Delta Treatment Systems • 9125 Comar Drive, Walker, LA 70785 • 1-800-219-9183 • www.deltatreatment.com

4

INTRODUCTION

THE DELTA AEROBIC WASTEWATER

TREATMENT SYSTEM AND HOW IT WORKS

The ECOPOD-N Fixed Film Wastewater Treatment System

you have purchased produces high quality water suitable for

various dispersal methods. It is used to enhance your on-

site wastewater dispersal system. You can be proud that by

purchasing your ECOPOD-N system, with a minimum amount

of maintenance, you can directly contribute to a cleaner, safer

environment.

All wastewater treatment systems of this type work by using

bacteria that nature provides. By pumping air into the system,

aerobic bacteria grow and thrive in large numbers. This

population of bacteria speeds up the process of breaking

down domestic wastewater, making it safer to release into the

environment. This entire process takes place within the walls

of your specially designed ECOPOD-N Treatment System. The

result of this process is a clear, odorless discharge.

By following a few simple steps that you will nd in this manual,

your ECOPOD-N Fixed Film Wastewater Treatment System

will provide you with years of service and the knowledge

that you are doing your part to protect public health and our

groundwater, lakes, rivers, and streams.

The ECOPOD-N Fixed Film Wastewater Treatment System may

be only one of several components required by your health

department to provide a complete on-site system.

