Industrial Rivet & Fastener Co. RK-9000M User manual

OPERATIONSMANUAL

FORTHEPNEUMATIC‐HYDRAULICRIVETINGTOOL

RK‐9000M

N‐8340000001132

(version2016)

TABLEOFCONTENTS:

1.GENERALSAFETYINSTRUCTIONSANDPRINCIPLES ........................................................3

2.DESCRIPTIONOFTHETOOL......................................................................................................4

2.1.Basicdimensions...............................................................................................................4

2.2.Technicaldata...................................................................................................................4

2.3.Rangeofusage..................................................................................................................5

2.4.Tooloperation...................................................................................................................5

3.TOOLMAINTENANCE...............................................................................................................7

3.1.Dailymaintenance.............................................................................................................7

3.2.Weeklymaintenance.........................................................................................................7

3.3.Generalmaintenance........................................................................................................9

4.SPAREPARTS...........................................................................................................................9

4.1.Ordering............................................................................................................................9

4.2.Listofquicklyexpendableparts.......................................................................................1 0

5.STORAGE...............................................................................................................................10

6.COMPLETETOOLEQUIPMENT...............................................................................................10

7.OPERATIONSANDWARRANTYCONDITIONS.........................................................................10

7.1.Operationconditions.......................................................................................................11

7.2.Warrantycondition.........................................................................................................11

- 3 -

1.GENERALSAFETYINSTRUCTIONSANDPRINCIPLES

ATTENTION!Readallinstructionsandprinciplescarefully.Everypersoninstalling,operatingormaintainingthe

toolmustbefirstthoroughlyacquaintedwiththisoperationsmanualandisobligedtoadheretothefollowing

safetyinstructionsandprinciples:

Thetoolmustnotbeusedforotherpurposesthanthoseforwhichitwasdesigned.

Thetoolmustnotbeusedinadifferentmannerthanthatrecommendedbythemanufacturer

Anyalterationsofthetool,itsaccessoriesorsparepartsremaininsoleresponsibilityofthecustomer.After

agreementthemanufacturerprovidetechnicalsupportindesigningandmakingadditionalalterations.

The tool must be kept in top condition and regularly tested for damage and proper operation. The tool

must be repaired only by an authorized technician or by a person trained by the manufacturer or

supplier.Shouldyouhaveanydemandfortraining,pleasecontactyoursalesagent.

Thetoolmustalwaysbeoperatedinaccordancewithrespectivesanitaryandsafetyregulations.

Allqueriesregardingproperandsafeoperationofthetoolshouldbeaddressedtoyoursalesagent.

Safetyprinciplesthatmustbeadheredtoin connectionwithoperationofthistoolmustbeknowntoall

workerswhooperatethetool.

Whenhandlingthetooltakeextracaretoavoidunwantedactivationandpossibleinjury.

Thetoolmust be during any kind of maintenanceorrepair(doesnotapplytoreplacingnose‐pieces and

emptyingthemandrelcontainer)disconnectedfromthesourceofcompressedair.

Beforeoperatingthetoolalwaystakeupfirmpostureandsteadyposition.

Itisnecessarytopreventbreak‐awayshanksendangeringsafeoperationofthetool.

Neveraimwiththetoolatanotherperson.

Alwayscheckthattheventholesarenotblockedorcoveredandthatthesupplyhoseareingoodcondition.

Workingpressuremustnotexceed95PSI.

Oxygenorotherflammablegassesfrompressurecylindersmustnotserveasadrivingagent.

Whenoperatingthetoolitisrecommendedtousesafetyglassesandutilitygloves.

Ifthecontinuouscycleofrivetingexceeds8hoursperday,itisrecommendedthattheoperatorsuseear

protectors.

When working with the tool the operator must not have loose parts of wear as e.g. a tie, long hair,

jewelleryetc.toavoidgettingcaughtbythetool.

Samesafetyinstructionsapplyforpersonsstandingclosetothetool.

Avoidunnecessarycontactwiththehydraulicfluidtopreventpossibleallergyreactionoftheskin.

Thetoolisnotdesignedforoutdoorandexplosiveenvironment.

Aftertheservicelife,discardthetoolaccordingtotheDisposalActno.185/01Coll.

