Infineon TRAVEO T2G family CYT4D Series User manual

Application Note Please read the Important Notice and Warnings at the end of this document 002-26071 Rev. *B

www.infineon.com page 1 of 80 2021-09-07

AN226071

Clock configuration setup in TRAVEO™ T2G

family CYT4D series MCUs

About this document

Scope and purpose

AN226071 describes how to set up the various clock sources in TRAVEO™ T2G family CYT4D series MCUs and

provides examples including configuring PLL/FLL and calibrating the ILO.

Associated part family

TRAVEO™ T2G family CYT4D series automotive microcontrollers

Intended audience

This document is intended for users who use the clock configuration setup in TRAVEO™ T2G family CYT4D series

MCUs.

Table of contents

About this document......................................................................................................................... 1

Table of contents .............................................................................................................................. 1

1Introduction ............................................................................................................................ 3

2Clock system for TRAVEO™ T2G family MCUs............................................................................... 4

2.1 Overview of the clock system .................................................................................................................4

2.2 Clock resources .......................................................................................................................................4

2.3 Clock system functions ...........................................................................................................................4

2.4 Basic clock system settings...................................................................................................................11

3Configuration of the clock resources.........................................................................................12

3.1 Setting the ECO .....................................................................................................................................12

3.1.1 Use case............................................................................................................................................13

3.1.2 Configuration ...................................................................................................................................13

3.1.3 Sample code for initial ECO configuration......................................................................................14

3.2 Setting WCO...........................................................................................................................................20

3.2.1 Operation overview..........................................................................................................................20

3.2.2 Configuration ...................................................................................................................................20

3.2.3 Sample code for the initial configuration of WCO settings ............................................................21

3.3 Configuring IMO.....................................................................................................................................22

3.4 Configuring ILO0/ILO1...........................................................................................................................22

3.5 Setting the LPECO .................................................................................................................................23

3.5.1 Use case............................................................................................................................................23

3.5.2 Sample code for the initial configuration of LPECO settings .........................................................24

4Configuration of the FLL and PLL ..............................................................................................26

4.1 Setting FLL.............................................................................................................................................26

4.1.1 Operation overview..........................................................................................................................26

Application Note 2 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Table of contents

4.1.2 Use case............................................................................................................................................27

4.1.3 Configuration ...................................................................................................................................27

4.1.4 Sample code for the initial configuration of FLL settings...............................................................28

4.2 Setting PLL.............................................................................................................................................31

4.2.1 Use case............................................................................................................................................33

4.2.2 Configuration ...................................................................................................................................33

4.2.3 Sample code for the initial PLL configuration ................................................................................39

5Configuring the internal clock ..................................................................................................48

5.1 Configuring CLK_PATHx........................................................................................................................48

5.2 Configuring CLK_HFx ............................................................................................................................50

5.3 Configuring the CLK_LF.........................................................................................................................51

5.4 Configuring CLK_FAST_0/CLK_FAST_1 ................................................................................................51

5.5 Configuring CLK_MEM...........................................................................................................................51

5.6 Configuring CLK_PERI ...........................................................................................................................51

5.7 Configuring CLK_SLOW.........................................................................................................................52

5.8 Configuring CLK_GR..............................................................................................................................52

5.9 Configuring PCLK ..................................................................................................................................53

5.9.1 Example of PCLK setting ..................................................................................................................54

5.9.1.1 Use case.......................................................................................................................................54

5.9.1.2 Configuration ..............................................................................................................................54

5.9.2 Sample code for the initial configuration of PCLK settings (example of the TCPWM timer).........55

5.10 Setting ECO_Prescaler ..........................................................................................................................57

5.10.1 Use case............................................................................................................................................58

5.10.2 Configuration ...................................................................................................................................58

5.10.3 Sample code for the initial configuration of ECO prescaler settings .............................................59

5.11 Configuring the LPECO_Prescaler ........................................................................................................61

5.11.1 Use case............................................................................................................................................61

5.11.2 Configuration ...................................................................................................................................62

5.11.3 Sample code for the initial configuration of LPECO prescaler settings .........................................62

6Supplementary information.....................................................................................................65

6.1 Input clocks in peripheral functions.....................................................................................................65

6.2 Use case of the clock calibration counter function..............................................................................66

6.2.1.1 Use case.......................................................................................................................................67

6.2.1.2 Configuration ..............................................................................................................................67

6.2.1.3 Sample code for the initial configuration of the clock calibration counter with ILO0 and ECO

settings ........................................................................................................................................68

6.2.2 ILO0 calibration using the clock calibration counter function.......................................................70

6.2.2.1 Configuration ..............................................................................................................................71

6.2.2.2 Sample code for the initial configuration of ILO0 calibration using clock calibration counter

settings ........................................................................................................................................71

6.3 CSV diagram and relationship of the monitored clock and reference clocks.....................................73

7Glossary .................................................................................................................................75

References ......................................................................................................................................77

Other references..............................................................................................................................78

Revision history...............................................................................................................................79

Application Note 3 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Introduction

1Introduction

TRAVEO™ T2G family MCUs, targeted at automotive systems such as instrument clusters and head-up display

(HUD), have a 2D graphics engine, sound processing, 32-bit automotive microcontrollers based on the Arm®

Cortex®-M7 processor with FPU (single and dual precision), and manufactured on an advanced 40-nm process

technology. These products enable a secure computing platform, and incorporate Infineon low-power flash

memory along with multiple high-performance analog and digital functions.

The TRAVEO™ T2G clock system supports high-, and low-speed clocks using both internal and external clock

sources. One of the typical use case for clock input is internal real-time clock (RTC). The TRAVEO™ T2G MCU

supports phase-locked loop (PLL) and frequency-locked loop (FLL) to generate clocks that operate the internal

circuit at a high speed.

The TRAVEO™ T2G MCU also supports the function to monitor clock operation and to measure the clock

difference of each clock with reference to a known clock.

To know more on the functionality described and terminology used in this application note, see the “Clocking

system”chapter in the architecture technical reference manual (TRM).

In this document, TRAVEO™ T2G family MCUs refer to CYT4D series.

Application Note 4 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Clock system for TRAVEO™ T2G family MCUs

2Clock system for TRAVEO™ T2G family MCUs

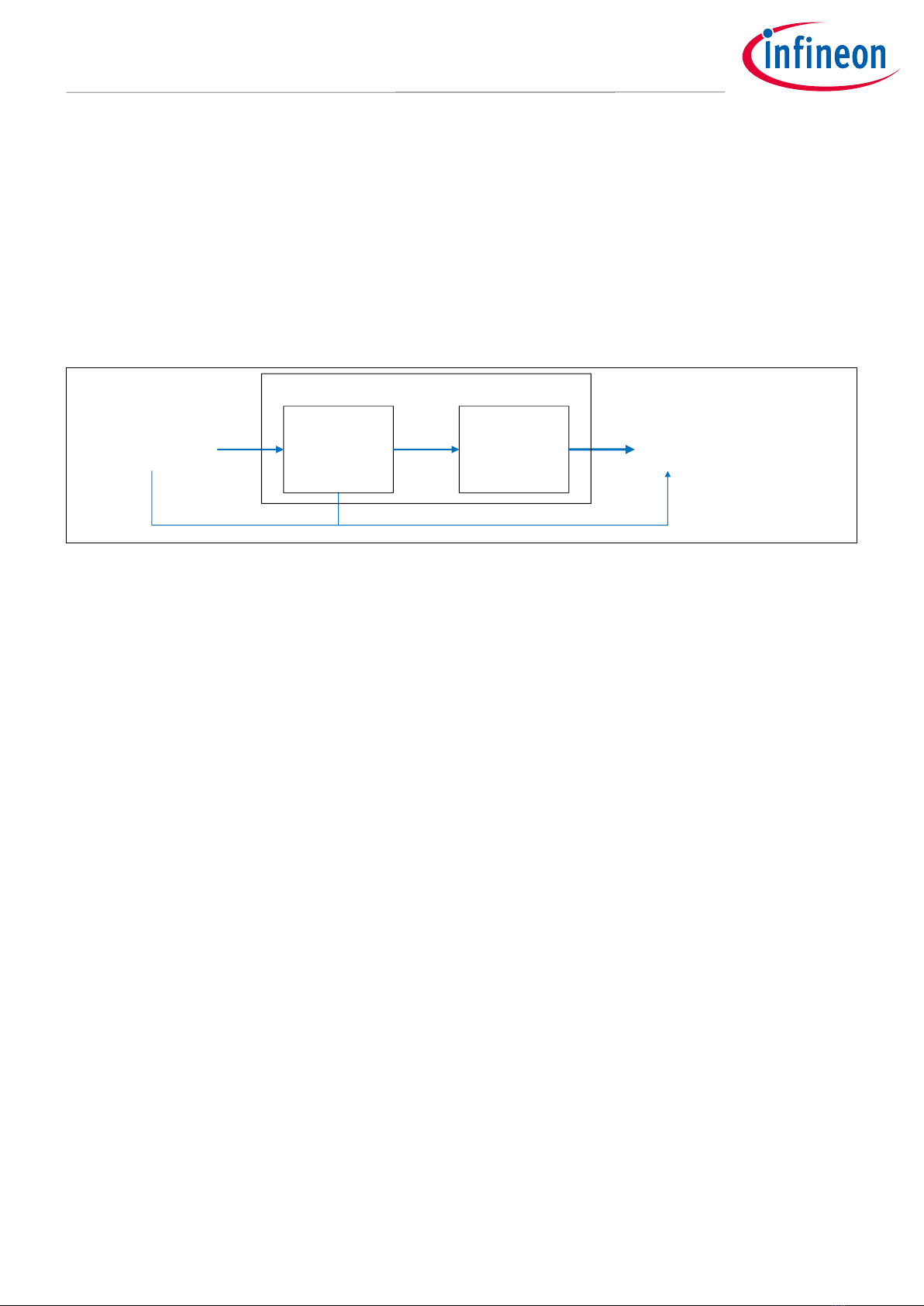

2.1 Overview of the clock system

The clock system in this series of MCUs is divided into two blocks. One block selects the clock resources (such

as external oscillation and internal oscillation) and multiplies the clock (using FLL and PLL). The other block

distributes and divides clocks to the CPU cores and other peripheral functions. However, there are some

exceptions where the RTC can connect directly to a clock resource.