PROCESS DESCRIPTION

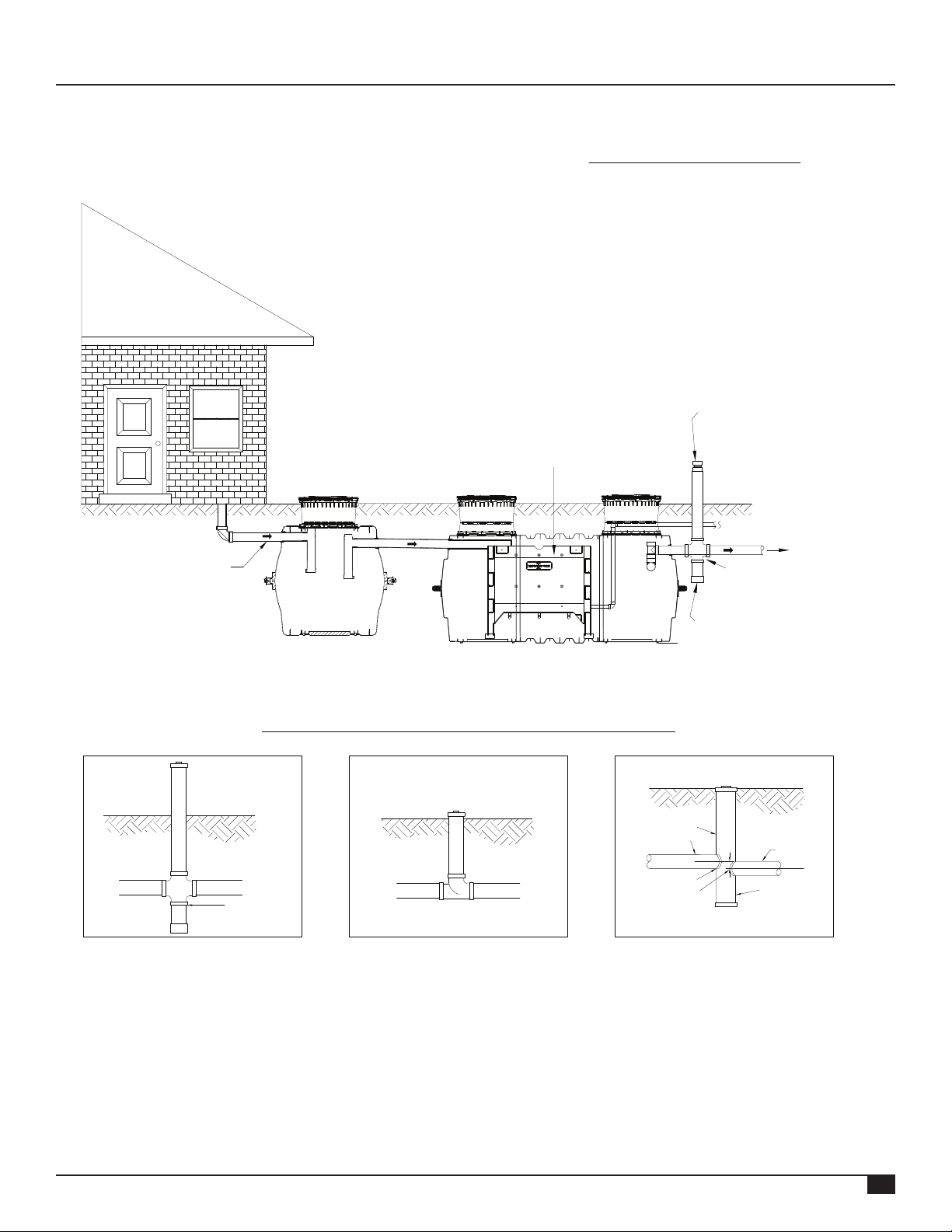

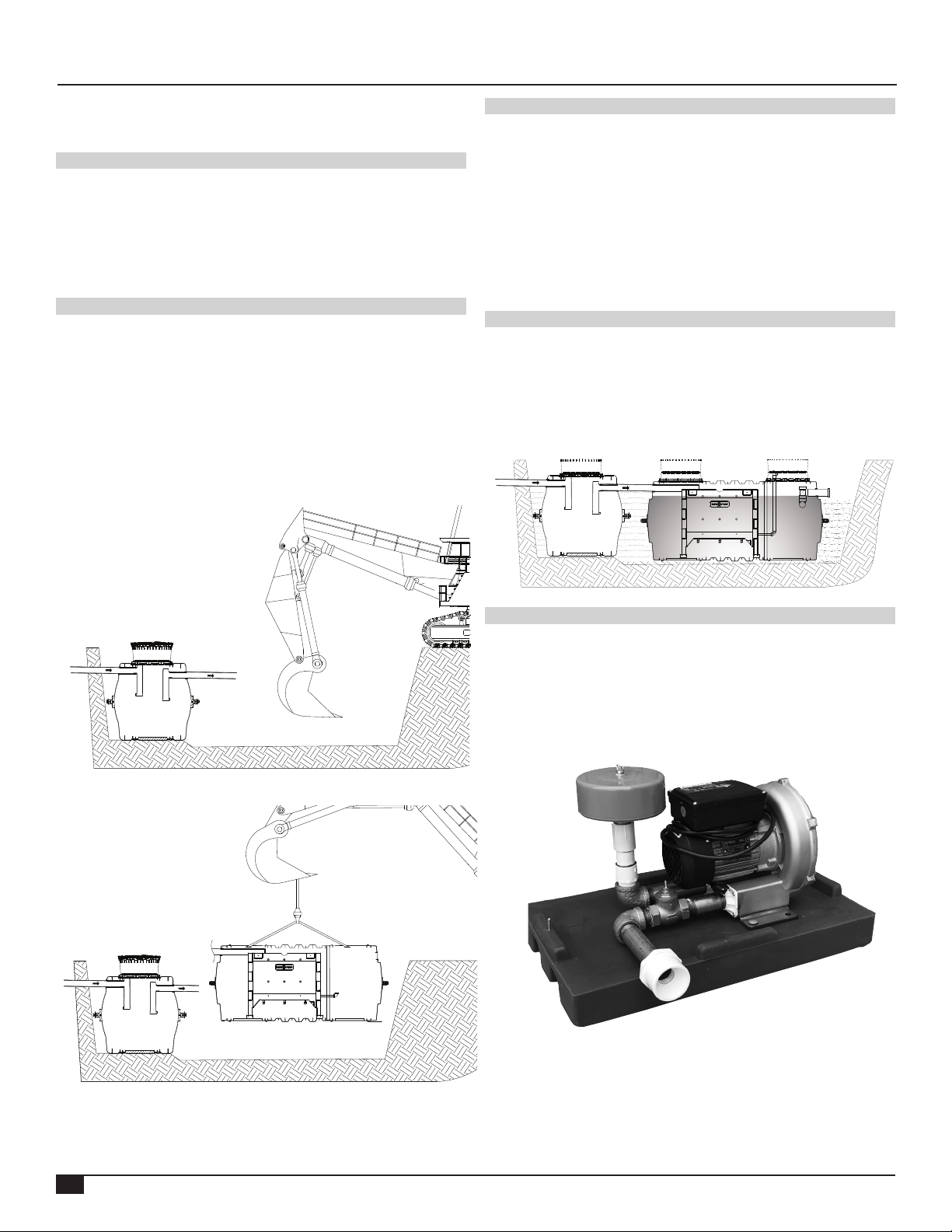

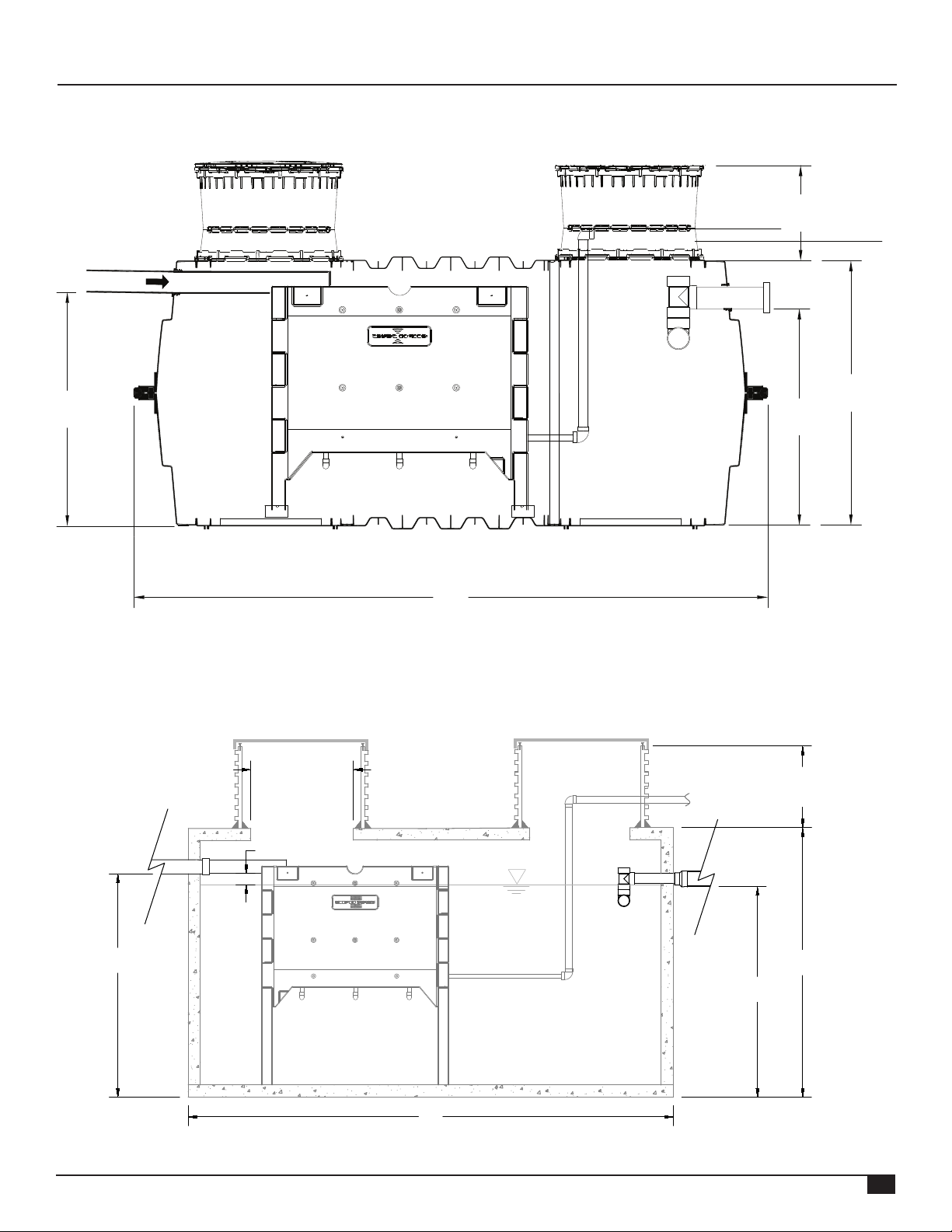

The ECOPOD-N Fixed Film Wastewater Treatment System is

a device that houses an engineered plastic media specically

designed to treat domestic wastewater. There are no moving

mechanical parts or lters in the chamber or tank that houses

the ECOPOD-N.

Wastewater rst enters a pretreatment/settling tank similar to

a conventional septic tank. In this tank, debris and settleable

solids settle to the bottom and are decomposed by anaerobic

bacteria. The claried wastewater then enters the ECOPOD-N,

which is submerged in a separate chamber or tank, where it

is introduced into an oxygen rich environment. An external air

compressor is connected to the ECOPOD-N and provides the

necessary air to the system. In this oxygen rich environment, a

colony of bacteria, called the biomass, develops and is capable

of digesting (breaking down) biodegradable waste. This is a

continuous process as the biomass is supplied with incoming

wastewater and oxygen.

In this system, conditions are favorable only to attached growth

bacteria. This means that the most common disadvantages of

other types of systems are eliminated. No rising sludge, oating

sludge or washouts can occur.

In addition to cBOD and TSS reduction, ammonia nitrogen is

one of the contaminants found in wastewater. Nitrication of

the ammonia and denitrication of nitrates occur within the

ECOPOD-N system. A 50%+ removal rate of total nitrogen

is common without any type of recirculation or cycling of the

blower.

HOMEOWNER CARE AND OPERATION

INSTRUCTIONS

The ECOPOD-N Fixed Film Wastewater Treatment System

has been designed and built to provide long term, reliable

and ecient service. Once the unit has been installed (see

installation instructions), the unit will operate with a minimum

amount of attention.

