Infineon XMC Link User manual

Chipsmall Limited consists of a professional team with an average of over 10 year of expertise in the distribution

of electronic components. Based in Hongkong, we have already established firm and mutual-benefit business

relationships with customers from,Europe,America and south Asia,supplying obsolete and hard-to-find components

to meet their specific needs.

With the principle of “Quality Parts,Customers Priority,Honest Operation,and Considerate Service”,our business

mainly focus on the distribution of electronic components. Line cards we deal with include

Microchip,ALPS,ROHM,Xilinx,Pulse,ON,Everlight and Freescale. Main products comprise

IC,Modules,Potentiometer,IC Socket,Relay,Connector.Our parts cover such applications as commercial,industrial,

and automotives areas.

We are looking forward to setting up business relationship with you and hope to provide you with the best service

and solution. Let us make a better world for our industry!

Contact us

Tel: +86-755-8981 8866 Fax: +86-755-8427 6832

Email & Skype: [email protected]om Web: www.chipsmall.com

Address: A1208, Overseas Decoration Building, #122 Zhenhua RD., Futian, Shenzhen, China

User's Manual R1.0

www.infineon.com 2015-12-11

UG_201512_PL30_004

XMC™Link

Based on SEGGER J-Link Technology

About this document

Scope and purpose

This is the user’s manual for the XMC™Link also called isolated debug probe, providing technical information

and hints on how to use it.

Intended audience

This document is intended for anyone who wants to use the XMC™Link.

Table of contents

About this document .............................................................................................................................................1

Table of contents...................................................................................................................................................1

1 Introduction.......................................................................................................................................2

1.1 Block diagram..........................................................................................................................................2

1.2 Getting started.........................................................................................................................................3

2 Hardware description ........................................................................................................................4

2.1 Known limitation.....................................................................................................................................4

2.2 Debug connector.....................................................................................................................................4

2.2.1 Pinout of debug connectors ..............................................................................................................5

2.3 Power supply...........................................................................................................................................6

2.4 Virtual COM Port (UART-to-USB Bridge).................................................................................................6

3 Production data .................................................................................................................................7

3.1 Schematics ..............................................................................................................................................7

3.1.1 Differences in hardware versions ......................................................................................................7

3.2 Components placement and geometry .................................................................................................9

3.3 List of material.........................................................................................................................................9

Revision history ...................................................................................................................................................11

User's Manual 2 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

1 Introduction

This document describes the features and hardware details of the XMC™Link. XMC™Link is an isolated debug

probe for all XMC™microcontrollers.

The debug probe is based on SEGGER J-Link debug firmware, which enables use with DAVE™and all major

third-party compiler/IDEs known from the wide ARM® ecosystem. Table 1 shows its specification.

Table 1 XMC™Link specification

Supported Processor All Infineon Cortex®-M based XMC™Microcontroller

Dimensions 62 x 33 mm (without cables plugged in)

Power PC side: 5 V via Micro-AB USB Connector

Target side: 2.5 V – 5 .5V via one of the debug connector (VDD)

Connectors •10-pin Cortex® Debug Connector

•8-pin XMC™MCU Debug Connector

•Micro –AB USB Connector

Supported Protocols •Serial Wire Debug (SWD)

•Single Pin Debug (SPD)

•Serial Wire Viewer (SWV via SWO pin)

•JTAG

•UART-to-USB Bride, Virtual COM (VCOM)

Others •1 kV functional isolation

1.1 Block diagram

The block diagram in Figure 1 shows the main components of the XMC™Link and their interconnections. There

are following main building blocks:

•XMC4200 Microcontroller in a VQFN42 package

•Isolating Device

•10-pin Cortex® Debug Connector

•8-pin XMC™MCU Debug Connector

•Micro-AB USB Connector

•2 LEDs: Debug LED and Communication LED

•12 MHz Crystal

User's Manual 3 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

Figure 1 Block diagram of the XMC™Link

1.2 Getting started

To operate the XMC™Link the installation of the J-Link Driver is required.

1. Please download the latest version from https://www.segger.com/jlink-software.html and install it on your

PC/laptop.

Note: The J-Link driver is also part of the typical installation of DAVE™and 3rd party tools supporting SEGGER J-

Link.