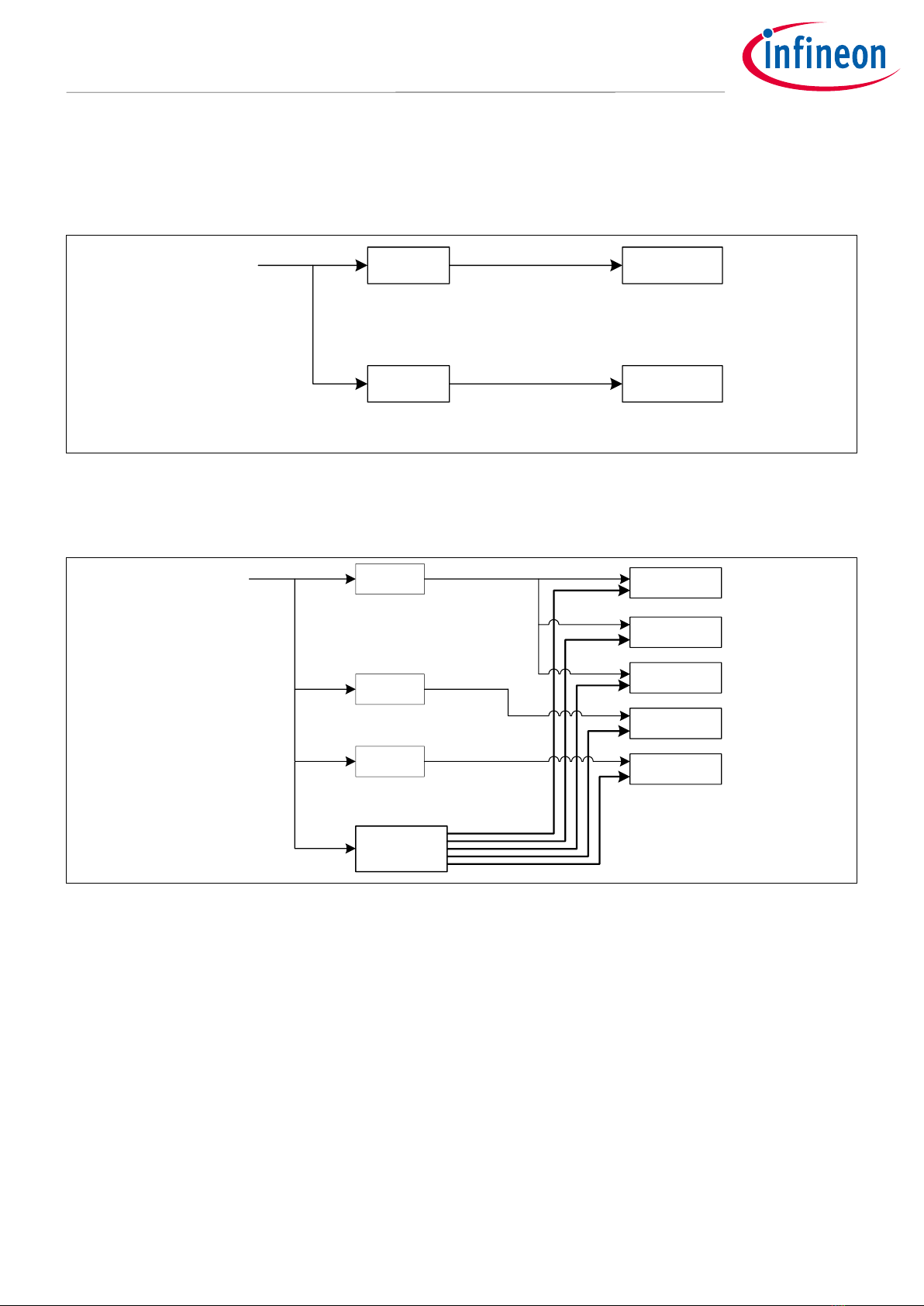

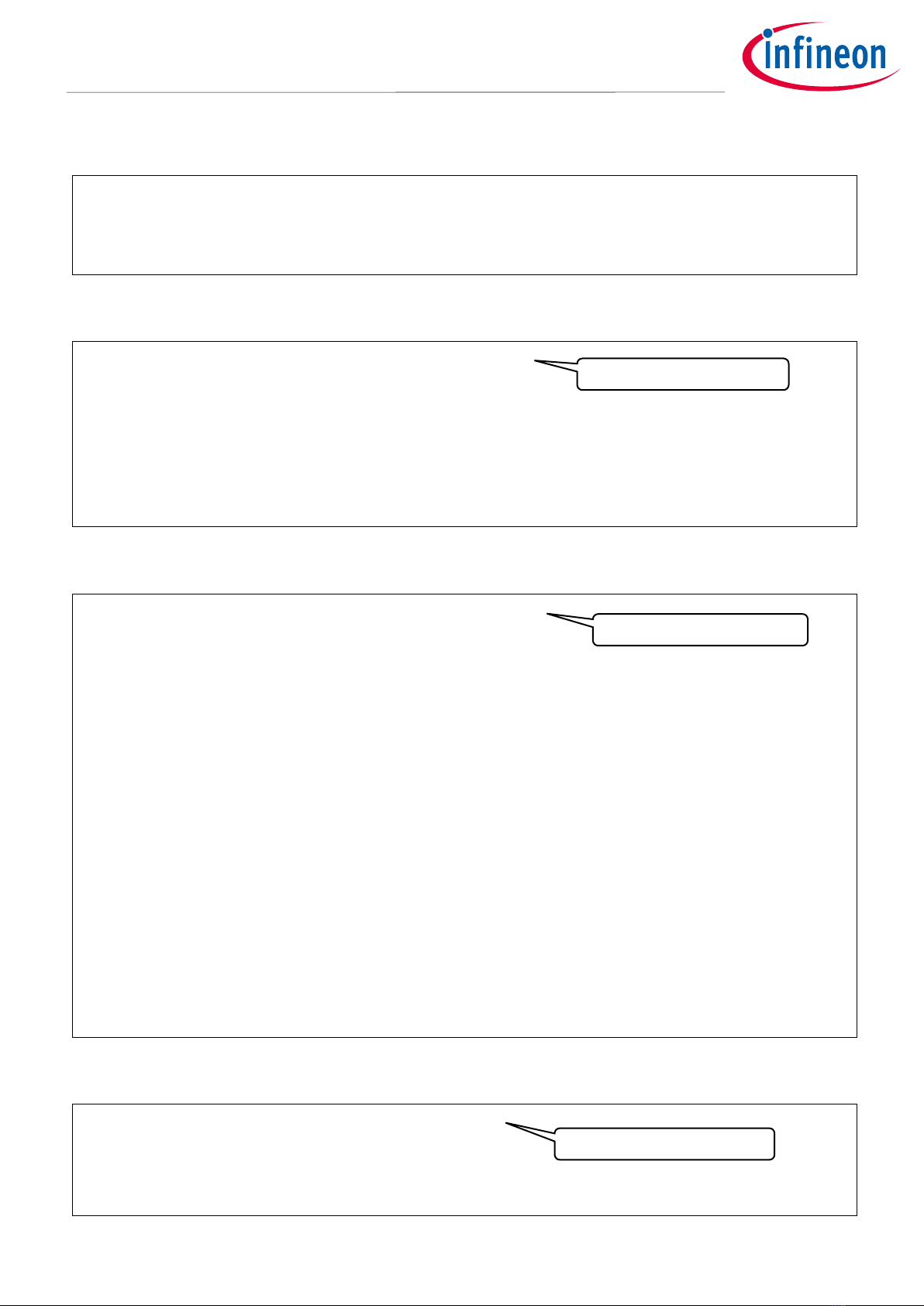

Figure 1 shows the overview of the clock system structure.

Clock distribution/

division

Clock selection

and multiplier

Internal circuit

(CPU core, peripheral functions,

etc.)

Clock sources

(External, Internal)

Clock system

Figure 1 Overview of the clock system structure

2.2 Clock resources

The MCUs support two types of resource inputs: internal and external. Each of these internally support three

types of clocks respectively.

•Internal clock sources (All these clocks are enabled by default):

−Internal main oscillator (IMO): This is a built-in clock with a frequency of 8 MHz (TYP).

−Internal low-speed oscillator 0 (ILO0): This is a built-in clock with a frequency of 32 kHz (TYP).

−Internal low-speed oscillator 1 (ILO1): ILO1 has the same function as ILO0, but ILO1 can monitor the clock

of ILO0.

•External clock sources (All these clocks are disabled by default):

−External crystal oscillator (ECO): This clock uses an external oscillator whose input frequency range is

between 3.988 MHz and 33.34 MHz.

−Watch crystal oscillator (WCO): This also uses an external oscillator whose frequency is stable at 32.768

kHz, mainly used by the RTC module.

−External clock (EXT_CLK): The EXT_CLK is a 0.25 MHz to 100 MHz range clock that can be sourced from a

signal on a designed I/O pin. This clock can be used as the source clock for either PLL or FLL, or can be

used directly by the high-frequency clocks.

−Low-power external crystal oscillator (LPECO): This clock uses an external oscillator. The input frequency

range is between 4 MHz and 8 MHz. The LPECO can be regarded as an ECO operating in low-power mode.

For more details on functions such as IMO, PLL, and so on, and numerical values such as frequency, see the

TRAVEO™ T2G architecture TRM and the datasheet.