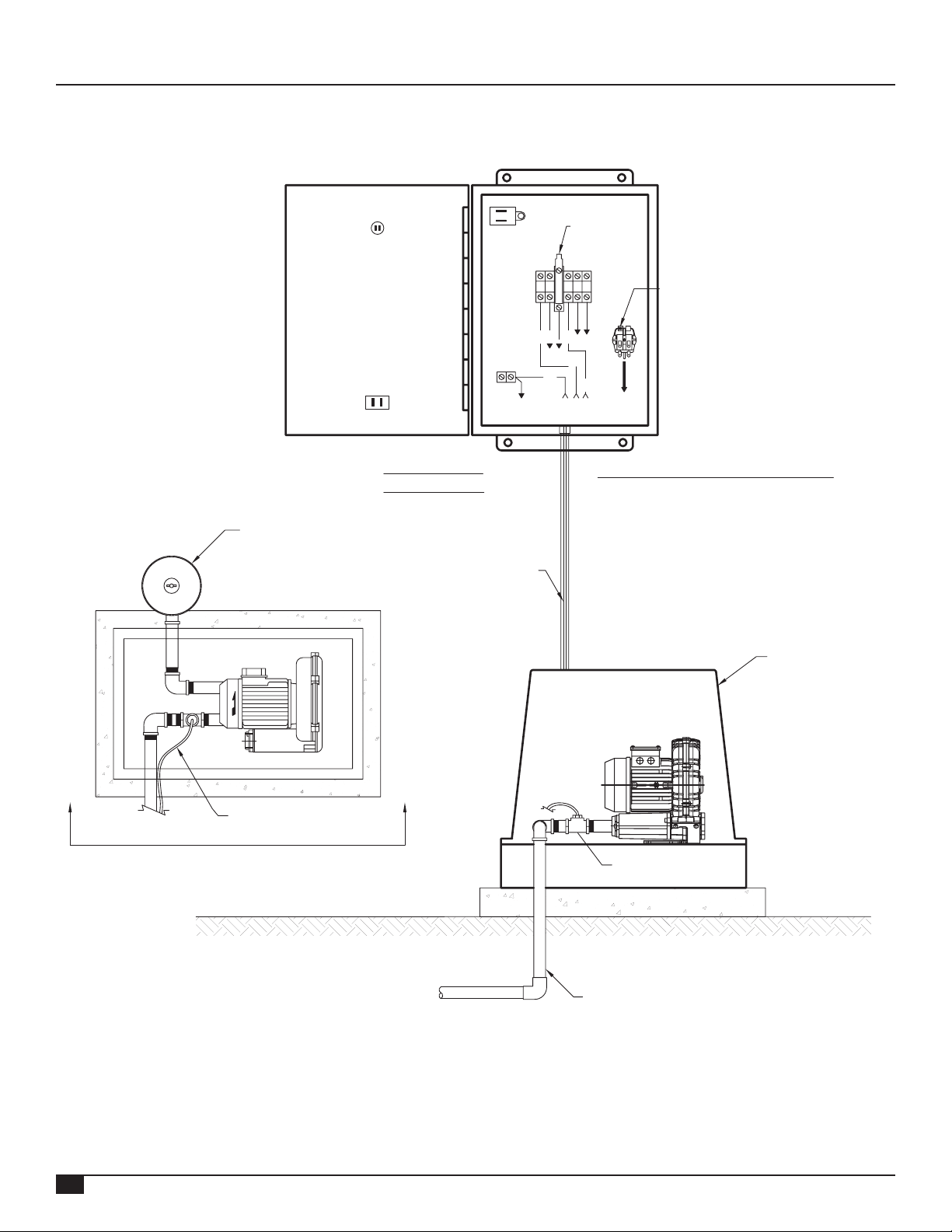

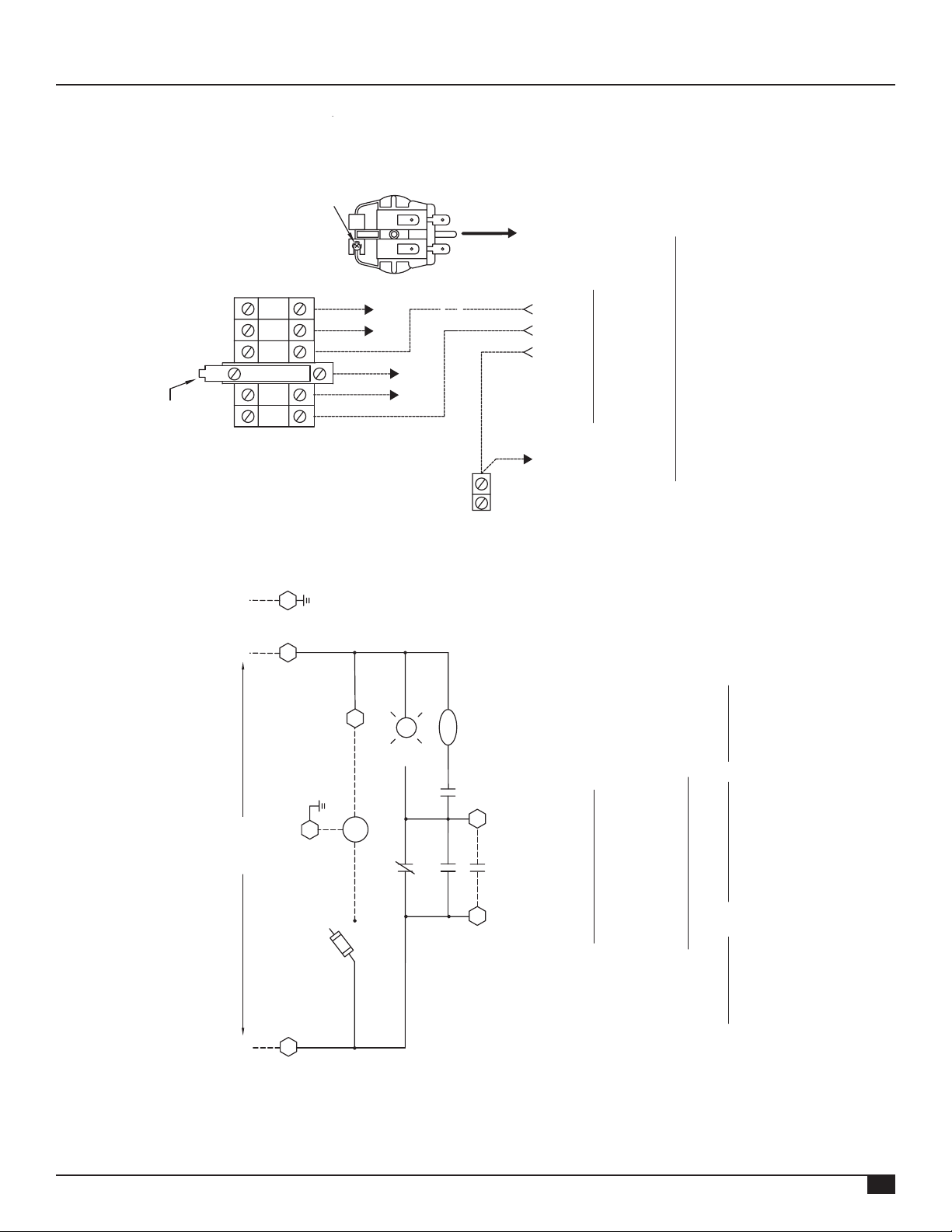

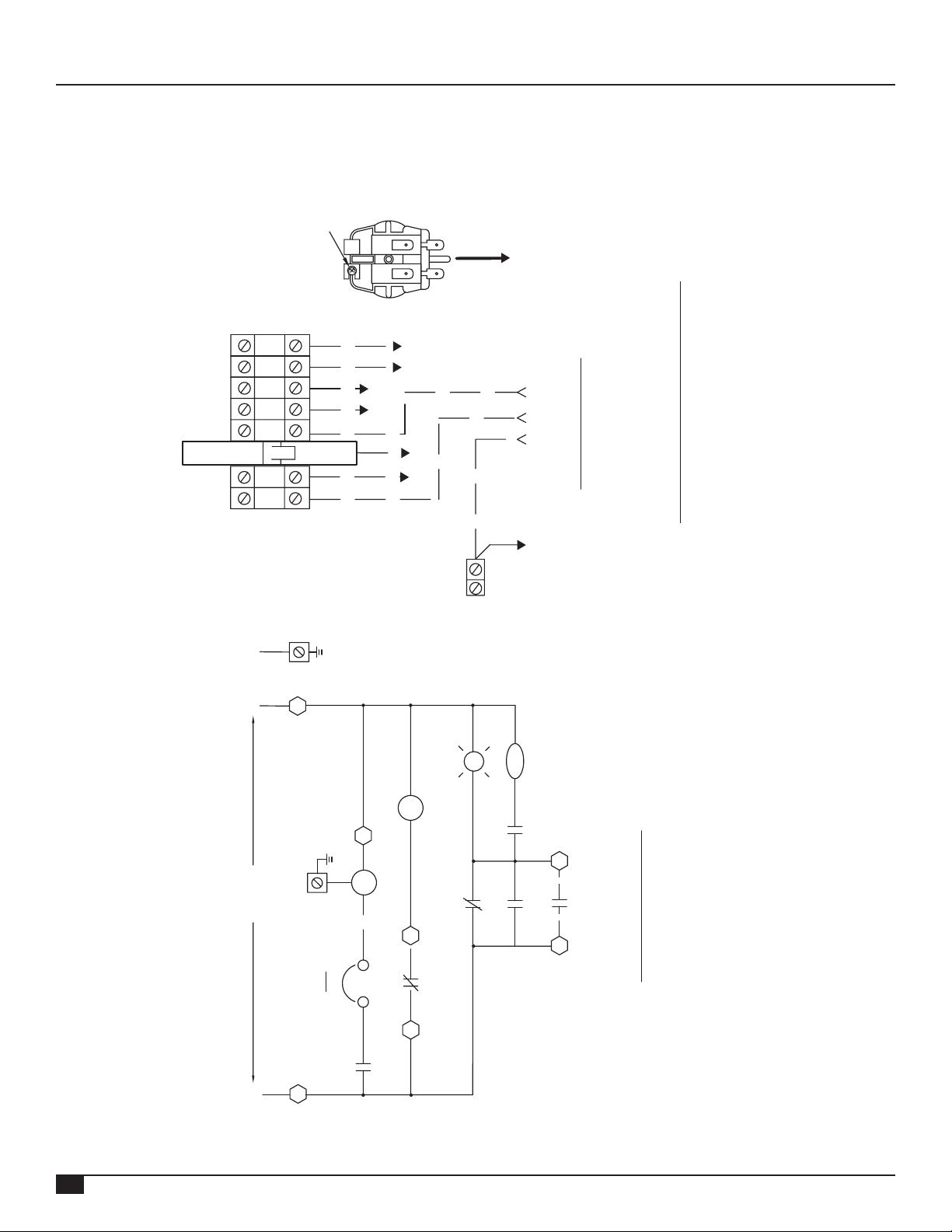

Please reference the system’s Data Plates that are located on

the air pump and the alarm panel in the event that a problem

arises or service is required.

The following should be performed as checks for system

functioning:

Daily

• Observe the warning device, which comes on when the power

to the air pump has been interrupted, when the air supply

system has malfunctioned, or there is a high water level in the

treatment plant. If the alarm is activated, check for a blown

fuse or thrown circuit breaker. Check the air pump to be sure

it is operating. Once accustomed to the soft humming sound

of a properly operating unit, any unusual noise is an indication

of malfunction. If an unusual noise is detected or total failure is

observed, call an authorized Delta service provider or dealer/

distributor.

Weekly

• Check the treatment plant for oensive odor. If such a

condition should develop, call an authorized Delta service

provider or dealer/distributor.

Every 6 Months

(performed by a certied service provider)

• Inspect and make any necessary adjustments to mechanical

and electrical components.

• Inspect the air lter on the air pump. Rinse with warm water

if necessary. (See installation instructions.) Do not use oil or

other solvents.

• Inspect euent quality’s color, turbidity and check for any

odor.

• Take a sample from the reactor tank to check the sludge level

described in the “Solids Removal” section.

• The homeowner must be notied in writing if any improper

operation is observed and cannot be corrected at the time of

service.

Ongoing Maintenance and Care

The following should not be used or disposed of into the

system:

• Greases, fats, oils, pesticides, herbicides, or any other toxins.

• Garbage disposal should be used sparingly. Dispose of food

waste, grease, etc., in the trash. Food waste represents

additional loading on the Fixed Film Wastewater Treatment

System and could increase pump-out frequency.