Infinitum Aircore EC Instruction manual

1

Infinitum 20230810 PRELIMINARY

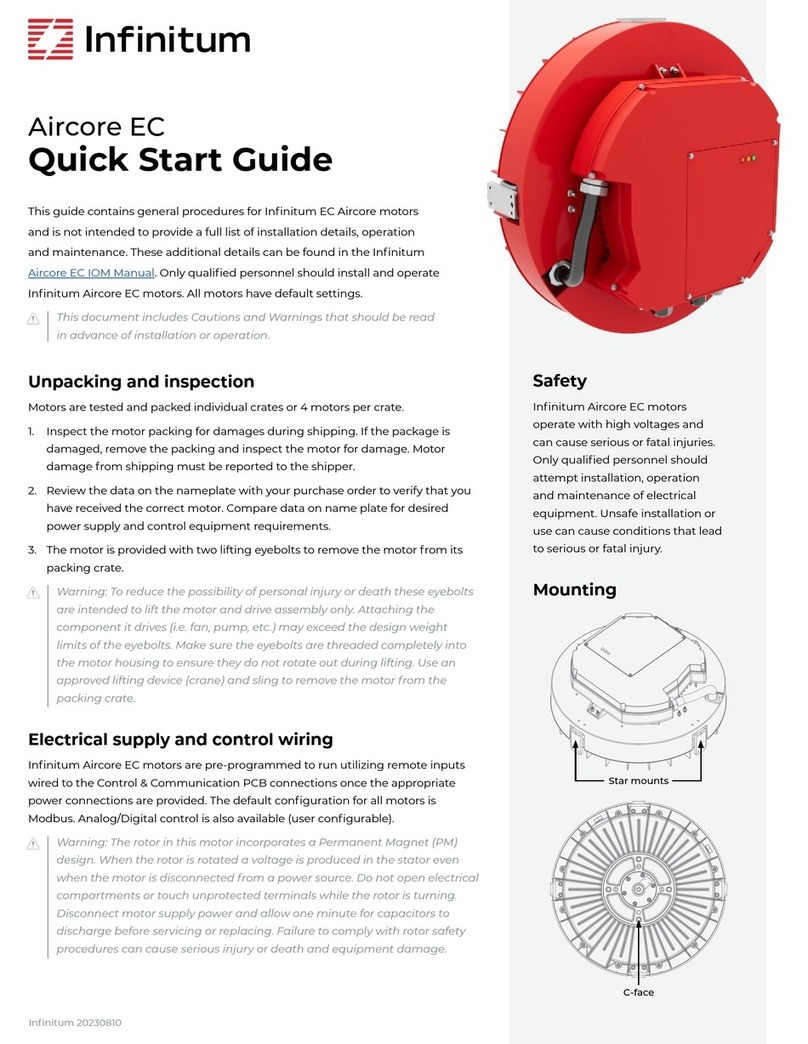

Aircore EC

Installation, Operation

& Maintenance Manual

2

1. About the manual 3

a. Warnings, cautions and notes 3

2. Motor technology 3

a. Motor overview 3

i. Aircore EC motor technology 3

ii. Infinitum Aircore EC stator 3

iii. Aircore EC motor components 3

3. Receiving inspection 4

a. Packing inspection 4

b. Remove motor from container 4

c. Compare nameplate data 4

d. Rotate motor output shaft 4

e. Ready spare storage 4

i. Motor bearings 5

ii. Scheduled output shaft rotation 5

4. Motor installation 5

a. Preparation 5

i. Operating ambient temperature 5

ii. Ingress protection 5

b. Motor location 5

c. Motor orientation 6

d. Motor mounting and alignment 6

i. Mounting options 6

ii. Peripheral mounting block 6

iii. C-face mounting 6

e. Mounting and aligning motor 6

f. Minimum motor connection requirements 7

g. Motor control connections 7

h. Motor ground circuit verification 7

i. Connecting motor 7

j. Conductor size and terminal data 8

k. Circuit breaker and wire sizing 8

l. Control connections 9

m. Analog control wire guidelines 9

n. Modbus RTU wiring guidelines 9

o. AC main input connections 9

p. Check motor rotation 10

q. Connect motor to driven equipment 10

r. Default and user programmable settings 10

5. Motor maintenance 10

a. Maintenance tasks 10

b. Mechanical 10

6. Motor drive parameters and data types 10

Table of contents

3

Infinitum 20230810 PRELIMINARY

1. About the manual

a. Warnings, cautions and notes

Warnings, cautions and notes are throughout the manual to alert

the technician of potential hazard or process information. Below is

an explanation of the use.