2.3 Clock system functions

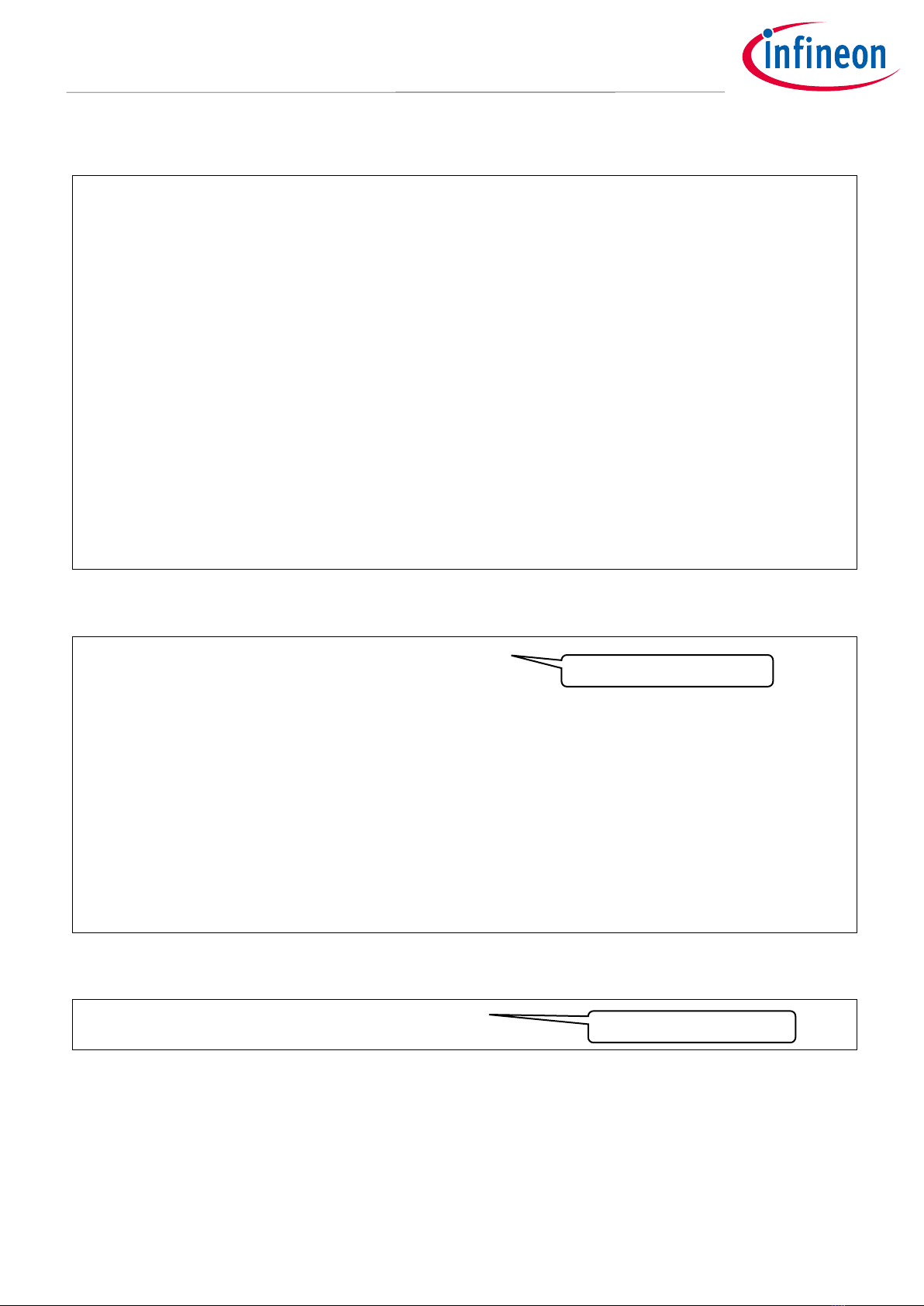

Figure 2 shows the details of the clock selection and multiplier block. This block generates root frequency

clocks CLK_HF0 to CLK_HF13 from the clock resources. This block has a capability to select one of the

Application Note 5 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Clock system for TRAVEO™ T2G family MCUs

supported clock resources, FLL, and PLL to generate the required high-speed clocks. These MCUs support two

types of PLLs: PLL without spread spectrum clock generation (SSCG) and fractional operation (PLL200#x), and

PLL with SSCG and fractional operation (PLL400#x).

PATH_MUX4

DSI_MUX4

IMO

EXT_CLK

Predivider

(1/2/4/8)

CSV

CLK_HF1

CLK_PATH0

FLL

CLK_PATH5

PLL400

#4

CLK_PATH6

PLL200

#0

CLK_PATH7

PLL200

#1

CLK_PATH8

PLL200

#2

Predivider

(1/2/4/8)

CSV

CLK_HF2

Predivider

(1/2/4/8)

CSV

CLK_HF3

Predivider

(1/2/4/8)

CSV

CLK_HF4

Predivider

(1/2/4/8)

CSV

CLK_HF5

Predivider

(1/2/4/8)

CSV

CLK_HF6

Predivider

(1/2/4/8)

CSV

CLK_HF7

Predivider

(1/2/4/8)

CSV

CLK_HF8

CLK_PATH9

ECO

Prescaler

ECO

ILO0

ILO1

WCO

CSV

CLK_REF_HF

CSV

CSV

CLK_LF

Active Domain

DeepSleep Domain

Hibernate Domain

REF_MUX

PATH_MUX9

DSI_MUX9

ROOT_MUX5

ROOT_MUX6

ROOT_MUX7

ROOT_MUX8

ROOT_MUX4

ROOT_MUX3

ROOT_MUX2

ROOT_MUX1

PATH_MUX8

DSI_MUX8

BYPASS_MUX8

PATH_MUX7

DSI_MUX7

BYPASS_MUX7

PATH_MUX6

DSI_MUX6

BYPASS_MUX6

PATH_MUX5

DSI_MUX5

BYPASS_MUX5

BYPASS_MUX0

LFCLK_SEL

CLK_SEL

CLK_ILO0

CLK_BAK

LPECO LPECO

Prescaler

Predivider

(1/2/4/8)

CSV

CLK_HF0

ROOT_MUX0

Predivider

(1/2/4/8)

CSV

CLK_HF9

Predivider

(1/2/4/8)

CSV

CLK_HF10

Predivider

(1/2/4/8)

CSV

CLK_HF11

Predivider

(1/2/4/8)

CSV

CLK_HF12

Predivider

(1/2/4/8)

CSV

CLK_HF13

ROOT_MUX10

ROOT_MUX11

ROOT_MUX12

ROOT_MUX13

ROOT_MUX9

CLK_PATH1

PLL400

#0

CLK_PATH2

PLL400

#1

CLK_PATH3

PLL400

#2

CLK_PATH4

PLL400

#3 BYPASS_MUX4

PATH_MUX3

DSI_MUX3

BYPASS_MUX3

PATH_MUX2

DSI_MUX2

BYPASS_MUX2

PATH_MUX1

DSI_MUX1

BYPASS_MUX1

PATH_MUX0

DSI_MUX0

Figure 2 Block diagram

Application Note 6 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Clock system for TRAVEO™ T2G family MCUs

Active domain

Region of operation in only Active power mode

DeepSleep domain

Region of operation in only Active and DeepSleep modes

Hibernate domain

Region of operation in all power modes

ECO prescaler

Divides the ECO and creates a clock that can be used with the CLK_LF clock.

The division function has a 10-bit integer divider and 8-bit fractional divider.

LPECO prescaler

Divides the LPECO and creates a clock that can be used with the CLK_BAK. The

division function has a 10-bit integer divider and 8-bit fractional divider.

DSI_MUX

Selects a clock from ILO0, ILO1, and WCO

PATH_MUX

Selects a clock from IMO, ECO, EXT_CLK, LPECO, and DSI_MUX output

CLK_PATH

CLK_PATHx 0 through 9 are used as the input sources for high-frequency

clocks.

CLK_HF

CLK_HFx 0 through 13 are recognized as high-frequency clocks.

FLL

Generates the high-frequency clock

PLL

Generates the high-frequency clock. There are two kinds of PLL: PLL200 and

PLL400. PLL200 is with SSCG and fractional operation and PLL400 is with SSCG

and fractional operation.

BYPASS_MUX

Selects the clock to be output to the CLK_PATH. In the case of FLL, the clock

that can be selected is either FLL output or clock input to FLL.

ROOT_MUX

Selects the clock source of the CLK_HFx. The clocks that can be selected are

CLK_PATHs 0 through 9.

Predivider

The predivider (divided by 1, 2, 4, or 8) is available to divide the selected

CLK_PATH.

REF_MUX

Selects the CLK_REF_HF clock source

CLK_REF_HF

Used to monitor the CSV of the CLK_HF

LFCLK_SEL

Selects the CLK_LF clock source

CLK_LF

MCWDT source clock

CLK_SEL

Selects the clock to be input to the RTC

CLK_BAK

Mainly input to the RTC

CSV

Clock supervision to monitor the clock operation

Application Note 7 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Clock system for TRAVEO™ T2G family MCUs