2. Connect XMC™Link with your PC/laptop using the Micro USB cable.

3. A proper connection and installation of the J-Link driver is indicated by a constantly illuminated DEBUG

LED.

4. Connect your XMC™target board with XMC™Link using one of the enclosed cables.

5. Select SEGGER J-Link as debugger in your preferred IDE e.g. DAVE™

6. Start the flash programming and debugging session

XMC4200

Micro-

controller

USBU0C1

U0C0

OCS

EVR

12 MHz

Crystal

Micro

USB

USB

GPIO

10-pin Cortex™

Debug Connector

IFX54441

Voltage

Regulator

5V3.3V

XMC™Link V1

BlockDiag.emf

Debug

LED

COM

LED

U1C0

JTAG

SWD

SPD

RX/TX

DIR

U1C1SWV

SPD

SWD

RX/TX

SPD

SWD

JTAG

SWV

RESET

2.5V -5.5V

8-pin XMC™MCU

Debug Connector

Isolating

Device

CCU80

User's Manual 4 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

2 Hardware description

The following chapters provide a detailed description of the hardware and how it can be used. The hardware is

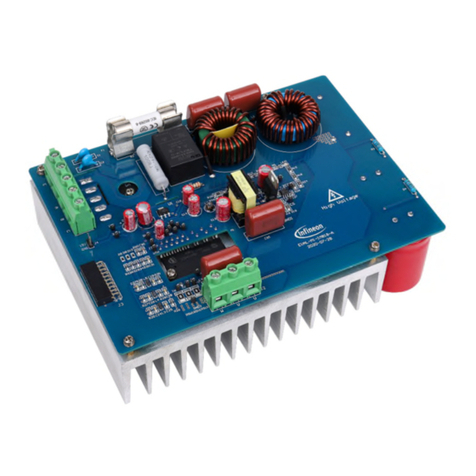

depicted in Figure 2.

Figure 2 PCB of the XMC™Link

2.1 Known limitation

XMC Link™V1 has a minor known limitation which could occur only during programming the BMI of a XMC1000

device in ASC-BSL mode to another BMI mode. This limitation is solved in the PCB version V1.1. The version

number is printed on the bottom side of the PCB below the USB connector.

The limitation can be avoided if the XMC™Link V1 is powered before the target XMC™will be powered.

2.2 Debug connector

The XMC™Link can be connected to the XMC™target microcontroller by either of the debug connectors:

•8-pin XMC™MCU Debug Connector (2 x 4 pin, 0.1”, 2.54mm)

•10-pin Cortex™Debug Connector (2 x 5 pin, 0.05”, 1.27mm)

The 8-pin XMC™MCU Debug Connector is mainly used for the XMC1000 applications. The 10-pin Cortex™Debug

Connector can be used for all XMC™families but is focusing on the XMC4000 family supporting Serial Wire

Viewer (SWV) via the SWO pin.

User's Manual 5 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

The common debug protocol supported by both connectors is Serial Wire Debug (SWD). Figure 3 provides an

overview on all supported debug protocols and communication channels.

XMC1000 Family XMC4000 Family

8-pin XMC™MCU

Debug Connector

10-pin Cortex™

Debug Connector

10-pin Cortex™

Debug Connector

Serial Wire Debug

(SWD)

Single Pin Debug

(SPD)

Serial Wire Viewer

(SWV/SWO)

Virtual COM Port

(UART-to-USB Bridge)

JTAG

Figure 3 Supported debug protocols

2.2.1 Pinout of debug connectors

The pinout of both debug connectors and to which pins of the XMC™the debugger must be connected can be

found in Table 2 and Table 3.