Warnings: are safety related. Serious injury, death and

equipment damage can result if the instructions in the

warning are not followed.

Cautions: apply to conditions that can cause equipment

damage. If instructions in the Caution are not followed,

motor and associated equipment damage may occur.

Notes: The text of the note is Italicized. Notes add information

that can aid in the completion of a process or step.

2. Motor technology

a. Motor overview

Infinitum has developed a new generation of electric motors

with unparalleled efficiency and durability. We’ve reinvented

axial air-core motors using lightweight materials and a modular

design that generates the same power with less weight than a

legacy motor. These motors include on optimized VFD (Variable

Frequency Drive) for maximum performance and efficiency at a

wide operating range. Infinitum has an established ecosystem of

configuration software as well as optional IoT connectivity for real-

time monitoring and analytics. These motors are manufactured at

a fraction of the carbon footprint created by conventional motors.

It is designed with future generations in mind taking the entire

lifecycle into account creating a huge leap in sustainability.

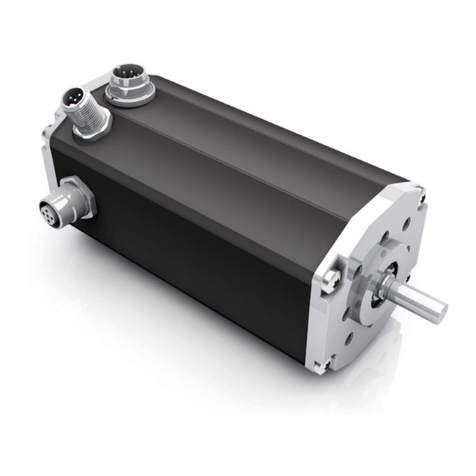

i. Aircore EC motor technology

The introduction of the Aircore EC motor surpasses motors

utilizing standard technology and construction. Like all motors,

Infinitum machines have a stator, the stationary part and a rotor.

The rotating component Aircore EC motors have two rotors. In

traditional motors the stator is located in the body of the motor

and is usually made of iron cores with copper windings. This iron

and copper adds to the overall weight of the motor. Additionally,

the insulation on these coil windings degrades with heat and time

requiring maintenance or eventual replacement of the motor.

ii. Infinitum Aircore EC stator

The Aircore EC stator is a Printed Circuit Board (PCB) rather than

utilizing a heavy iron core and with copper windings. The Infinitum

motor is designed utilizing a PCB stator sandwiched between two

rotors (Figure 1). Permanent magnets are attached to the surface

of the two rotors. Since there is no iron in the magnetic path, the

motors can be classified as an air-core design.

