacers from

drawing moisture.

WARNING

Hazardous voltages are present in this equipment. Lock

out and tag the branch circuit disconnect switch before

working on this heater.

Mechanical Instructions

Site Selection

Review the NEMA Type rating of the heater noted on the

INDEECO Application Data. Do not install a heater in an

area not consistent with its rating. The standard configuration

provided is NEMA Type 4, intended for outdoor use.

Allow sufficient free space around heater installation site.

Work space for heater maintenance should be at least three

feet in front and on either side of the heater. The minimum

pull space for the heating element installation or removal from

the pipe/tube should be at least four feet. The heating

element is designed to be flexible and can be curved if

necessary.

Leave a minimum of 6” clearance to any SCR heat sinks

mounted through the side of panels to allow proper cooling.

2

Electric heaters are capable of developing high temperatures.

Therefore, extreme care should be taken to

avoid mounting heaters in an atmosphere containing

combustible gases, vapors, dusts, or fibers unless properly

marked as suitable for the condition.

Heater Orientation

This style of heater is intended for horizontal use only. The

open coil resistance wire must not be mounted in a vertical

orientation or failure could occur from the coil sagging.

The heater must be mounted plumb horizontally to assure

proper operation.

Thermal expansion of the heater pipes must be considered

when locating the heater. It can be approximated as:

Pipe

Length

(Inches) x .00001 x Max Pipe

Operating

Temp (°F) - 70°F

If the heater is installed in a pressurized tank, a relief valve

must be installed. As a minimum, the valve must be sized to

relieve at a rate equal to the rate that the heater can thermally

expand fluid in the tank.

Pipe Assembly Installation

On assemblies provided with ANSI flanged connections, take

care to prevent scratching the flange faces. INDEECO

supplies a non-asbestos nitrile bonded fiber flange gasket

unless otherwise requested. The user must confirm that the

gasket is suitable for the application. The user must supply

high strength studs or bolts and nuts, such as A-193 GR. B7

and A194 GR. 2H, rated for the design conditions. Bolts must

be properly installed and tightened to prevent leaks.

When an adapter box is provided, the assembly is welded

directly to the user’s tank wall. A rectangular cutout is

required; not to exceed the adapter box dimensions plus ¼”.

Heater pipes must be supported inside the user’s tank.

Supports must not prevent the pipes from thermally

expanding. Supports should be located on a maximum

spacing of 10 feet.

Where buildup of solids in the bottom of the tank is expected,

the pipes must be located above that level. The pipes must

also be located below the minimum operating fluid level of the

tank.

Heater pipes must be perfectly clean before installation of

heating element. Use only a clean dry cloth to clean. Never

use a lubricant. Compressed air with a long wand may be

used to remove ceramic chips, etc.

Insulation

WARNING

Surfaces of the heater pipes extending beyond the

user’s vessel may be extremely hot. Avoid contact to

p

revent

p

ersonnel in

j

ur

y

or fire.

The customer may prefer to insulate the flange or adapter

box at the tank for personnel safety and energy conservation.

WARNING

Do not insulate the terminal enclosure or the first 2” of

the pipe. Dangerous over-heating of the terminal box

wirin

g

could result.

The heating elements are provided with a “cold section”

where stainless steel bussing is used to connect to the

heating coils. This area must be packed with insulation to

prevent over-temperature of the terminal enclosure.

Insulation was factory installed before shipment.

Electrical Instructions

The potentially high operating and ambient temperatures of

Storage Tank Heaters require field wiring to the heater be

carefully matched to the application, to avoid serious injury or

damage to the equipment. The wiring must be de-rated for

the expected terminal box temperature. Terminal box

temperatures are typically below 120oF. Lower temperatures

can be expected for heaters used in cold climates for freeze

protection. If the cold section of the heater is properly

insulated, 90oC minimum wire may typically be used. Refer

to the National Electrical Code.

