Inel ST-01RL User manual

1

ST-01RL roller blind control unit

Instructions for installation and use

Safety guidelines

Basic guidelines

The ST-01RL controller can be safely installed and used provided all of the following instructions of installation and use as well as

obligatory health and safety regulations are adhered to.

The installation and repairing of electrical equipment should be carried out only by persons with appropriate legal qualifications.

Reconstructing or making changes to the ST-01RL controller is forbidden. During the guarantee period repairs only the manufacturer

may carry out repairs. Even after the guarantee period has expired only original parts and accessories may be used.

The guarantee is only valid when the ST-01RL controller has been used in accordance with the manufacturer’s instructions. The

boundary values given in the technical specifications must NOT be exceeded under any circumstances.

Supplementary safety regulations

When installing, using or carrying out maintenance work all binding health and safety regulations should be followed. Particular

attention should be paid to the following:

1. European Standards

2. Fire regulations

3. Accident avoidance regulations

GENERAL COMMENTS REGARDING HAZARDS AND SAFETY PRECAUTIONS

.

The following comments serve as general guidelines to the application of INEL drivers with other devices. These

guidelines must always be adhered to when installing and operating these devices

Warning – this signal warns of possible damage to the control system or other equipment if appropriate safety measures

are not taken.

Before installing the control system and setting the end switches check all bolt connections are properly

fastened.

Danger – this signal indicates danger to the user’s life and health if appropriate safety measures are not taken.

Follow all health and safety regulations relevant to the equipment (e.g. gates, roller blinds) used.

When changing fuses the equipment must be first disconnected from the mains, the fuses changed and only then may the

equipment be reconnected to the mains.

The ST-01RL controller should be installed in accordance with appropriate safety regulations and with appropriate safety

devices.

INEL equipment connected to the mains beyond a building’s safety fuse system needs to be installed with its own safe

disconnecting devices (e.g. safety fuses and safety switches) in such a way so as to ensure that all the units may be easily and

safely cut off from the mains.

Electric wiring and cables should be regularly checked to ensure the insulation is intact and there are no breaks in the wire.

If any damage to the wiring is found, the unit should be immediately disconnected from the mains and the damaged wiring

replaced.

Before connecting any equipment, one should first make sure that it is adapted to be used with the local voltage in the mains.

PERSONAL SAFETY WARNING

Do not allow children to play with any of the control devices.

Keep all remote control devices out of the reach of children.

Observe the opening or shutting of the blinds, shutters, awnings or gates and ensure all persons stand clear until the operation

is completed.

Control system operators need to undergo preliminary instruction and training and also be made aware of all the potential

dangers that can be encountered. A person should only be authorised to use the control system only once the employer,

administrator or owner is satisfied that that person has been properly instructed.

It is not permitted to dispose of waste equipment together with other waste. Dispose only in specially designated areas.