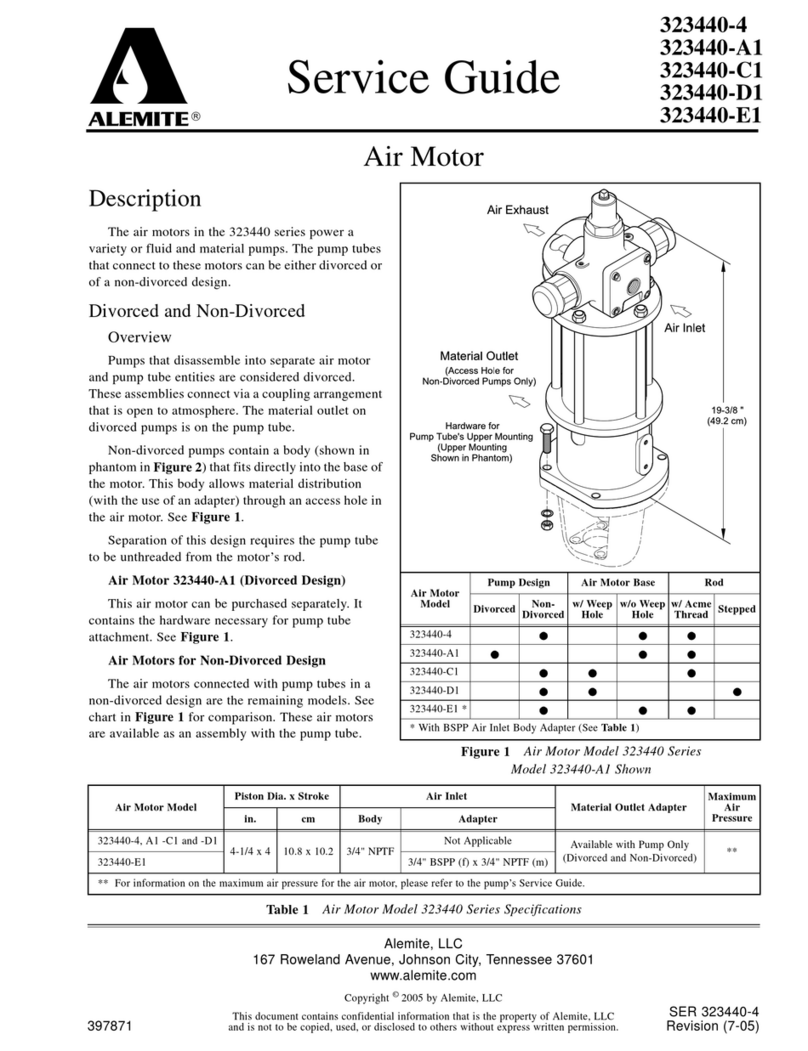

iii. Aircore EC motor components

The PCB stator design allows for a smaller motor that weighs

significantly less than a conventional motor. Key components are

identified by the drawing in Figure 2.

Figure 2: Aircore EC motor components

Figure 1: Aircore EC stator

Direction of rotation

Rotor

Stator

Rotor

Access

cover

Drive

cover

Control

interface

module

VFD Drive

housing

Impeller Back

motor

housing

PCB

stator &

rotors

Mounting

pads

Front motor

housing

Bearing

Grounding

brush

4

Infinitum 20230810 PRELIMINARY

c. Compare nameplate data

• Compare data on nameplate with purchase order to verify

receipt of proper motor.

• Compare data on nameplate for desired power supply and

control equipment requirements.

d. Rotate motor output shaft

Warning: The rotor in this motor incorporates a Permanent

Magnet (PM) design. When the rotor is rotated a

voltage is produced in the stator even when the motor is

disconnected from a power source. Do not open electrical

compartments or touch unprotected terminals while the

rotor is turning. Disconnect motor supply power and allow

one minute for capacitors to discharge before servicing or

replacing. Failure to comply with rotor safety procedures

can cause serious injury or death and equipment damage.

Make sure all motor wire connections are properly terminated

and insulated. Turn motor rotor (output shaft) by hand. It should

turn freely with some drag from the bearing seals.

e. Ready spare storage

Motors purchased for ready spares are not placed into service

immediately. These motors should be stored in a clean, dry

space. Avoid spaces with large temperature swings to reduce

condensation. Storage temperature is -40 to 185 °F (-40 to 85 °C).

Cover motors to prevent airborne dust and dirt particles. If

storage area location is prone to vibration, place vibration

dampers under motor base to prevent premature wear and

damage to bearings.

Figure 3: Typical pallet

Figure 4: Lifting lugs

3/8-16 UNC THRU

(FOR LIFTING EYE BOLT)

3. Receiving inspection

Review and complete all appropriate sections prior to motor

installation. The motor is shipped in a robust container. The

container and motor can be moved by using a dolly, pallet jack or

fork truck (Figure 3).

a. Packing inspection

Inspect the motor packing for damages during shipping. If the

package is damaged, remove the packing and inspect the motor

for damage. Motor damage from shipping must be reported to

shipper.

b. Remove motor from container

Warning: The motor is provided with threaded holes for a

lifting lug. Lifting lugs may or may not be shipped with the

motor. (Figure 4). The lugs are intended to lift the motor

assembly only. Attaching the component it drives will

exceed the design weight limits. To reduce the possibility

of personal injury or death and equipment lift the motor

only, make sure the lugs are completely threaded into the

motor, and ensure they do not rotate out during lifting.

