Industrial Rivet & Fastener Co. RK-797 Series User manual

INDUSTRIAL RIVET & FASTENER CO.

RIVETING TOOL MANUAL

MODEL #

RK-797

MANUAL

VERSIO

N

1.5

FREESET

Technical Data Sheet

MODEL# RK-797-1 RK-797-3

Device Stroke 25mm 25mm

Setting Force 18kn 18kn

Drive Brushless DC motor Brushless DC motor

Lighting Power LED Power LED

Battery Li-Ion 18V Li-Ion 18V

Weight 1.9 kg w/o battery 2.0 kg w/o battery

Application 3/16” and ¼” Lockbolts 3/16” and ¼” Lockbolts with Process Monitoring

Table of Contents

BASIC INFORMATION ............................................................. 1

1PURPOSE OF THIS DOCUMENT ................................... 1

1.1Intended Use ........................................................................ 1

1.2Improper Use ........................................................................ 1

1.3Warranty and Liability ........................................................... 2

1.4Copyright .............................................................................. 2

2BASIC SAFETY INFORMATION ..................................... 3

2.1Information contained in this document ................................ 3

2.2Owner Responsibilities ......................................................... 3

2.3Personnel Responsibilities ................................................... 3

2.4Personnel Training ............................................................... 3

2.5Risks When Using This Tool ................................................ 3

2.6Electrical Hazards ................................................................ 4

2.7Basic Safety Measures ......................................................... 4

2.8Electrical Safety .................................................................... 5

2.9Personal Safety .................................................................... 5

2.11Use and care of the power tool............................................. 6

2.12Service ................................................................................. 6

2.13Lithium Ion Battery ............................................................... 7

2.14Battery Chargers .................................................................. 8

2.15Structural Modifications ........................................................ 8

2.16Cleaning the tool and disposal ............................................. 9

2.17Risk of injury and tool damage ............................................. 9

3CONTENTS & OPTIONS ............................................... 10

3.1Standard Components ....................................................... 10

3.2Optional Nose Equipment .................................................. 10

3.3Freeset Anatomy ................................................................ 11

3.4Technical Details (ALL MODELS) ...................................... 12

4OPERATION .................................................................. 13

4.1Quick Start ......................................................................... 13

4.2Checklist ............................................................................. 13

4.3Inserting The Battery .......................................................... 15

4.4Emptying The Container ..................................................... 16

4.5Setting The First Rivets ...................................................... 17

5MAINTENANCE AND SERVICE .................................... 18

5.1Service Principles ............................................................... 18

5.2Preventive Maintenance ..................................................... 18

5.3Approved Lubricants .......................................................... 19

5.4Removing The Jaws ........................................................... 19

5.5Removing The Nose Piece .... Error! Bookmark not defined.

6LED STATUS LIGHT ..................................................... 20

7QUICKDRAW FUNCTION ............................................. 21

7.1Enabling QuickDraw ........................................................... 21

8DRAWINGS ................................................................... 22

8.1Main Components ............................................................. 22

8.2Drive Shaft Assembly PRIV-B1 ..................................... 23

8.3Limit Switch Circuit Board PRIV-B3 .................................... 23

8.4Drive Unit Assembly PRIV-B2 ............................................ 24

8.5Motor Assembly & Main Circuit Board PRIV-B4 ................. 25

8.6Mandrel Container Assembly PRIV-B5 .............................. 25

8.7Mandrel Container Holder PRIV-B6 ................................... 26

8.8Tool Holder PRIV-B8 .......................................................... 26

8.9Nose Assembly Parts ......................................................... 27

9Parts Ordering ................................................................ 28

RIVETKING FREESET MANUAL RK-777

1

BASIC INFORMATION

1 PURPOSE OF THIS DOCUMENT

This document is intended for persons responsible for the operation of the FreeSet

lockbolt setting tool (the "tool"). Please read, understand and follow all instructions

contained in this document. Please read this document prior to starting to use the tool

and pay attention to the safety information. The information contained in this

document is important for avoiding workplace mishaps and ensuring problem-free

operation. We assume no liability for damage or business disruption due to failure to

adhere to the instructions contained in this document. Should you Nonetheless

encounter problems, please contact us and we will do our utmost to assist you.

1.1 Intended Use

This tool may only be used for setting lock bolts and blind rivets as described in this

document.

NOTE!

Intended use also includes

- Compliance to all information in this document

- Compliance with inspection and maintenance procedures

Any other use is considered improper use of the tool.