- 4 -

2. DESCRIPTIONOFTHETOOL

2.1.Basicdimensions

2.2.Technicaldata

weight............................................1,84kg

workingpressure...........................85‐95PSI

strokeforceat0,6MPa.................12,5kN

airconsumption.............................2,0l/stroke

stroke............................................21mm

height............................................275mm

length............................................272mm

width(overtheaircoupling)……....120mm

- 5 -

2.3.Rangeofusage

Thepneumatic‐hydraulictoolisdesignedforrivetingwithblindrivets:

Typeofrivet Al(aluminium) St(steel) Rv(stainlesssteel) Recommendednose‐pieces*

standard Ø4,0 Ø4,0 Ø4,0 nose‐pieceno.4

standard Ø4,8‐Ø5,0 Ø4,8‐Ø5,0 Ø4,8‐Ø5,0 nose‐pieceno.5

standard Ø6,0 Ø6,0 Ø6,0 nose‐pieceno.6

standard Ø6,4 Ø6,4 Ø6,4 nose‐pieceno.6.4

*Recommendednose‐pieceswithrespecttorivetdiameters(doesnotapplyforalltypesofrivets)

2.4.Tooloperation

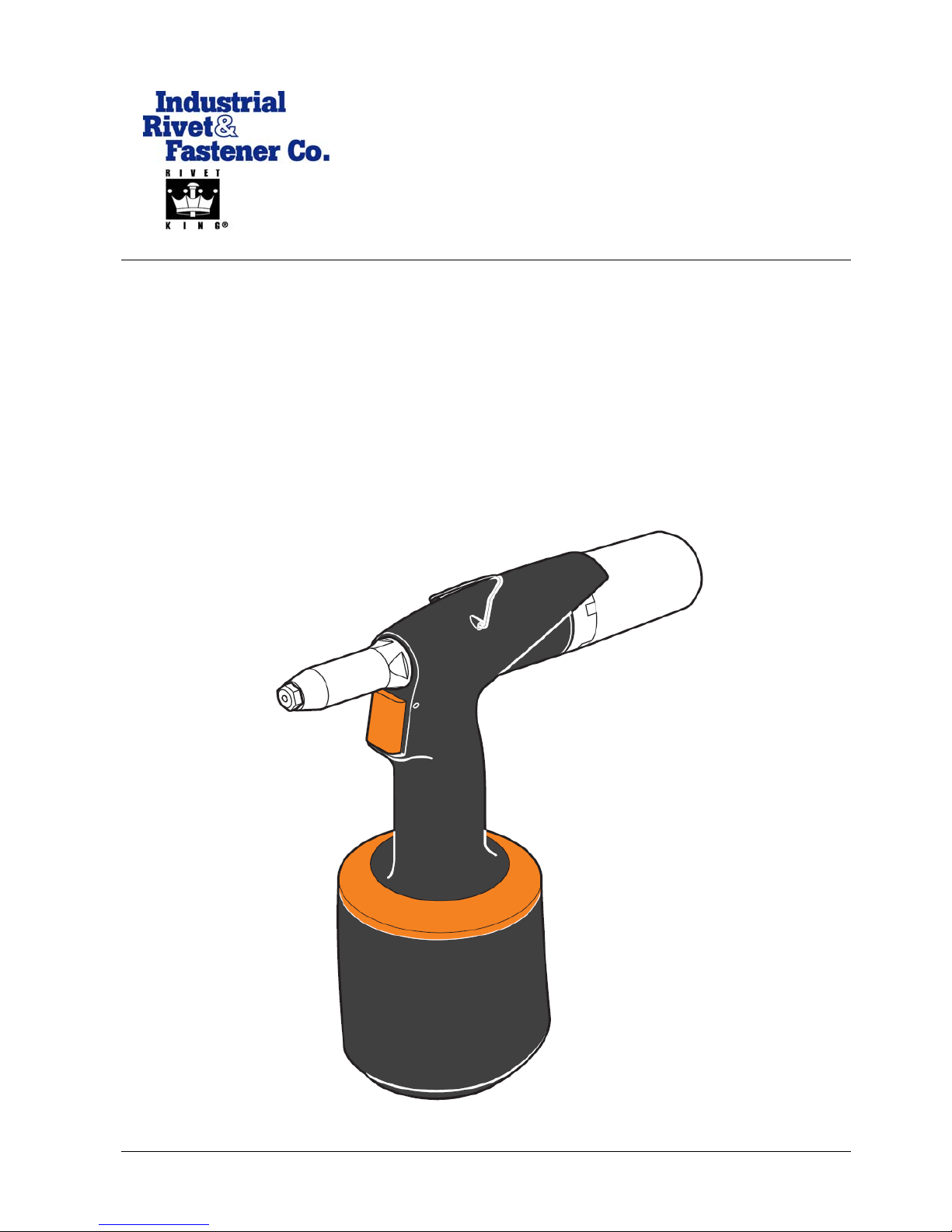

Fig.1

The manufacturer equipped the tool with a nose‐piece /fig.1 – pos.1/ for a rivet Ø 6.4.Riveting with blind

rivets of different diameters (further on referred to as BR) requiresuse ofappropriatenose‐piecesthatare

locatedintheaccessoriescasingofthetool.

Replacementofnose‐pieces:Connectthetooltothesourceofcompressedair,depressthetriggerandscrew

outthe nose‐piece/fig.1–pos.1/withaspannerno.12.Screwonanewnose‐piece/acc.tothechart/and

tightenit.Nowyoucanreleasethetriggerofthetool.

The tool is equipped with revolving air supply /fig.1 – pos.A75/ which enables manipulation with air supply

beforeaswellasduringtooloperation,airhosedoesnotobstructrivetinginanyposition.

Thetoolisequippedwithmultifunctiontrigger/fig.1‐pos.74/whichenablesfollowing:

1)Rotationalmovementofthetriggeraroundthepin‐riveting.

