Industrial Scientific OLDHAM 300 Series Operating instructions

300 SERIES

L

LE

EL

L

D

DE

ET

TE

EC

CT

TO

OR

R

D

DE

ET

TE

EC

CT

TO

OR

R-

-T

TR

RA

AN

NS

SM

MI

IT

TT

TE

ER

R

F

FO

OR

R

C

CO

OM

MB

BU

US

ST

TI

IB

BL

LE

E,

,

T

TO

OX

XI

IC

C

G

GA

AS

SE

ES

S

A

AN

ND

D

O

OX

XY

YG

GE

EN

N

O

OP

PE

ER

RA

AT

TI

IO

ON

N

A

AN

ND

D

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

M

MA

AN

NU

UA

AL

L

Ref.: NP300 GB

Revision G

3

GAS DETECTION

Thank you for purchasing an INDUSTRIAL SCIENTIFIC instrument. We appreciate your business.

We trust that our commitment to the technical excellence of our products will ensure your complete

satisfaction.

Please read the following document carefully.

L

LI

IM

MI

IT

TA

AT

TI

IO

ON

N

O

OF

F

L

LI

IA

AB

BI

IL

LI

IT

TY

Y

* INDUSTRIAL SCIENTIFIC will not be liable under any circumstances for material losses, personal injury or

death resulting in whole or in part from the inappropriate use of this equipment, the installation or storage of this

equipment not in conformance with the instructions and warnings presented in this manual and/or not in

conformance with current standards and regulations.

* INDUSTRIAL SCIENTIFIC neither allows nor authorizes any other company, individual or legal entity to make

any claims as to the liability of INDUSTRIAL SCIENTIFIC, even if said company, individual or legal entity is

directly involved in the sale of INDUSTRIAL SCIENTIFIC products.

* In no event will INDUSTRIAL SCIENTIFIC be liable for any direct or indirect damage including those resulting

from the sale and the use of its products IF THOSE PRODUCTS WERE NOT SPECIFIED AND SELECTED

BY INDUSTRIAL SCIENTIFIC FOR SUCH USE.

O

OW

WN

NE

ER

RS

SH

HI

IP

P

C

CL

LA

AU

US

SE

ES

S

* The images, blueprints, specifications and information contained in this document belong to INDUSTRIAL

SCIENTIFIC.

* This information may not be physically, electronically or otherwise reproduced, copied, disclosed or translated,

either in part or in whole, or used in the manufacturing or sale of INDUSTRIAL SCIENTIFIC equipment, nor for

any other reason without prior permission from INDUSTRIAL SCIENTIFIC.

W

WA

AR

RN

NI

IN

NG

GS

S

* This document is not contractual. On behalf of its clients, INDUSTRIAL SCIENTIFIC reserves the right to

modify the technical characteristics of its equipment without notice to improve product performance.

* CAREFULLY READ THIS DOCUMENT BEFORE USING THE PRODUCT: this document should be

carefully read by any individual who has or who will have the authority to use, maintain or repair this equipment.

* Any and all warrantees and performance claims will only be valid if the equipment is operated, maintained

and repaired in accordance with INDUSTRIAL SCIENTIFIC directives, by INDUSTRIAL SCIENTIFIC

personnel or by personnel appointed by INDUSTRIAL SCIENTIFIC.

W

WA

AR

RR

RA

AN

NT

TY

Y

*Two-year return to factory warranty under normal operating conditions on parts and labor, consumable materials

excluded (sensors, filters, etc.)

4

CONTENTS

I. INTRODUCTION ...................................................................................................................... 5

1. General Information ...............................................................................................................................5

2. Composition.............................................................................................................................................5

II. INSTALLATION AND CONNECTIONS ................................................................................... 5

1. INSTALLING THE DETECTORS.........................................................................................................5

1.1 Layout...............................................................................................................................................5

1.2 Mechanical installation....................................................................................................................6

2. ELECTRICAL CONNECTIONS............................................................................................................7

2.1. Wiring specifications........................................................................................................................7

2.2. Cable glands and cable types...........................................................................................................7

2.3. Connections for the various types of sensors ...................................................................................7

2.4. Operating mode..............................................................................................................................10