Table 2 Pinout of the 10-pin Cortex™debug connector

Pin Function XMC1000 Connection (Pin name) XMC4000 Connection (Pin name)

1 VCC Power Supply 2.5 V – 5.5 V (VDD) Power Supply VDDP 3.3 V (VDDP)

2 SWIO/TMS Serial Wire Data (P0.14 | P1.3) Serial Wire Data, JTAG-TMS (TMS)

3 GND Ground (VSS) Ground (VSS)

4 SWCLK/TCK Serial Wire Clock (P0.15 | P1.2) Serial Wire Clock, JTAG-TCK (TCK)

5 GND Ground (VSS) Ground (VSS)

6 SWO/TDO Not connected Serial Wire Output, JTAG-TDO (P2.1) (optional)

7 KEY Not connected Not connected

8 TDI Not connected JTAG-TDI (P0.7)(optional)

9 GNDDetect Can be used to switch off an on-board debug probe (PORST# of OBD) (optional)

10 RESET# Not connected PORST# (mandatory)

Table 3 Pinout of the 8-pin XMC™MCU debug connector

Pin Function XMC1000 Connection (Pin name)

1 SC Serial Wire Clock (P0.15 | P1.2)

2 SD Serial Wire Data (P0.14 | P1.3)

User's Manual 6 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

Pin Function XMC1000 Connection (Pin name)

3 + Power supply 2.5 V – 5.5 V (VDD)

4 0 Ground (VSS)

5 0 Ground (VSS)

6 + Power supply 2.5 V – 5.5 V (VDD)

7 TX (PC-TX)) Transmissstion line of PC/laptop, receive line of XMC™device (optional)

8 RX (PC-RX) Receive line of PC/laptop, transmission line of of XMC™device (optional)

2.3 Power supply

XMC™Link is powered from the Micro USB plug and typically draws about 70 mA. The on-board voltage

regulator IFX54441LDV33 generates the required 3.3 V for the XMC4200 microcontroller out of the 5 V USB

voltage. The debug probe is not designed to provide power for the target device.

The target application must power the isolated part of the debugger. The isolated side the XMC™Link draws a

few mA of current from the target application.

2.4 Virtual COM Port (UART-to-USB Bridge)

The 8-pin XMC™MCU Debug Connector supports communication between a PC/laptop and target XMC™device

via Virtual COM Port (UART-to-USB Bridge). Therefore UART pins of the target XMC™device needs to be

connected to TX/RX pins of the debug connector (see Table 3).

Note: Take care of the UART cross connection: TX pin of debugger needs to be connected to RX pin of the

XMC device. RX pin of debugger needs to be connected to TX pin of the XMC device.

User's Manual 7 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

3 Production data

This chapter covers schematics, board dimensions, component placement and the list of material.

3.1 Schematics

Figure 4 shows the schematics of XMC™Link V1 in hardware version 1.1.

3.1.1 Differences in hardware versions

In hardware version 1.1 compared to hardware version v1.0 (V1) the pull-down resistor R20 was added to the TX

line. The version number is printed on the bottom side of the PCB below the USB connector.

User's Manual 8 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

Figure 4 Schematic of the XMC™Link V1 (Hardware Version 1.1)

