INDUSVISION iVEX-PL Series Specification sheet

ProductinstructionManual

NoticeonCopyrightandTrademarkUsage

Productsandcompanynamesmentionedinthismanualaretrademarksor

registeredtrademarksbelongingtothecompany.

WARRANTY

Iftheproductisnotnormallyinstalledduetoadefectundernormaluseconditions,

Themanufacturerwillrepairitfreeofchargethroughtheplaceofpurchase.

Thewarrantyperiodis1years,andthefollowingsituationsareexcludedfromthewarranty.

• Abnormalities caused by product changes over time or natural wear and tear during use

• Damage to fastening parts due to negligence when assembling the product

※Theappearanceandspecificationsoftheproductmaybechangedwithoutpriornotice

toimproveperformance.

iVEX-PL Series

ProductUserManual

• Component information

• Product classification and part names

• About the contents of the manual

• Identification method

• Checklist before product installation

• Select product installation location

• Product installation and precautions

• Maintenance after product installation

• Network connection and settings

• How to set OSD

• Installation Inspection Check Sheet

• Technical drawing

04

05

07

08

10

11

12

16

17

24

25

26

Outline

* CPU: Intel Core 2 Duo 2.4 GHz or higher (when using 1920x1080 30fps)

Intel Core i7 2.8 GHz or higher (when using 1920x1080 60fps)

* Resolution: 1280x1024 or higher (32-bit color)

* Memory: 2GB or more

* Supported OS: Windows XP, VISTA, 7, 8, 10 / Mac OS 10.7 or later

* Supported web browsers: Microsoft Internet Explorer (Ver. 8~11),

Microsoft Edge (Ver. 94 ~118) Latest 118

Mozilla Firefox (Ver. 9~19) Latest 85

Google Chrome (Ver. 15~15) Latest 88

Apple Safari (Ver. 6.0.2) Latest 14

- Windows 8 is supported only in desktop mode.

- Beta version or developer version other than the version released on the

official site Not supported.

- For IPv6 access, Windows 7 or later is recommended.

- Safari Browser is supported only on Mac OS X.

* Video memory: 256MB or more

- The video memory card driver is not installed correctly, or the latest version is

not available. If not, the video may not play normally.

- When using two or more monitors, playback performance may

decrease depending on system specifications.

may fall.

Index PCSystem RecommendedSpecifications

Picture Qty Explanation Picture Qty Explanation

1L-Wrench set

(M5,M4,M3,

M1.5) 1Hex Bolt Set

(M8*15)

1Copper tube

Terminal (M6) 1 Knife block Set

1Spare Bolt

Set 1Product

instruction

Manual

Componentinformation

BasicComponents Optionalcomponents(purchasedseparately)

Before starting the installation, carefully check the following components enclosed inthe product box toensure that no parts aremissing during installation.

Picture Qty Explanation Picture Qty Explanation

1 Wall Bracket 1 Sealing

Bracket

1 Anchor Bolt

iVEX-PL-30 Series

Series

name Model name Details

iVEX-

PL-30

Series

IVEX

-PL-30

Vari

-Focal(2.7-12mm/DC iris) + IP 2M(IMX-307) + ROUND

IVEX

-PL-3011R

Vari

-Focal(3.6-11mm)+ IP 2M(IMX-385) + ROUND

IVEX

-PL-3011RA

Vari

-Focal(2.7-12mm) + IP 2M(IMX-307) + ROUND

IVEX

-PL-3111R

Vari

-Focal(2.7-12mm) + HD 2M(IMX-307) + ROUND

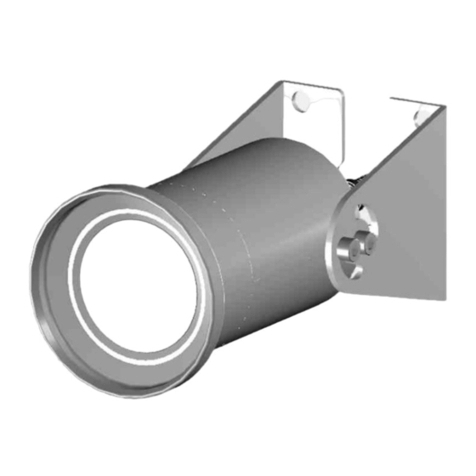

No Detailed name No Detailed name

1

SUN Shield

11

2

Front Cover

12

3

Main Body

13

4

Mount Bracket

14

5

Ring Bracket

15

6

Cable Gland NPT ½”

16

7

Rear Cover

17

8

Ground hole

18

919

10 20

Straight Type

Front Cover Round Type

Front Cover

Please familiarize yourself with the part names of each product as they areimportant to provide fast and accurate service for problems in each part.

