Failure to comply with these installation instructions may invalidate the warranty.

Contact Infiltrator Systems’ Technical Services Department for assistance at 800-221-4436.

3. Backfill should not have stones greater than 3 inches (75 mm) in

diameter or excessive clods that do not break apart during placement

and compaction. Backfill must be capable of occupying the spaces

between the tank ribs.

4. Standard field soil classification methods shall be used to determine

the soil textural class.

5. Under most circumstances, the determination of soil dilatancy will

not be required. Dilatancy shall be determined in the field using a test

that does not require specialized equipment, per ASTM D2488, Section

14.3, and as described below.

a). Mold a ½-inch-diameter (13 mm) soil test specimen in the palm of

the hand. The test specimen shall be representative of the prospective

tank backfill soil.

b). Mold the test specimen, adding water if necessary, until it has a soft,

but not sticky consistency.

c). Smooth the soil ball in the palm of one hand with a spatula or equal.

d). Shake the soil sample by striking the hand vigorously against the

other hand approximately 5 times. Do not strike hand in a manner that

results in an injury.

e). Immediately following shaking, gently squeeze the soil in the palm

of the hand.

f). Repeat shaking test if necessary to evaluate soil.

g). Note whether water appears on the surface of the soil specimen

during shaking and squeezing.

i. If water appears on and disappears from the surface of the soil

specimen, the soil is dilatant, and is suitable.

ii. If no visible change or only a slight visible change in the soil

specimen occurs due to shaking or squeezing, the soil is not dilatant,

and is unsuitable.

6. Do not backfill top of tank before sidewalls are completely backfilled.

7. Place backfill around the four sidewalls in a progressive, alternating

manner, so that the backfill height along the four sidewalls is maintained

within a 12-inch (300 mm) tolerance.

8. Continue to place backfill along the sidewalls in 12-inch (300 mm)

lifts. Place backfill between the ribs on the sidewalls such that the space

between the ribs is completely filled with soil.

9.

Compact backfill material either by hand tamping or mechanical

compaction (includes backhoe bucket). Compact each lift prior to placement

of next lift. Compact backfill from tank walls to excavation sidewalls.

10. Complete backfilling and grade the area.

11. A minimum 6-inch-thick (150 mm) layer of suitable soil must be

placed over the top of the tank. The balance of backfill placed to finish

grade above the tank may be either suitable or unsuitable soil.

12. Establish a strong stand of erosion-resistant vegetation.

Note: Grade to prevent the backfilled excavation from filling with surface runoff. If

the water level in the backfilled excavation exceeds the height of the outlet pipe

saddle, tank structural integrity may be compromised. Follow Table 4 guidelines.

Table 1: Tank models1and conditions requiring buoyancy control2

Water height

above tank

bottom

Soil cover depth above tank3

6” (min)

(150 mm)

12”

(300 mm)

18”

(450 mm)

Above outlet

pipe saddle

Do not install Do not install Do not install

36” (900 mm) to outlet

pipe sadle

4All models TW-300/500 None

30” (750 mm) to

36” (900 mm)

All models except

IM -1060 TW-300/500 None

24” (600 mm) to

30” 750 mm) TW-300/500 None None

Less than

24” (600 mm) None None None

1TW-300, TW-500, TW-900, TW-1050, IM-1060, TW-1250, TW-1500.

2See Infiltrator IM- and TW-Series Septic Tank Buoyancy Control Guidance for

more information.

3No controls are required for soil cover depths exceeding 12” (300 mm).

4The tank shall not be installed where the water level outside the tank exceeds

the height of the outlet pipe saddle. Follow Table 4 guidelines.

Failure to comply with these installation instructions may invalidate the warranty.

Contact Infiltrator Systems’ Technical Services Department for assistance at 800-221-4436.