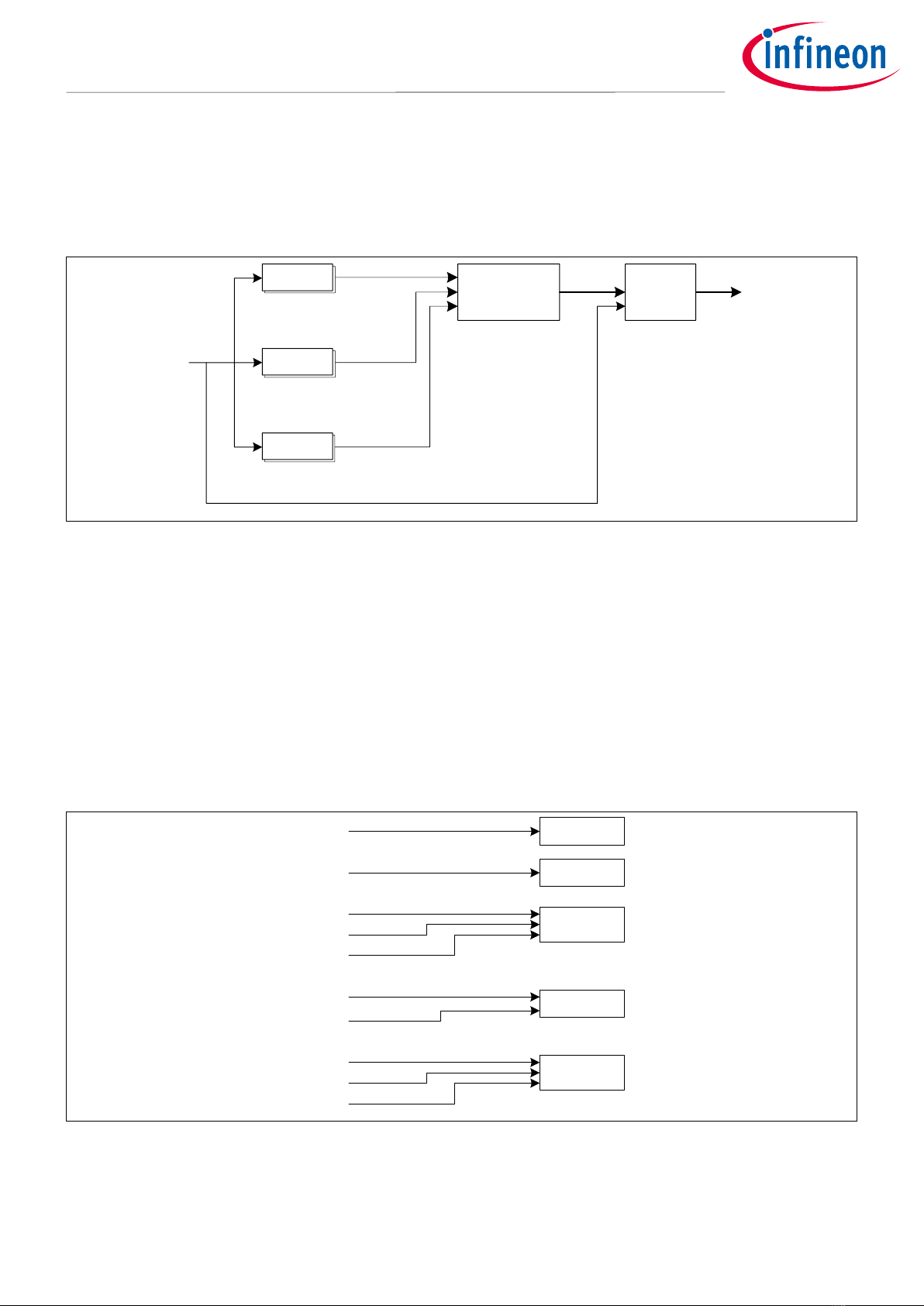

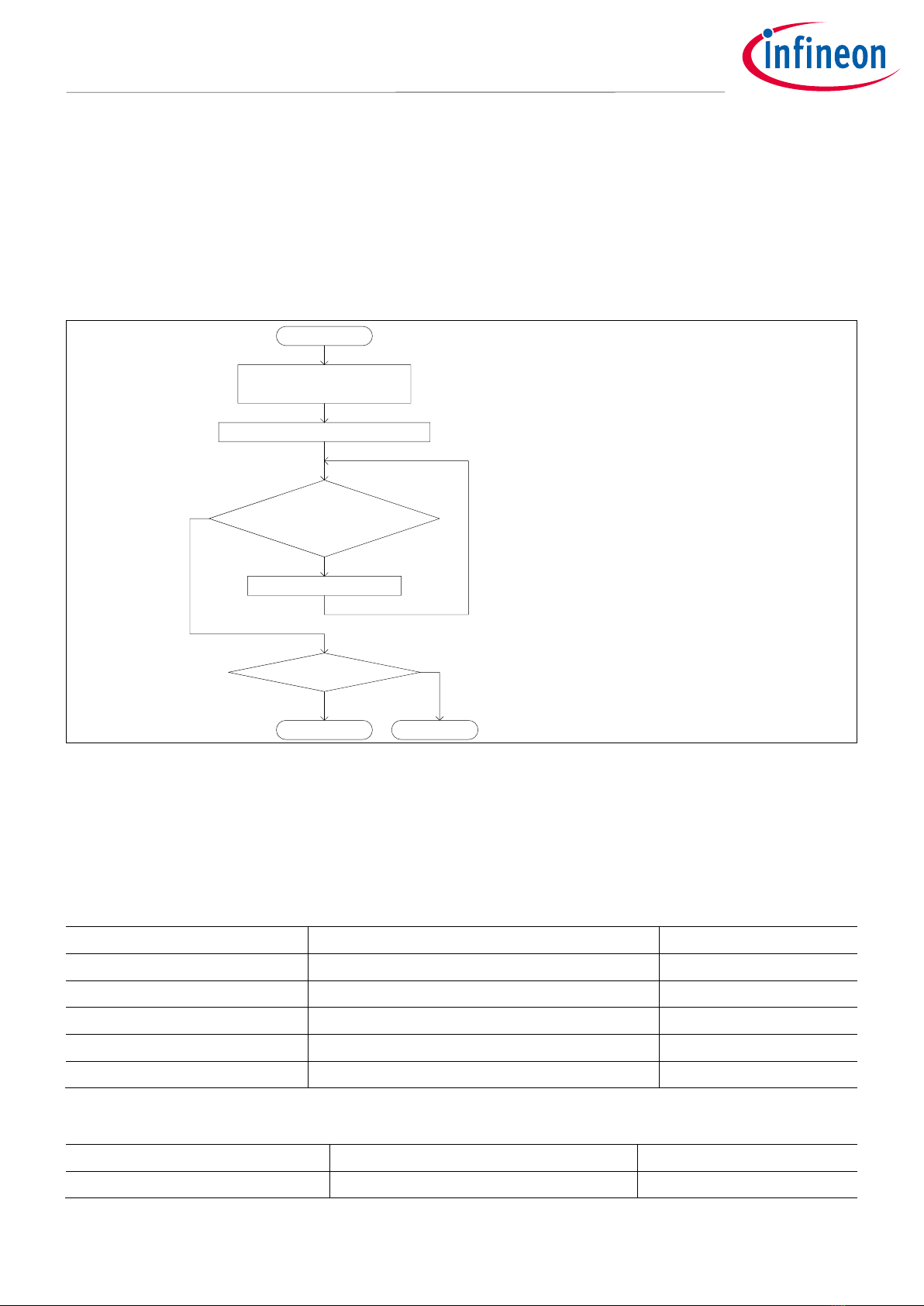

Figure 3 shows the distribution of the CLK_HF0.

The CLK_HF0 is the root clock for the CPU subsystem (CPUSS) and peripheral clock dividers. For details on

Figure 3, see the architecture TRM and datasheet.

CLK_TRC_DBG

CLK_GR3

CLK_MEM

PCLK

CLK_SLOW

SLOW_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

CLK_HF0

CM0+

ROM / SRAM / Flash

CPUSS

slow infrastructure

P-DMA / M-DMA

CRYPTO

MEM_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

PERI_GR3_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

CLK_PERI

PERI_CLOCK_CTL register, INT_DIV

bit

Divider

(1-256)

Event generator

SMIF

CPUSS

fast infrastructure

SRSS

EFUSE

Ethernet

CLK_GR4

PERI_GR4_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

IOSS

TCPWM[0]

CLK_GR8

PERI_GR8_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

AUDIOSS

CPUSS(DEBUG)

TRC_DBG_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

Peripheral

clock divider #0

PERI

VIDEOSS

Figure 3 Block diagram for CLK_HF0

CLK_MEM

Clock input to the CPUSS of the fast infrastructure, Ethernet, and serial

memory interface (SMIF)

CLK_PERI

Clock source for the CLK_GR and peripheral clock divider

CLK_SLOW

Clock input to the CPUSS of Cortex®-M0+ and slow infrastructure, SMIF, and

VIDEOSS

CLK_GR

Clock input to peripheral functions. The CLK_GR is grouped by the clock gater.

CLK_GR has six groups.

PCLK

Peripheral clock used in peripheral functions. The PCLK can be configured

each channel of IPs independently and select one divider to generate the

PCLK.

Application Note 8 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Clock system for TRAVEO™ T2G family MCUs