Productdivisionandpartnames

iVEX-PL-10 Series

Series

name Model name Details

iVEX-

PL-10

Series

IVEX

-PL-1011R

30X Zoom + IP 2M(Ambarella)+ ROUND

IVEX

-PL-1111R

30X Zoom + HD 2M + ROUND

IVEX

-PL-

1000SGT

+ ROUND( + )

No Detailed name No Detailed name

1

Sun Shield

11

2

Front Cover

12

3

Main Body

13

4

Mount Bracket

14

5

Ring Bracket

15

6

Cable Gland NPT ½”

16

7

Rear Cover

17

8

Ground hole

18

919

10 20

Straight front

cover Type Round front

cover Type

GE Glass +

Protection Grid

Type

Please familiarize yourself with the part names of each product as they areimportant to provide fast and accurate service for problems in each part.

Productdivisionandpartnames

Please read the product user manual carefully before installing and using this product, and keep the manual in a separateplace for future reference.

Aboutthecontentsofthemanual

Safetyrules

1. Explosive hazard

- This product complies with applicable standard code EN/IEC 60079-14, EN/IEC 60079-17,etc.

Installation andmaintenancemust be performedby qualifiedpersonnel accordingto national

standards.

- Do not openthe product while power is supplied within an explosion-proofarea.

- Installation of the product should be carried out using appropriatetools.

- The manufacturer recommends using explosion-proof tools.

- Connection testing and maintenance work in non-hazardous areas is recommended.

- Groundingis essential to reduce therisk of ignition of products installedin explosive

environments.

- The device must be connectedto protective earth.

At this time, it is recommended to use an approvedmaterial for thegrounding cable.

- Before turning on the product in a potentiallyexplosive place, check that the connectionparts

such as cable glands are properly closed. Check it out.

- If the surface temperature of the device is raised by direct sunlight exposure, the device's surface

temperature rating is rated against direct sunlight.

It is judged only by ambient air temperaturewithout consideration.

- Ensure that all devices are certified for the application and the environment in which it is installed.

- Any changes not approved by the manufacturer are not guaranteed.

2. Risk of electric shock

- When installing or performing maintenancewith the breaker turned on, make sure that the

product is turnedoff.

- A power-off device must be included in the electrical installation and can be recognizedvery

quickly and turned OFF when necessary. Need to check.

- An earth leakage breakerwith a maximum of 16Ais recommendedfor the electrical installation

to which the device is connected.

-The minimum gap between circuit breaker contacts must be 3 mm (0.1”).

- Do not useworn or corroded cables.

- All cablesmust comply with IEC 60332-1-2,IEC 60332-1-3 andIEC/EN 60079-14.

- When installing and operating, the characteristics of the power supply provided by the facility

and the characteristics of the power supply required by the product match Check if you do

- This product is not suitable for use in locations where children may be present.

3. Work attention

- Confirm that the installation methodmeets the explosion-proof regulationsand specifications.

After connection,it is recommendedto install aftertestingin a non-hazardousarea before

installation in the field.

- Use an appropriate cable that can withstand the operating temperature.

- All unusedcables must be electrically insulated.

- This product can only be installed in standard locations.

- Proceed with the installation after confirming whether the power supply source of the product is

PoE or DC power and the appropriate power source.

- Unauthorized modification by the manufacturer, use of non-genuinespare parts, unauthorized

use. Damage caused by installation, maintenance and repair by unskilled personnel

We accept no responsibility for any damage to the instrument.

- For technical service, refer only to authorized technicians.