The size and type of incoming field wiring will depend upon

the heater terminal box temperature, heater current draw per

conductor, number of conductors per conduit, and wire

insulation rating. Field supplied conductors must be sized for

at least 125% of the circuit current.

To calculate the circuit current (in amps):

KW x 1000Single phase

Line current Line Voltage

KW x 1000KW x 1000Three phaseThree phase

Line currentLine current 1.732 x Line Voltage1.732 x Line Voltage

3

For wiring recommendations refer to the wiring diagram. An

additional copy is provided inside the heater terminal box.

For wiring recommendations refer to the wiring diagram. An

additional copy is provided inside the heater terminal box.

WARNING

Retighten all electrical connections that may have

loosened during shipment. Failure to do so may result

in damage to the heater or risk of fire.

Wiring to the heater should be permanently installed in

metallic or non-metallic electrical grade conduit in accordance

with all applicable electrical codes, and should include a

grounding conductor if non-metallic conduit is used.

Wiring to the heater should be permanently installed in

metallic or non-metallic electrical grade conduit in accordance

with all applicable electrical codes, and should include a

grounding conductor if non-metallic conduit is used.

Confirm all unused conduit holes in the terminal box are

sealed with plugs suitable for the heater environment.

Confirm all unused conduit holes in the terminal box are

sealed with plugs suitable for the heater environment.

Attach a ground conductor to the mounting screw for the

heater in the terminal box, or by other appropriate means, per

NEC Article 250.

Attach a ground conductor to the mounting screw for the

heater in the terminal box, or by other appropriate means, per

NEC Article 250.

Field supply wiring must be rated for 600Vac. Use copper

conductors.

Field supply wiring must be rated for 600Vac. Use copper

conductors.

Be sure the terminal box cover is properly installed at all

times to ensure personnel protection. Also, contaminants can

create leakage, (shock) hazards, permanent heater damage

or failure and should be avoided.

Be sure the terminal box cover is properly installed at all

times to ensure personnel protection. Also, contaminants can

create leakage, (shock) hazards, permanent heater damage

or failure and should be avoided.

The electrical installation should include a service disconnect

switch in sight of the heater, as well as branch circuit over-

current protection and over-temperature protection, if not

provided with the heater.

The electrical installation should include a service disconnect

switch in sight of the heater, as well as branch circuit over-

current protection and over-temperature protection, if not

provided with the heater.

It is recommended to perform an insulation resistance test

prior to energizing the equipment. If the value is less than 1

Meg Ohm using a 500Vdc or similar tester, refer to

Maintenance and Troubleshooting sections.

It is recommended to perform an insulation resistance test

prior to energizing the equipment. If the value is less than 1

Meg Ohm using a 500Vdc or similar tester, refer to

Maintenance and Troubleshooting sections.

Where thermocouple extension wire is required between the

heater and remote controls, verify it is connected with proper

polarity, as shown on the wiring diagram. Failure to do so

may result in an uncontrolled heater. Refer to the wiring

diagram for the required wire type. Shielded wire is

recommended to reduce signal interference.

Where thermocouple extension wire is required between the

heater and remote controls, verify it is connected with proper

polarity, as shown on the wiring diagram. Failure to do so

may result in an uncontrolled heater. Refer to the wiring

diagram for the required wire type. Shielded wire is

recommended to reduce signal interference.

OPERATIONOPERATION

Cautions and SetupCautions and Setup Pipe

Material Maximum

Pipe Temperature

Steel 750°F

Stainless Steel 304 1400°F

CAUTION

Equipment should be operated by qualified personnel

only to prevent equipment damage or failure.

Ensure power ahead of the panel is off and perform the

following steps:

WARNING

DO NOT TURN ON HEATING ELEMENTS UNTIL

TANK IS COMPLETELY FULL OF FLUID.

Permanent damage may result if elements are

energized and the heater is not completely

submerged.

1. Exercise all switches, circuit breakers and operating

mechanisms to confirm they operate freely.

2. Conduct an insulation resistance to ensure the system is

free from short circuits or grounds.