Industrial Rivet is not liable for damage resulting from improper use.

1.2 Improper Use

We assume no liability for damage or business disruption due to failure to adhere to

the instructions contained in this document or due to improper use of the setting tool.

Sectio

n

1

2

1.3 Warranty and Liability

Warranty and liability claims for personal and property damage are excluded if they

occur as the result of one or more of the following:

•Improperuse

•Improperinstallation,placementintoservice,operationandmaintenance

•Operatingthetoolwithdefectivesafetyequipmentor

improperly installed or non-functioning safety and protective devices

•Failuretocomplywiththeinformationcontainedinthisdocumentregarding

transport,storage, assembly, placement into service, operation, and maintenance of

the tool

•Unauthorizedmodificationstothetool

•Improperlyperformedrepairwork

•Catastrophiceventsbeyondhumancontrolandactsofgod

1.4 Copyright

This document is intended only for the owner and personnel authorized to operate the

tool.

It contains the relevant rules and information, which may not be:

- Duplicated

- Distributed or

- Otherwiseshared,eitherinwholeorinpart.

ThecopyrightforthisdocumentremainswithIndustrialRivetandFastenerCo.

Addressofthemanufacturer:

IndustrialRivetandFastenerCo.,Inc.

200ParisAvenue

Northvale,NewJersey07647

Ph.201‐750‐1040

3

2 BASIC SAFETY INFORMATION

2.1 Information contained in this document

•Toensuresafeuseandproblem‐freeoperation,pleasemakesurethat

youarefamiliarwiththebasicsafetyinformationandguidelines.

•Alsobesuretoobservealllocalrulesandregulations.

2.2 Owner Responsibilities

The owner is responsible for ensuring that all persons using the tool are familiar with

basic work safety and accident prevention rules and have been briefed on tool

operation. Safety practices should be reviewed regularly with all personnel operating

the tool.

2.3 Personnel Responsibilities

All persons assigned to work with the tool should be aware of the basic work safety

and accident prevention rules prior to commencing work.

2.4 Personnel Training

Personnel must be trained and briefed before operating this tool.

Personnel responsibilities for installation, placement into service, operation,

maintenance andrepairmustbeclearlydefined.Personnel in training may operate

the tool only under the supervision of an experienced person.

2.5 Risks When Using This Tool

All possible safety risk factors must be addressed immediately.

Warning!

The tool is designed using state-of-the-art technology and according to

recognized safety standards. Nonetheless, operating the tool involves the

risk of life-threatening injury to the user, third parties, and/or property.

Warning!

The tool may only be used:

- For intended purposes

- If the tool is in proper and safe working order.

4

2.6 Electrical Hazards

Warning!

Work on this tool is to be performed only by a qualified electrician. Inspect

the tool’s electrical components on a regular basis. Repair loose

connections and damaged cables immediately. Remove the battery before

performing tool repairs.

Note!

The tool must always be kept locked in a secure location.

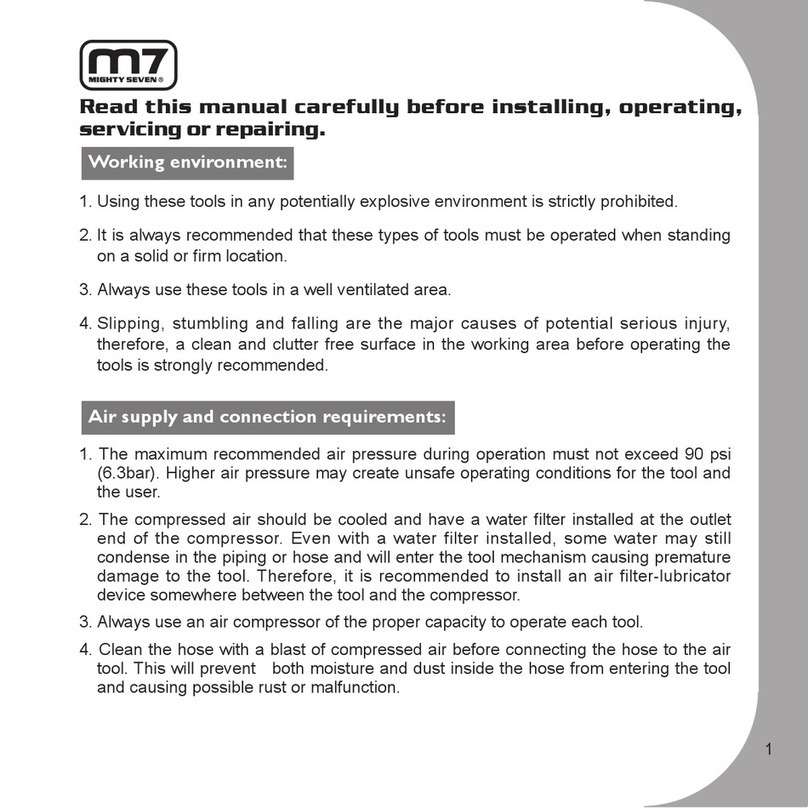

2.7 Basic Safety Measures

Warning!

