pre-treatment devices (if required), piping, and bed

bottom. Install sedimentation and erosion control

barriers as necessary.

3. Excavate and level the designated area.

4. Rake the bottom and sides if smearing has

occurred while excavating. Verify the bottom of

the bed is level using a transit, laser or level.

5. Prepare the chamber bed’s sub grade soil as

outlined in the designer’s plans.

6. Place a minimum 3-inch layer of 1-1/2 to 2-inch

washed, crushed stone over the entire bottom

surface of the bed.

7. Compact the stone using at least two per-

pendicular passes of the vibratory roller with full

dynamic force applied to achieve a flat surface.

(Maximum gross vehicle weight of 12,000 lbs and a

maximum dynamic force of 20,000 lbs).

S

PECIFIED FILL MATERIAL

1. If a specified fill material is required, the fill

should be placed in lifts not exceeding 6 to 12

inches. The compaction of the fill should meet a

minimum density equivalent to 95 percent of the

soils Maximum Standard Proctor Density Value

(ASTM-D698).

2. The fill material, as a minimum, should meet

state and local criteria. However, sands with less

than 5% passing the U.S. #200 sieve are usually

acceptable provided their saturated hydraulic

conductivity (after compaction) is greater than

5 feet per day.

3. Compact the fill using a large piece of

machinery, (example: backhoe or bulldozer) or a

vibratory roller with its full dynamic force applied

to achieve a flat surface. (Maximum gross vehicle

Contact Infiltrator Water Technologies Inc. 1-800-221-4436 for additional technical and product information.

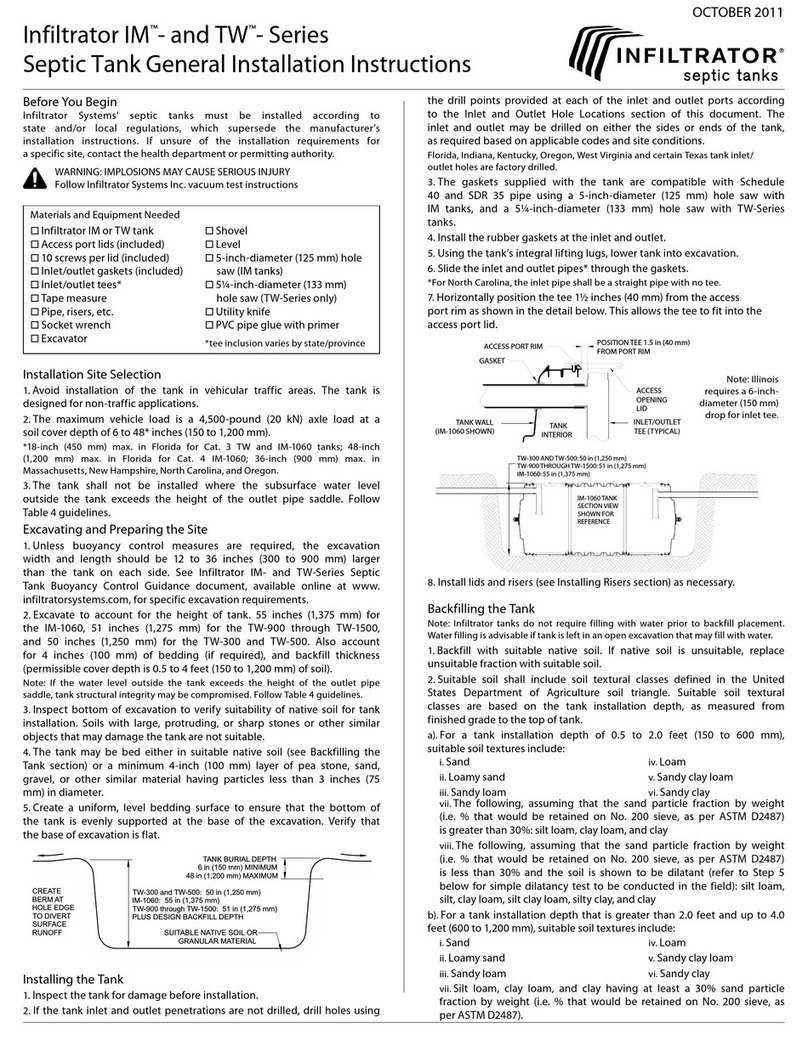

BEFORE YOU BEGIN

It is important to note that the High Capacity

H-20 chamber is the only Infiltrator chamber

warranted to be installed in traffic applications.