INDEECO recommends that all safety interlocks be tested

during initial startup to ensure they properly disable the

heater. After 10 days of operation, retighten all electrical

connections.

Carefully review all instructions and become familiar with the

equipment, safety interlocks, and process temperature

controller provided before energizing the equipment.

For solid state non-indicating controllers, it is recommended

to dial the high limit controller set-point down to a point below

normal operating temperature, either during initial startup

operation or with only the control circuit on, and verify that the

contactors open, disconnecting heater power. Return the

controller to the desired setpoint.

DO NOT operate heaters at voltages in excess of that

marked on the heater. Excess voltage can shorten heater life

or overload the branch circuit wiring.

DO NOT operate heaters unless properly filled with liquid.

DO NOT leave heating systems operating unattended unless

a closed-loop process controller and over-temperature safety

equipment have been completely validated.

PID controlled systems must be auto-tuned after initial

installation to optimize control accuracy.

Refer to information noted below on Control Methods.

DO NOT operate heaters at pipe temperatures higher than

the recommended maximum. Excess temperatures can

cause premature failure. Generally, pipe materials are limited

to the following maximum temperatures.

During initial heating, it is recommended to slowly ramp up

the process setpoint and inspect the heating system for

problems such as excess pressure buildup, or binding of

equipment due to thermal expansion.

Initial Operation

Turn the Control Circuit Switch to the OFF position.

Turn on power ahead of the panel and close main disconnect

switch.

If a digital indicating process controller is included with the

panel, place the controller in the “Standby” mode and adjust

the process setpoint to ambient. Refer to manufacturer’s

instructions for controller setup. When process control is

from a remote DCS system or controller, disable the

controller output signal or reduce the setpoint to ambient.

Review the setup of the process controller. INDEECO

factory-configures the controller inputs and outputs unless a

special controller is specified by the user.

Place the process controller in the “Standby” mode any time

that the control circuit switch will be in the OFF position

longer than a few seconds. This is important to prevent the

process controller from driving to 100% output when the

control circuit switch is returned to the ON position.

Turn the Control Circuit Switch to the ON position.

Inspect for alarm pilot lights. Push any red illuminated reset

pilot lights to attempt resetting. All alarm lights should be

reset.

Remove the controller from the Standby Mode.

Increase the process setpoint 10 or 20 degrees and confirm

operation without alarms.

Once all alarm conditions are cleared, follow instructions in

process controller manual for auto-tuning (not applicable for

ON-OFF control), and refer to information noted below on

Heater Control Methods for tuning.

Note that auto-tuning must be initiated while the temperature

of the process fluid is below the normal operating

temperature.

Gradually increase the control setpoint and observe the

system for proper operation.

Adjust high limit temperature controllers by setting as close to

the operating conditions as possible without nuisance

tripping.

After any alarm condition, the system should be investigated

and the problem remedied. Do not operate the equipment

with safety devices disabled or serious damage to the system

may result.

On flange mounted heaters, re-tighten flange bolts after the

heater has completed one or two heating cycles.

Shut Down

The heating system may be shut down by reducing the

process setpoint to ambient.

Turn the control circuit switch to OFF. Turn off main power

disconnect switch.

Normal Operation

Turn on disconnect switch.

Adjust process controller to the desired setpoint.

Turn control circuit switch to ON.

Note: be sure to use the Standby mode if the above steps

can not be accomplished quickly.

CONTROL METHODS

Heater Control Methods

Many factors affect the setpoint tolerance and control of

heating systems. Control method, heat load fluctuations,

sensor location, controller tuning, and fluid thermal properties

are significant factors that impact process control.

Control methods for electric heaters can either be:

1. ON / OFF

2. Proportional, Integral, and Derivative (PID).

ON/OFF Systems

On/off systems utilize a process similar to a thermostat that

operates a home furnace. A typical heater control circuit is

provided with digital indicating process controller which

accepts a thermocouple input from the process. The

controller is configured to a SSR output to pull power

contactors in and out to cycle the load.