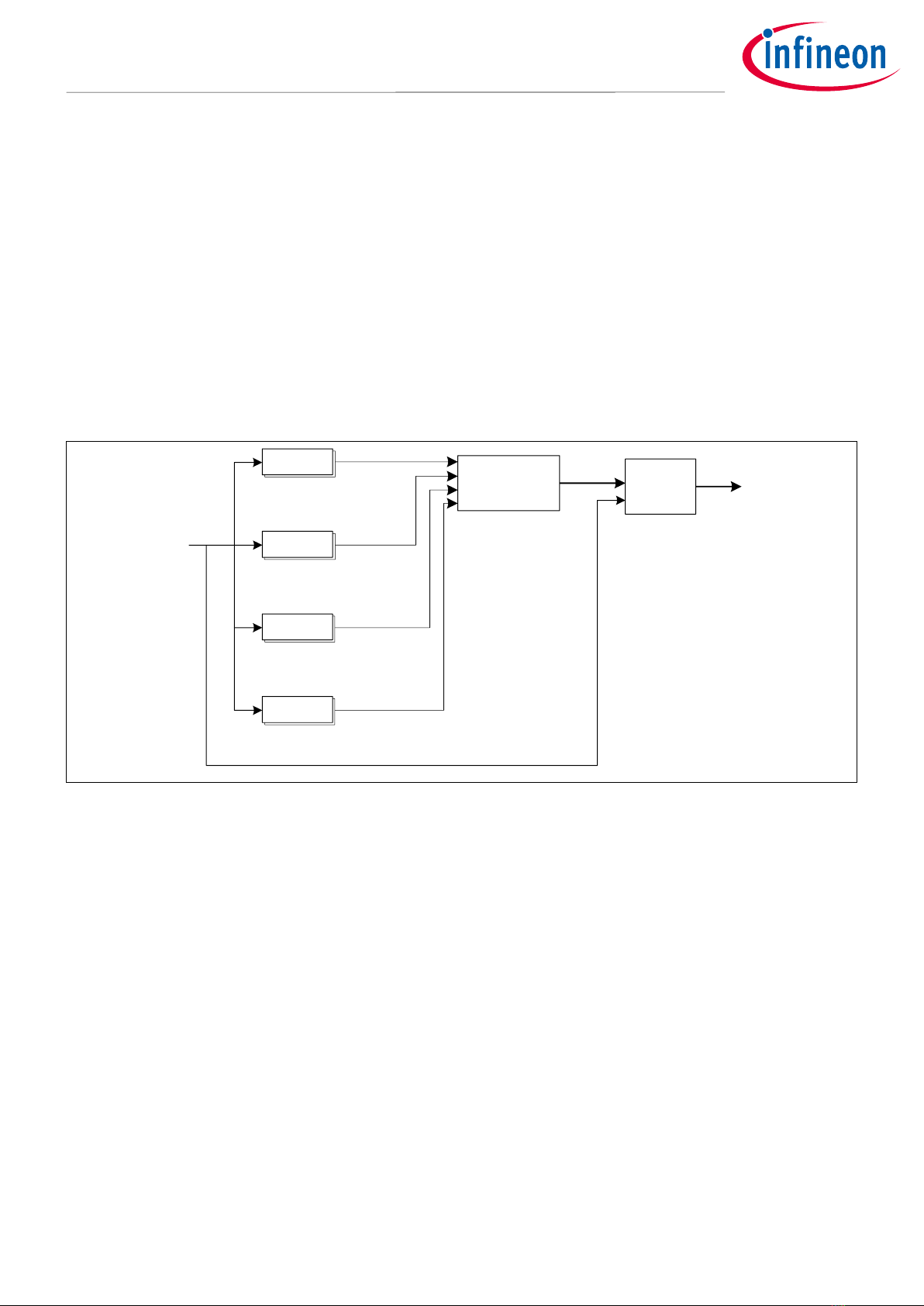

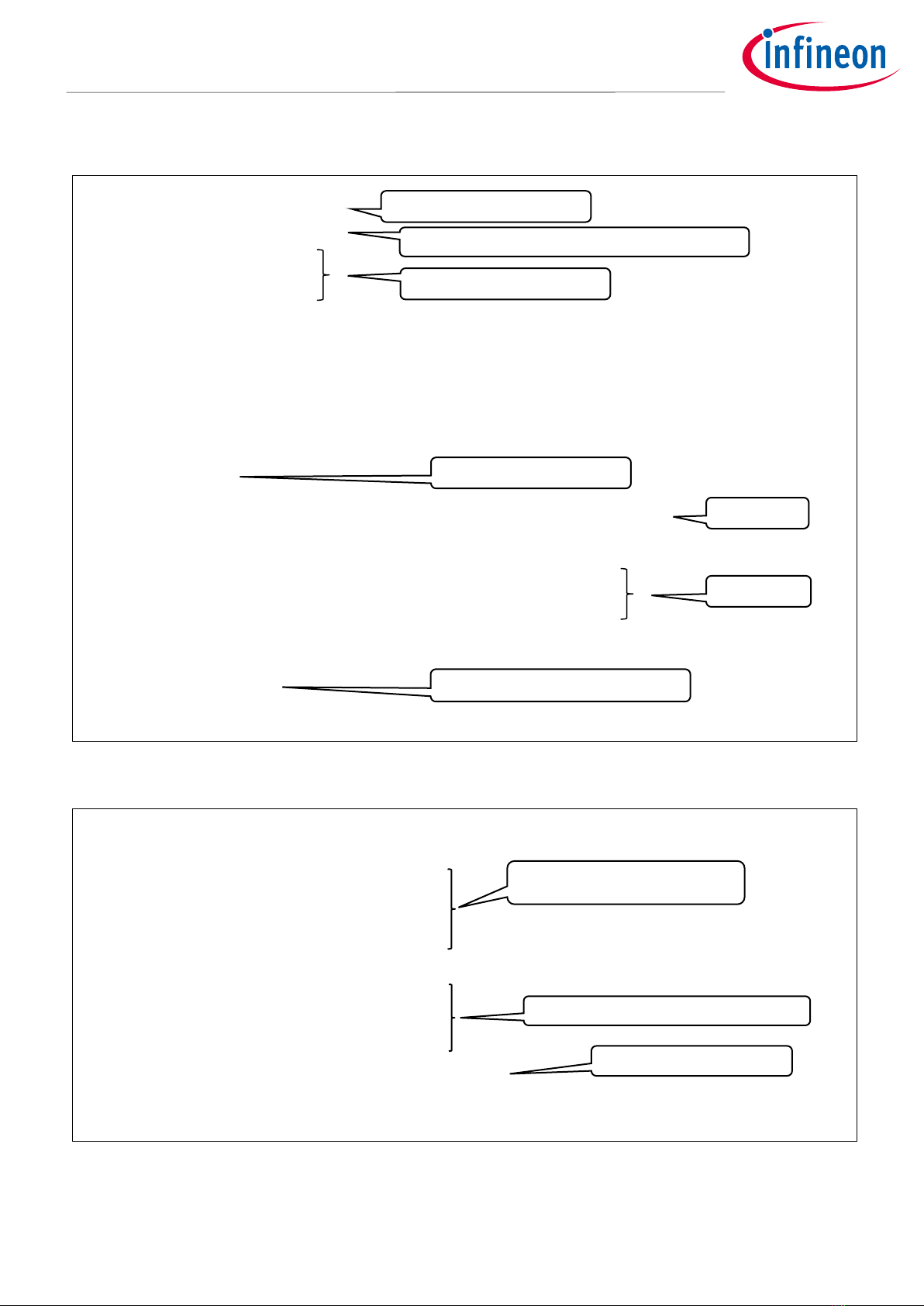

Figure 4 shows details of the peripheral clock divider #0.

These MCUs need a clock to each peripheral unit (say, the serial communication block (SCB), the timer,

counter, PWM (TCPWM), and so on) and its respective channel. These clocks are controlled by their respective

dividers.

This peripheral clock divider #0 has many peripheral clock dividers to generate the peripheral clock (PCLK). See

the datasheet for the number of dividers. The output of any of these dividers can be routed to any peripheral.

Note that dividers already in use cannot be used for other peripherals or channels.

PCLK

Clock divider

8.0

CLK_PERI

PERI_DIV_8_CTL register, INT8_DIV

bit

Clock divider

16.0

PERI_DIV_16_CTL register,

INT16_DIV bit

Clock divider

16.5

PERI_DIV_16_5_CTL register,

FRAC5_DIV bit & INT24_DIV bit

PERI_CLOCK_CTL register,

TYPE_SEL bit & DEV_SEL bit

9 dividers

16 dividers

7 dividers

124 mu ltiplexers

Clock

Generation

Clock divider

24.5

PERI_DIV_24_5_CTL register,

FRAC5_DIV bit & INT24_DIV bit

3 dividers

Clock enable multiplexing

Figure 4 Block diagram for the peripheral clock divider #0

CLK_TRC_DBG

Clock input to the CPUSS (DEBUG).

Divider

Divider has a function to divide each clock. It can be configured from 1 division

to 256 divisions.

Clock divider8.0

Divides a clock by 8

Clock divider16.0

Divides a clock by 16

Clock divider16.5

Divides a clock by 16.5

Clock divider24.5

Divides a clock by 24.5

Clock enable multiplexing

Enables the signal output from the clock divider

Clock generator

Divides the CLK_PERI based on the clock divider

Application Note 9 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Clock system for TRAVEO™ T2G family MCUs

Figure 5 shows the distribution of the CLK_HF1.

The CLK_HF1 is a clock source of the CLK_FAST_0 and CLK_FAST_1. The clock distribution of the CLK_HF1 is

shown in Figure 5. The CLK_FAST_0 and CLK_FAST_1 are the input sources for CM7_0 and CM7_1 respectively.

CLK_FAST_0

CLK_HF1 CM7_0

FAST_0_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

CLK_FAST_1 CM7_1

FAST_1_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

Figure 5 Block diagram for the CLK_HF1

Figure 6 shows the distribution of the CLK_HF2, which is a clock source for the CLK_GR and PCLK.

CLK_GR5

PCLK

Peripheral

Clock Divider #1

PERI_GR5_CLOCK_CTLregister,

INT_DIV bit

Divider

(1-256)

LIN

CAN FD

CLK_GR6

PERI_GR6_CLOCK_CTL register,

INT_DIV bit

Divider

(1-256)

SCB

CLK_GR9

PERI_GR9_CLOCK_CTLregister,

INT_DIV bit

Divider

(1-256) SAR ADC

CLK_HF2

CXPI

Figure 6 Block diagram for the CLK_HF2

Application Note 10 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Clock system for TRAVEO™ T2G family MCUs

Figure 7 shows details of the peripheral clock divider #1.

The peripheral clock divider #1 has many peripheral clock dividers to generate the PCLK. See the datasheet for

the number of dividers. The output of any of these dividers can be routed to any peripheral. Note that the

dividers already in use cannot be used for other peripherals or channels.

PCLK

Clock divider

8.0

CLK_HF2

PERI_DIV_8_CTL register, INT8_DIV

bit

Clock enable multiplexing

Clock divider

16.0

PERI_DIV_16_CTL register,

INT16_DIV bit

Clock divider

24.5

PERI_DIV_24_5_CTL register,

FRAC5_DIV bit & INT24_DIV bit

PERI_CLOCK_CTLregister,

TYPE_SEL bit & DEV_SEL bit

3 dividers

4 dividers

7 dividers

124 mu ltiplexers

Clock

generation

Figure 7 Block diagram for the peripheral clock divider #1

Figure 8 shows the distribution of the CLK_HF3, CLK_HF4, CLK_HF5, CLK_HF6, CLK_HF7, CLK_HF8, CLK_HF9,

CLK_HF10, CLK_HF11, and CLK_HF12. For details on these functions in Figure 8, see the architecture TRM.

CLK_HF4 Ethernet

CLK_HF5 AUDIOSS

CLK_HF8

CLK_HF3 Event generator

SMIF

CLK_HF6

CLK_HF7

CLK_HF9

CLK_HF10 VIDEOSS

CLK_HF11

CLK_HF12

Figure 8 Block diagram for the CLK_HFx (x = 3 to 12)

The CLK_HF13 is dedicated to the CSV. See the architecture TRM for the CSV description.

Clock divider8.0

Divides a clock by 8

Clock divider16.0

Divides a clock by 16

Clock divider24.5

Divides a clock by 24.5

Clock enable multiplexing

Enables the signal output from the clock divider

Clock generator

Divides the CLK_PERI based on the clock divider

Application Note 11 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Clock system for TRAVEO™ T2G family MCUs

2.4 Basic clock system settings

This section describes how to configure the clock system based on a use case using the sample driver library

(SDL) provided by Infineon. The code snippets in this application note are part of the SDL. See Other

references.

The SDL has a configuration part and a driver part. The configuration part configures the parameter values for

the desired operation. The driver part configures each register based on the parameter values in the

configuration part. You can configure the configuration part according to your system.

Application Note 12 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

3Configuration of the clock resources

3.1 Setting the ECO

The ECO is disabled by default and needs to be enabled for usage. Also, trimming is necessary to use the ECO.

This device can configured with the trimming parameters that control the oscillator according to crystal unit

and ceramic resonator. The method to determine the parameters differs between the crystal unit and ceramic

resonator. See the Setting ECO parameters section in the TRAVEO™ T2G user guide for more information.