XMC BootKit

Cortex Debug

10nF/040210nF/0402

10uF/10V/060310uF/10V/0603

10uF/10V/060310uF/10V/0603

100nF/0402

15pF/040215pF/0402

15pF/040215pF/0402

100nF/0402100nF/0402

100nF/0402100nF/0402

100nF/0402100nF/0402

100nF/0402100nF/0402

100nF/0402100nF/0402

100nF/0402100nF/0402

4u7F/6.3V/06034u7F/6.3V/0603

10uF/10V/060310uF/10V/0603

10uF/10V/060310uF/10V/0603

100nF/0402100nF/0402

100nF/0402100nF/0402

100nF/0402100nF/0402

10uF/10V/060310uF/10V/0603

100nF/0402100nF/0402

100nF/0402100nF/0402

100nF/0402100nF/0402

10uF/10V/060310uF/10V/060310uF/10V/060310uF/10V/0603

10uF/10V/060310uF/10V/0603

GNDGND

GNDGND

GND

GND

GNDGND

GNDGND GNDGND

GND

GND

BLM18PG600BLM18PG600

LED-GN/D/0603

LED-RT/D/0603

12MHZ/S/3.2X2.512MHZ/S/3.2X2.5

680R/0603

680R/0603

22R/040222R/0402

510R/0402510R/0402 22R/040222R/0402

4k7/040210k/0402

1M/0402

100k/0402

100k/0402100k/0402

100k/0402100k/0402

100R/0402100R/0402

100R/0402100R/0402

100R/0402100R/0402

100R/0402100R/0402

100R/0402100R/0402

100R/0402

100R/0402

no ass./0R/0603no ass./0R/0603

10k/0402

10k/0402

VDDP

GNDISO

VDDP

VISO3.3VISO3.3

VISO3.3VISO3.3

VISO3.3VISO3.3

GNDISO

GNDISO

GNDISO

VISO5

GNDISO GNDISO

VDDPVDDP

VDDP

VDDP

VDDP

VDDP

GNDISO

VISO3.3VISO3.3

VISO3.3

VISO3.3VISO3.3

VISO5

VISO3.3VISO3.3

VISO3.3VISO3.3

GNDISO

GNDISO GNDISO

GNDISO GNDISO

GNDISO GNDISOGNDISO

GNDISO

GNDISO

IFX54441LDV33

XMC4200_QFN48

SI8652BB-B-IS1

74LVC1G126GW

NL17SZ07DF

SI8652BB-B-IS1

ESD8V0L2B-03LESD8V0L2B-03L

VDDPVDDP

VDDP

FTS-105-01-L-DV

TSM-104-01-F-DH-ATSM-104-01-F-DH-A

ZX62-AB-5PA

no ass. ADJ_1 ADJ_2 ADJ_3

C1C1

C2C2

C3C3

C4

C5C5

C6C6

C7C7

C8C8

C9C9

C10C10

C11C11

C12C12

C13C13

C14C14

C15C15

C16C16

C17C17

C18C18

C19C19

C20C20

C21C21

C22C22

C23C23C24C24

C25C25

L1L1

LED1

LED2

Q1Q1

R1

R2

R3R3

R4R4 R5R5

R6R7

R8

R9

R10R10

R11R11

R12R12

R13R13

R14R14

R15R15

R16R16

R17

R18

R19R19

R20

R21

BYP 5

EN

7

EXP EXP

GND

6

IN

9*2 OUT 1*2

SENSE/ADJ 4

U1

EPAD

EPAD

HIB_IO_0 7

P0.0 2

P0.1 1

P0.2 48

P0.3 47

P0.4 46

P0.5 45

P0.6 44

P0.7 43

P0.8 42

P1.0 40

P1.1 39

P1.2 38

P1.3 37

P1.4 36

P1.5 35

P2.0

26 P2.1

25 P2.2

24 P2.3

23 P2.4

22 P2.5

21

P14.0 16

P14.3 15

P14.4 14

P14.5 13

P14.6 12

P14.7 11

P14.8 20

P14.9 19

PORST#

32

RTC_XTAL_1

8

RTC_XTAL_2

9

TCK

34

TMS

33

USB_D+ 4

USB_D- 3

VAGND

17 VAREF

18

VBAT 10

VDDC 6

VDDC1 31

VDDP 5

VDDP1 28

VDDP2 41

VSS

27

XTAL1

29