- This product should only be repaired by properly trained personnel or under the supervision

of the manufacturer's personnel.

- When repairing, use only the manufacturer'sgenuine parts.

4. Understanding the installation process

- Installers must comply with general accident prevention standards when handling the product.

- Before proceedingwith the installation, compare/checkwith the componentsin the user

manual to check whether they match.

- Equipment installation in explosion-proof areas must be performed by professional technicians.

- The manufacturer assumes all responsibility for damages caused by improper use of the

device mentioned in this user manual.

doesn't support We also reserve the right to changesome parts without comment.

- It is the responsibility of the user to select the surfaceon which the productis to be fixed, so

there are instructions for attaching the product to a specific surface

Fixtures are not provided. It is the installer's responsibility to select the appropriate fixture for

their particular application.

Use installation methods and materials capable of supporting at least four times the weight of

the product.

- For all product maintenance, we recommend that you receive repairs by sending the product to

the manufacturer.

[KOR Ver.]

,

[JPN Ver.]

,

[ENG Ver.]

Identificationmethod

Productspecificationinspection

Explosion Proof Certification Label Description

Precautions

Manufacturer and address

Model name

Serial number: 10 digits of product model code –2 digits for

production year and month –consists of manufacturing serial number

Operating temperature: Ambient temperature (-40˚C≤Ta≤+Tx˚C,

-40˚C≤Ta≤Tx˚C or Tx˚C)

T Class (Tx or Tx... Tx)

IP protection level

Maximum surface temperature (Tx˚C or Tx˚C... Tx˚C)

Safety certification number

Safety certification issuing authority

Identificationmethod

Certification IVEX-PL-3X Series Certification Number

IECEx IECEx DEK 15.0030X

ATEX DEKRA 15ATEX0051X

JPEx DEK18.0011X

KCs 22-KA2BO-0609X~0620X

Certification IVEX-PL-1X Series Certification Number

IECEx IECEx DEK 15.0030X

ATEX DEKRA 15ATEX0051X

JPEx DEK18.0010X

KCs 22-KA2BO-0609X~0620X

• Manufacture : Shinhwa Industrial Electric.

• Entry threads : NPT 1/2”-14 According to ANSI/ASME B1.20.1

• Model No : ECG

• Protection type : Ex d ⅡC, IP65

• Certi. No : KGS 16-GA2BO-0835

• C.B : Korea Gas Safety Corporation

• IP Rating : IP65

• Operating Temperature : -60˚C to 100˚C

• Manufacture : OSCG.

• Entry threads : NPT 1/2”-14 According to ANSI/ASME B1.20.1

• Model No : OS-A2F-U

• Protection type : Ex d ⅡC, IP65

• Certi. No : IECEx PRE 17.0062X , Presafe 17 ATEX 11454X

KCS 18KA2BO-0364X

• C.B : Korea Testing Laboratory

• IP Rating : IP66/67

• Operating Temperature : -60℃~110℃

• Manufacture : Hummel AG

• Entry threads : NPT 1/2”-14 According to ANSI/ASME B1.20.1

• Model No : EXIOS A2F NPT 1/2” 9~16mm, INOX 1.4404

• Protection type : Ex d e IIC Gb, Ex ta IIIC Da

• Certi. No : IECEx DEK 12.0039X

• C.B : DEKRA Certification B.V.

• IP Rating : IP66, 67 and 68(5bar)

• Operating Temperature : -60˚C to 105˚C

• Model No. : DONG A Bucheon Korea CE1180

(A2FC 20-C (M)NPT1/2” X (F)NPT1/2”)

• Entry Threads : NPT 1/2”

• Protection Type : Ex db IIC Gb, Ex eb IIC Gb, Ex tb IIIC Db

• Certificate No : Baseefa08 ATEX 0011X / IECEx BAS08.0003X

• BS, IEC & CENELEC According to Zone1,Zone2, Zone21,

Zone22, gas group IIA, IIB, IIC Suitable for use in

• IP Rating : IP66, IP67

• Operating Temperature : -60℃~+100℃

Cable gland inspectionProductCertificationNumberInspection

No L wrench specification No L wrench specification

1

M5 (Equippedwith sun shield)

11

2

M4 (Ground

-coppertube terminal) 12

3

M1.5 (Front cover tanning bolts)

13

4

M5 (Mount bracket)

14

5

M3 (Ring bracket)

15

616

717

818

919

10 20

Check the packing box

- When delivering the product, check that the packaging is intact and has not

been dropped or torn.