III. POWERING UP AND USE..................................................................................................... 11

1 Powering up...........................................................................................................................................11

2. 4-20 mA analog output..........................................................................................................................12

IV. MAINTENANCE .................................................................................................................... 12

1. Calibration.............................................................................................................................................13

1.1. Recommendations...........................................................................................................................13

1.2. CEX 300 calibration.......................................................................................................................14

1.3. CTX 300 calibration.......................................................................................................................15

1.4. COX 300 Calibration, “OXYGEN” type........................................................................................17

1.5. CSC 300 (semiconductor) calibration............................................................................................18

1.6. CTX300 CO2calibration ................................................................................................................19

1.7. CTX300 CO2 Linearization card ...................................................................................................20

2. Replacing a sensor .................................................................................................................................26

3. Disposal .................................................................................................................................................26

4. Replacement Parts List ..........................................................................................................................26

4.1. CEX 300-type Combustible Sensor ................................................................................................26

4.2 CTX/COX 300 Toxic or Oxygen Sensor .........................................................................................28

4.3 CSC300 Semiconductor Sensor......................................................................................................30

4.4 CTX300 CO2 Sensor ......................................................................................................................30

V. PARTICULAR SPECIFICATIONS FOR USE IN EXPLOSIVE ATMOSPHERES IN

ACCORDANCE WITH THE EUROPEAN ATEX 94/9/CE DIRECTIVE. ........................................ 31

1. SPECIFICATIONS FOR MECHANICAL AND ELECTRICAL INSTALLATIONS IN

EXPLOSIVE ZONES. ................................................................................................................... 31

2. PERFORMANCE SPECIFICATIONS FOR THE CEX 300 EXPLOSIVE GAS DETECTOR ... 31

2.1. Technical Specifications and Particular Instructions for the CEX300 Explosive Gas Detector ...32

3MARKINGS: .......................................................................................................................... 34

VI CERTIFICATIONS ................................................................................................................. 35

ANNEX 1 ...................................................................................................................................... 39

ANNEX 2 ......................................................................................................................................

41

ANNEX 3 ...................................................................................................................................... 42

5

I. INTRODUCTION

1. General Information

300 Series gas detectors are designed to measure combustible toxic gases or vapors and oxygen.

With robust materials, a specifically-adapted design, appropriate accessories, INOX bolts, and a

polyamide case (IP66) (IP55 for the CO2version), 300 series detectors are designed to withstand the

roughest conditions.

.

2. Composition

Sensor type CEX 300

CTX 300

Toxic

Oxygen

Semiconductor

CO2

Gases detected

Combustible gas

Common toxic

gases detected

Oxygen

- Combustible gas

- Solvents

- Some Freons

CO

2

Detection method

Catalytic oxidation

Electrochemical

sensors

1

Electrochemical

sensor

Semiconductor sensor

Infrared

absorption

Type of sensor

pack

Explosion-proof

sensor

Pre-calibrated

removable

sensor pack2

Pre-calibrated

removable sensor

pack: 0-30% scale

or 0-100%

volume.

Removable sensor pack,

not pre-calibrated

Removable

sensor pack

Infrared

column, not

pre-calibrated

Options

Cable gland for

flexible cable or

armored cable3

With display

With display

Certification

ATEX II 2GD4

None

None

None

None

II. INSTALLATION AND CONNECTIONS

For use in explosive atmospheres: in accordance with the European directive ATEX 94/9/EC, you

must read the “Particular Specifications” paragraph.

