Infinitum 20230810

Aircore EC

Quick Start Guide

This guide contains general procedures for Infinitum EC Aircore motors

and is not intended to provide a full list of installation details, operation

and maintenance. These additional details can be found in the Infinitum

Aircore EC IOM Manual. Only qualified personnel should install and operate

Infinitum Aircore EC motors. All motors have default settings.

This document includes Cautions and Warnings that should be read

in advance of installation or operation.

Unpacking and inspection

Motors are tested and packed individual crates or 4 motors per crate.

1. Inspect the motor packing for damages during shipping. If the package is

damaged, remove the packing and inspect the motor for damage. Motor

damage from shipping must be reported to the shipper.

2. Review the data on the nameplate with your purchase order to verify that you

have received the correct motor. Compare data on name plate for desired

power supply and control equipment requirements.

3. The motor is provided with two lifting eyebolts to remove the motor from its

packing crate.

Warning: To reduce the possibility of personal injury or death these eyebolts

are intended to lift the motor and drive assembly only. Attaching the

component it drives (i.e. fan, pump, etc.) may exceed the design weight

limits of the eyebolts. Make sure the eyebolts are threaded completely into

the motor housing to ensure they do not rotate out during lifting. Use an

approved lifting device (crane) and sling to remove the motor from the

packing crate.

Electrical supply and control wiring

Infinitum Aircore EC motors are pre-programmed to run utilizing remote inputs

wired to the Control & Communication PCB connections once the appropriate

power connections are provided. The default configuration for all motors is

Modbus. Analog/Digital control is also available (user configurable).

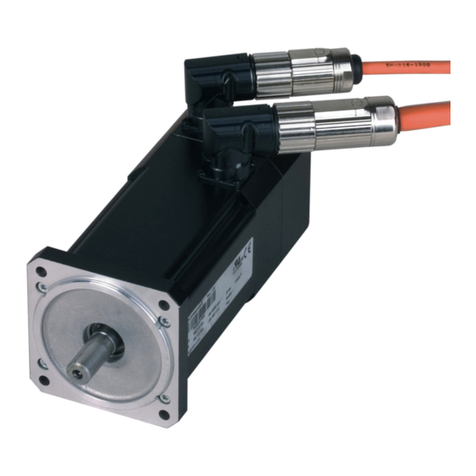

Warning: The rotor in this motor incorporates a Permanent Magnet (PM)

design. When the rotor is rotated a voltage is produced in the stator even

when the motor is disconnected from a power source. Do not open electrical

compartments or touch unprotected terminals while the rotor is turning.

Disconnect motor supply power and allow one minute for capacitors to

discharge before servicing or replacing. Failure to comply with rotor safety

procedures can cause serious injury or death and equipment damage.

Safety

Infinitum Aircore EC motors

operate with high voltages and

can cause serious or fatal injuries.

Only qualified personnel should

attempt installation, operation

and maintenance of electrical

equipment. Unsafe installation or

use can cause conditions that lead

to serious or fatal injury.

Mounting

C-face

Star mounts