The process controller must be configured to limit the cycle

rate to avoid quickly wearing out the power contactors.

Contactors are typically rated for 100,000 cycles of operation.

Two methods can be used: “Hysteresis” or “Cycle Time”.

Hysteresis defines a temperature range around the setpoint

where the process controller will not change the state of the

power contactor. A hysteresis value of 5oF would define the

“error” or tolerance from setpoint that the user can accept.

This is sometimes referred to as deadband.

Cycle Time is a method to define the minimum time that the

controller must wait between de-energizing and re-energizing

the power contactor. A Cycle Time of 3-5 minutes on

equipment operating continuously would wear out power

contactors in about 2 years. If the Cycle Time is set for 3

minutes, but the temperature has not yet dropped below the

setpoint, the heater will not come on until the temperature

drops low enough.

4

5

PID Control

PID control utilizes Proportional, Integral, and Derivative

control methods to scale the output from a process controller

(typically 4-20mA) to an SCR Power Controller or Electronic

Multi-Stage Sequencer. Note that reverse acting signals are

used with heating systems where the heater is OFF at 4mA

and fully on at 20mA.

SCR Power Controllers employ heavy duty SCR switching

modules to switch the power. The SCR uses a fixed time

base of typically 4 seconds. Within every 4 second time

base, the SCR closes to energize the heater for a time frame

proportional to the control signal. A 50% signal, or 12mA,

would mean the heater is on for 2 and off for 2 seconds every

4 seconds. The result of cycling the heater frequently, but

proportional with the load requirement, is more accurate

temperature control.

An Electronic Multi-Stage Sequencer, or Step Controller,

accepts the scaled control signal output from a PID Controller

and pulls contactors in and out as required. This method is

similar to ON/OFF control with multiple stages. The

sequencer has an adjustable Cycle Time similar to that used

for ON/OFF process controllers. The default used on

sequencers is a 40 second delay between stages. This

method is effective on high amperage units because the

multiple stages help split the load into manageable circuits.

For further details about PID control, refer to the process

controller instruction manual.

Factors Impacting System Control

Many factors affect the setpoint tolerance and control of

heating systems. Control Method (noted above), Heat Load

Fluctuations, Sensor Location & Thermal Lag, Controller

Tuning, and Fluid Properties are all significant factors.

Heat Load Fluctuation, or changes in the process, can

cause wide temperature fluctuations. Some typical changes

to a heating process loop are:

1. Addition of fluid at a temperature below the process

temperature.

2. Opening or closing tank access covers.

3. Starting or stopping fluid agitators.

4. Ambient temperature changes.

5. Fluid flow rate changes.

6. Insulation thickness.

7. Power available can be affected due to user voltage

fluctuations.

Process Sensor Location / Lag in the tank or piping can

impact temperature control. For flowing systems, the sensor

must be in the flow stream down-stream from the heater. For

stagnant systems, If the sensor is located close to or on the

heater, the controls may short-cycle before the tank is up to

temperature. Locating the sensor away from the heater will

cause a temperature lag and allow fluid temperatures close to

the heater to exceed desired temperatures. Thermal Lag is a

term relating to process control. Lag is typically a slow

reaction by the process sensor to a change in the operating

temperature. This is often caused by thermowells. The mass

of the thermowell requires heat-up time or “time lag” before

the sensor can detect that the operating temperature has

reached the setpoint, thus causing overshoot of the setpoint.

The PID controller must be tuned down to minimize this

impact, which has the result of less accurate temperature

control.

Controller Tuning is necessary on systems with SCR’s or

Sequencers and PID control. Tuning allows the proportional,

integral, and derivative values to be set based on the actual

process conditions. Process controllers are provided with an

auto-tuning feature that measures the thermal

responsiveness of the heating system. During auto-tuning,

the process controller drives the system to heat up, hold, heat

up, and finally, hold. If an alarm condition is encountered

during auto-tuning such as a high limit alarm, the cause of the

alarm must be remedied and the auto-tune must be repeated.