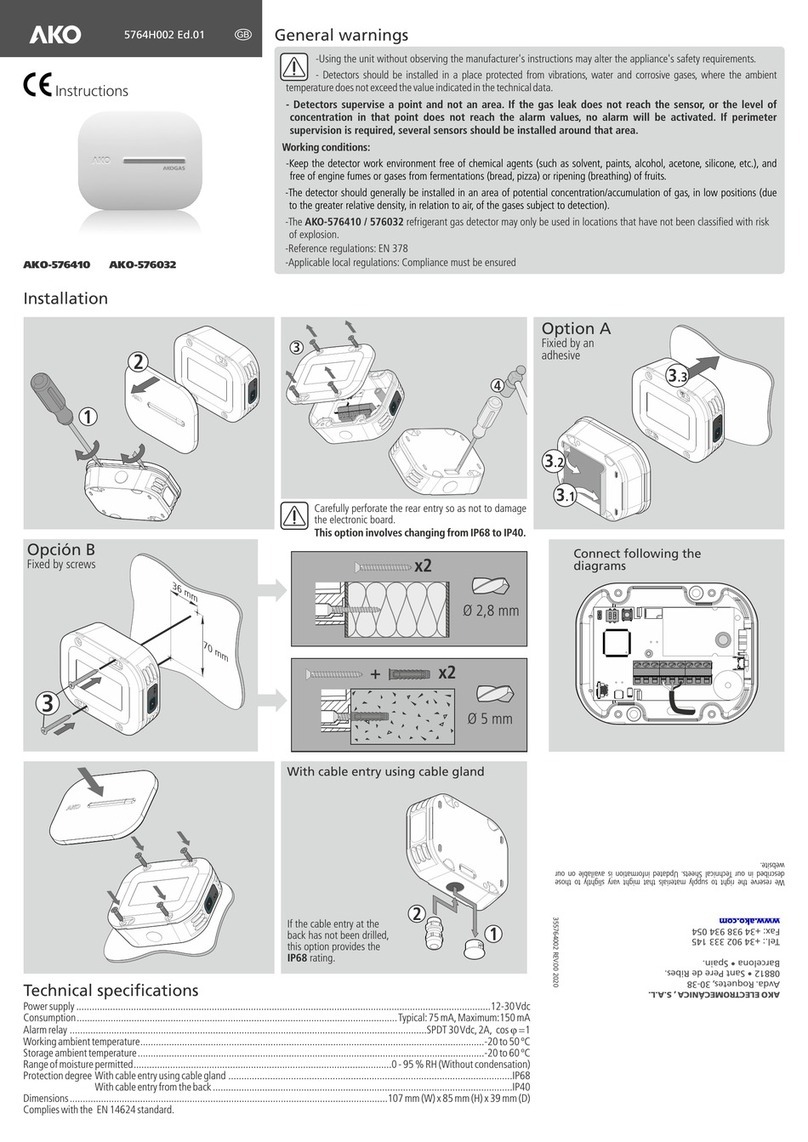

1. INSTALLING THE DETECTORS

1.1 Layout

While the measuring sensor is always located on the underside of the detector, several factors

determine where the detector should be located:

•If the gas being measured is lighter than the air, place the detector near the ceiling.

•If the gas is heavier than the air (CO2and Freons, for example) place the detector close to the

floor.

•Near offtake points.

•Generally, in locations where gas may accumulate, taking into consideration both

- the effects of temperature, and

- the direction of winds.

1Specific to each gas

2Choice between several scales

3Requires grounding

4EEx ed IIC T6 (-20 to 60°C)

6

Factors to consider when determining the best placement for the detector:

⇒Potential sources for vapor and gas emissions

⇒Characteristics of gases and vapors (density)

⇒Air circulation

-inside: mechanical or natural ventilation

-outside: wind direction and velocity

⇒Effects of temperature

⇒Local constraints (air flow, water)

Detectors should always be located in an easily accessible location for maintenance purposes.

Special accessories may be necessary to protect the equipment against any liquid projectiles, dust,

direct sunlight or low temperatures in the area.

1.2 Mechanical installation

Method 1: wall-mounted

Drilling diagram

Method 2: ceiling-mounted

Same drilling diagram, support brace used

1

3

2

7

REF.

No.

DESCRIPTION

OFSA REF

MATERIAL

1

1

CEX / CTX300 BRACE

6132380

INOX

2

4

CHC LI2 SCREW

6902218

INOX

3

4

A25 ACCD WASHER

6905518

.

2. ELECTRICAL CONNECTIONS

2.1. Wiring specifications

If needed: consult the grounding instructions for INDUSTRIAL SCIENTIFIC instruments and

related connection materials in Annex 1.