- Thetriggerisonthefrontextremeposition,notpressed.

- Depressingthetriggershallfixtherivet.

- 6 -

2)Verticalmovementofthetrigger–switchingoffthesuction.

- Pressandlockthetrigger(afterpressingshiftitupcca1,5mm),thenreleasethetrigger,thesuctionis

switchedoff.

- Unlockthetrigger(shiftingthetriggerdowntothestop)andreleaseit.Thesuctionisswitchedonand

thetriggerisinpositionseefig.1.

The tool is equipped with a multifunctional mandrel container /fig.1 – pos.32/ which has the following

positions:

Position0–mandrelcontainerremoved

Position1–mandrelcontainermounted,suctionisswitchedoff

Position2–mandrelcontainermounted,suctionisswitchedon

1)Mountingthemandrelcontainer:

Putandpush themandrelcontainer/fig.1 ‐pos.5/intotheringrelief/fig.1–pos.6/end‐to‐end,thusyou

depressthearrestmentelement,andturntoposition1or2.Themandrelcontainershallthusbeinplace.The

suctionshallinitiateinposition2.Relativepositionofthemandrelcontainerwithairoutlets/fig.1‐pos.7/and

theringrelief/fig.1–pos.7/ensuresthattheoutletairpressuregoesoutinasuitabledirection(e.g.Offward

theoperatorofthetool).

2)Removingthemandrelcontainer:

Turnthemandrelcontainer/fig.1‐pos.32/end‐to‐endtoposition0andpullitoutoftheringrelief/fig.1–

pos.26/.Thesuctionshallthusswitchoff.

- 7 -

Thetoolcanbeoperatedinthefollowingmanners:

1)withthemandrelcontainerremovedinposition0:

Suctionswitchesoffbyturningandremovingthemandrelcontainer/fig.1‐pos.32/.InsertBRintotheriveting

toolthroughthenose‐piecehole.DepressthetriggertomovethejawsoffwardtheBRhead.Themovement

endswhenreachingmax.stroke,correctBRwithrespectformaterialgaugeshalltearofftheshank(riveting)

foronestrokeof thetool.Releasingthetriggershallreturnthejawstoinitialpositionandreleasedtorn‐off

shankcanberemovedfromthenose‐piecebytiltingthetool./fig.1‐pos.1/.