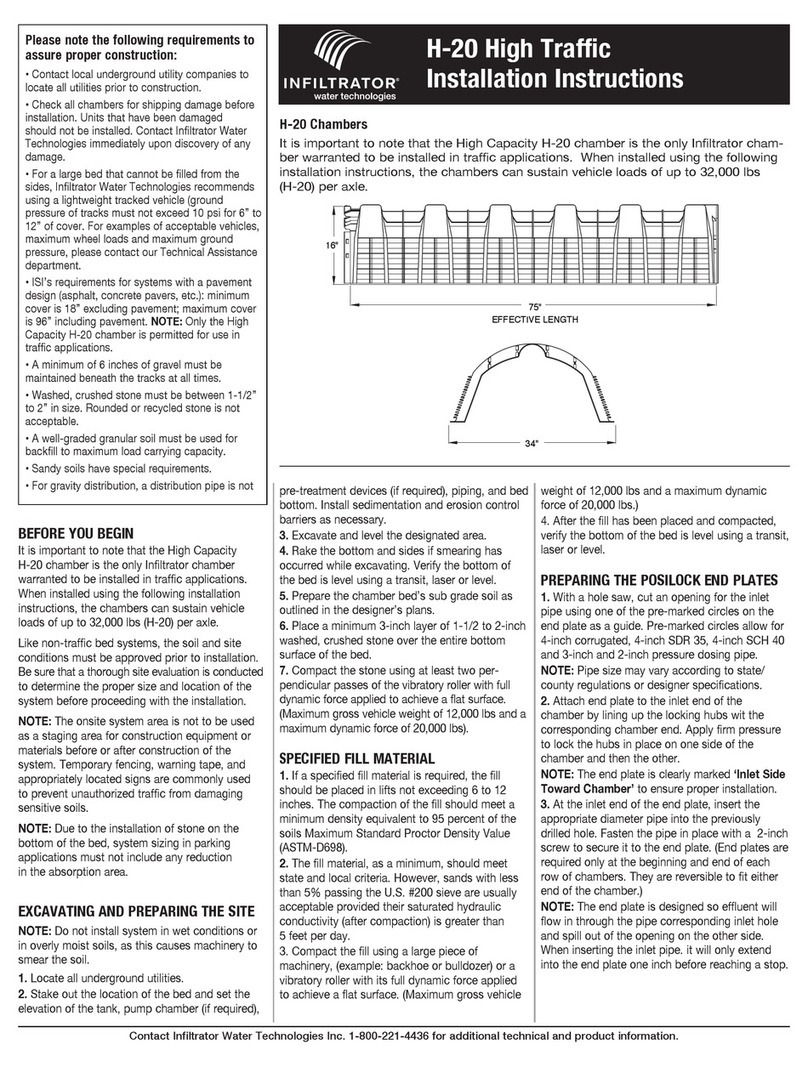

MOUND BACKFILL FOR

POSITIVE DRAINAGE

3" (76mm)

MAXIMUM

PARTICLE SIZE

PLACE SOIL IN

12" (304 mm)

LIFTS AND

COMPACT

PLACE SOIL

BETWEEN RIBS

SUITABLE NATIVE

SOIL BACKFILL

SUITABLE SOIL

COVER FILL

12" - 36"

MINIMUM 6" SOIL COVER

(305 - 914 MM) IM-1060 TANK END VIEW SHOWN FOR REFRENCE

Table 2: Infiltrator Tank Nominal Volume Chart

Height1 TOTAL LIQUID VOLUME IN TANK AT INDICATED HEIGHT

TW-300 TW-500 TW-900 TW-1050 T W-1250 T W-150 0 IM-106 0

in cm Gallons Liters Gallons Liters Gallons Liters Gallons Liters Gallons Liters Gallons Liters Gallons Liters