- In the case of returning a broken product, we recommend that you reuse

the packaging box provided for transportation. Recommended.

- The box label attached to the product box contains the information shown in

the picture above.

- Before discarding the box, back up the information entered on the label to

prevent product operation problems. wish.

Safe Disposal of Packaging Materials

- Among packaging materials, PE foam, excluding paper, is subject to

separate discharge. Therefore, please separate and dispose according to

the separate collection method or regulations.

[Box]

[IVEX-PL-30]

[IVEX-PL-10]

Checklistbeforeproductinstallation

Check the specifications of the L wrenchCheckproductoperationinformationandappearancestatus

* On the product label on the product packagingbox and on the

tag on the sunshield portion of the product

After checking the information necessary for initial operation

such as IP address, ID, password, etc. Keep it so you don't lose it.

When selecting the initial location to install the product, consider the following.

If the environment in which the product is installed is smaller than the bottom size of the product's mount bracket, there is a risk of the product falling, making it unsuitable for installation.

Check if the size of the mounting part, such as the ‘wall mount bracket’ and H-beam, provided by the manufacturer is suitable for installation.

Check that the environment where the product is installed is not an area where lightning often occurs, and install it in a place where there is no influence of lightning if possible.

If the environment in which the product is installed receives many external factors such as high temperature, high humidity and low temperature due to direct sunlight,

it is recommended to avoid this influence.

In preparation for the length of the wall bracket in the environment where the product is installed, the calculated length of the curvature of the product and flexible must be reflected

and installed.

After receiving the product, be sure to remove the protective sponge inserted in the back of the cable gland to prevent damage to the cable sheath while moving the product.

If the environment where the product is installed has severe vibration, it may affect the image, so it is recommended to install after attaching a device that can attenuate vibration such

as a separate damper.

If the environment in which the product is installed is poor and the weight of the product (about 5Kg) cannot be supported, safety may be a problem, so it is recommended to install

it in another safe place.

Selectproductinstallationlocation

When selecting a location to install the product, be sure to install it in a place that does not have any inconsistenciesas in the case below.

Thingstoconsiderwheninstallingtheproduct

- First, select the installation method from the picture above.

- Place the base bracket where it will be installed and mark the perforation point.

- Insert the knife block provided with the product into the perforation.

- Insert the cross piece provided with the product into the knife block position on the

bracket.

- Loosen the bolts on the base bracket slightly to adjust the height and level of the

video and finish.

- Equipment for wall perforation is not provided.

[Floor installation] [Wall mount] [Ceiling installation]

The manufacturer is not responsible for any problems caused by installing a bracket other than the genuine bracket provided by the manufacturer.

Productinstallationandprecautions

Installationusingtheproduct'smountbracket

- The wall mount bracket can be fixed on a vertical wall.

- The sealing bracket can be fixed to the ceiling surface.

Attach the bracket to the wall with the supplied set anchors capable of withstanding

at least four times the weight of the unit. Please fix.

- Then, fix the device to the bracket using the supplied hex bolt SET.

At this time, check that there are no foreign substances in the thread or fastening hole

of the product.

- After applying enough locking compound (Loctite 263) on the 4 bolts, tighten the bolts.

lock.

- The thread compound should set for one hour, during which time the installation

should be completed.

- When tightening the bolts, tighten the torque to 35Nm.

[Loctite 263] [Loctite 263]

Installationusingwallmountbracketsandceilingbrackets

Productinstallationandprecautions

- When installing the two types of wall brackets provided by the manufacturer,

depending on the wall bracket model

The installer should be aware that the method is not applicable.

- It is recommended to install the camera through the method of , ,

suggested in the manual.

[WB-02Use] [WB-01Use]

The manufacturer is not responsible for product failure damage caused by lightning or surge caused by improper grounding of the product.