2)withthemandrelcontainermountedinposition1:

Mountingandturningthe mandrelcontainer/fig.1‐pos.32/toposition1shallarrestit.InsertBRintothe

riveting tool through the nose‐piece hole. Depress the trigger to move the jaws offward the BR head. The

movementendswhenreachingmax.stroke,correctBRwithrespectformaterialgaugeshalltearofftheshank

(riveting)foronestrokeofthetool.Releasingthetriggershall return the jaws to initial position and the

releasedtorn‐offshankcanbetransportedintothemandrelcontainerbytiltingthetool.

3)withthemandrelcontainermountedinposition2:

Suctionswitchesonbyturningthemandrelcontainer/fig.1‐pos.32/toposition2.Inthispositionthesuction

holdsBRinthenose‐piece/fig.1‐pos.1/whichenablesrivetinginanypositionwithoutdangerofBRfallingout

ofthenose‐pieceofthetool.Depressingthetriggershallperformriveting.Releasingthetriggershalltransport

theshankintothemandrelcontainer.Ifthemandrelcontainerisfullwithshanktoappx.70%,itisnecessaryto

removeandemptyitinaspecifiedmanner(e.g.toapreparedcontainer).Overfillofthemandrelcontainer

mayresultinfailureoftherivetingtool.

3.TOOLMAINTENANCE

Duringmaintenancethetoolmustbedisconnectedfromthesourceofcompressedair!!!

3.1.Dailymaintenance

Before starting work, apply severaldropsoflubricatingoil(werecommendhydraulicoilHYSPINAWHM32

CASTROL) into the air inlet of the tool, on condition there is no lubricating device connected in the air

distribution.

Checkthetoolforairleakage,ifnecessaryreplacedamagedhosesandclasps.

Ifthepressureregulatorisnotequippedwithafilter,blowthroughtheairhosebeforeitsconnectiontothe

toolinordertogetridofimpuritiesandwater.Ifthepressureregulatorhasafilter,dryitout.

Checkwhetherthefixednose‐piececorrespondstotheBRdiameterandthatallscrewthreadsandjointsare

tightenedproperly.

Checkwhethertheholesforpassagearereallyempty.Ifitisnotso,itisnecessarytoremovethedamaged

part,cleantheholeorreplacethedamagedpartwithanewone,seeparagraph3.2weeklymaintenance.

3.2.Weeklymaintenance

Cleaningofthetoolandreplacementofwornornon‐functionalparts.