2

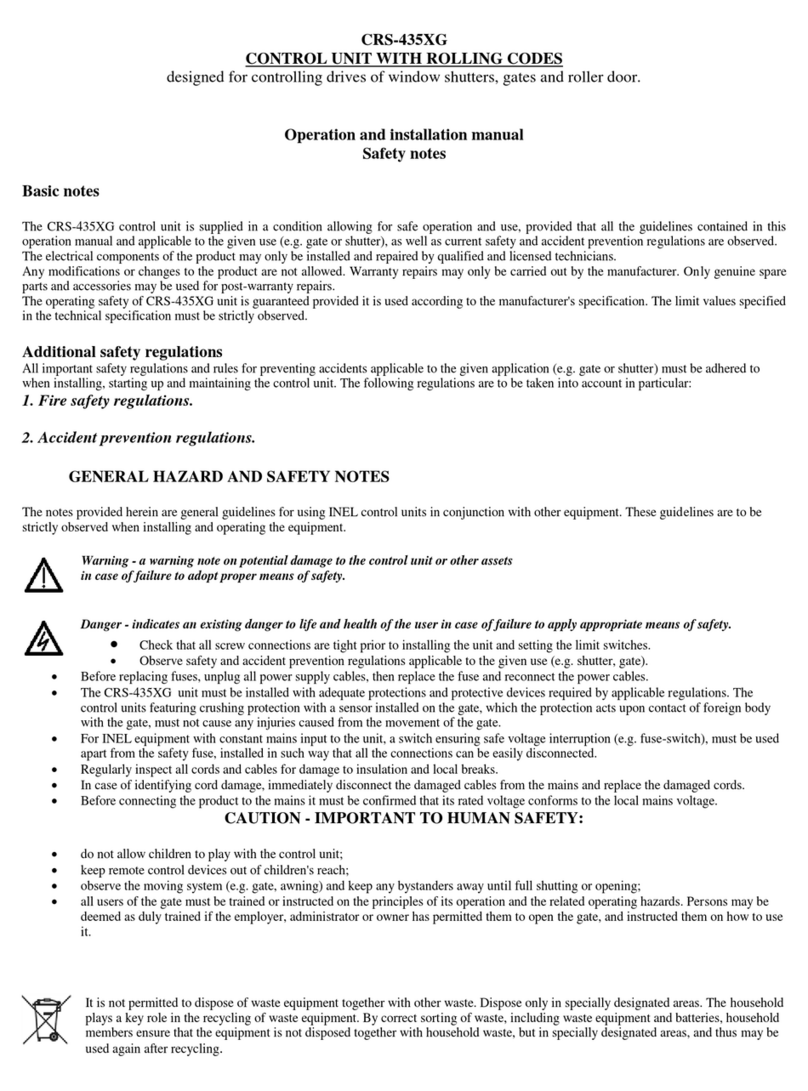

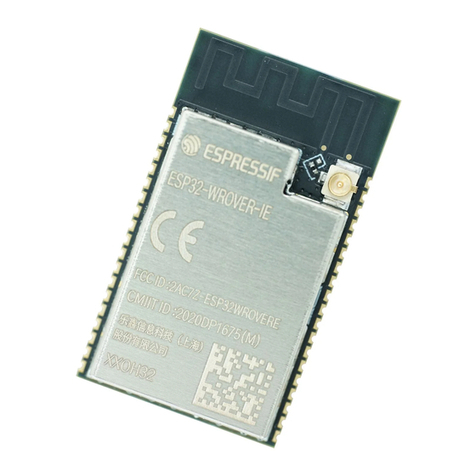

CONTROLLER DESCRIPTION

The controller enables to operate the roller shutters with 230 VAC motors via the following remote controls: PIL-02XT, PIL-02XK,

PIL-02XB, PIL-04XT, PIL-04XB, PIL-01PT, PIL-01/04NS, PIL-01/05/09HT and PIL-99xx. The controller programming method can

be used to configure a flexible roller shutter system control. The roller shutters can be opened and closed individually, in a group or all

at once with a single command. The PIL-99GP remote control enables to program all available roller shutters in the building. The

operation is automatic based on hourly and daily profiles.