Tuning may need to be repeated after any change in the

process which affects the thermal responsiveness of the

system such as the heat load, flow rate, or fluid properties.

Systems which are unsteady may require manual tuning.

Refer to the process controller manual for instructions.

Fluid Thermal Properties can greatly impact temperature

control. Fluids such as water, with high thermal conductivity,

are easy to heat without experiencing large temperature

gradients. Fluids such as wax or tar pitch have such low

thermal conductivity that heaters must be designed with a

much lower sheath watt density than with most fluids.

Temperature gradients can be significantly reduced in tanks

by using an agitator. Solids buildup on the heaters can also

reduce the heat transfer.

To obtain optimum control, the use of PID control, properly

tuned for the application, is recommended.

MAINTENANCE

6

Periodically check all electrical connections, including field

and factory-made connections for tightness, and all wiring for

deterioration at least once a year.

Periodically inspect for leakage and retighten flange bolts

when required.

Inspect the terminal enclosure and conduit connections for

evidence of water leaks or moisture collection. Tighten

connections as required. Do not continue using a heater with

signs of damage.

Heating Element Installation & Removal

Remove electrical terminal connections after noting how they

are connected. Remove insulation blanket in the bottom

section of the terminal box to provide access to the heating

elements.

To remove the heating element from a heater pipe, first

remove the fastening nut at the terminal end. Hold the

ceramic insulator firmly in order to avoid undue pressure on

the ceramic and possible breakage. If obstructions are

encountered, rotate the heater slightly back and forth while

pulling out.

Since heating elements can be of considerable length, it may

not always be possible to remove the element in a straight

line, due to space limitations. Since the element bar is

flexible, the element may be curved on a radius of 4 feet

minimum. It is recommended that at least 2 people be used

for this procedure, in order to avoid breaking the ceramics.

After the element bar has been removed, it should be

carefully stretched out on a clean table for inspection. Broken

ceramics must be replaced and burn spots should be cleaned

with a dry clean paper or cloth towel. Oil or other

contamination on the heater will cause a failure.

When installing the heating element into the heater pipe,

reverse the steps noted above.

Heater pipes must be perfectly clean before installation of

element. Use only a clean dry cloth to clean. Never use a

lubricant. Compressed air with a long wand may be used to

remove ceramic chips, etc.

CAUTION

Troubleshooting and repairs should only be attempted

by qualified maintenance personnel.

CAUTION -Hazard of Electric Shock

Heaters must be bolted into position at the terminal

end to prevent movement, which could allow the

heater to short out against the pipe.

See figures attached for mounting configurations.

WARNING

Hazardous voltages are present in this equipment.

Lock out and tag the branch circuit disconnect switch

before working on this heater.

The heating element is only intended to be installed with the

sheet metal strip on the bottom. Do not rotate the heater in

the pipe.

Thermal insulation must be installed between the first few

ceramics in the “cold” section of the heater where the

resistance wire is not coiled. A loose fill cerafiber (INDEECO

P/N 1008466) or equal, rated for 2000°F, is preferred. The

insulation must be free of moisture or contamination in order

to provide electrical isolation. The insulation is necessary to

allow 90°C rated field wiring.

Caution, INDEECO recommends replacing the entire pipe

insert assembly under most conditions. The condition of the

ceramics must be considered before attempting to replace

coils. Field replaced heating coils must be installed properly

or failure may occur.

If field-replacing one or more heating coils, mechanical

connections at the end ceramics need to be removed.

Remove the burned out coil from both ends by pulling lightly,

and at the same time turning the coil back and forth. Check

the ceramics near the area where the burnout occurred.

Broken ceramics must be replaced, and burn spots should be

cleaned with a dry clean paper or cloth towel. Oil or other

contamination on the heater will cause a failure.

The new coil should be stretched to the correct length (do not

over stretch), and then inserted from the far end by lightly

pushing with a constant back and forth turning motion. After

the coil is in place, the loop at the end of the coil should be

guided over the bolt on the end ceramic and then tightened in

place with the previously removed unit.