- 8 -

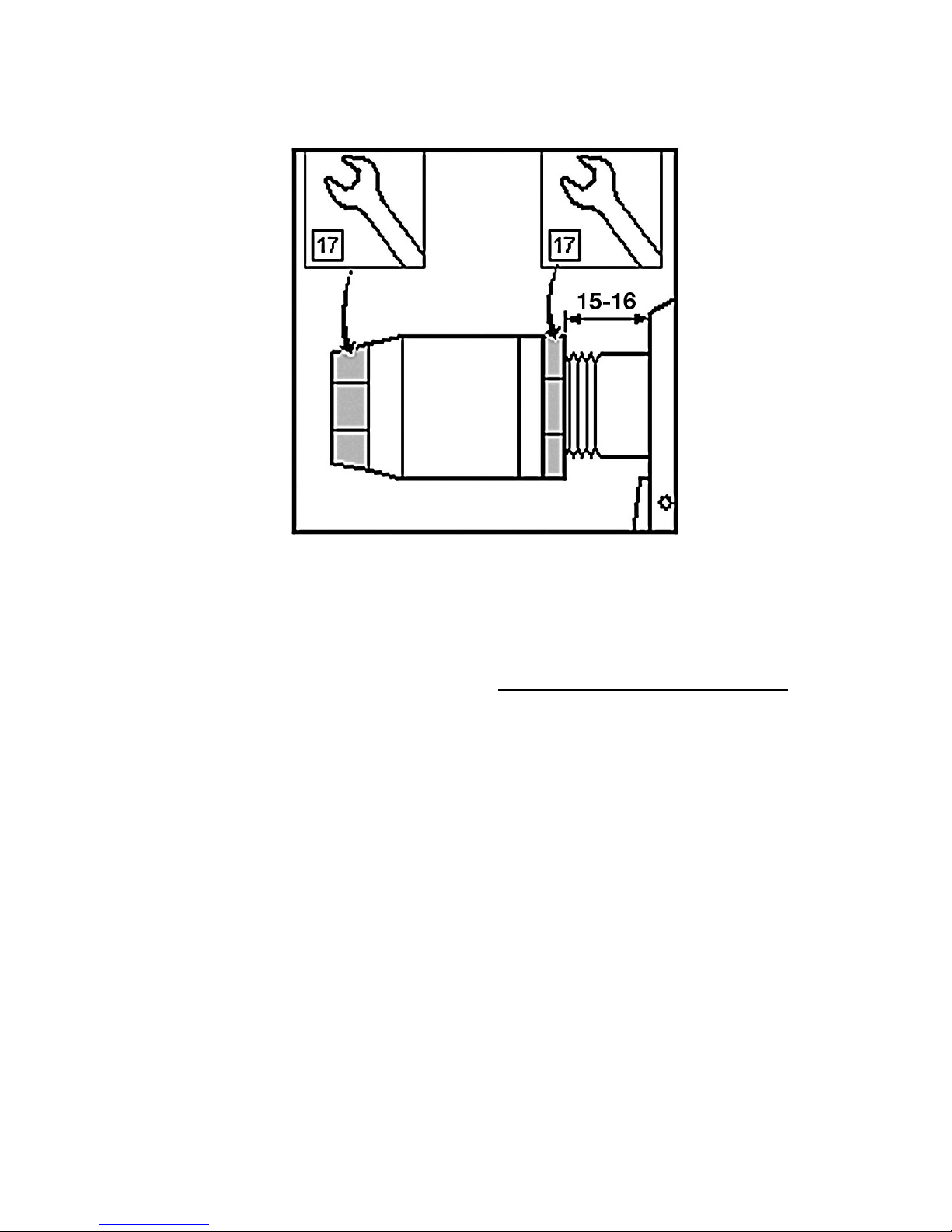

Fig.2

Disassembly:

Disconnectthetoolfromthesourceofcompressedair,unscrewthefrontnozzle/fig.2‐pos.9/bymeansofa

spannerno.23,setthespannerno.17(15)ontotheclampingsleeve/fig.2‐pos.3/,setthespannerno.17onthe

backnut/fig.2‐pos.6/andloosen.Unscrewtheclampingsleeve,replacethejaws/fig.2‐pos.2/andconduit‐

suction complet /fig.2 ‐ pos.8/. All used threads are clockwise. Clean the dismounted parts thoroughly and

checkthemvisually,especiallythefollowing:

1)Jaws/fig.2–pos.2/‐ifwornordamaged,replaceit,ifdirty,cleanitwithawirebrush.

2)Nose‐piece/fig.2–pos.1/‐forwearoffunctionalsurfacesofthetaper.

3)Conduit‐suctioncomplet/fig.2‐pos.8/‐inspectpartsoftheassembly,jawpusher/fig.2‐pos.804/,spring

/fig.2‐pos.803/,washerofspring/fig.2‐pos.805/,O‐ring/fig.2‐pos.802/andconduit‐suction/fig.2‐

pos.801/‐ifdamagedorworn,replaceitwithanewone.

4)Frontnozzle/fig.2‐pos.9/‐checkfordamageoftheinternalsurface(Ø20).

5)Scraperring/fig.2‐pos.5/‐ifdamagedorworn,replaceitwithanewone.

6)Mandrelcontainer‐ifthemandrelcontaineroritsbottomarewornordamaged,replacethemwithnew

ones,otherwisethereisdangerofthetorn‐offshankpoppingout.

Assembly:

Mount the parts (see par. disassembly) in a reverse order. On theoutersurfaceofthejaws/fig.2–pos.2/

applyadropoflubricatingoil(werecommendhydraulicoilHYSPINAWHM32CASTROL),applythinlayerof

plastic lubricant MOGUL LV 2‐3 to the conduit‐suction complet /fig.2 – pos.8/. Basic set‐up of the jaws is

performedasinfig.3.

- 9 -

Fig.3

3.3.Generalmaintenance

General maintenance shouldbeperformed after about 500000strokes oronce every threeyears. The tool

mustbecompletellydisassembledandallsealsandwornpartsmustbereplaced.Thisrepairmaybecarried

outbyanauthorizedtechnicianonlyorapersontrainedbythemanufacturerorsupplier.