2.2. Cable glands and cable types

Sensor types Cable gland type Cable entry

CTX 300 (TOX and OX)

CTX 300 SC

CTX 300 CO2

Nickel-plated brass

Neoprene

Between 6–11 mm

CEX 300 with shielded cable

Nickel-plated brass

Between 6–11 mm

CEX 300 with armored cable5

Double compression nickel-

plated brass

Between 8.5–16 mm

2.3. Connections for the various types of sensors

CEX 300 CTX 300 (TOX

and OX)

CTX 300 (TOX

and OX)

without display

CTX 300

SC and

CO2

without

display

Output

signal voltage 4-20 mA 4-20 mA 4-20 mA

Number of

wires 3 wires 3 wires 2 wires 3 wires

Max.

impedance

(Z) of the line

Refer to the characteristics for the central controller

The CEX 300 sensor only connects to INDUSTRIAL SCIENTIFIC

central controllers

5Here, the CEX 300 case is equipped with a grounding reclaim screw to connect the cable armor to the ground cable.

8

a) Connection of a 3-wire sensor to an INDUSTRIAL SCIENTIFIC central controller

- 1 wire (+) continuous power supply →No. 3

- 1 wire (-) continuous power supply (0 volt mass) →No. 2

-1 output signal wire →No. 1

b) Connection of a 2-wire sensor to an INDUSTRIAL SCIENTIFIC central controller

-1 wire (+) →No. 3

-1 signal wire →No. 1

c) Connection of a 3-wire CTX300 sensor to a non-INDUSTRIAL SCIENTIFIC controller and

to an internal power supply.

(R) Maximum resistance = 200 Ω.

(1) 15 ≤ VCC ≤ 32

18 ≤ VCC ≤ 30 for CO2

Max I: 130 mA

1

2

3

Control Unit

Detector

+ 24 Vcc

GND

Signal

3

2

1

Control Unit

Detector

+ 24 Vcc

Signal

3

2

1

3

2

1

-

Power

Detector

Control

Unit«

other »

3

2

1

+ 24 Vcc

GND

Signal

+

R

(1)

Formant la boucle de courant 4/20 mA sur 2 fils

9

d) Connection of a 2-wire 4-20mA sensor to a non-INDUSTRIAL SCIENTIFIC controller and to

an internal power supply.

(1) 15<VCC<32V Max I = 30 mA

e) Connection of two CEX 300-type EXPLO sensors to the same measuring line

(1) and (2) Check to ensure that terminals 1 and 4 are not connected

This only applies when the 2 sensors are located in the same room, protecting the same installation.

Control

unit

« other»

(+)

(1)

signal

ALIM

1

2

3

Detector

-

+

24 Vcc

Cable 4 wires

(2)

Cable 3 wires

CONTROL

UNIT

1

2

3

1

2

3

1 2 3 4

4 3 2 1

Sensor 2

Detector CEX 300 Nb1

Detector CEX 300 Nb 2

Junction Box

Ref. 6313539

Sensor 1

1

2

3

4

1

2

3

4

(1)

10

2.4. Operating mode

a) CTX300 with display

- Remove the 4 screws (Ref. 1 in Fig. 1)

- Remove the cover (Ref. 2 in Fig. 1)

- Gently remove the screw (Ref. 3 in Fig. 2)

- Completely remove the screw (Ref. 4 in Fig. 2)

- Turn the display circuit as shown above (Ref. 5 in Fig. 3)

- Connect the cable (see 2-3: Connections for the various types of sensors) to the connector (Ref. 6,

Fig. 3)

- Return the display circuit to its original position and replace the cover

b) CEX 300 and CTX 300 without display

- Lift the cover (Ref. 1 in Fig. 1)

- Remove the cover (Ref. 2 in Fig. 2)

and proceed to wire the sensor according to the terminal location

FIG. 1

Ref. 2

Ref. 1

FIG 2

Rep3

Rep4

FIG. 3

Ref. 6

FIG. 2

Ref. 3

Ref. 4

Ref.

11

III. POWERING UP AND USE

1 Powering up

The sensor turns on when connected to a power supply. If the sensor has a display, the green LED

will be lit (Ref 1 in Fig 4) and a value will appear on the display screen (Ref. 2 in Fig 4).

Fig. 4

In case of a problem, verify that the maintenance switch (Ref. 1), located on the main circuit is in

the “MES” (measure) position.