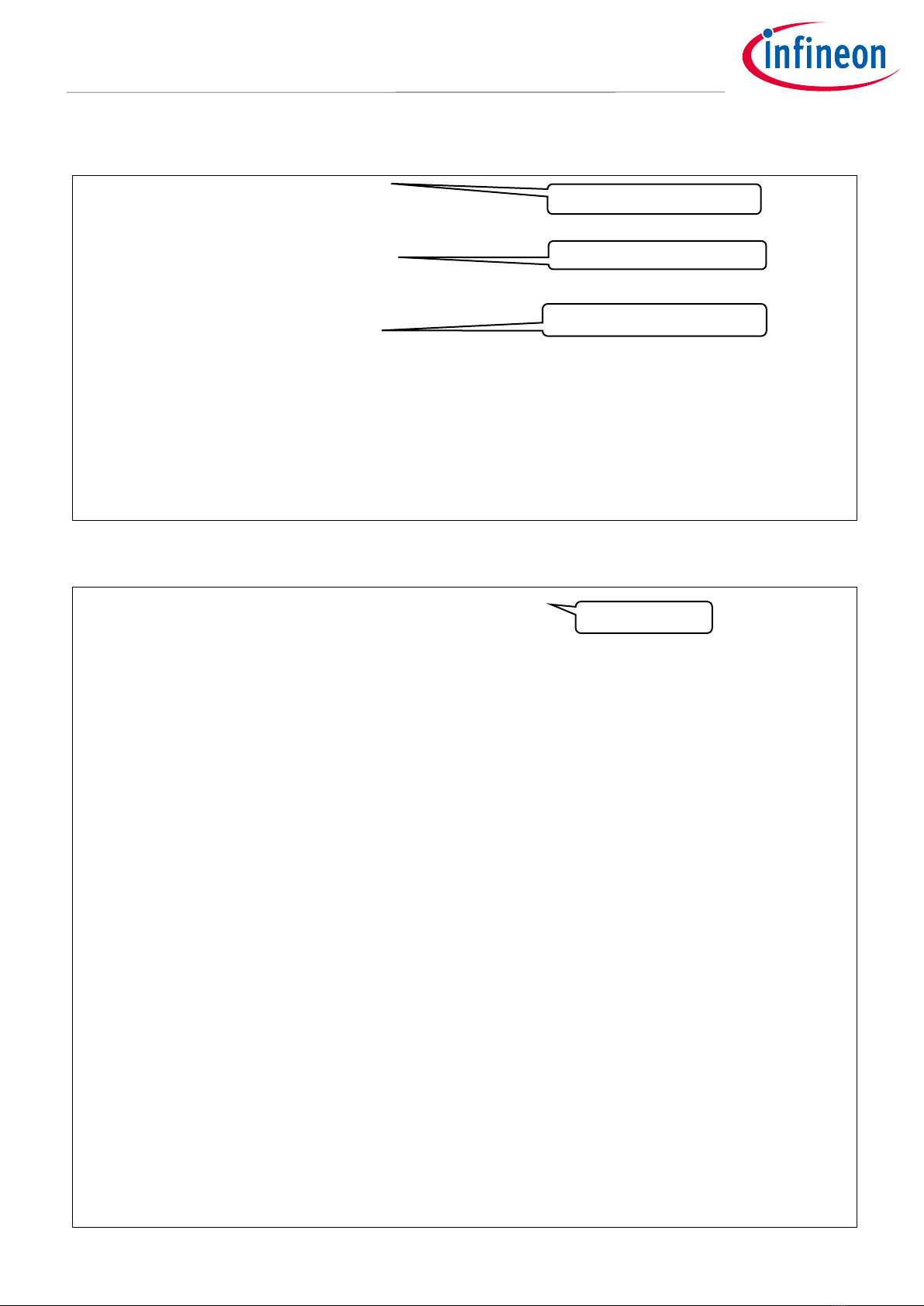

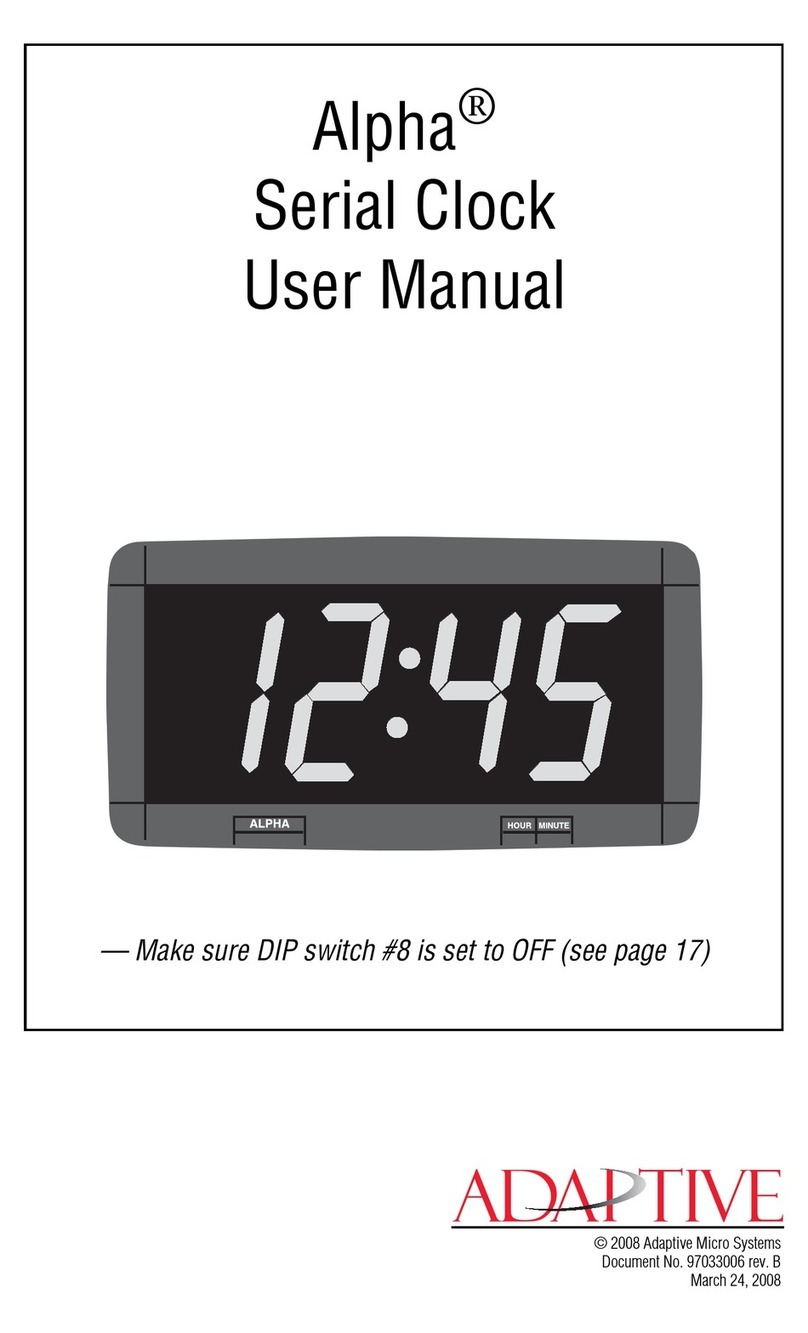

Figure 9 shows the ECO setting steps.

Start

Write "1" to ECO_EN

Check the state of

ECO_OK and the state of

TIMEOUT?

Yes

End(Success)

No

Define variable to count timeout

Configure the initial value of TIMEOUT

ECO_OK is already 1?

End(No change)

Define TIMEOUT variable

Configure TIMEOUT value

Write "1" to ECO_EN and to be available ECO

TIMEOUT= 0?

Subtract TIMEOUT value

End(Timeout)

Yes

No

No

Yes

Check whether the processing exited the loop at TIMEOUT

Configure trim Set ECO trimming data and AGC disabled

1. Calculate trim data

2. Trim settings by ECO user guide

(1)*

(2)

(3)

(4)

(5)

(6)

* Use to select the trimming data calculated by the software or the data calculated according to the ECO user guide.

Figure 9 Enabling the ECO

Application Note 13 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

3.1.1 Use case

•Oscillator to use: Crystal unit

•Fundamental frequency: 16 MHz

•Maximum drive level: 300.0 µW

•Equivalent series resistance: 150.0 ohm

•Shunt capacitance: 0.530 pF

•Parallel load capacitance: 8.000 pF

•Crystal unit vendor’s recommended value of negative resistance: 1500 ohm

•Automatic gain control: OFF

Note:These values are decided in consultation with the Crystal unit vendor.

3.1.2 Configuration

Table 1 lists the parameters and Table 2 lists the functions of the configuration part of in the SDL for ECO trim

settings.

Table 1 List of ECO trim settings parameters

Parameters

Description

Value

CLK_ECO_CONFIG2.WDTRIM

Watchdog trim

Calculated from Setting ECO parameters in

TRAVEO™ T2G user guide

7ul

CLK_ECO_CONFIG2.ATRIM

Amplitude trim

Calculated from Setting ECO parameters in

TRAVEO™ T2G user guide

0ul

CLK_ECO_CONFIG2.FTRIM

Filter trim of 3rd harmonic oscillation

Calculated from Setting ECO parameters in

TRAVEO™ T2G user guide

3ul

CLK_ECO_CONFIG2.RTRIM

Feedback resistor trim

Calculated from Setting ECO parameters in

TRAVEO™ T2G user guide

3ul

CLK_ECO_CONFIG2.GTRIM

Startup time of the gain trim

Calculated from Setting ECO parameters in

TRAVEO™ T2G user guide

3ul

CLK_ECO_CONFIG.AGC_EN

Automatic gain control (AGC) disabled

Calculated from Setting ECO parameters in

TRAVEO™ T2G user guide

0ul [OFF]

WAIT_FOR_STABILIZATION

Waiting for stabilization

10000ul

PLL_400M_0_PATH_NO

PLL number for PLL_400M_0

1ul

PLL_400M_1_PATH_NO

PLL number for PLL_400M_1

2ul

PLL_200M_0_PATH_NO

PLL number for PLL_200M_0

3ul

PLL_200M_1_PATH_NO

PLL number for PLL_200M_1

4ul

CLK_FREQ_ECO

Source clock frequency

16000000ul

SUM_LOAD_SHUNT_CAP_IN_PF

Sum of load shunt capacity (pF)

17ul

Application Note 14 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

Parameters

Description

Value

ESR_IN_OHM

Equivalent series resistance (ESR) (ohm)

250ul

MAX_DRIVE_LEVEL_IN_UW

Maximum drive level (uW)

100ul

MIN_NEG_RESISTANCE

Minimum negative resistance

5 * ESR_IN_OHM

Table 2 List of ECO trim settings functions

Functions

Description

Value

Cy_WDT_Disable()

Disable the watchdog timer

–

Cy_SysClk_FllDisable

Sequence(Wait Cycle)

Disable the FLL

Wait cycle =

WAIT_FOR_STABILIZATION

Cy_SysClk_Pll400M

Disable(PLL Number)

Disable the PLL400M_0

PLL number =

PLL_400M_0_PATH_NO

Disable the PLL400M_1

PLL number =

PLL_400M_1_PATH_NO

Cy_SysClk_PllDisable

(PLL Number)

Disable the PLL200M_0

PLL number =

PLL_200M_0_PATH_NO

Disable the PLL200M_1

PLL number =

PLL_200M_1_PATH_NO

AllClockConfiguration

()

Clock configuration

–

Cy_SysClk_EcoEnable

(Timeout value)

Set ECO enable and timeout value

Timeout value =

WAIT_FOR_STABILIZATION

Cy_SysLib_DelayUs(Wait

Time)

Delay by the specified number of

microseconds

Wait time = 1u (1us)

3.1.3 Sample code for initial ECO configuration

Code Listing 1 provides a sample code.

