2 – Inepro Metering – P O Series

1Inde

2

Safety instructions ......................................................................................................... 3

3

Foreword ........................................................................................................................ 5

4

Certificates ..................................................................................................................... 6

5

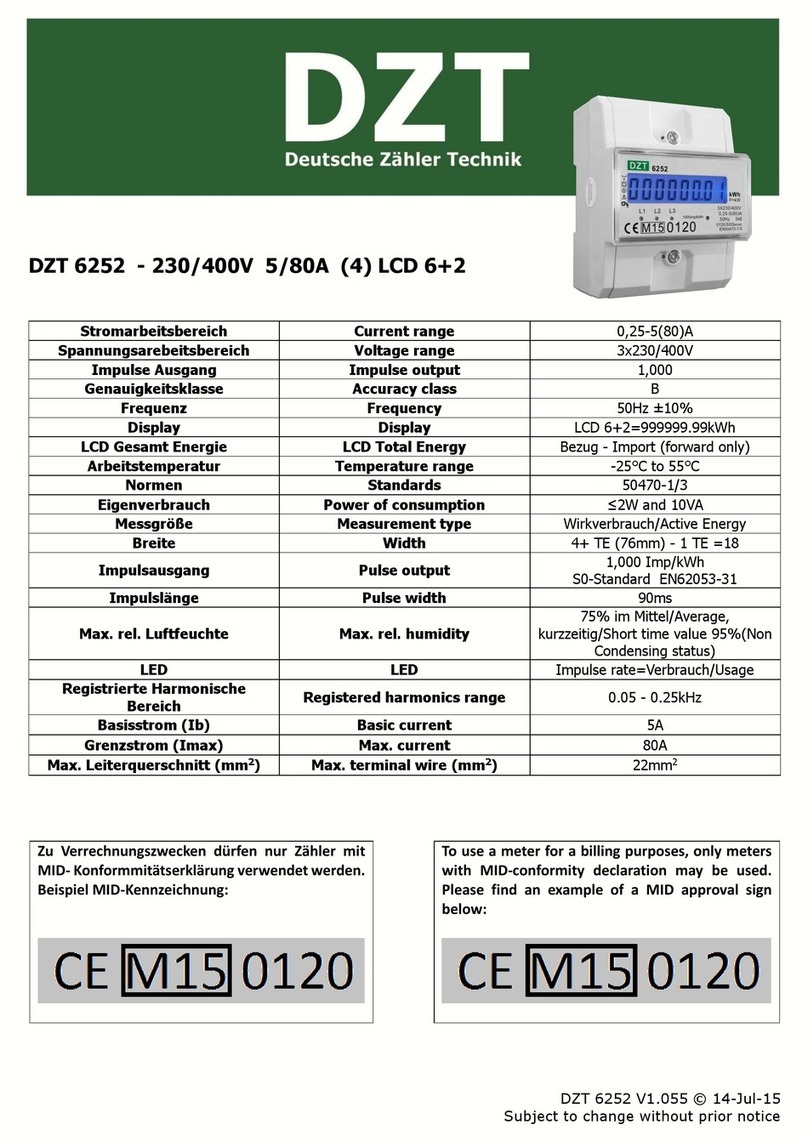

Specifications ................................................................................................................. 7

5.1

Performance criteria ........................................................................................... 7

5.2

Basic errors ....................................................................................................... 8

5.3

Infra-red specification ........................................................................................ 8

5.4

M-bus communication specifications (P O380-Mb only) ........................................ 8

5.5

S485 communication specifications (P O380-Mod only) ..................................... 8

5.6

Dimensions ........................................................................................................ 9

5.7

Connection Diagram ......................................................................................... 11

6

Operation ......................................................................................................................12

6.1

Energy flow indication ...................................................................................... 12

6.2

e-active energy indication ............................................................................... 12

6.3

Tariff indication ................................................................................................ 12

6.4

eading the meter ........................................................................................... 12

6.5

LCD display of the meter .................................................................................. 12

6.6

Scrolling function ............................................................................................. 13

6.7

Changing the CT-ratio (only CT versions) .......................................................... 14

6.8

Back light ........................................................................................................ 14

6.9

S0 pulse output................................................................................................ 15

6.10

Setting the total (combined) energy calculation ................................................. 16

6.11

Communicating via the M-bus output(P O380-Mb only) ..................................... 16

6.12

Communicating via the Modbus output(P O380-Mod only) ................................. 16

7

Troubleshooting ...........................................................................................................17

7.1

Errors / Diagnostics display ............................................................................... 18

7.2

Technical support ............................................................................................. 18

1

Appendi PRO380 2 tariff function ..............................................................................19

2

Appendi PRO380-Mb ..................................................................................................20

3

Appendi PRO380-Mod ................................................................................................20

4

Appendi Infra-Red PC software ..................................................................................22

5

Appendi Registry matri .............................................................................................23