Ref. 2

Ref. 1

Fig. 6

Ref. 1

CIRCUITBOARD CTX 300 SC

Ref. 1

Fig. 5

CIRCUITBOARD CTX 300

CAL

MEAS

12

CO2CIRCUIT

Fig. 7

2. 4-20 mA analog output

For CTX 300 sensors, except for the CO2sensor, the 4-20 mA output current is proportional to the

gas level.

Notes:

•The CO2sensor can be equipped with a linearization board.

•MX 15 and MX 32 central controllers that integrate with the linearization of the CO2sensor are

available upon request

•The MX6 2 integrates with the linearization of CO2sensors.

The various states of the output current include:

•≤1 mA to indicate a fault

•2 mA in “calibration” position (except for the CO2sensor that does not have a calibration

function)

•between 4 and 20 mA for measurement values

•≥ 20 mA if levels exceed measurement range

IV. Maintenance

Warning: The adjustment operations in this paragraph are reserved for authorized, trained personnel

because they may compromise detection reliability.

Gas detectors are safety devices. In consideration of this, Industrial Scientific recommends regular

testing of fixed gas detection installations. This type of test consists of injecting a standard gas of

sufficient concentration into the sensor to set off the pre-adjusted alarms. This test does not, in any

event, replace a full calibration of the sensor.

Industrial Scientific also recommends completely calibrating detectors with a known and certified

concentration of gas every three or four months.

Frequency of gas testing depends on the industrial application in which the sensors are used.

Inspection should occur frequently during the months following installation startup, later it may be

spaced out if no significant problem is observed. Time intervals between tests should not exceed

three months.

13

If a detector does not react upon contact with gas, it must be calibrated. Calibration frequency

should be adapted based on test results. However, it should not be greater than one year.

Industrial Scientific recommends using a test gas to calibrate detectors.

The site manager is responsible for implementing the safety procedures on his site. Industrial

Scientific is not responsible for implementing safety procedures.

The CEX 300

To reach a SIL Capability 1 level according to European standard EN50402, (requirement relative

to the functional safety of fixed gas-detection systems), the maintenance period for explosive-gas

detectors must be no more than six months. In SIL2 level installations, the maintenance period must

be at most three months.

These recommendations are compliant with the standards and directives for safety in industrial

sites. Nevertheless, Industrial Scientific – Oldham shall not be held responsible for safety

procedures put into effect on a site.

1. Calibration

1.1. Recommendations

Calibration consists of adjusting the zero of the clean air sensor and adjusting sensitivity with a test

gas. Adjustments are made at the sensor level or on the control unit (as for CEX 300).

To adjust settings (ZERO and SENSITIVITY) on the control unit, refer to the notice displayed

therein.

Equipment needed to calibrate the detector correctly:

-flexible plastic tubing (Ref. 1)

-manometer + regulator valve for the compressed gas tanks (Ref. 2 – Fig. 8)

-0 to 601/h flow meter (if the tank is not equipped with one).

-calibration pipe (Fig. 8 – Ref. 3), which may vary depending on the nature of the gas (see

Annex)

-one tank of test gas (Ref. 4)

Ref. 1

Ref. 2

Ref. 3

Ref. 4

Fig. 8

14

Zero adjustment should be performed in a gas and vapor free area. If this is not possible, synthetic

bottled air can be injected at a rate of 60l/h.

Use a bottle of test gas to adjust sensor sensitivity (concentration close to the alarm threshold or

corresponding to 30% of the measurement range at a minimum). The recommended rate is 60l/h.

Note: When dealing with dangerous gases, you MUST consult a specialized INDUSTRIAL

SCIENTIFIC technician or use another sensor pack recently pre-calibrated at a factory.

Note: The detector should be calibrated using the intended flow-rate. The actual concentration of

gas may be underestimated if the detector was calibrated with too high of a flow rate.

IMPORTANT: For CEX 300 sensors, the calibration gas should contain 21% oxygen.