0000000000000000

1 3 1 2 2 8 10 37 11 43 14 53 17 64 311

2 5 2 9 5 19 22 82 25 95 30 115 37 140 13 49

3 8 5 19 8 30 41 156 48 181 58 218 71 267 28 106

410 934 13 49 62 236 72 273 87 330 107 404 46 174

513 15 57 20 76 84 317 97 368 117 444 143 543 65 246

615 21 79 28 106 106 400 122 463 148 558 180 683 86 326

718 28 106 37 14 0 128 483 148 560 178 674 218 825 107 405

820 36 136 48 182 150 567 174 657 209 791 256 968 129 488

923 43 163 59 223 172 653 200 756 240 910 294 1,112 152 575

10 25 50 189 71 269 195 739 226 855 272 1,029 332 1,257 176 666

11 28 57 216 83 314 218 826 252 956 304 1,149 371 1,40 4 200 757

12 30 65 246 95 360 242 915 279 1,057 336 1,270 410 1,551 225 852

13 33 72 273 105 397 265 1,004 306 1,160 368 1,393 449 1,700 251 950

14 36 80 303 118 4 47 289 1,093 334 1,263 400 1,516 489 1, 849 277 1,049

15 38 87 329 130 492 313 1,184 361 1,367 433 1,640 528 2,000 303 1,147

16 40 95 360 142 537 337 1,276 389 1,472 466 1,765 569 2,152 330 1, 249

17 43 102 386 154 583 361 1, 368 417 1, 578 500 1,892 609 2,305 357 1,351

18 46 110 416 166 628 386 1,461 445 1,685 533 2,019 650 2,459 384 1,454

19 48 118 447 179 678 411 1,555 474 1,792 567 2,146 690 2,614 411 1,556

20 50 126 477 191 723 436 1,650 502 1,901 601 2,275 732 2,769 438 1,658

21 53 134 507 204 772 462 1,747 532 2 ,012 636 2,407 774 2,928 465 1,760

22 56 141 534 216 818 488 1, 847 562 2,126 671 2,541 816 3,091 493 1,866

23 58 149 564 228 863 515 1,948 592 2, 241 708 2,678 860 3,256 521 1,972

24 61 156 590 241 912 542 2,053 624 2, 361 745 2,819 905 3,425 549 2,078

25 64 164 621 253 958 569 2,154 654 2,475 781 2,955 948 3,589 577 2,184

26 66 171 647 265 1,003 595 2,251 683 2,587 815 3,086 990 3,747 605 2,290

27 69 178 674 277 1,048 620 2,346 712 2,695 849 3, 215 1,031 3,903 633 2,396

28 71 186 704 289 1,094 644 2,439 740 2,802 883 3,342 1,072 4,057 662 2,506

29 74 193 731 300 1,136 669 2,533 769 2,909 916 3,469 1,112 4,210 691 2,616

30 76 200 757 312 1,181 693 2,625 796 3, 015 950 3,594 1,152 4,362 719 2,722

31 79 208 787 324 1,226 718 2,717 824 3,120 982 3,719 1,192 4,514 747 2,828

32 81 215 814 336 1, 272 741 2,807 852 3,223 1,015 3,842 1,232 4,663 775 2,934

33 84 222 840 347 1,313 765 2,895 878 3,325 1,047 3,964 1,271 4,810 802 3,036

34 86 230 871 359 1,359 788 2,983 905 3,426 1,079 4,084 1,309 4,956 830 3,142

35 89 236 893 370 1,400 811 3,070 931 3,526 1,110 4,203 1,347 5,101 857 3,244

36 91 243 920 382 1,446 834 3,155 957 3,624 1,141 4,320 1,385 5,243 884 3,346

37 94 251 950 393 1,488 856 3,240 983 3,721 1,172 4,436 1,422 5,384 911 3,449

38 97 258 977 404 1,529 877 3,320 1,008 3,814 1,201 4,548 1,458 5,521 938 3,551

39 99 264 999 416 1,575 898 3,398 1,031 3,904 1,230 4,657 1,494 5,654 965 3,653

40 102 271 1,026 427 1,616 920 3,484 1,057 4,003 1,261 4,772 1,532 5,798 992 3,755

41 104 278 1,052 438 1,658 938 3,549 1,078 4,080 1,286 4,869 1,562 5,915 1,018 3,854

42 107 285 1,079 449 1,699 957 3,623 1,100 4,166 1,314 4,972 1,596 6,042 1,044 3,952

43 109 292 1,105 460 1,741 976 3,695 1,123 4,249 1,340 5,074 1,629 6,167 1,069 4,047

44 112 299 1,132 471 1,783 994 3,765 1,14 4 4,331 1,366 5,172 1,661 6,288 1,094 4,141

45 114 304 1,151 481 1,821 1, 011 3,829 1,16 4 4,406 1,390 5,263 1,690 6,399 1,118 4,232

46 117 310 1,173 490 1,855 1,025 3,878 1,179 4,465 1,410 5,337 1,715 6,492 1,142 4,323