XTAL2

30

U2

A1

2

A2

3

A3

4

A4

5

A5

6

B1 15

B2 14

B3 13

B4 12

B5 11

EN1

7EN2 10

GND1

8GND2 9

VDD1

1VDD2 16

U3

A

2GND 3

OE

1VCC 5

Y4

U4

A

2

GND 3

VCC

5

Y4

U5

A1

2

A2

3

A3

4

A4

5

A5

6

B1 15

B2 14

B3 13

B4 12

B5 11

EN1

7EN2 10

GND1

8GND2 9

VDD1

1VDD2 16

U6

V2

1

2

3

V2

1 2

3 4

5 6

7 8

9 10

X1

X2

12

34

56

78

X2

1

2

3

4

5

X3C

1

2

3

4

5

X4

COM_LED#

CS

CS

DEBUG_LED#

ISO_SWIO/TMS*

ISO_SWIO/TMS*

OBD_OFF#

OBD_TCK

OBD_TMS

PC_RX*

PC_RX*

PC_TX*

PC_TX*

RESET#

RESET#

RESET#*

RESET#*

RESET#_OD

RESET#_OD

RX

RX

SWCLK/TCK

SWCLK/TCK

SWCLK/TCK

SWCLK/TCK*

SWCLK/TCK*

SWCLK/TCK*

SWD_DIR

SWD_DIR

SWD_DIR*

SWD_DIR*

SWD_IN

SWD_IN

SWD_OUT

SWD_OUT

SWD_OUT*

SWD_OUT*

SWIO/TMS*

SWIO/TMS*

SWIO/TMS*

SWO/TDO

SWO/TDO

SWO/TDO

SWO/TDO*

SWO/TDO*

TDI

TDI

TDI*

TDI*

TX

TX

A

B

C

D

E

1 2 3 4 5 6 7 8

A

B

C

D

E

1

2

3

4

5

6

7

8

XMC-Link-V1.1

02.12.2015 12:23:57

1/1

Sheet:

Legal Disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics. With respect to any examples or hints given herein, any typical values stated herein and/or any

information regarding the application of the device, Infineon Technologies hereby disclaims any and all warranties

and liabilities of any kind, including without limitation, warranties of non-infringement of intellectual property rights

of any third party.

USB

Supply

Analog

Digital

Hibernate/RTC

D1

D2

SCLKOUT-P1.1

DX0B-P1.4

SPI Slave

SWD_OUT

SWCLK/TCK

MOSI

CLK_OUT

MISO

CS_IN

CLK_IN

CS_OUT

SPI Master U0C0

U0C1

DOUT0-P1.5

SELO0-P1.0

DX2A-P2.3

DX1A-P2.4

RX

TX

UART2

RXD

TXD

DX0A-P0.4

DOUT0-P0.5

U1C0

TX_ACTIVE# GPIO-P0.6

RESET# GPIO-P0.3

DEBUG_LED# DEBUG_LED# GPIO-P0.2

TX_ENABLE GPIO-P0.7

SWD DIR GPIO-P1.3SWD_DIR

SWD_IN

UART

RXD DX0D-P0.0

MISO DOUT0-P2.5

COM_LED# AUX_LED# GPIO-P0.1

UART

SPD

No RESET Pin

Level Shifter

COM LED

SWV

JTAG

ON-BOARD DEBUGGER (OBD) and ISO IF

CONTROL GPIOs

Debug Connectors

Power 3,3V

MOSI DX0A-P2.2

TDI

SWO/TDO

U1C1

SWV

RESET#

Configure Debugger RESET# signal at P0.3 as open-drain output.

User's Manual 9 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

3.2 Components placement and geometry

Figure 5 shows the board dimensions and the placement of components on the PCB.

Figure 5 Components placement and geometry

3.3 List of material

The list of material is valid for the XMC™Link V1 in hardware version 1.1.

