wizmart

2 32-0049-r01_2013-12

Wizmart Technology Inc. 2F, 41-2, Sec 1, Chang-an East Road, Taipei 104, Taiwan

© 2013 Wizmart Technology Inc. All rights reserved. All specifications and other information shown were current at the date of publication and

subject to change without notice.

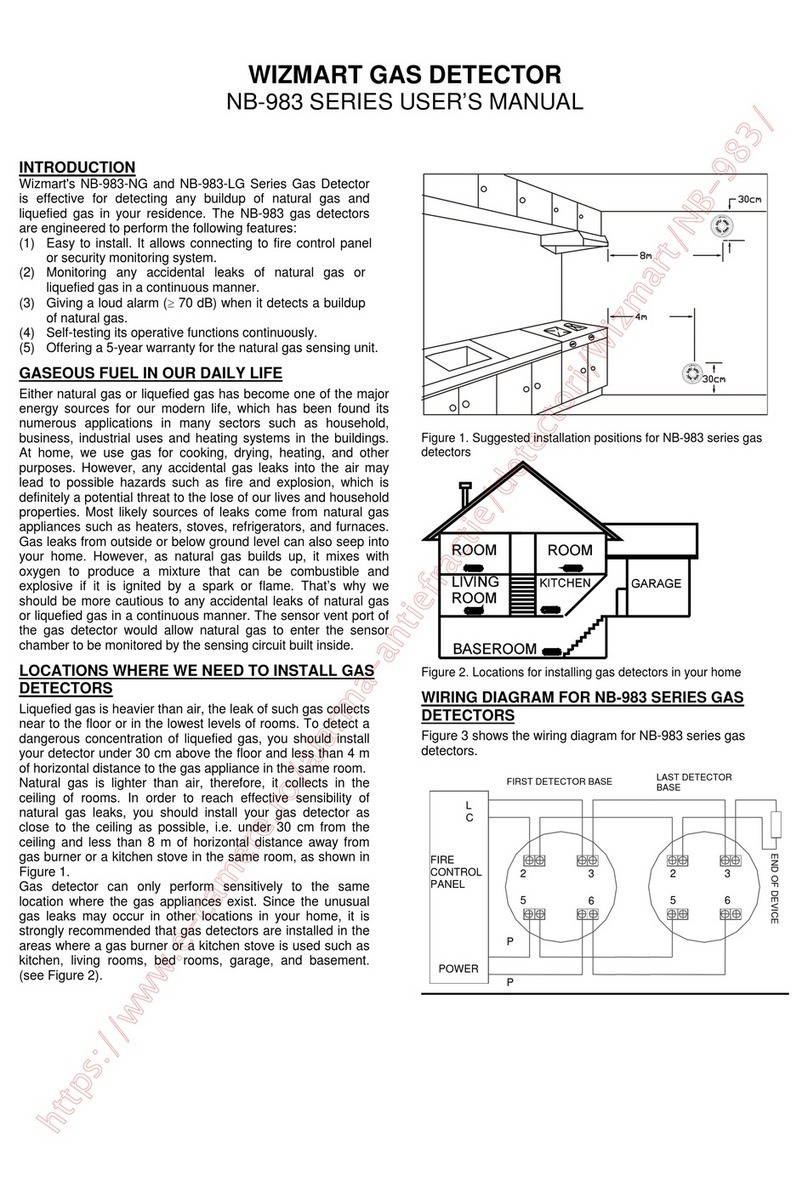

Fig. 3: Adjusting the output relay – NB983-LP and NB983-NG

Detector

WARNING: Do not install the detector head until the area

is thoroughly cleaned of construction debris, dust, etc.

1. Align the components as shown in Fig. 4.

2. Mate the detector head onto the base and rotate it

clockwise to secure it. The home alignment mark

should be aligned with the detector mark.

Fig. 4: Fitting the detector to the base

Commissioning

Equipment

WARNING: Test gases can kill. Use only a purpose-

designed test gas source, pipe and hood for testing. Be

sure to comply with safe handling and use requirements.

Ensure there are no naked flames within the test area.

Gas Detector

1. Ensure all the alarm signal services, releasing devices

and extinguisher systems are disabled during the

commissioning period.

2. Connect power to the detector for approximately

10 min.

3. During the start-up time, check that the green LED

flashes every 0.5 s. If the LED fails to light, it indicates

the detector is not operating. Check the wiring for the

correct voltage and earth leakage. Replace the

detector if necessary.

4. At the end of the start-up time, check that the green

LED lights continuously.

5. Cover the detector with a test hood and release the

test gas for at least 10 s from a test source.

6. When sufficient gas has entered the chamber, the

detector will signal an alarm, by continuous flashing of

the red LED and activation of the internal sounder.

7. Upon alarm, immediately remove the gas source.

8. Wait for the gas to clear and the detector to

automatically reset. The LED will change to green and

the sounder will silence.

9. If the alarm signal is latched at the control and

indicating equipment, reset the control and indicating

equipment.

Hush

1. Cover the detector with a test hood and release the

test gas for at least 10 s from a test source.

2. When sufficient gas has entered the chamber, the

detector will signal an alarm, by continuous flashing of

the red LED and activation of the internal sounder.

3. Upon alarm, immediately remove the gas source and

place a magnet adjacent to the cover of the detector

(see Fig. 2 or 3 for location).

4. Check that the detector enters the Hush condition, the

LED is red and sounder is silenced.

Output Relay

1. Activate the detector using the gas source, as

described above.

2. Monitor the output relay for activation.

3. Wait for the gas to clear and the detector to

automatically reset.

4. Monitor the output relay for reset to its quiescent

setting.

Reed Switch Test

1. Place a magnet adjacent to the cover of the detector

(see Fig. 2 or 3 for location).

2. Check that the detector signals an alarm, by

continuous flashing of the red LED and activation of

the internal sounder.

3. Remove the magnet and allow the detector to

automatically reset.

The auto-reset will typically reset the detector within 30 s

of the removal of the magnet.

Final Conditions

Ensure all the alarm signal services, releasing devices and

extinguisher systems disabled for the commissioning are

returned to their previous condition.

References

Document Description

31-0062 NB983 conventional (non-addressable) gas

detector datasheet

Limited Warranty

Wizmart Technology Inc. declares that this product is free from

defects in material and workmanship and it will repair or replace

any product or part thereof which proves to be defective in

workmanship or material for a period of twelve (12) months from

the date of purchase but not to exceed eighteen (18) months from

the date of manufacture. Please contact Wizmart Technology Inc.

directly for a return merchandise authorization (RMA) number

before returning goods under warranty. Shipment must be prepaid

and Wizmart Technology Inc. will repair or replace the product if

the failure was caused by a manufacturing defect.

View the complete range of

products at www.wizmart.com