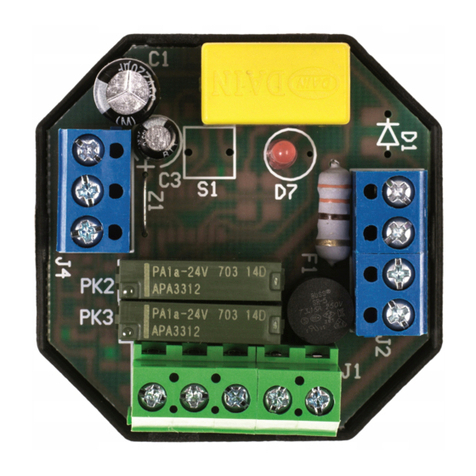

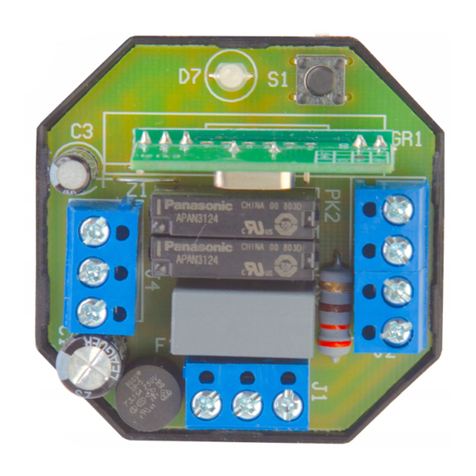

The following figure shows a system consisting of 10 roller shutter controllers grouped in several rooms. The key feature is the

ability to register each remote control channel to the controller/radio controlled motors. Up to 15 various channels for the same or

different remote control can be registered to a single controller. A single or a group of roller shutters can be operated after registering

the remote control channels to each controller indicated in the figure. Channel 1 on the remote control is programmed for each

controller in the living room. It controls all roller shutters in the living room. Each controller, for which any channel is programmed on

any remote control, will also be controlled with channel 00 on this remote control. Channel 2 was programmed for all roller shutters in

the other room. Channel 2 controls all roller shutters in the other room. Two groups are available: command 1 - living room and

command 2 - other room. Command 00 controls all roller shutters in the living room and the other room. It is recommended to assign

individual numbers for the individual controllers as follows: if the group is assigned channel 1, the controllers in this room has numbers

1x; it is easy to remember that the living room has channel 1 assigned for group control and channel 11, 12, 13 etc. assigned for

individual roller shutters. Similar for other roller shutters in the other rooms, a clear and convenient roller shutter control plan can be

established.

Connecting controllers to motors

Registering the remote controls

A motor connected to ST-01RL controller can be controlled with any channel via any remote control, if the channel is registered to a

specific controller.

To enter the programming mode on ST-01RL controller:

1. Each time the controller is connected to the mains, the devices remain in the programming mode for 10 seconds.

2. The programming mode can also be entered with a previously registered remote control.

Group 1

Group 2

Group 3

Group 4

WHITE

BLUE

BLACK

BROWN

3

The following procedure should be used for a factory set controller or to register a new remote control:

Activate the remote control and select the channel to register.

Connect 230 VAC power supply to the controller. Within 10 seconds:

- press ▲ and ▼ simultaneously on the PIL-01/04NS, PIL-01/05/09HT, PIL99xx remote control or

- press “1 and 2” simultaneously on the PIL-02XT, PIL-02XK, PIL-02XB, PIL-04XT, PIL-04XB remote control or

- press PROGRAM on the PIL-01PT remote control

The drive connected to ST01RL controller will move up and down. Register the channel within the next 10 seconds:

- press ▲ for the channel to be registered on the PIL-01/04NS, PIL-01/05/09HT, PIL-99xx remote control,

- press key for the channel to be registered on the PIL-02XT, PIL-02XK, PIL-02XB, PIL-04XT, PIL-04XB remote control,

- press the connected roller blind switch on the PIL-01PT remote control.

Short up and down movement will verify the correct registration.

NOTE: The procedure will erase all previously registered channels from the memory. A remote control can be registered to a

controller, when no registered remote controls are available (new controller, lost or stolen remote control).

NOTE: Remember to assign unique channel numbers for easy change of channel numbers in any controller

. This way other controllers can be programmed without disconnecting the power supply to other controllers.

If registered remote control is available other channels of the same or different remote control may be registered without

disconnecting the power supply. Enter programming mode with a registered remote control.

Press ▲ and ▼ simultaneously on the PIL-01/04NS PIL-01/05/09HT, PIL-99xx remote control. The roller shutter

will move up and down in a series of short movements, corresponding to the number of channels programmed. The controller

remains in the programming mode for the next 10 seconds. Press ▲ on the selected PIL-01/04NS, PIL-01/05/09HT, PIL-

99xx remote control channel to register a new channel on the same or different remote control.