WallBracketUsageGuide

- Product grounding must be performed using an external cable (12AWG) with

a cross section of 3mm².

- The lug to be used for connection to the grounding power supply is connected

to the grounding copper tube terminal provided with the product.

Use the M5*8 (wrench bolt) screw and fix it to the ground hole with the

provided L wrench.

- A separate crimping machine is required for crimping copper tube terminals.

At this time, the manufacturer does not provide a separate press.

•M5 copper tube terminal

•Material: copper, tin alloy

Ground(ground)installation

OK OK OK

Productinstallationandprecautions

Connect the product and explosion-proof installation materials in the order below.

IVEX-PL Series products

Elbow ( NPT ½” to NPT ½” )

Reducer ( NPT ½” to PF 22 )

EXP-Flexible ( PF 22 to PF 22 ) –Length: 700mm

Cable gland ( PF 22 to PF 22 )

Joint box ( PF 22 )

Plug ( PF 22 )

Cable gland ( PF 22 to PF 22 )

EXP-Flexible ( PF 22 to PF 22 ) –Length: 700mm

Steel wire pipe ( PF 22 )

When using a sealing fitting + nipple instead of a cable gland, the inside of the sealing

fitting must be Please finish with compound.

Among the explosion-proof installation materials below, cable glands can be replaced with sealing fittings.

Installationusingexplosion-proofinstallationmaterials

Connect the product and explosion-proof installation materials in the order below.

IVEX-PL Series products (integrated explosion-proof armored cable)

Cable gland ( PF 22 )

Joint box ( PF 22 )

Plug ( PF 22 )

Cable gland ( PF 22 to PF 22 )

EXP-Flexible ( PF 22 to PF 22 ) –Length: 700mm

Steel wire pipe ( PF 22 )

When using a sealing fitting + nipple instead of a cable gland, be sure to clean the

inside of the sealing fitting. Please finish with compound.

Installationusingarmoredcables

When working with the network cable through the RJ-45 tool, it is essential to check through the tester

as there is a possibility of network failure due to miswiring or operator error.

- The IVEX-EMC-300 Teflon cable in is a dedicated 8P network cable.

Therefore, according to the site situation, after cutting according to the length of the

cable, refer to the line arrangement in the figure . Cable length can be adjusted.

- The IVEX-EMC-A302 explosion-proof armored cable in is a dedicated 8P network

explosion-proof cable.

Therefore, according to the site situation, after cutting according to the length of the

cable, refer to the line arrangement in the figure . Cable length can be adjusted

- The IVEX-EMC-200 multi-cable in is a multi-output cable.

Therefore, it is impossible to adjust the length, and the length initially provided by the

manufacturer is used. Any excess length of cable must be handled inside the joint box.

Also, this cable needs to be connected with the OUTPUT cable, and this connection

must be made with a joint It must be done inside the box.

1

8

1

8

[IVEX-EMC-300 Teflon]

[IVEX-EMC-A302 Explosion proof armor]

[IVEX-EMC-200 Multi]

[CVBS –14.5Ø ]

[NETWORK(Female)–20Ø ]

[DC INPUT –15.7mm]

Productinstallationandprecautions

Configurationdiagramforeachbuilt-incable

- Like , PoE connection can be made using the terminal block inside the joint box.

At this time, No. 4,5 of the RJ45 array are ‘+’ and No. 7,8 are ‘-’, and No. 1,2,3,6 are

connected to the terminal block.

Connect 1, 2, 3, 4, pair 4, 5 to 5, pair 7, 8 and connect to 6 Can be used.

- As shown in , you can use the RJ45 connector as it is and use a coupler to

connect easily. can.

However, coupler terminals may be corroded due to moisture in the joint box, which

may cause poor contact. there is.

- As shown in , multi-cables can be connected to each cable connected to the

explosion-proof junction box. there is.

At this time, after connecting the CVBS (or AHD output) terminal and RS-485

terminal, be sure to insulate them.

It is taped with tape, and it is taped in the same way after connecting multiple cables.

to maintain insulation from external leakage current.