The following description will help you understand the register notation of the driver part of the SDL:

•SRSS->unCLK_ECO_CONFIG.stcField.u1ECO_EN is the SRSS_CLK_ECO_CONFIG.ECO_EN mentioned in the

Registers TRM. Other registers are also described in the same manner.

•Performance improvement measures

To improve the performance of register setting, the SDL writes a complete 32-bit data to the register. Each

bit field is generated in advance in a bit-writable buffer and written to the register as the final 32-bit data.

tempTrimEcoCtlReg.u32Register = SRSS->unCLK_ECO_CONFIG2.u32Register;

tempTrimEcoCtlReg.stcField.u3WDTRIM = wdtrim;

tempTrimEcoCtlReg.stcField.u4ATRIM = atrim;

tempTrimEcoCtlReg.stcField.u2FTRIM = ftrim;

tempTrimEcoCtlReg.stcField.u2RTRIM = rtrim;

tempTrimEcoCtlReg.stcField.u3GTRIM = gtrim;

SRSS->unCLK_ECO_CONFIG2.u32Register = tempTrimEcoCtlReg.u32Register;

See cyip_srss_v2.h under hdr/rev_x/ip for more information on the union and structure representation of

registers.

Application Note 15 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

Code Listing 1 General configuration of ECO settings

:

/** Wait time definition **/

#define WAIT_FOR_STABILIZATION (10000ul)

:

#define CLK_FREQ_ECO (16000000ul)

:

#define PLL_400M_0_PATH_NO (1ul)

#define PLL_400M_1_PATH_NO (2ul)

#define PLL_200M_0_PATH_NO (3ul)

#define PLL_200M_1_PATH_NO (4ul)

:

#define SUM_LOAD_SHUNT_CAP_IN_PF (17ul)

:

#define ESR_IN_OHM (250ul)

:

#define MIN_NEG_RESISTANCE (5 * ESR_IN_OHM)

#define MAX_DRIVE_LEVEL_IN_UW (100ul)

:

static void AllClockConfiguration(void);

:

int main(void)

{

/* disable watchdog timer */

Cy_WDT_Disable();

:

/* Disable Fll */

CY_ASSERT(Cy_SysClk_FllDisableSequence(WAIT_FOR_STABILIZATION) == CY_SYSCLK_SUCCESS);

/* Disable Pll */

CY_ASSERT(Cy_SysClk_Pll400MDisable(PLL_400M_0_PATH_NO) == CY_SYSCLK_SUCCESS);

CY_ASSERT(Cy_SysClk_Pll400MDisable(PLL_400M_1_PATH_NO) == CY_SYSCLK_SUCCESS);

CY_ASSERT(Cy_SysClk_PllDisable(PLL_200M_0_PATH_NO) == CY_SYSCLK_SUCCESS);

CY_ASSERT(Cy_SysClk_PllDisable(PLL_200M_1_PATH_NO) == CY_SYSCLK_SUCCESS);

/* Enable interrupt */

__enable_irq();

/* Set Clock Configuring registers */

AllClockConfiguration();

:

/* Please ensure output clock frequency using oscilloscope */

for(;;);

}

Code Listing 2 AllClockConfiguration() function

static void AllClockConfiguration(void)

{

:

/***** ECO setting ******/

cy_en_sysclk_status_t ecoStatus;

ecoStatus = Cy_SysClk_EcoConfigureWithMinRneg(

CLK_FREQ_ECO,

SUM_LOAD_SHUNT_CAP_IN_PF,

ESR_IN_OHM,

MAX_DRIVE_LEVEL_IN_UW,

MIN_NEG_RESISTANCE

);

CY_ASSERT(ecoStatus == CY_SYSCLK_SUCCESS);

{

SRSS->unCLK_ECO_CONFIG2.stcField.u3WDTRIM = 7ul;

SRSS->unCLK_ECO_CONFIG2.stcField.u4ATRIM = 0ul;

SRSS->unCLK_ECO_CONFIG2.stcField.u2FTRIM = 3ul;

SRSS->unCLK_ECO_CONFIG2.stcField.u2RTRIM = 3ul;

SRSS->unCLK_ECO_CONFIG2.stcField.u3GTRIM = 0ul;

SRSS->unCLK_ECO_CONFIG.stcField.u1AGC_EN = 0ul;

ecoStatus = Cy_SysClk_EcoEnable(WAIT_FOR_STABILIZATION);

CY_ASSERT(ecoStatus == CY_SYSCLK_SUCCESS);

}

:

return;

}

Either (1)-1 or (1)-2 can be used.

Comment out or delete unused code snippets in (1)-1 or (1)-2.

Define the TIMEOUT variable.

Define the oscillator parameters to use for software calculation.

Define the PLL number.

Watchdog timer disable

Disable the FLL.

Disable the PLL.

Trim and ECO setting. See Code Listing 2.

(1)-1. Trim settings for software calculation.

See Code Listing 4.

(1)-2. Trim settings according to the ECO user guide

ECO enable. See Code Listing 3.

Application Note 16 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

Code Listing 3 Cy_SysClk_EcoEnable() function

cy_en_sysclk_status_t Cy_SysClk_EcoEnable(uint32_t timeoutus)

{

cy_en_sysclk_status_t rtnval;

/* invalid state error if ECO is already enabled */

if (SRSS->unCLK_ECO_CONFIG.stcField.u1ECO_EN != 0ul) /* 1 = enabled */

{

return CY_SYSCLK_INVALID_STATE;

}

/* first set ECO enable */

SRSS->unCLK_ECO_CONFIG.stcField.u1ECO_EN = 1ul; /* 1 = enable */

/* now do the timeout wait for ECO_STATUS, bit ECO_OK */

for (;

(SRSS->unCLK_ECO_STATUS.stcField.u1ECO_OK == 0ul) &&(timeoutus != 0ul);

timeoutus--)

{

Cy_SysLib_DelayUs(1u);

}

rtnval = ((timeoutus == 0ul) ? CY_SYSCLK_TIMEOUT : CY_SYSCLK_SUCCESS);

return rtnval;

}

Code Listing 4 Cy_SysClk_EcoConfigureWithMinRneg() function

cy_en_sysclk_status_t Cy_SysClk_EcoConfigureWithMinRneg(uint32_t freq, uint32_t cSum, uint32_t esr, uint32_t

driveLevel, uint32_t minRneg)

{

/* Check if ECO is disabled */

if(SRSS->unCLK_ECO_CONFIG.stcField.u1ECO_EN == 1ul)

{

return(CY_SYSCLK_INVALID_STATE);

}

/* calculate intermediate values */

float32_t freqMHz = (float32_t)freq / 1000000.0f;

float32_t maxAmplitude = (1000.0f * ((float32_t)sqrt((float64_t)((float32_t)driveLevel / (2.0f *

(float32_t)esr))))) /

(M_PI * freqMHz * (float32_t)cSum);

float32_t gm_min = (157.91367042f /*4 * M_PI * M_PI * 4*/ * minRneg * freqMHz * freqMHz * (float32_t)cSum *

(float32_t)cSum) /

1000000000.0f;

/* Get trim values according to caluculated values */

uint32_t atrim, agcen, wdtrim, gtrim, rtrim, ftrim;

atrim = Cy_SysClk_SelectEcoAtrim(maxAmplitude);

if(atrim == CY_SYSCLK_INVALID_TRIM_VALUE)

{

return(CY_SYSCLK_BAD_PARAM);

}

agcen = Cy_SysClk_SelectEcoAGCEN(maxAmplitude);

if(agcen == CY_SYSCLK_INVALID_TRIM_VALUE)

{

return(CY_SYSCLK_BAD_PARAM);

}

wdtrim = Cy_SysClk_SelectEcoWDtrim(maxAmplitude);

if(wdtrim == CY_SYSCLK_INVALID_TRIM_VALUE)

{

return(CY_SYSCLK_BAD_PARAM);

}

(2) Check if ECO_OK is already enabled.

(3) Write “1” to the ECO_EN bit, and

make ECO available.

(4) Check the state of ECO_OK

and the state of TIMEOUT.

(5) Subtract the TIMEOUT value.

Wait for 1 us.

(6) Check whether processing exited the

loop at TIMEOUT.

Trim calculation by software

Get the Atrim value. See Code Listing 5.

Get the AGC enable setting. See Code Listing 6.

Get the Wdtrim value. See Code Listing 7.

Application Note 17 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

Code Listing 4 Cy_SysClk_EcoConfigureWithMinRneg() function

gtrim = Cy_SysClk_SelectEcoGtrim(gm_min);

if(gtrim == CY_SYSCLK_INVALID_TRIM_VALUE)

{

return(CY_SYSCLK_BAD_PARAM);

}

rtrim = Cy_SysClk_SelectEcoRtrim(freqMHz);

if(rtrim == CY_SYSCLK_INVALID_TRIM_VALUE)

{

return(CY_SYSCLK_BAD_PARAM);

}

ftrim = Cy_SysClk_SelectEcoFtrim(atrim);

/* update all fields of trim control register with one write, without changing the ITRIM field: */

un_CLK_ECO_CONFIG2_t tempTrimEcoCtlReg;

tempTrimEcoCtlReg.u32Register = SRSS->unCLK_ECO_CONFIG2.u32Register;

tempTrimEcoCtlReg.stcField.u3WDTRIM = wdtrim;

tempTrimEcoCtlReg.stcField.u4ATRIM = atrim;

tempTrimEcoCtlReg.stcField.u2FTRIM = ftrim;

tempTrimEcoCtlReg.stcField.u2RTRIM = rtrim;

tempTrimEcoCtlReg.stcField.u3GTRIM = gtrim;

SRSS->unCLK_ECO_CONFIG2.u32Register = tempTrimEcoCtlReg.u32Register;

SRSS->unCLK_ECO_CONFIG.stcField.u1AGC_EN = agcen;

return(CY_SYSCLK_SUCCESS);

}

Code Listing 5 Cy_SysClk_SelectEcoAtrim () function

__STATIC_INLINE uint32_t Cy_SysClk_SelectEcoAtrim(float32_t maxAmplitude)

{

if((0.50f <= maxAmplitude) && (maxAmplitude < 0.55f))

{

return(0x04ul);

}

else if(maxAmplitude < 0.60f)

{

return(0x05ul);

}

else if(maxAmplitude < 0.65f)

{

return(0x06ul);

}

else if(maxAmplitude < 0.70f)

{

return(0x07ul);

}

else if(maxAmplitude < 0.75f)

{

return(0x08ul);

}

else if(maxAmplitude < 0.80f)

{

return(0x09ul);

}

else if(maxAmplitude < 0.85f)

{

return(0x0Aul);

}

else if(maxAmplitude < 0.90f)

{

return(0x0Bul);

}

else if(maxAmplitude < 0.95f)

{

return(0x0Cul);

}

else if(maxAmplitude < 1.00f)

{

return(0x0Dul);

}

else if(maxAmplitude < 1.05f)

{

return(0x0Eul);

}

else if(maxAmplitude < 1.10f)

{

return(0x0Ful);

}

else if(1.1f <= maxAmplitude)

{

Get the Gtrim value. See Code Listing 8.