The terms “tool” and “power tool” used in the safety information refers

to tools powered from a wall outlet (with power cord) and battery –

powered tools (without a power cord).

1. Keep your working area clean and well lighted.

A cluttered or poorly illuminated working area may result in accidents.

2. Do not operate the tool in areas which explosions can occur.

Where flammable liquids, gases, or dusts are located. Power tools produce

sparks that can ignite dust or vapors.

3. Pay attention to environmental conditions

Do not expose the tools to rain or water.

Do not use tools in a damp or wet environment.

4. Keep children and other persons away when using the tool.

Distractions may cause you to lose control of the tool.

5

2.8 Electrical Safety

1. Avoid contact with grounded surfaces such as pipes, heaters, stoves,

and refrigerators.

When your body is grounded there is an increased risk of electrical shock.

2. Keep the tool away from rain and humidity

The penetration of water into a tool increases the risk of electrical shock.

3. Keep the tool away from heat, oil, sharp edges or moving parts

4. Minimize the effects of ESD “Electro Static Discharge”

ESD can effect the performance of electronic components on the tool.

2.9 Personal Safety

1. Alwayspaycloseattentionandusecautionwhenworkingwitha

powertool.Donotoperatepowertoolswhenyouaretiredorunderthe

influenceofdrugs,alcohol or medications. Even one moment of carelessness

when operating the tool can result in serious injury.

2. Alwayswearpersonalprotectivegearandsafetygoggles.Wearing

personal protective gear appropriate to the type of tool and the work being

performed, such as a dust mask, non-slip safety shoes, a safety helmet and ear

protection, minimizes the risk of injury.

3. Avoid accidentally starting the tool. Make sure that the tool is switched off

before connecting it to the battery, picking it up or carrying it.

Carryingthetoolwithyourfingeronthepowerswitchorconnecting to a

power source when it is switched on may result in accidents.

4. Maintainanergonomicworkingposture.Standfirmlyandalways

maintainbalance.Bydoingthis,you can control the tool better in unexpected

situations.

5. Wear suitable clothing. Do not wear loose clothing or jewelry. Keep hair,

clothing, and gloves away from moving parts. Loose clothing, jewelry or long

hair can get caught in moving parts.

6

2.11 Use and care of the power tool

1. Do not overload the tool. Use the appropriate tool for your work. Using the

correct tool allows you to perform yourworkmoreefficientlyandsafely.

2. Donotuseapowertoolthathasadefectivepowerswitch.Power

tools that cannot be switched on and off are dangerous and must be repaired.

3. Removethebatterybeforechangingtoolsettings,replacing

accessorypartsor storing. By doing this, you can prevent the tool from

starting accidentally.

4. Keep unused tools out of the reach of children. Do not allow anyone to use

the tool who is unfamiliar with it or has not read this document. Power tools

are hazardous when used by inexperienced persons.

5. Maintain the tool carefully. Make sure that moving parts are in good working

condition and do not jam, and check for broken or damaged parts that may

impair proper function. Ensure that any damaged parts are repaired before

using the tool.

Poorly maintained power tools are responsible for many accidents.

6. Keep tools clean. Carefullymaintainedtoolsjamlessfrequentlyandare

easiertooperate.

7. Followtheseinstructionswhenusingthetoolandaccessories.Take

into account the working conditions and the work to be performed. Using

power tools for unintended purposes may be hazardous.

8. Use the correct tool. Donotusetoolswithinsufficientpowertoperform

thetask.Do not use tools for purposes and work for which they are not

intended.

9. Check your tool for damage. Beforeusingthetool,checkfordamaged

partsandensurethatsafetyequipmentis in good working order and

functions as intended. Check that moving parts are in working order and do not

jam, that all parts are properly mounted and none are broken, and that all

conditions are correct for operating the tool. Damagedprotectiveequipment

andpartsshouldbeproperlyrepairedbyacustomerservice workshop or

replaced,unlessthisdocumentspecifiesotherwise.Damaged power

switches must be replaced by a customer service workshop. Do not use a tool if

the start switch does not function properly.