Lifting eye-bolts are M10x1.5t thread, 20mm shank or 1/2”-13

thread, 1 1/2” shank length, depending on motor. Consult the

appropriate drawing for that motor to be sure.

Warning: To reduce the possibility of personal injury and

equipment damage, only use a lifting device and straps

that are rated for the motor weight. Do not lift the motor

without mechanical assistance. Always inspect straps for

damages and weight certification prior to use.

Remove top of the packing crate and install the supplied lifting

lugs (Figure 3). Make sure the lugs are threaded completely into

the motor housing. Use an approved lifting device and sling to

remove the motor from the packing crate.

5

Infinitum 20230810 PRELIMINARY

i. Motor bearings

The bearings (Figure 5) used in this motor are lubricated and

sealed at the factory. The motor does not require bearing

lubrication in the field or during storage.

ii. Scheduled output shaft rotation

Warning: The rotor in this motor incorporates a Permanent

Magnet (PM) design. When the rotor is rotated a

voltage is produced in the stator even when the motor is

disconnected from a power source. Do not open electrical

compartments or touch unprotected terminals while the

rotor is turning. Disconnect motor supply power and allow

one minute for capacitors to discharge before servicing or

replacing. Failure to comply with rotor safety procedures

can cause serious injury or death and equipment damage.

Figure 5: Bearings

It is recommended the rotor (output shaft) be rotated five to ten

times per every quarter (three months). This distributes grease

in the bearings and reduces the chance of corrosion formation

on bearing rolling elements and raceways. Bearing seals can add

some resistance to turning the rotor.

4. Motor installation

a. Preparation

Review this entire manual prior to scheduling the motor

installation. All equipment related to systems operation must be

secured and have an active LOTO (Lock Out Tag Out) procedure

in accordance with application specific safety policies. All users of

should be notified of equipment outage.

i. Operating ambient temperature

The ambient temperature of the air supplied to the motor cooling

inlet should not exceed 40° C (104° F) or be less than -25° C (-13° F).

Power can be derated at higher temperatures by 2% per degree

C up to 50° C. Consult Infinitum for ambient temperatures not

within these requirements.

ii. Ingress protection

Infinitum motor Ingress Protection (IP) ratings are identified by

their respective nameplates. To maintain this IP rating, cable

glands or seals must be used at all wiring ports and all gaskets in

place with covers.

b. Motor location

Warning: This motor is not certified to operate in any

hazardous environments. Operating a motor in areas

contaminated with explosive gases can cause explosions

resulting in serious injury or death and equipment damage.

Electric motors have guidelines for the location and operating

environment. These guidelines are listed below:

• The motor should be located in a ventilated enclosure and

should be in an area that allows air circulation.

• Air cooling inlets and outlets must not be obstructed.

• The enclosure cannot be located in an area with harmful or

explosive gasses.

• The area should be free from dust and metallic particles.

• The motor should be easily accessed for cleaning and

maintenance.

• The motors are intended for indoor applications.

6

Infinitum 20230810 PRELIMINARY

c. Motor Orientation

Gen4 Aircore EC motors can be used in any orientation,

horizontal, shaft up or shaft down.

d. Motor mounting and alignment

The Aircore EC motor system is supplied with an integrated VFD.

The motor and drive are the major components of the assembly.

Refer to motor datasheets for detailed dimension drawings.

i. Mounting options

Driven equipment (for example, a fan wheel) should be mounted

to the shaft using as much of the available shaft length as

possible. A shaft key-way and shaft key are provided for secure

coupling of hubs to the shaft.

There are two mounting options for the motor, peripheral

mounting or C-face mounting.

ii. Peripheral mounting block

There are four mounting blocks on the surface of the motor,

spaced at 90º intervals. Each block has provisions for a lifting lug

that can be used to lift the motor, and mounting holes at the

drive end (DE) face and transverse surface.