Get then Rtrim value. See Code Listing 9.

Get the Ftrim value. See Code Listing 10.

Get the Atrim value.

Application Note 18 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

Code Listing 5 Cy_SysClk_SelectEcoAtrim () function

return(0x00ul);

}

else

{

// invalid input

return(CY_SYSCLK_INVALID_TRIM_VALUE);

}

}

Code Listing 6 Cy_SysClk_SelectEcoAGCEN() function

__STATIC_INLINE uint32_t Cy_SysClk_SelectEcoAGCEN(float32_t maxAmplitude)

{

if((0.50f <= maxAmplitude) && (maxAmplitude < 1.10f))

{

return(0x01ul);

}

else if(1.10f <= maxAmplitude)

{

return(0x00ul);

}

else

{

return(CY_SYSCLK_INVALID_TRIM_VALUE);

}

}

Code Listing 7 Cy_SysClk_SelectEcoWDtrim() function

__STATIC_INLINE uint32_t Cy_SysClk_SelectEcoWDtrim(float32_t amplitude)

{

if( (0.50f <= amplitude) && (amplitude < 0.60f))

{

return(0x02ul);

}

else if(amplitude < 0.7f)

{

return(0x03ul);

}

else if(amplitude < 0.8f)

{

return(0x04ul);

}

else if(amplitude < 0.9f)

{

return(0x05ul);

}

else if(amplitude < 1.0f)

{

return(0x06ul);

}

else if(amplitude < 1.1f)

{

return(0x07ul);

}

else if(1.1f <= amplitude)

{

return(0x07ul);

}

else

{

// invalid input

return(CY_SYSCLK_INVALID_TRIM_VALUE);

}

}

Code Listing 8 Cy_SysClk_SelectEcoGtrim() function

__STATIC_INLINE uint32_t Cy_SysClk_SelectEcoGtrim(float32_t gm_min)

{

if( (0.0f <= gm_min) && (gm_min < 2.2f))

{

return(0x00ul+1ul);

}

else if(gm_min < 4.4f)

{

return(0x01ul+1ul);

Get the AGC enable setting.

Get the Wdtrim value.

Get the Gtrim value.

Application Note 19 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

Code Listing 8 Cy_SysClk_SelectEcoGtrim() function

}

else if(gm_min < 6.6f)

{

return(0x02ul+1ul);

}

else if(gm_min < 8.8f)

{

return(0x03ul+1ul);

}

else if(gm_min < 11.0f)

{

return(0x04ul+1ul);

}

else if(gm_min < 13.2f)

{

return(0x05ul+1ul);

}

else if(gm_min < 15.4f)

{

return(0x06ul+1ul);

}

else if(gm_min < 17.6f)

{

// invalid input

return(CY_SYSCLK_INVALID_TRIM_VALUE);

}

else

{

// invalid input

return(CY_SYSCLK_INVALID_TRIM_VALUE);

}

}

Code Listing 9 Cy_SysClk_SelectEcoRtrim() function

__STATIC_INLINE uint32_t Cy_SysClk_SelectEcoRtrim(float32_t freqMHz)

{

if(freqMHz > 28.6f)

{

return(0x00ul);

}

else if(freqMHz > 23.33f)

{

return(0x01ul);

}

else if(freqMHz > 16.5f)

{

return(0x02ul);

}

else if(freqMHz > 0.0f)

{

return(0x03ul);

}

else

{

// invalid input

return(CY_SYSCLK_INVALID_TRIM_VALUE);

}

}

Code Listing 10 Cy_SysClk_SelectEcoFtrim() function

__STATIC_INLINE uint32_t Cy_SysClk_SelectEcoFtrim(uint32_t atrim)

{

return(0x03ul);

}

Get the Rtrim value.

Get the Ftrim value.

Application Note 20 of 80 002-26071 Rev. *B

2021-09-07

Clock configuration setup in TRAVEO™ T2G family CYT4D series MCUs

Configuration of the clock resources

3.2 Setting WCO

3.2.1 Operation overview

The WCO is disabled by default. Accordingly, the WCO cannot be used unless it is enabled. Figure 10 shows how

to configure registers for enabling the WCO.

To disable the WCO, write ‘0’ to the WCO_EN bit of the BACKUP_CTL register.

Start

Write "1" to the WCO_EN bit

Check the state

of WCO_OK and the state of TIMEOUT ?

Yes

End(Success)

No

Define variable to count timeout

Configure the initial value of TIMEOUT

Define variables TIMEOUT

Configure TIMEOUT value

Write "1" to the WCO_EN bit, and make WCO available

TIMEOUT= 0?

Subtract TIMEOUT value

End(Timeout)

Yes

No

Check whether the processing exited the loop at TIMEOUT

(1)

(2)

(3)

(4)

Figure 10 Enabling WCO

3.2.2 Configuration

Table 3 lists the parameters and Table 4 lists the functions of the configuration part of in the SDL for WCO

settings.

Table 3 List of WCO settings parameters

Parameters

Description

Value

WAIT_FOR_STABILIZATION

Waiting for stabilization

10000ul

PLL_400M_0_PATH_NO

PLL number for PLL_400M_0

1ul

PLL_400M_1_PATH_NO

PLL number for PLL_400M_1

2ul

PLL_200M_0_PATH_NO

PLL number for PLL_200M_0

3ul

PLL_200M_1_PATH_NO

PLL number for PLL_200M_1

4ul

Table 4 List of WCO settings functions

Functions

Description

Value

Cy_WDT_Disable()

Disable the watchdog timer

–

Table of contents

Popular Clock manuals by other brands

Adaptive Micro Systems

Adaptive Micro Systems Alpha user manual

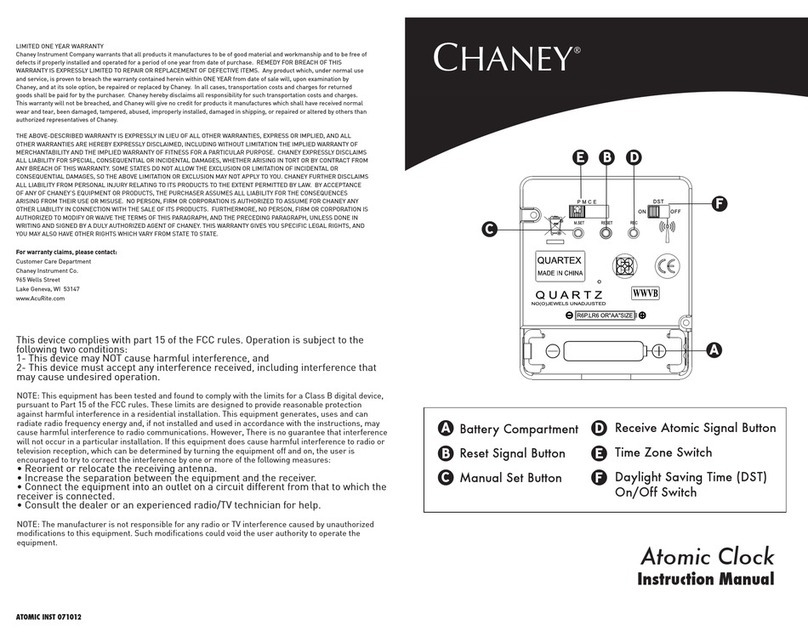

Chaney Instrument

Chaney Instrument Atomic Clock instruction manual

La Crosse Technology

La Crosse Technology C75723-AU Setup guide

Masterclock

Masterclock NTD200 user manual

ADE

ADE CK 2308 operating instructions

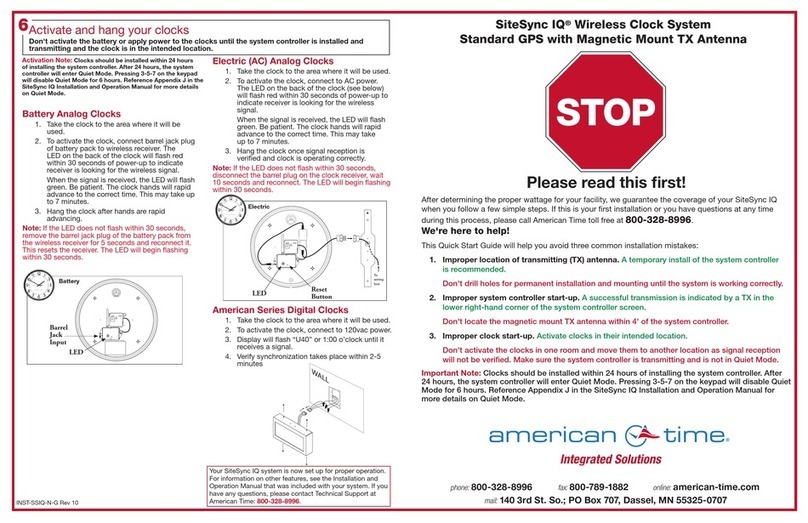

American Time

American Time SiteSync IQ Quick start installation guide

Ambient Weather

Ambient Weather Fischer Instruments 1434TD-22 user manual

OzSpy

OzSpy HDESKX10 Quick reference guide

La Crosse Technology

La Crosse Technology 513-1417ALv4 quick start guide

procontrol

procontrol Church Clock manual

BANGGOOD

BANGGOOD ECL-132 manual

Mobatime

Mobatime DC Series instruction manual