47 119 313 1,185 498 1,885 1,036 3,923 1,193 4,517 1,427 5,402 1,737 6,574 1,165 4, 410

48 122 313 1,185 502 1,900 1,0 45 3,954 1,203 4,553 1,439 5,446 1,750 6,626 1,187 4,493

49 124 313 1,185 504 1,908 1,055 3,994 1,212 4,588 1,448 5,481 1,762 6,669 1,208 4,573

50 127 ––––––––––––1,228 4,648

51 130 ––––––––––––1,247 4,720

52 132 ––––––––––––1,265 4,789

53 135 ––––––––––––1,278 4,838

54 137 ––––––––––––1,287 4,872

1. Height measured from inside surface at bottom of corrugation in tank.

Short and Long-Term Groundwater Control

It may be necessary to implement groundwater control measures during

tank installation. Maintain dry conditions by expanding the excavation to

create a short-term groundwater collection sump for temporary placement

of a dewatering pump if needed. Long-term groundwater control measures

such as underdrains and interceptor trenches may be sensible if the site

is amenable to construction of a control system and such systems are

not prohibited by regulation or law, and the tank location is not subject

to flooding. Properly installed underdrains and groundwater interceptor

trenches may prevent the need for tank buoyancy control measures.

Installing Risers

1. Compatible risers include 24-inch (600 mm) diameter products such

as the Infiltrator TW-Riser, EZset by Infiltrator, PolyLok®, Inc., and Tuf-

Tite®Corporation, in addition to 24-inch (600 mm) diameter corrugated

HDPE and IPEX Ultra Rib®PVC pipe. Follow Infiltrator’s IM- and TW-

Series Septic Tank Riser Connection Guidance.

2. Oregon watertightness testing shall include filling with water at least 2

inches above riser connection, with no more than 1 gallon leakage per

24 hours, per OAR 340-073-0025(3).

Installing Pumps and Related Equipment

Pumps may be supported on a stable, level 16 x 16 inch (400 x 400 mm)

platform positioned on the bottom of the tank. Precast concrete block

is acceptable pump support material. One 16 x 16 inch block or two 8

x 16 inch (200 mm x 400 mm) side-by-side blocks may be used. The

support block(s) should be placed below an access opening and level

upon the tank bottom. If two blocks are used, they should be oriented

perpendicular to ribs on the tank bottom, if present, for stability.

Installation of products such as electrical conduit and wiring, pumps,

water level control equipment, valves, siphon equipment, etc. shall be in

accordance with the product manufacturer’s instructions and compliant

with applicable state or local rules and regulations. Appurtenances shall

be fastened to the tank riser system and not the tank body or access

opening rim. Where possible, appurtenances shall be installed to

facilitate maintenance and repair access via the tank access openings.

General Specifications

• Failure to comply with installation instructions may void warranty.

• Prior to ground disturbance, check for subsurface obstructions and

utilities in conformance with applicable requirements.

• Operating water temperature shall be less than 100° F (40° C).

• Tanks are not fire resistant. Store away from ignition sources.

• Removal of structural bulkheads is prohibited; removal of locking clips

on the IM-1060 mid seam connection is also prohibited.

• Suitable for potable applications only if the tank bearing an NSF/ANSI

61 certification mark, otherwise tank is recommended for use in septic,

rainwater/stormwater storage, and pump applications only.

• Infiltrator tanks are designed for installation underground. Contact

Infiltrator Systems for above-ground use requirements.

WARNING: IMPLOSIONS MAY CAUSE SERIOUS INJURY

Follow Infiltrator Systems Inc. vacuum test instructions

Installing Under Shallow Groundwater Conditions

Buoyancy control measures may be required if the Infiltrator tank is to

be installed with less than 18 inches (450 mm) of soil backfill cover, and

where the water level outside the tank has the potential to rise 24 inches

(600 mm) or more above the elevation of the tank bottom. Otherwise,

no control measures are required (see Table 1). The need for buoyancy

control measures must be determined based on backfill cover depth

and height of water outside of tank above the tank bottom according

to the following table. Refer to Infiltrator IM- and TW-Series Septic Tank

Buoyancy Control Guidance document for more information.