When installed using the following installation

instructions, the chambers can sustain vehicle

loads of up to 32,000 lbs (H-20) per axle.

Like non-traffic bed systems, the soil and site

conditions must be approved prior to installation.

Be sure that a thorough site evaluation is conducted

to determine the proper size and location of the

system before proceeding with the installation.

NOTE: The onsite system area is not to be used

as a staging area for construction equipment or

materials before or after construction of the

system. Temporary fencing, warning tape, and

appropriately located signs are commonly used

to prevent unauthorized traffic from damaging

sensitive soils.

NOTE: Due to the installation of stone on the

bottom of the bed, system sizing in parking

applications must not include any reduction

in the absorption area.

EXCAVATING AND PREPARING THE SITE

NOTE: Do not install system in wet conditions or

in overly moist soils, as this causes machinery to

smear the soil.

1. Locate all underground utilities.

2. Stake out the location of the bed and set the

elevation of the tank, pump chamber (if required),

Please note the following requirements to

assure proper construction:

• Contact local underground utility companies to

locate all utilities prior to construction.

• Check all chambers for shipping damage before

installation. Units that have been damaged

should not be installed. Contact Infiltrator Water

Technologies immediately upon discovery of any

damage.

• For a large bed that cannot be filled from the

sides, Infiltrator Water Technologies recommends

using a lightweight tracked vehicle (ground

pressure of tracks must not exceed 10 psi for 6” to

12” of cover. For examples of acceptable vehicles,

maximum wheel loads and maximum ground

pressure, please contact our Technical Assistance

department.