4.SPAREPARTS

4.1.Ordering

Orderthesparepartsexclusivelyfromthemanufacturerorfromyoursalesagent.

Theordermustcontain:

a) toolserialnumber

b) numberoforderedpart

c) numberofpieces

d) nameofyourcompanyandpreciseaddress

e) yourtaxidentificationnumberandidentificationnumber

- 10 -

4.2.Listofquicklyexpendableparts

Nose‐piece4.........................................................… RK9000‐BP1‐3

Nose‐piece5.........................................................… RK9000‐BP1‐4

Nose‐piece6.........................................................… RK9000‐BP1‐5

Nose‐piece6,4..………………………………………………..… RK9000‐BP1‐6

Clampingsleeve......................................................RK9000‐BP3

Setofjaws................................................................ RK9000‐BP2

Conduitsuction…...........................................……….. RK9000M‐BP7

"O"ring7,1/1,6........................................................RK9000‐BP8

Springofjawpusher………………………………………….….RK9000‐BP9

Jawpusher.…………………………………………..……..…….RK9000MLS‐BP10

Scraperring..………………………………………….…….……... RK9000‐BP4

NutHP..………………………………………….…………….……. RK9000‐BP5

Mandrelcontainer…………………………………………..…… RK9000M‐BP42

5.STORAGE

Thepneumatic‐hydraulictoolembeddedinashippingcontainermustbestoredinenvironmentwithrelative

humidityto70%andtemperaturerangingfrom+5oCto+40oC,withoutaggressiveevaporationofsalts,acids

andcaustics.

6.COMPLETETOOLEQUIPMENT

Replaceablenose‐pieceslocatedinaplasticplate,Operationsmanual,Certificateofwarranty.

7.OPERATIONSANDWARRANTYCONDITIONS

For

reliable function

of

the tool we recommend to use treated

compressed

air.

Treated

compressed air means compressed atmospheric air bare

of

solid

particles

and

water,reduced

to required pressure and lubricated with anti-corrosive

oil.

- 11 -

7.1.Operationconditions

Forreliablefunctionofthetoolitisnecessarytousetreatedcompressedair.Treatedcompressedairmeans

compressed atmospheric air bare of solid particles and water, reduced to required pressure and lubricated

withanti‐corrosiveoil.Immediatelybeforethetooltheremustbearegulationvalvesettomaximumoutlet

pressureof0,7MPa,airfilterandlubricationinthecircuitofcompressedair.

Sound‐pressurelevelofimpulsenoise,LpAI=107,7dB(A),peakC‐weightedsoundpressure,CLCpeak=114,1

dB(C), against which during continuous and long‐term operation it is recommended to use ear protectors.

AverageoverallvibrationtotalvalueLavw,T=126,8dBre10‐6m.s‐2,averageoverallvibrationtotaleffective

valueavw,T=2,188m.s‐2.

Thetriggerenablessafecontrolofthetoolwithaforcemax.10N<50Nwithoutreleasingthegrip‐handle

accordingtothehealthregulation.

7.2.Warrantyconditions

Forreliableandsafefunctionofthetoolitisnecessarytoadheretoinstructionsandprinciplesstatedabove.

Forthe warrantyperiodthecustomermustnotperformanyalterationsotherthanthosepermittedbythe

manufacturer, see paragraph 2. 1, 3. 1, 3. 2. Other non‐detachable parts are secured with paint. In case of

neglecting this protection the manufacturer shall not admit possible warranty repairs. To admit warranty

repair the customer must submit confirmed warranty certificate ofthetool,Certificateofqualityand

completenessorproofofpurchase.Thewarrantyperiodis24monthsfromthedayofpurchaseconfirmedin

theWarrantycertificateifthepurchasecontractdoesnotstateotherwise.

Warrantyisvalidprovidedthatthefollowing:

Generalsafetyinstructionandprinciples(paragraph1)

Tooloperation(paragraph2.4)

Dailyandweeklymaintenance(paragraph3.1and3.2)

Storage(paragraph5)

Operationsandwarantyconditions(paragraph7)

Warrantydoesnotapplytoquicklyexpendableparts(seeparagraph4.2.

Table of contents

Other Industrial Rivet & Fastener Co. Rivet Tools manuals