The transverse face of the mounting block has threaded holes for

four mounting bolts. All four mounting bolts should be installed

for secure motor mounting. See the respective motor diagram for

a its mounting hole pattern in Figure 6.

iii. C-face mounting

Infinitum Aircore EC motors are not a NEMA standard frame size

but utilize a NEMA 182TC faceplate mounting configuration.

The DE face of the mounting block has threaded holes for four

bolts (M8X1.25). All bolt holes should be used for secure mounting

of the motor to equipment (Figure 7).

Caution: Use care when installing the driven equipment

onto the rotor shaft. Do not force the hub or coupling onto

the shaft since this may damage the motor bearings. If the

hub or coupling does not slide without resistance, check

alignment of the equipment with the rotor shaft.

Maintain adequate clearance between the front of the motor

body and the equipment to prevent mechanical obstruction that

may cause damage or injury.

The motor and stator assembly must be mounted on a structure

that will support the operational weight of the motor. Use

vibration dampers at motor assembly mounts to reduce motor

vibration. Align the stator output shaft centerline with the driven

component and install mounting hardware but do not tighten.

This is completed with the alignment process.

Figure 6: Circumference mounting pads and shaft keyway

4x Mounting pads

Figure 7: DE face

4x C-face mounting

e. Mounting and aligning motor

The motor may be directly mounted to equipment such as fan

wheels or may be connected through a belt or pulley system.

It may also be attached through a shaft coupling, e.g., to an

independently mounted pump, or to a torque meter in a

laboratory setting. Ensure proper alignment is maintained in all

arrangements.

Use driven equipment manufacturer’s recommendations for

aligning the motor with the fan drive or coupling. Tighten all bolts

and nuts on the motor mount.

Motor rotation must be verified after electrical connection.

Incorrect rotation can damage equipment.

7

Infinitum 20230810 PRELIMINARY

f. Minimum motor connection requirements

Warning: Always disconnect power to the motor and

practice all application specific safety procedures when

installing, troubleshooting, or repairing a motor. Always

verify power is secured with a multimeter prior to work.

Failure to disconnect power from motors can result in

serious personal injury or death and equipment damage.

Warning: The rotor in this motor incorporates a Permanent

Magnet (PM) design. When the rotor is rotated in a

disconnected motor voltage is produced. Do not touch

unprotected terminals while the rotor is turning. Disconnect

motor supply power and allow one minute for capacitors to

discharge before servicing or replacing. Failure to comply

with rotor safety procedures can cause serious injury or

death and equipment damage.

Warning: To reduce the possibility of personal injury or

death and equipment damage, always make sure wire

connections are secure and wires are in the correct location.

Caution: To prevent the possibility of motor damage, always

use terminating ferrules for all supply wires. Terminating

ferrules create a single connection point that is more secure

than stranded wire.

Wire tensile forces can affect the point of termination during

installation and motor operation. Terminal blocks with the correct

wiring installed ensure safe motor operation. Using the correct

wire gauge and amount of exposed conductor length with ferrules

installed on each wire satisfies the requirements.

Make sure the source of power to the motor has been

disconnected.

Strip wires and crimp on wire ferrules. Install each wire into the

appropriate terminal block as provided in the wiring instructions.

Verify all connections are tight and installed to specifications.

NEC 70 and NEMA MG2 standards should be followed for proper

motor power wiring.

g. Motor control connections

Infinitum Aircore EC motors support standard industry control

methods. The following are supported:

• Analog/Digital

• Modbus RTU

• Modbus TCP

Infinitum also supplies proprietary configuration and control

software known as I-con (motor control software).

h. Motor ground circuit verification

Warning: Motors must be properly grounded. Adhere to all

guidelines when installing the motor ground circuit. Failure

to ground a motor can cause personal injury, death, and

equipment damage.

It is advised to conduct resistance readings with a multimeter on

the motor ground circuit. Never apply power to a motor that does

not have a complete ground circuit.

i. Connecting motor

Each of the circuit boards and housing components has a

separate design function. Only two of the circuit boards have

user inputs. The main circuit boards and connection points are

highlighted in Figure 8.

1. Power board: Connections for three-phase supply. Rectifiers

convert AC to DC for internal use on this board.