Press “1” and “2” simultaneously on the PIL-02XT, PIL-02XK, PIL-02XB, PIL-04XT, PIL-04XB remote control.

The roller shutter will move up and down. Press the key already registered on this remote control. The roller shutter will

move up and down again in a series of short movements, corresponding to the number of channels programmed. The

controller remains in the programming mode for the next 10 seconds. Press selected channel (key) on the PIL-02XT, PIL-

02XK, PIL-02XB, PIL-04XT, PIL-04XB remote control to register a new channel on the same or different remote control.

Any channel can be registered to any controller, provided that the registered remote control is already available.

CAUTION: The controller is ready to use after approx. 10 seconds.

Roller shutter direction change: (PIL-01/04NS, PIL-01/05/09HT, PIL-99xx remote control only)

To change roller shutter direction (opposite to the directions on the remote control), enter

programming mode (use already registered remote control) and press STOP on the remote control.

Caution - for safety reasons and to avoid damage caused by static electricity, the controller programming and

deleting stored codes should be carried out on a work table after taking all the precautions and ensuring protection

against electrocution and static electricity.

PIL – 99A/G/GP

Detailed instructions are included with the remote control.

The remote control is available in three versions:

PIL-99A - multi-channel remote control with alphanumeric display;

PIL-99G - multi-channel remote control with graphic display and function of adding names, e.g. living

room, bedroom etc.

PIL-99GP - as above, with programming of individual or group of roller shutters operation with daily and

hourly programs.

4

PIL-02XT, PIL-02XK, PIL-02XB, PIL-04XT, PIL-04XB

PIL-02XT – dual-channel remote control (blue dot).

PIL-02XK – dual-channel remote control with cover.

PIL-02XB – dual-channel remote control with cover.

PIL-04XT – 4-channel remote control,

PIL-04XB – 4-channel remote control.

Activating the roller shutter

Press the registered channel key to activate the motor. Press again to stop the motor. The remote control operates in the loop: up – stop

– down – stop etc.

PIL-01PT remote control

A single-channel, flush mounted remote control compatible with ST-01R, ST-01RL controllers and motors

with a built-in YYGL-35R / YYGL-45R radio receiver.

Back box mounted. The PIL-01PT remote control is fitted with two CR-2032 batteries and a roller blind switch

connector.

Registering PIL- 01PT remote control to the controllers:

Connect the roller blind switch to terminal J1 (▲ COM ▼) to register the PIL-01PT remote control.

The PIL-01PT remote control can be used as a wireless manual switch to group any number of roller blinds controlled with a single

roller blind switch. Repeat the procedure and press any key on the roller shutter switch connected to the remote control within the next

10 seconds to program the PIL-01PT remote control. The remote control can control a group of roller shutters.

Activating the roller shutter

Press a key on the roller blind switch to move the roller blind up or down. Press any key to stop the roller shutter anytime.

PIL – 01/05/09HT

Detailed instructions are included with the remote control.

The remote control is available in three versions:

PIL-01HT – single-channel remote control with one LED.

PIL-05HT – five-channel remote control with five LEDs.

PIL-09HT – nine-channel remote control with SSD.

The PIL-01/05/09HT remote control features five keys:

▲ “UP” key

■ “STOP” key

▼ “DOWN” key

► “RIGHT” key

◄ “LEFT” key

PIL -01/04NS

Detailed instructions are included with the remote control.

The remote control is available in two versions:

PIL-01NS – single-channel remote control with one LED and three touch fields

o ▲ “UP”

o -- “STOP”

o ▼ “DOWN”

PIL-04NS – four-channel remote control with four LEDs and four touch fields.

o ▲ “UP”

o -- “STOP”

o ▼ “DOWN”

o ═ “CHANGE CHANNEL”

Table of contents

Other Inel Control Unit manuals