1.2.CEX 300 calibration

PROCEDURE

CONTROL UNIT DETECTOR

Put the line in calibration mode

Wait for the signal to stabilize and adjust the zero

on the display using the corresponding “ZERO”

potentiometer

Wait for the signal to stabilize and adjust the

sensitivity according to the calibration gas

Return the measuring line to normal operation mode

Determine if the air is clean. If not,

inject the sensor with synthetic or reconstituted air at a

flow rate of 60l/h.

Inject the recommended calibration gas at a flow rate

of 60l/h.

Stop injecting the sample gas and remove the

Gas injection pipe – Then wait and verify that the

sensor returns to ZERO (if not, repeat procedure)

CALIBRATION COMPLETE

15

1.3.CTX 300 calibration

Method 1: CTX 300 with display (excluding O2, see page 17)

The sensor is operating: the green light (Ref. 1, Fig. 10) is lit and the display screen shows the

measurement level.

Flip the maintenance switch (Ref. 2, Fig 9) into the “CAL” (calibration) position: the yellow light

(Ref. 3, Fig. 10) will be lit and the sensor will send a 2 mA current to the central controller

(maintenance mode).

Verify that the sensor is located in a clean-air environment. If not, inject synthetic air at a flow rate

of 30 l/h.

Wait for the measurement to stabilize (displayed on screen) and adjust the ZERO by using the

ZERO potentiometer located on the sensor pack. (Ref. 1, Fig. 11)

Inject the recommended calibration gas at a flow rate of 30 l/h.

Wait for the measurement to stabilize and adjust the sensitivity by using the sensitivity

potentiometer located on the sensor pack. (Ref. 2, Fig. 11)

Ref. 2

Ref. 3

Fig. 9

Ref. 1

CAL

Fig. 11

Ref. 1

Ref. 2

Fig. 12

16

Stop injecting the calibration gas. Remove the gas injection pipe, then wait and verify that the signal

returns to ZERO (repeat procedure if it does not).

Flip the maintenance switch into the “MES” (measure) position. The yellow light will turn off.

CALIBRATION COMPLETE

Method 2: CTX 300 without display except for O2– SC – CO2

The sensor is operating:

Flip the maintenance switch (Ref. 13, Fig 5) into the “CAL” (calibration) position: the sensor will

send a 2 mA current to the central controller (maintenance mode)

Verify that the sensor is located in a clean-air environment. If not, inject synthetic air at a flow rate

of 30 l/h (follow the instructions included in the calibration kit)

Connect a voltmeter to the V+ and V- terminals (caliber mV/DC) (Ref. 1, Fig. 13).

Wait for the signal to stabilize and adjust the ZERO by using the ZERO potentiometer located on

the sensor pack. (Ref. 1, Fig. 14) The output signal should be 0m V

Ref. 1

Ref. 2

Fig. 14

Ref. 5

-

V

+

Rep1

Fig. 13

MES

CAL

17

Now inject the recommended test gas at a flow rate of 30 l/h (use the calibration kit and follow all

recommendations)

Wait until the signal has stabilized, read the mV value on the voltmeter (Fig. 13, rep 1), with the full

scale at 1600 mV, calculate the value to be read as a function of your test gas. Adjust using the

potentiometer (Fig. 14, rep 2).

Example: CO sensor scale 0-300 ppm / test gas injected at a content of 100ppm

Reading

533 mV

Shut off the calibration gas injection and withdraw the gas injection pipe. Then wait and check that

the scale has returned to zero (otherwise repeat the procedure).

Switch the maintenance on/off switch to the “MES” (measure) position (rep 5, Fig. 3)

1.4. COX 300 Calibration, “OXYGEN” type

COX 300 “oxygen” with display screen.

See paragraph 1 – 3 (Method 1). Proceed with adjusting sensitivity ONLY by injection of test gas.

COX 300 “oxygen” without display screen or diodes (DEL)

See paragraph 1 – 3.( Method 2). Proceed ONLY with sensitivity adjustment.

Signal value in mV =

-1600 mV for full scale = 30% O2

-1115 mV for 20.9 % O2

-0 mV for 0% O2

Notes:

The signal sent from the CTX/COX 300 (toxic or oxygen) sensor to the central controller can be

measured on the main circuit by connecting a millivoltmeter to the pins designed for this purpose

(Fig. 16).