2. Communication interface module (CIM). This circuit board

contains advanced controls and communications.

3. AC Input: Ground terminal is in chassis. (Figure 10)

Figure 8: Main motor boards

3

2

1

AC input

Power board

Communication

Interface Module

Note: Safety cover removed for illustration purposes.

8

Infinitum 20230810 PRELIMINARY

j. Conductor size and terminal data

Board Terminals

Maximum conductor size Exposed

conductor

length

Terminal type

mm^2 AWG

Communication interface module Control terminals 1.3 16 8 mm Spring terminal

Power board AC Mains-U, V & W 5.2 / 3.3 10 / 12 12 mm Spring terminal

Screw terminal Earth ground 1.6 14 12 mm Lug and screw

Max torque 2 Nm

k. Circuit breaker and wire sizing

Fuses or breakers should be used to provide protection

for the input power cables. These should be installed

in the incoming supply lines according to Table 1

(below). UL listed non-time-delay type T or RK1 fuses are

recommended. Type B circuit breakers of equivalent

rating to the fuses may be used. Other fuse or breaker

types may be acceptable. Fuses and breakers should

comply with any local codes or regulations.

The input wiring should be sized based on the current

requirements of the motor. The connector minimum

and maximum wire sizes are included in Table 2.

The maximum permissible short circuit current at the

drive input power terminals is 5kA.

Table 1: Breakers and fuses (3-phase 480V AC (+/- 10%) – 3-phase 460V output)

Power (HP) Rated Current (A) UL Fuses (Class T or RK1)

or UL Type B Breakers

Minimum Suggested

Wire Size (AWG)

56.0 10 16

7.5 9.0 15 16

10 12.0 15 14

15 18.0 25 12

Table 2: Terminal connection data

min. max.

Rigid cable cross-section 0.2 mm² 6 mm²

Flexible cable cross-section 0.2 mm² 6 mm²

Cross section AWG 24 10

Wire-end ferrules (w/insulating collar) 0.2 mm² 4 mm²

9

Infinitum 20230810 PRELIMINARY

l. Control connections

Remove the VFD cover for access to Analog/Digital and

Modbus connections.

1. Relay (1) – NO/NC (COM must be used)

• Max voltage: 125 VAC / 30 VDC

• Max current: NO-10A VAC, 5 A

• VDC: NC – 3A VAC or VDC

2. Digital input (4) – DIN1, DIN2, DIN3 & DIN4

3. Digital output (2) – DO1 & DO2.

• Open drain output

• Maximum switching voltage 40 VDC

• Maximum switching current 350 mA

4. Auxiliary Voltage (1) +24v (GND must be used)

Warning: (Do not exceed 24V on this input)

5. Analog output (1) – A_OUT (GND must be used)

6. Analog input (1) – A_IN (GND must be used)

7. EIA-485 interface (1) – 485_P & 485_N (GND must be used)

Note: Use wirenut to connect shield wires. Do not tie to GND.

8. Modbus termination switch. (Default is Off)

9. RJ45 for I-con (motor control software) connection

Terminals on the interface board (Figure 9) feature push-

button spring clips. The push-button on each terminal must be

depressed while inserting the wire. Releasing the push-button

clips the wire into place.

m. Analog control wire guidelines

To control the unit using Analog control please utilize the wiring

guidelines on the CIO board (Figure 9).

Caution: DIN1-DIN4 are limited to 24VDC input. AI1 is

rated 0-10V @ 100mA max. Exceeding these voltages will

permanently damage the communication board. Do not

insert external wiring larger than 16 AWG (0.05” or 1.3mm)

into control terminals.

Start/Stop

switch

Modbus RTU

Wiring

Analog control

Modbus RTU

1

2

3

4

5

6

7

Figure 9: CIM board

n. Modbus RTU wiring guidelines

To control the motor with Modbus RTU please utilize the wiring

guidelines to connect to the Communication I/O (Figure 9).

• The last unit on a daisy-chain configuration should have the

Modbus Termination DIP switch “ON”.

• All other units must have the DIP switch in the “OFF” position.