Re-install the heating element in the pipe by reversing the

instructions above.

Use care when making connections to the heating element to

avoid breaking the end ceramic.

Where the heater is installed in cold climates, consider safety

precautions to prevent damage due to freezing fluid when the

heater is not in service.

TROUBLESHOOTING

7

The nature of the ceramic insulators used to electrically

isolate and support the nickel chromium resistance wire in

the heating elements is such that over a long period of

storage, they will absorb considerable moisture from the

atmosphere unless the pipe and conduits are sealed. It is

recommended to perform an insulation resistance test prior

to energizing the equipment. If the value is less than 1 Meg

Ohm using a 500Vdc or similar tester, care must be taken to

dry out the heater to prevent failure. It is recommended that

the elements be turned on at a reduced voltage at first, to

boil off the moisture. Meg Ohm readings may drop initially

after a few minutes of operation, indicating moisture being

forced out of the elements. The terminal enclosure lid

should be left open during this period to allow the moisture

to escape.

If the heater has a manual-reset high limit thermostat, be

sure that the reset button is pressed in.

If reduced heat output is suspected, verify the condition of

the heating elements by using an ammeter to check the

current draw of each input line. All input lines should draw

approximately equal current, which should agree with

nameplate rating. If they do not, one or more of the heating

elements could be damaged.

HAZARDOUS AREAS

(where applicable)

CAUTION

Troubleshooting and repair should only be

attempted by qualified maintenance personnel.

Per article 500-516 of the National Electrical Code, a

hazardous area is defined by a “Class”, “Division”, “Group”,

and “Temperature Code”. The Class can be I or II, where

Class I indicates that the hazard classification is due to the

presence of an explosive vapor. Class II indicates an

explosive dust. The division can be either 1 or 2. Division 1

indicates a hazard is ALWAYS considered to be present.

Division 2 means the hazard is only present under abnormal

conditions. The Group defines the explosiveness of the

hazard. The Temperature Code specifies the temperature at

which a hazard will ignite.

INDEECO can provide designs suitable for all of the above

conditions, but a heater should never be placed in an

environment not noted on the heater nameplate.

NEVER operate the heater in an atmosphere with an ignition

code temperature LOWER THAN the nameplate rating. The

user must determine the actual area classification.

Special design considerations for electric heaters used in

hazardous locations:

1. Locate all electrical connections in an appropriate

enclosure.

2. Prevent surface temperatures of the heater from

exceeding the design ignition temperature.

INDEECO Storage Tank Heaters designed for hazardous

locations are typically provided with a purged terminal

enclosure.

WARNING – Explosion Hazard

INDEECO strongly recommends installation be performed

by qualified personnel familiar with the National Electrical

Code and all local codes and standards regarding

explosion-proof equipment. It is the responsibility of the

installer to verify the safety and suitability of the

installation.

When the design temperature of the process exceeds the

rated ignition temperature, it is critical that the heater and all

customer piping is properly insulated.

A hazardous area heater must be powered and controlled by

a heater control panel designed to provide necessary over-

temperature safety interlocks. Contact INDEECO if

assistance is required to properly control and protect the

heater.

Never apply power to a heater in a hazardous atmosphere

unless all terminal box covers are properly installed with all

cover bolts.

All conduits entering the heater terminal box must be sealed

within 18” of the heater using an explosion-proof conduit seal.

Any unused openings must be properly sealed with a steel

pipe plug. Follow the NEC for specific conduit requirements

such as the requirement for Rigid Conduit.

To ensure proper flamepath, all threaded conduits must use

rated fittings and be tight, with a minimum of 5 good threads

engaged. Any machined metal-to-metal surfaces on terminal

boxes must be handled carefully to prevent scratches which

may void the explosion-proof rating.

WARNING - Risk of Explosion

Operating the heater at a voltage higher than the

nameplate value may result in elevated

temperatures and amperage above the design

ratings.