-400 mVCC 4 mA

-2 VCC 20 mA

-

V

+

Circuit principal du capteur

Fig. 16

18

1.5. CSC 300 (semiconductor) calibration

Flip the switch (Ref. 1, Fig. 17) into the “CAL” position.

Ensure that the sensor is in clean air, otherwise inject synthetic air into it using the calibration kit

and referring to the recommendations below:

Important:to correctly calibrate a sensor equipped with a semi-conductor cell, use of a

humidifier kit is MANDATORY (ref: 6335919) – Fig. 18

USING THE HUMIDIFIER KIT

Lift the lid (Fig. 18 ref. A) and, using a washbottle, moisten the filter, without saturating it, with

distilled water.

Replace the lid and check that all parts are properly assembled and that the assembly is fully

airtight.

Adjust the flow rate to 60 l/h and wait 10 minutes until the humidifier is fully purged.

Apply the gas introduction pipe to the nose of the sensor and wait at least five minutes for the

measurement to stabilize.

Note: the sensor must be powered for at least two hours before any adjustment can be made.

Connect a voltmeter as indicated (Fig. 19 – Ref. 3) and adjust, using potentiometer P5 (Fig. 19, Ref.

1). The output signal must be equal to 880 mV.

Rep 1

Fig. 17

Circuit du capteur CTX/CSC 300

MES

CAL

Vers capteur

Entrée gaz

Fig. 18

Gas

To detector

19

Next, inject the calibration gas at a flow rate of 30 l/h (See Annex 2).

Wait for the signal to stabilize and adjust the signal with the sensitivity potentiometer (Ref. 2, Fig.

19).

The output signal should be:

EXAMPLE:

Sensor measure (% of full

range)

Output signal (mV)

0 880

50

2640

100 4400

Stop injecting the calibration gas and verify that the reading returns to zero (880 mV). If it does not,

repeat the procedure.

CALIBRATION COMPLETE

Flip the switch (Ref. 1, Fig. 17) into the “MES” position.

1.6. CTX300 CO2calibration

Warning: the sensor should be turned on for 15 minutes before adjustments are made.

The following text describes the steps necessary to adjust the transmitter (first calibration)

Fig. 20

(P 5)

Ref. 1

Ref. 2

V

Fig. 19

Ref. 3

U = 880 mV + 3520 mV

Sensor measurement range

S3

S2

S1

1

2

3

ISC Devices

20

! ! WARNING! !

Adjustment

If the current loop of the output signal has an impedance of 500 ohms, the power supply should

never fall below 23 V DC.

OUTPUT SIGNAL ZERO ADJUSTMENT = 4 mA

Inject nitrogen at a rate of 30 l/h.

On the X1 terminal board, place an ammeter between terminals 1 and 2 (-). With the

potentiometer Z, adjust the current to 4 mA.

With the ammeter still connected, inject the test gas at a rate of 60 l/h. Adjust the sensitivity

with the potentiometer S (Ref. 1, Fig 21). Refer to the following calibration curves for sensors

without linearization cards.

If this fails, flip the J2 jumper and begin again.

Fig. 21

1.7.CTX300 CO2 Linearization card

If you use a linearization card, the connection is the following :

Ref. 1

J2

S

21

CALIBRATION

CURVES

CO2 – IR Transmitter Output Signal

This manual suits for next models

5

Table of contents

Other Industrial Scientific Gas Detector manuals

Industrial Scientific

Industrial Scientific TANGO TX2 User manual

Industrial Scientific

Industrial Scientific Radius BZ1 User manual

Industrial Scientific

Industrial Scientific Ventis Pro Series User manual

Industrial Scientific

Industrial Scientific MX62 User manual

Industrial Scientific

Industrial Scientific Oldham MX52 User manual

Popular Gas Detector manuals by other brands

Wizmart

Wizmart NB983 installation instructions

Duomo

Duomo HCF100 Operation

Autronica

Autronica AutoPath HC800 instructions

Atest Gaz

Atest Gaz SmArtGas 4 user manual

Crowcon

Crowcon IRmax Installation, Operating and Maintenance Instruction

S&S Northern

S&S Northern Merlin GDP4 Installation operation & maintenance