• Modbus RTU operation requires changes to the motor

configuration parameters.

o. AC main input connections

The AC main inputs (Figure 10) are on the power board.

The supply voltage connections are:

1. Supply voltage phase A

2. Supply voltage phase B

3. Supply voltage phase C

The AC input terminals feature spring clips. The orange tab must

be raised to insert the wire. Closing the orange tab secures the wire

into place.

The grounding post is located off the power board on the

chassis itself.

9

8

Figure 10: AC main input

L1 L2 L3

Grounding post

NC

NO

COM

DIN4

DIN3

DIN2

DIN1

DO2

DO1

GND

+24V

GND

A_OUT

GND

A_IN

GND

485_P

485_N

GND

0-10V Speed

Signal

Power board

10

Infinitum 20230810 PRELIMINARY

We reserve the right to make technical changes or modify the contents of this document

without prior notice. Copyright© 2023 Infinitum Electric, Inc. All rights reserved.

106 Old Settlers Blvd

Suite D106

Round Rock, TX 78664

info@goinfinitum.com

goinfinitum.com

support.goinfinitum.com

Office Contact

p. Check motor rotation

Note: If the motor has been tested and the technician has

verified motor rotation prior to installation, the facility can elect

not to perform this test because of redundancy.

Prerequisites: The motor has been installed, aligned and

electrically connected. The fan belt is removed, or coupling is

disconnected. The motor must be briefly energized to check for

proper rotation.

Steps are outlined below:

1. Review all installation instructions and all warnings prior to

testing the motor.

2. Connect AC power

3. Follow all safety precautions and energize the motor briefly to

determine rotation. If the motor rotates opposite of intended

direction, switch the direction command utilizing I-con

software tool.

4. Disconnect AC power.

q. Connect motor to driven equipment

Warning: Always disconnect power and practice all safety

procedures when installing, troubleshooting, or repairing

a motor. Always verify power is secured with a multimeter

prior to work. Failure to adhere follow industry standard

safety practices can result in serious personal injury or death

and equipment damage.

Prerequisite: Motor rotation has been verified. The final series of

steps will place the load on the motor and test system operation.

Steps outlined below:

1. Disconnect power from the motor

2. Attach driven equipment confirming alignment

3. Install all safety covers and connect power

4. Start the system and verify the motor operates properly.

r. Default and user programmable settings

Infinitum EC Aircore motors are shipped with factory default

settings for maximum speed, control methods and other values.

To change your motor’s settings, download the I-con software.

5. Motor maintenance

a. Maintenance tasks

This motor requires inspections and tasks be completed on a

Quarterly (3 months) basis or 500 hours whichever occurs first.

Maintaining this motor requires completion of both inspection

and tasks. Review above warnings. The basic tasks are outlined

below:

1. Disconnect motor line power and all associated operating

equipment and allow one minute for motor capacitors to

discharge.

2. Examine driven equipment for looseness or damage.

3. Inspect the motor output shaft for damages. Replace

damaged components and tighten any loose set screws.

4. Make sure the cooling fins and area around the motor are free

from dust and debris.

5. Make sure the mounting bolts and hardware are tight and

secure.

6. If used, check rubber vibration isolators for cracks and damage.

7. Make sure all wire connections are tight.

8. Inspect internal wires for signs of heat damage.

Any damages noted must be repaired before placing the motor

into service.

b. Mechanical

Problems with alignment can cause bearing wear. Lack of

maintenance, improper installation, and loose mounting bolts can

cause premature bearing wear and motor overloads.

6. Motor drive parameters and data types

The Aircore EC motor parameters can be found here.

Other manuals for Aircore EC

2

Table of contents

Other Infinitum Engine manuals

Popular Engine manuals by other brands

BAFANG

BAFANG H400 Dealer's manual

Ametek

Ametek dunkermotoren BG 66x25 dMove Translation of the original function and connection guide

WPT POWER

WPT POWER PILOTLESS Installation & maintenance manual

BONFIGLIOLI

BONFIGLIOLI BMS series Installation use and service manual

Volvo Penta

Volvo Penta TAMD103A Operator's manual

Maco

Maco HAUTAU SA 650N Mounting and operating instructions