Proper grounding of equipment in hazardous areas is critical

to eliminate potential sources of sparking.

Replacement of electrical components should only be done

by authorized personnel familiar with the requirements of

maintaining electrical equipment in an explosion-hazard area.

INDEECO

425 Hanley Industrial Court

St. Louis, MO 63144

Phone: (314) 644-4300 Fax: (314) 644-5332

www.indeeco.com 78-2200-83-1

8

Table of contents

Other Indeeco Heater manuals

Indeeco

Indeeco 908X Series Guide

Indeeco

Indeeco ZCA Series Assembly instructions

Indeeco

Indeeco UCI Series Manual

Indeeco

Indeeco INVIZATHERM STS-U12-0871B User manual

Indeeco

Indeeco process Assembly instructions

Indeeco

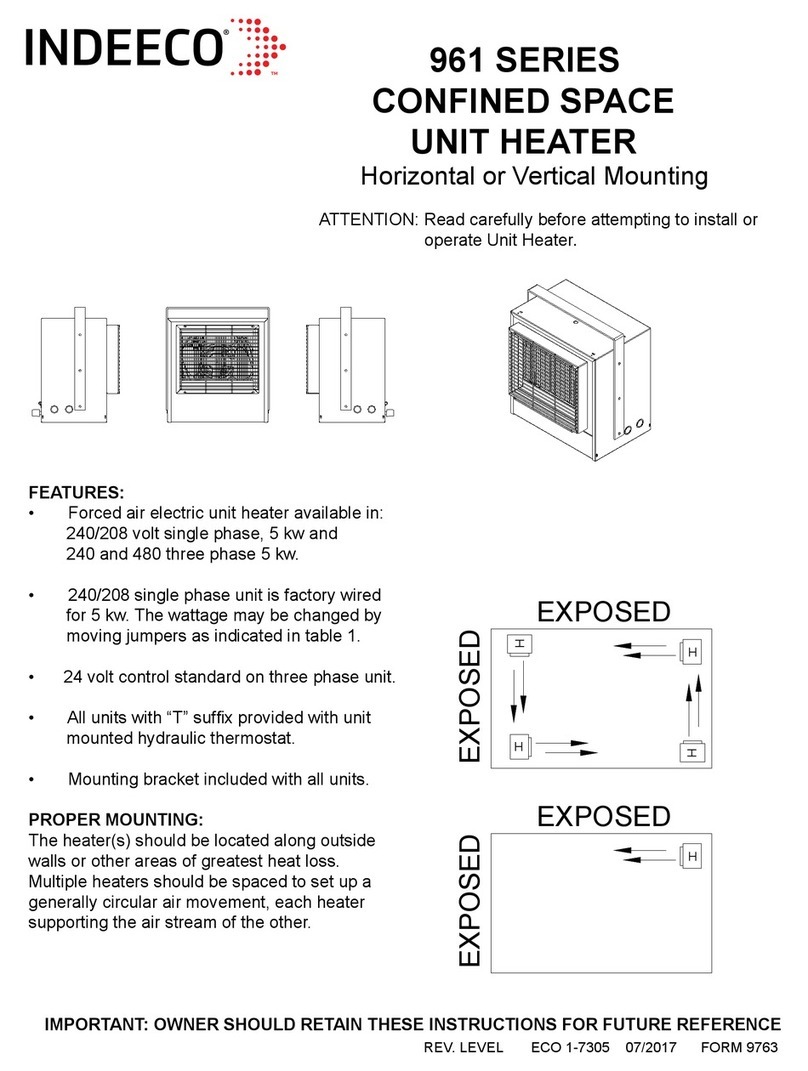

Indeeco 961 Series User manual

Indeeco

Indeeco 907 Series Installation instructions manual

Indeeco

Indeeco IUH Series User manual

Indeeco

Indeeco Invizatherm Thin Series User manual

Indeeco

Indeeco 931 F Series User manual