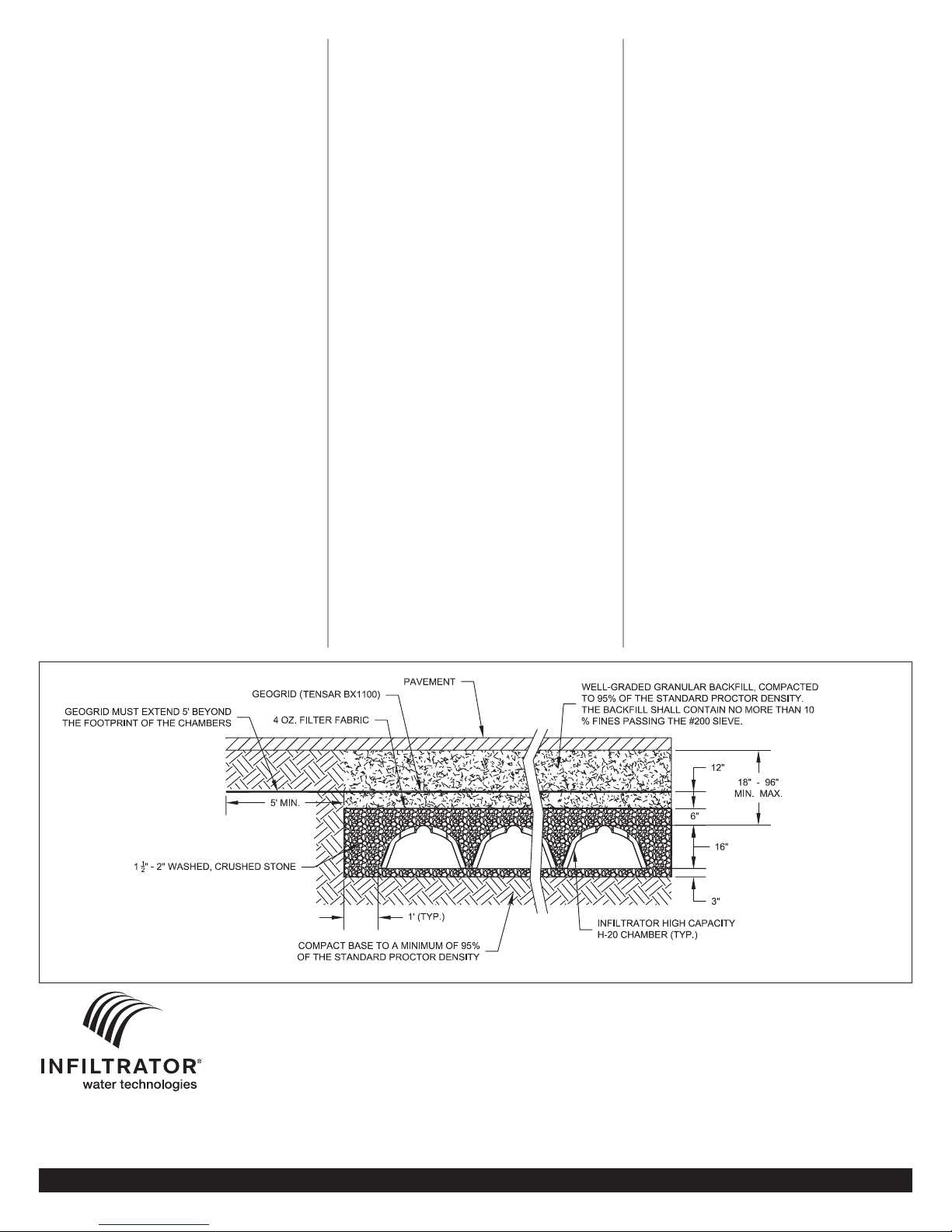

• ISI’s requirements for systems with a pavement

design (asphalt, concrete pavers, etc.): minimum

cover is 18” excluding pavement; maximum cover

is 96” including pavement. NOTE: Only the High

Capacity H-20 chamber is permitted for use in

traffic applications.

• A minimum of 6 inches of gravel must be

maintained beneath the tracks at all times.

• Washed, crushed stone must be between 1-1/2”

to 2” in size. Rounded or recycled stone is not

acceptable.

• A well-graded granular soil must be used for

backfill to maximum load carrying capacity.

• Sandy soils have special requirements.