2.12 Service

Warning!

All repairs should be carried out by qualified personnel, using only original

replacement parts available from Industrial Rivet and Fastener Co. Doing

this will ensure that the tool safety is maintained.

7

2.13 Lithium Ion Battery

Warning!

Please observe the following when handling the provided lithium ion

batteries.

a) Use only devices recommended by the manufacturer to charge the

batteries. Using an improper charger may ruin the battery.

b) Usethecorrectbatteriesinthepowertools.Usingotherbatteriesmay

resultininjuryandfirehazard.

c) Ifthebatteryisnotusedforanextendedperiod,itshouldnotremain

in the charger or in the tool. If it is expected that the riveting tool will remain

unused for more than 3 hours, the battery must be removed. Failure to do so

entails the risk of permanent battery damage.

d) Forsafetyreasons,thelithiumionbatteryshouldnotremaininan

activechargingdevice for more than 36 hours. After charging, remove the

battery from the charger as soon as possible.

e) Anemptybatteryshouldnotremaininthetoolorinanunpowered

chargingdevice foranextendedperiodoftime.Inbothcases,the

residualcurrentflowmay completely discharge and ruin the battery.

f) Ifpossible,rechargethelithiumionbatteryimmediatelyafteruse

anddo not store whenempty. If the battery is stored separately from the

tool and the charger, it will retain its charging capacity for a longer time.

(Maximum loss 5% per year)

g) Alwaystransportthebatteryseparatelyfromthetoolwhenever

possible.This ensures that the tool is not accidentally switched on, thus

preventing the battery from discharging.

h) Donotexposethelithiumionbatterytohightemperatures

(120°F/50°C)ordirect sunlight. If the battery temperature exceeds

120°F/50°C during operation (charging or discharging), it must be removed

from the charger or riveting tool immediately.

i) Keepunusedbatteriesawayfrompaperclips,coins,keys,nails,

screwsorothersmallmetalobjectsthatcouldcreateashortcircuit

betweenthebatterycontacts.Donotopenorshort‐circuitthe

battery.A short circuit between the battery contacts may result in burns,fire

orexplosion.

8

j) Batteriesmayleakunderextremeoperatingconditionsorhigh

temperatures.Ifabatteryleaks,avoidcontactwiththeskinoreyes.

Batteryfluidiscorrosiveandcancausechemicalburnstobodytissues.If

fluidcomesincontactwiththeskin,washoffimmediatelyusingsoapand

water,andthenapplylemonjuiceorvinegar.Shouldfluidgetintheeyes,

rinseforatleast10minuteswithwaterandconsultaphysician

immediately.

k) Donotdropthelithiumionbatteryorsubjectittophysicalshock.

l) Cleanthebatterycontactsregularlyusingcottonswabsdippedin

alcohol.

Warning!

Lithium ion batteries hold their charge almost indefinitely and are

not subject to memory effects.

With proper care, you can reliably charge your battery for years to come

(approx. 700-1000 charging cycles).

Avoid completely discharging or overcharging the lithium ion

batteries under all circumstances. Doing so will prematurely will

ruin them.

2.14 Battery Chargers

a) DonotchargethebatteryattemperaturesUNDER50°F/10°Cor

OVER100°F/40°C.

b) Thebatterychargermustnotbeconnectedtoastep‐uptransformer,

generatororDCoutlet.

c) Makesurethatthebatterychargerairventsarenotcoveredor

blocked.

d) Donotstorethetool,batterychargerorbatteryinplaceswherethe

temperaturemightexceed120°F/50°C.

e) Neverchargethebatteryinaboxoraclosedcontainer

2.15 Structural Modifications

No changes, additions or modifications may be made to the tool components without

the written permission of the manufacturer. All modifications require written

confirmation by Industrial Rivet and Fastener Co.

Warning!

Should repairs or maintenance be required, use only original replacement

parts.

9

2.16 Cleaning the tool and disposal

Handling and disposal of used substances and chemicals, especially when cleaning with

solvents.

Do not place used batteries into household garbage, fire or water. Ask the dealer

or manufacturer to handle disposal.

2.17 Risk of injury and tool damage

1. Attach the mandrel collection container before using the tool. Failure to do so

will allow the mandrels to be thrown off when they detach, which may result

in injury.