Table 4 List of material

Value Device Qty Reference Designator

15pF 50V 10% 0402 Capacitor COG 2C5, C6

10uF 10V 20% 0603 Capacitor X5R 8

C2, C3, C14, C15, C19, C23, C24,

C25

100nF 16V 10% 0402 Capacitor X7R 13

C4, C7, C8, C9, C10, C11, C12,

C16, C17, C18, C20, C21, C22

10nF 16V 10% 0402 Capacitor X7R 1 C1

4u7F 6.3V +-10% 0603 Capacitor X7R 1 C13

ZX62-AB-5PA Connector Micro USB AB SMD Hirose 1 X3

12MHz 3.2x2.5 Crystal 12MHz 4Pad NX3225SA NDK 1 Q1

ESD8V0L2B-03L TSLP-3-1 Diode Protection Infineon 1 V2

BLM18PG600SN1D 0603 Ferrite Bead 60R 500mA Murata 1 L1

SI8652BB-B-IS1 NB-SOIC-16 Isolation IC 2 U3, U6

LSQ971-Z LED-GN 0603 LED SMD gn 1 LED1

LSQ976-Z LED-RT 0603 LED SMD rt 1 LED2

74LVC1G126GW TSSOP5 Line Driver 1 U4

60mm

30mm

ADJ_1ADJ_1

ADJ_2ADJ_2

ADJ_3ADJ_3

C1C1

C2C2

C3C3

C4C4

C5C5

C6C6

C7C7

C8C8

C9C9

C10C10

C11C11

C12C12

C13C13

C14C14

C15C15

C16C16

C17C17

C18C18

C19C19

C20C20

C21C21

C22C22

C23C23

C24C24

C25C25

L1L1

LED1LED1

LED2LED2

Q1Q1

R1R1

R2R2

R3R3

R4R4

R5R5

R6R6

R7R7

R8R8

R9R9

R10R10

R11R11

R12R12

R13R13

R14R14

R15R15

R16R16

R17R17

R18R18

R19R19

R20R20

R21R21

U1U1

U2U2

U3U3

U4U4

U5U5

U6U6

V2V2

X1X1

X2X2

X3X3

X4X4

User's Manual 10 R1.0

2015-12-11

Table of contents

XMC™Link

Based on SEGGER J

-

Link Technology

Value Device Qty Reference Designator

SN74LVC1G07 SC70-5 Line Driver 1 U5

XMC4200-Q48K256 QFN48 Microcontroller XMC4200 Infineon 1 U2

FTS-105-01-L-DV 2x5pin

0.05" Pin Header SMD Samtec 1

X1

TSM-104-01-F-DH-A 2x4pin

0.1" Pin Header SMD Samtec 1

X2

no ass. 1x5pin 0.1" Pin Header THT 1 X4

100R 1% 0402 Resistor 7 R12, R13, R14, R15, R16, R17, R18

100k 1% 0402 Resistor 3 R9, R10, R11

10k 1% 0402 Resistor 3 R7, R20, R21

1M 1% 0603 Resistor 1 R8

22R 1% 0402 Resistor 2 R3, R5

4k7 1% 0402 Resistor 1 R6

510R 1% 0402 Resistor 1 R4

680R 1% 0603 Resistor 2 R1, R2

no ass. 0R 0603 Resistor 1 R19

IFX54441LDV33 PG-TSON-10 Voltage Regulator 3.3 V Infineon 1 U1

User's Manual 11 R1.0

2015-12-11

Revision history

XMC™Link

Based on SEGGER J

-

Link Technology

Revision history

Major changes since the last revision

Page or reference Description of change

Trademarks of Infineon Technologies AG

µHVIC™, µIPM™, µPFC™, AU-

ConvertIR™, AURIX™, C166™, CanPAK™, CIPOS™, CIPURSE™, CoolDP™, CoolGaN™, COOLiR™, CoolMOS™, CoolSET™, CoolSiC™,

DAVE™, DI-POL™, DirectFET™, DrBlade™, EasyPIM™, EconoBRIDGE™, EconoDUAL™, EconoPAC

K™, EconoPIM™, EiceDRIVER™, eupec™, FCOS™, GaNpowIR™,

HEXFET™, HITFET™, HybridPACK™, iMOTION™, IRAM™, ISOFACE™, IsoPACK™, LEDrivIR™, LITIX™, MIPAQ™, ModSTACK™, my-

d™, NovalithIC™, OPTIGA™,

OptiMOS™, ORIGA™, PowIRaudio™, PowIRStage™, PrimePACK™, PrimeSTACK™, PROFET™, PRO-

SIL™, RASIC™, REAL3™, SmartLEWIS™, SOLID FLASH™,

SPOC™, StrongIRFET™, SupIRBuck™, TEMPFET™, TRENCHSTOP™, TriCore™, UHVIC™, XHP™, XMC™

Trademarks updated November 2015

Other Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2015-12-11

UG_201512_PL30_004

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2016 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: [email protected]

Document reference

IMPORTANT NOTICE

The information contained in this application note

is given as a hint for the implementation of the

product only and shall in no event be regarded as a

description or warranty of a certain functionality,

condition or quality of the product. Before

implementation of the product, the recipient of this

application note must verify any function and other

technical information given herein in the real

application. Infineon Technologies hereby

disclaims any and all warranties and liabilities of

any kind (including without limitation warranties of

non-infringement of intellectual property rights of

any third party) with respect to any and all

information given in this application note.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may

contain dangerous substances. For information on

the types in question please contact your nearest

Infineon Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of

the product or any consequences of the use thereof

can reasonably be expected to result in personal

injury.

Table of contents

Other Infineon Measuring Instrument manuals