[Terminalblock]

[Coupler]

[Multi cable]

[Joint box] [PoE Hub]

[Explosion proof

junctionbox]

Connectiondiagrambetweenjointboxes

Maintenanceafterproductinstallation

- Regular cleaning should be performed so that no more than 5mm of dust

accumulates on the surface of the product. do. (for anti-static purposes)

- Tempered Glass Glass should be cleaned with mild soapy water diluted with

water.

- Be sure to clean the surface of the device with a damp cloth.

When replacing or maintaining the camera, be sure to move to a safe area, not an explosion-proof area.

Periodiccleaning Disassembly/assemblyofproductsforinspection

- After separating the sun shield and mount bracket as shown in ,

disassemble the ring bracket and remove the bolts on the exterior.

Remove all.

- As shown in , remove the head bolt on the top of the main body and turn

the main body clockwise. disassemble.

- You can inspect the module inside by disassembling the front cover + main

body assembly as shown in . there is.

- When disassembling the product, it must be disassembled/inspected in a

place without ambient moisture, and For dew condensation caused by

moisture inflow during disassembly/inspection, the manufacturer

not responsible.

NetworkConnectionandSetup

- Run the Internet browser of the local PC.

- Enter the IP address of the camera you want to access in the browser's address bar.

- From a remote PC on the external Internet in a LAN environment to a camera installed

in a LAN environment When connecting, if port forwarding is not done or if a firewall is

installed, the connection is not possible. may not be

In this case, contact your network administrator.

-When the product is shipped, the IP address is a fixed IP as in ‘Checking product

operation information and appearance status’ It is set.

InstallingthecameradirectlyinaLAN environment

- Direct connection between user computer and network camera.

-Use the IP Search program to find the IP address of the camera from the user’s

computer to the Internet.

Change it to an IP address that can be accessed through a browser.

- Connect to the web viewer using an internet browser.

- Move to the [Setup] page.

- Go to [Network] - [DDNS] setting page and set DDNS.

- [Basic] - Go to the [IP & Port] setting page and set the IP type to [DHCP].

- Disconnect the camera from the user's computer and connect it directly to the modem.

- Reboot the camera.

Installingthe camera directlyin aLAN environment

You can set the network environment of the camera according to the user's network connection configuration.

Switch

CAMERA

CAMERA

Local PC

Internet

DDNS Server

(Data Center, KOREA)

CAMERA Internet

External remote pc

DDNS Server

(Data Center, KOREA)

DSL/Cable Modem

External remote pc

NetworkConnectionandSetup(IVEX-PL-10Series)

The IP address range of the user's computer and the IP address range of the camera must match for normal web viewer access.

- If there are more than 2 cameras, camera 1 (192.168.0.3), camera 2

(192.168.0.4), etc. Set different IP addresses and use the same subnet

mask and gateway.

- HTTP Port: HTTP used when accessing the camera using an Internet browser Port,

the initial value is 80.

- RTSP Port: This is the port that controls real-time streaming, and the initial value is 554..

Tip Tip

UsingtheIPSearchprogram PCnetworksettingsdependingonwhetheranIPsharerisused

- Click the icon such as on the IP Search program downloaded to the user's computer

Run.

- When the IP Search program is executed, click icon to start IP search.

If the IP address is normally searched as shown in , double-click the searched IP

address to open the web viewer.

can connect. (default IP address: 10.20.30.40 / ID: root / PW: root)

- If you need to change the IP address, click the corresponding icon as in the IP

Search program. Click to change IP address.

- As in , connect to the internal network settings of the user's router.

(The menu name or access method may differ depending on the router manufacturer.)

- IP Address: Set according to the private IP range provided by the IP sharer.

Ex) 192.168.1.2~254, 192.168.0.2~254, 192.168.XXX.2~254

- Subnet Mask: If the <Subnet Mask> of the IP router is the <Subnet Mask> of the

camera It's possible.

- Gateway: The IP router's <Local IP Address> becomes the camera's <Gateway> value.

-Check if the IP settings of the same band are set in the network settings of the user’s

computer. Check.