2. Make sure that there are no damaged tool parts. All damaged parts must be

repaired before use.

3. Working with damaged tool parts creates the risk of injury. If you work in an

elevated area, wear a safety harness, be mindful of falling rivets, and avoid

dropping the tool. Failure to do so could result in injury and substantial

damage.

4. Remove the battery before cleaning or performing general maintenance on the

tool.

5. Keep your face away from the exhaust vents.

6. Avoid skin contact with substances such as lubricants and grease. These

substancesareflammableontheskin.Ifyoushouldcomeincontact with

them, wash the affected area carefully.

7. Avoid unsafe working positions. You could fall and injure yourself.

8. Take good care of your tool. Follow the operating instructions for maintenance

and cleaning. Keep the handgrip free from lubricants and dirt.

9. Use the tool carefully and make sure to operate it correctly. Use the tool with

care. Proper working conditions should exist. Maintain concentration and

focus while working.

10

3 CONTENTS & OPTIONS

3.1 Standard Components

POS. DESCRIPTION

Q

TY

1 Batter

y

p

ower tool FreeSet® 1

2 Batter

y

Char

g

er 1

3 Batter

y

2.5a

h

1

4

T

ool Han

g

er 1

5 Nose Piece Se

t

1

3.2 Nose Equipment

POS. PULLIN

G

HEAD

A

DAPTERS

RK7971-NA Nose Adapter included with Model RK-797-1, without force sensor

RK7973-NA Nose Adapter included with Model RK-797-3, with force sensor

POS. NOSE ASSEMBLIES **

p

urchased as an o

p

tio

n

MG06-722-20 3/16” MagnaGrip Nose Assembly

MG08-722-20 ¼” MagnaGrip Nose Assembly

LB06-722-20 3/16” C6L Nose Assembly

LB08-722-20 ¼” C6L Nose Assembly

* Included with tool

NOTE: Nose Piece must match the desired lockbolt

11

3.3 Freeset Anatomy

POS. Description

1 Nose Assembly (not included)

Nose Adapter (included)