• For gravity distribution, a distribution pipe is not

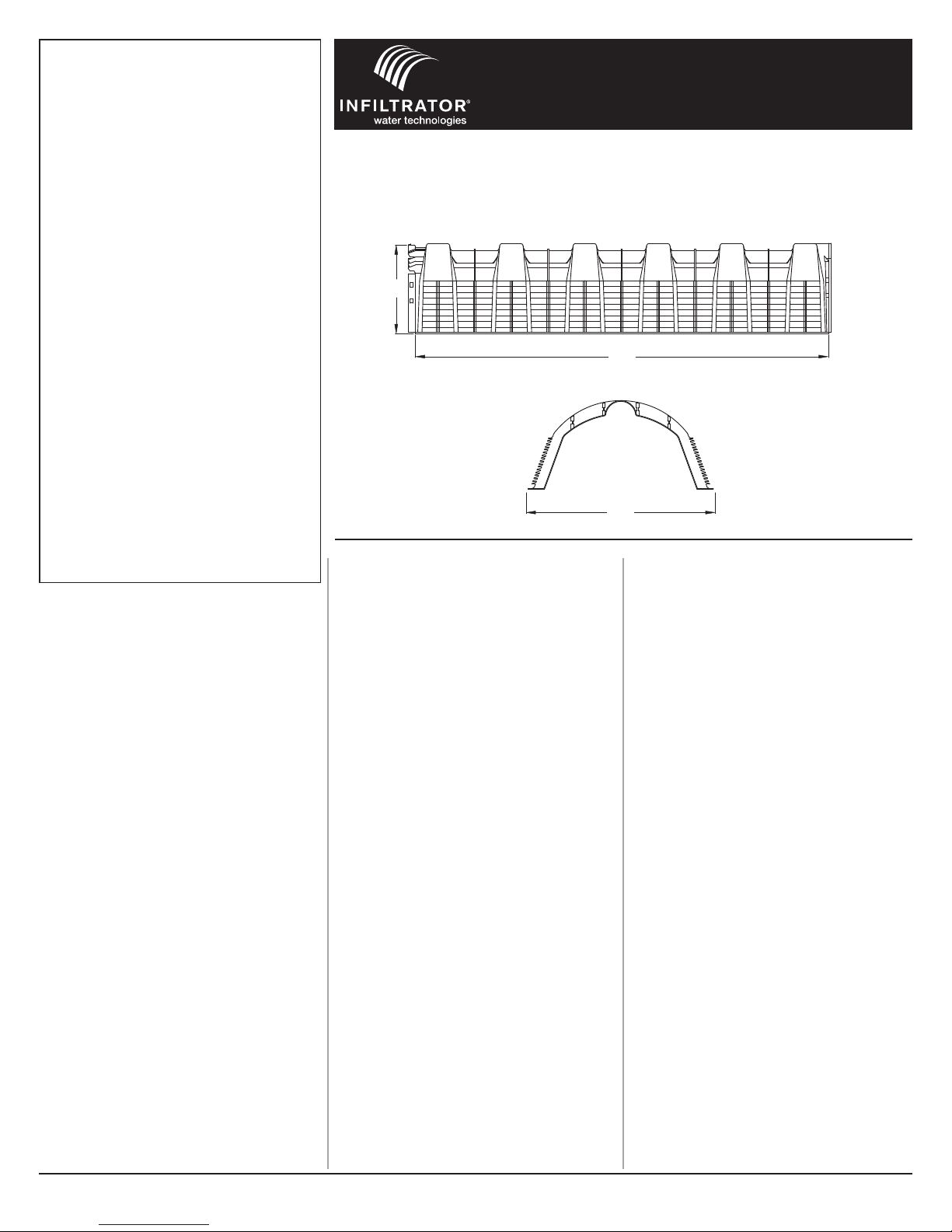

H-20 High Traffic

Installation Instructions

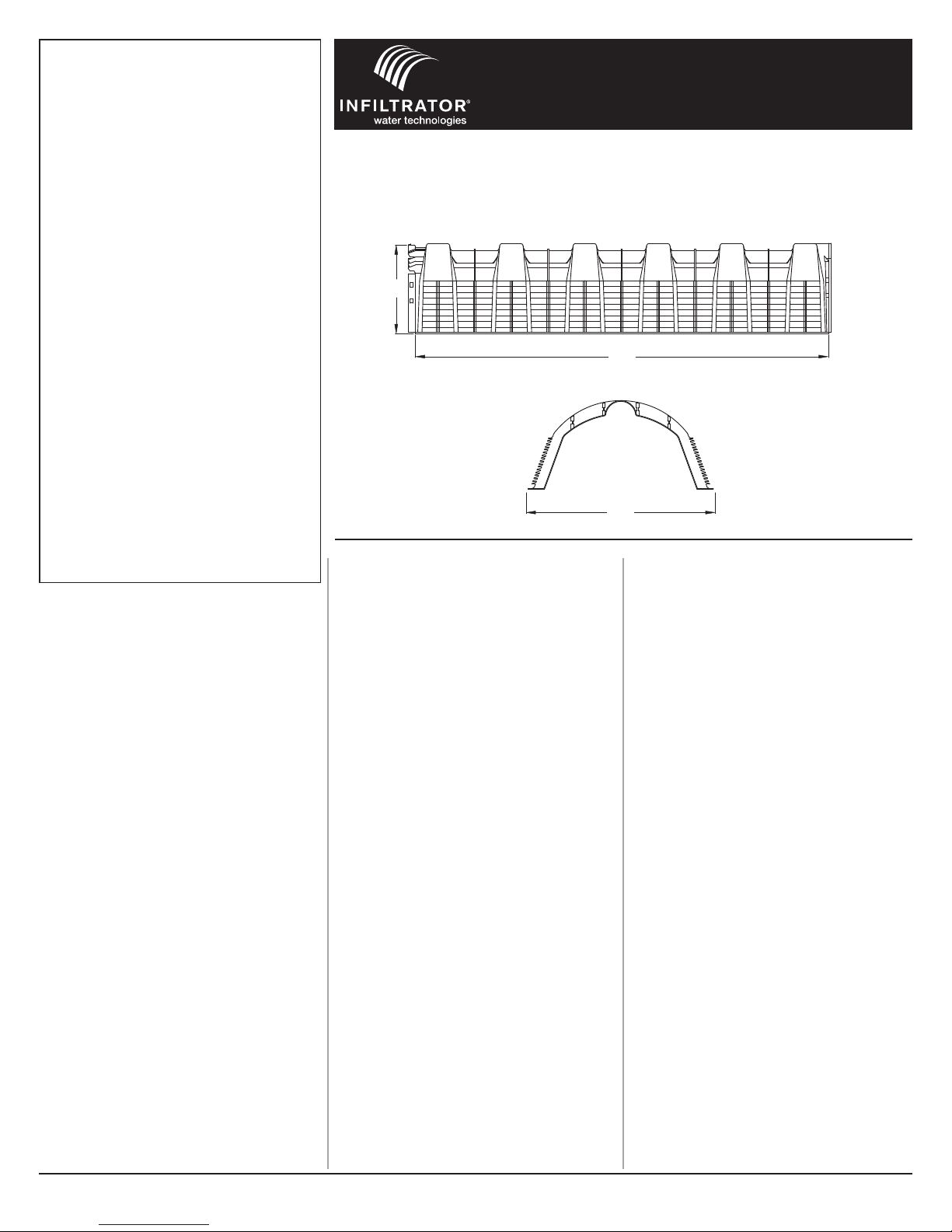

H-20 Chambers

It is important to note that the High Capacity H-20 chamber is the only Infiltrator cham-

ber warranted to be installed in traffic applications. When installed using the following

installation instructions, the chambers can sustain vehicle loads of up to 32,000 lbs

(H-20) per axle.

34"

75"

EFFECTIVE LENGTH

16"

weight of 12,000 lbs and a maximum dynamic

force of 20,000 lbs.)

4. After the fill has been placed and compacted,

verify the bottom of the bed is level using a transit,

laser or level.

PREPARING THE POSILOCK END PLATES

1. With a hole saw, cut an opening for the inlet

pipe using one of the pre-marked circles on the

end plate as a guide. Pre-marked circles allow for

4-inch corrugated, 4-inch SDR 35, 4-inch SCH 40

and 3-inch and 2-inch pressure dosing pipe.

NOTE: Pipe size may vary according to state/

county regulations or designer specifications.

2. Attach end plate to the inlet end of the

chamber by lining up the locking hubs wit the

corresponding chamber end. Apply firm pressure

to lock the hubs in place on one side of the

chamber and then the other.

NOTE: The end plate is clearly marked ‘Inlet Side

Toward Chamber’ to ensure proper installation.

3. At the inlet end of the end plate, insert the

appropriate diameter pipe into the previously

drilled hole. Fasten the pipe in place with a 2-inch

screw to secure it to the end plate. (End plates are

required only at the beginning and end of each

row of chambers. They are reversible to fit either

end of the chamber.)

NOTE: The end plate is designed so effluent will

flow in through the pipe corresponding inlet hole

and spill out of the opening on the other side.

When inserting the inlet pipe. it will only extend

into the end plate one inch before reaching a stop.