Network settings

Server Name

HTTP Port

IP type Fix

Network

IP address

Netmask

Default gateway

Model Mac Address IP Address IP Type Server Name HTTP Port Version

Set save options

Save settings

Do not Save settings

Certification

Admin ID

Admin Password

Save Cancel

Network settings

Control Panel > All Control Panel Items > Network Connections

Ethernet

Network 1

internal network

settings

advanced settings

internal network settings

IP address

Gateway

Ethernet properties

Protocol version 4 (TCP/IPv4)

Internet ProtocolVersion 4 (TCP/IPv4) Properties

Use the following IP address

IP address

Subnet mask

Gateway

root

root

NetworkConnectionandSetup(IVEX-PL-10Series)

- Run a web browser such as Chrome or Edge on the user's computer.

- Enter the IP address set on the camera into the web browser address bar.

- If you connect to the camera normally as in and press the ‘LIVE’ button on

the top left of the screen, the same as

The ID/PW input window is executed, and input the initial ID/PW ‘root’.

(For security, be sure to change the initial ID/PW after setting.)

- As shown in , you can check the OSD window for PTZ control along with

the output of the live screen. there is.

Webvieweraccess

Web viewer access can be checked in normal operation through Google Chrome and Microsoft Edge browsers.

- There is a SETUP menu that displays the 'ADMIN' icon in on the live

screen. Now.

- You cannot go back to the static IP and DHCP status for the camera IP

address by clicking the 'IP Address' menu.

it's okay. Static IP allows you to change your IP address.

- When all changes are complete, click the 'Apply' button to save the settings.

- After 30 seconds, you can connect to the changed IP address in your

web browser.

ChangeIPSettingsinWebViewer

If the IP address you want to change is an IP address that is being used by

another device in the same band You may not be able to access the web

viewer due to an IP conflict.

When operating the web viewer in Internet Explorer 11, ‘Active X’ must be

downloaded and executed.

Tip Tip

Please log in to access this site.

Authorization required f or H TTP://10.20.30.40

Your connection to this site is not secure.

User Name

Password

Log IN Cencel

NetworkConnectionandSetup(IVEX-PL-10Series)

-Service: Set whether to use RTP/RTSP.

-RTSP Port: Sets the RTSP Port. The default value is 554.

-Packet Size: This is the menu to set the Packet Size to be transmitted via RTP/RTSP.

If the value is low, compatibility with many S/Ws is maintained. It divides and transmits small

amount of packets.

The higher the value, the fewer packets are divided and transmitted.

However, if the program does not support a high value, no video is displayed.

-Keep-Alive: Sends the current camera status through continuous UDP communication. Some

S/W and equipment are not supported.

-RTP Auth Algorithm: Determines the RTP encryption authentication method.

-MD5 is highly compatible with many S/W. If set to SHA256, stronger encryption is applied, but

It cannot be played on S/W or devices that do not support SHA256, such as VLC.

Unicast Primary Stream (1 Channel) : rtsp://camera IP/cam0_0

Unicast Secondary Stream (2 Channel) : rtsp://camera IP/cam0_1

Unicast Tertiary Stream (3 Channel) : rtsp://camera IP/cam0_2

Multicast Primary Stream (1 Channel) : rtsp://camera IP/mcam0_0

Multicast Secondary Stream (2 Channel) : rtsp://camera IP/mcam0_1

Multicast Tertiary Stream (3 Channel) : rtsp://camera IP/mcam0_2

When setting RTSP, you must first check if the ‘554 PORT’ of the router is open.

RTSPsettings

-Press the ‘ADMIN’ icon at the top of the web viewer to enter the SETUP menu.

-Press the ‘UPDATE’ menu as in and click the ‘Fimware Update -> Start’

button at the top of the menu. Click.

- When a pop-up window like appears, click the ‘Select File’ button to specify

the file to be upgraded. do.

-Click the ‘NEXT’ button at the bottom of the pop-up window in to proceed

with the upgrade.

- If the firmware update is not completed normally, the product cannot be used.

- Please note that this problem must be returned to the manufacturer and

repaired.

Tip

Firmwareupdatemethod

This manual suits for next models

7

Table of contents

Other INDUSVISION Security Camera manuals