2 Serial Number

3 Mandrel Collector

4

Model Number

5 Status LED

6

T

ri

gg

er

7 Workli

gh

t

8 Batter

y

12

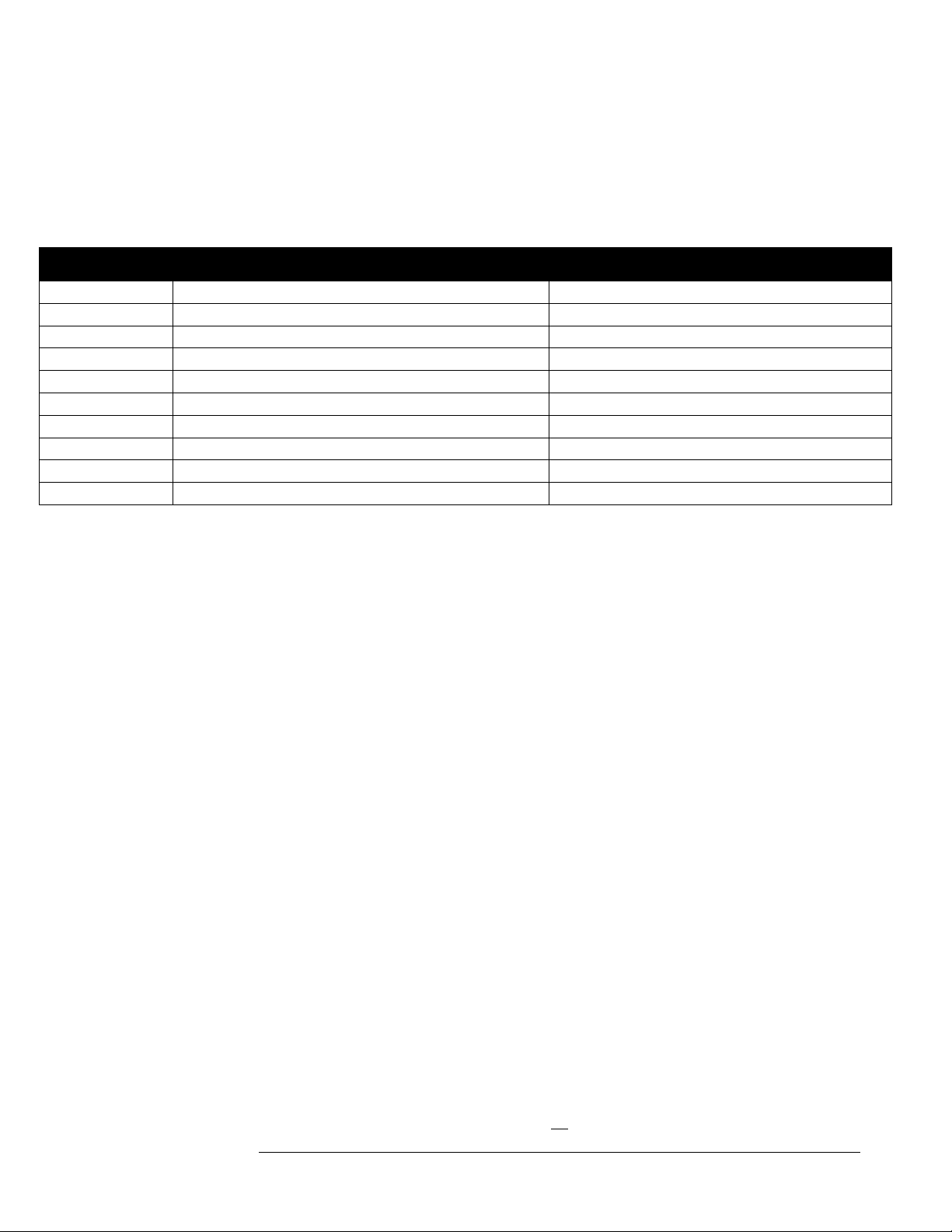

3.4 Technical Details (ALL MODELS)

* WEIGHT NOTED WITHOUT BATTERY

** TOOLS COME WITH PROGRAMMING FEATURES

MODEL# RK-797-1 RK-797-3**

Device Stroke 25mm 25mm

Setting Force 18kn 18kn

Drive Brushless DC motor Brushless DC motor

Lighting Power LED Power LED

Battery Li-Ion 18V Li-Ion 18V

Weight 1.9 kg w/o battery and nose assembly 2.0 kg w/o battery and nose assembly

Application 3/16” and ¼” Lockbolts 3/16” and ¼” Lockbolts with Process

13

4 OPERATION

4.1 Quick Start

This section describes how to start operating the RK-797-1 FreeSet and setting rivets.

See section x for details about additional setup options on RK-797-3 in the FreeSet

Manager Software.

4.2 Checklist

Check the following before using the riveting tool:

The housing is closed and there are no obvious defects

The battery is correct for the riveting tool and shows no damage

Thenosepiecefitstherivetstobeused.

Iftherivetdoesnotfitintothenosepieceoristooloose,another

nosepiecemustbe used.

The mandrel container is attached

Note!

Only batteries approved by Industrial Rivet and Fastener Co., Inc for

use in FreeSet tools may be used.

Using incorrect batteries can ruin both the batteries and the riveting

tool. Industrial Rivet assumes no liability for the use of incorrect

batteries

14

15

4.3 Inserting The Battery

To attach the battery (1), align the battery tab with the groove in the housing such that

it slides easily into place.

Always attach the battery completely so that it locks into place with a click. If the

battery is not properly attached to the tool, it can become detached and cause

substantial damage.

Never use force when attaching the battery. If the battery does not slide into place, it is

not correctly aligned. In this case, remove the battery and guide it once again into the

grooves.

To remove the battery, press down the clip (2) on the front of the battery. The battery

can now easily be removed by sliding it forward out of the holder.

After the battery has been inserted, a green light will appear in the LED status display

if there is enough battery power to operate. Subsequently, the light will go off.

Press the start switch “trigger” (1)

16

4.4 Emptying The Container

The detached mandrels must be emptied from the container. The nail container should

be emptied when full. The container can be opened and closed through turn left or

right.

Turn the collection container by hand to the left or right to remove it. After emptying

the container it can be mounted in the same way it was opened.

Note!

The mandrel container must be emptied regularly, otherwise mandrels

will become jammed in the tool which can cause costly damage.

This manual suits for next models

2

Table of contents

Other Industrial Rivet & Fastener Co. Rivet Tools manuals

Popular Rivet Tools manuals by other brands

Rivet King

Rivet King FreeSet RK-777C-1Q operating instructions

Gesipa

Gesipa taurus 1 Operating manual with spare parts list

Rivet King

Rivet King RK-59SPS Operation manual

Würth

Würth HNG 26 N Translation of the original operating instructions

Sealey

Sealey VS0204B.V2 manual

Power Fist

Power Fist 8843708 manual