8

MAINTENANCE SECTION

Always use protective eyewear when performing main-

tenance on a motor or when operating a motor.

Always turn off the air supply and disconnect the air

supply line before installing, removing or adjusting

any accessory on this motor or before performing any

maintenance on this motor. Failure to do so could re-

sult in injury.

DISASSEMBLY

General Instructions

1. Do not disassemble the motor any further than neces-

sary to replace or repair damaged parts.

2. Do not disassemble the motor unless you have a com-

plete set of new gaskets and o--rings for replacement.

3. When grasping a tool in a vise, always use leather--

covered or copper--covered vise jaws to protect the

surface of the part or motor and help prevent distor-

tion. This is particularly true of threaded members

and housings.

4. Do not remove any part which is a press fit in or on a

subassembly unless the removal of that part is neces-

sary for repairs or replacement.

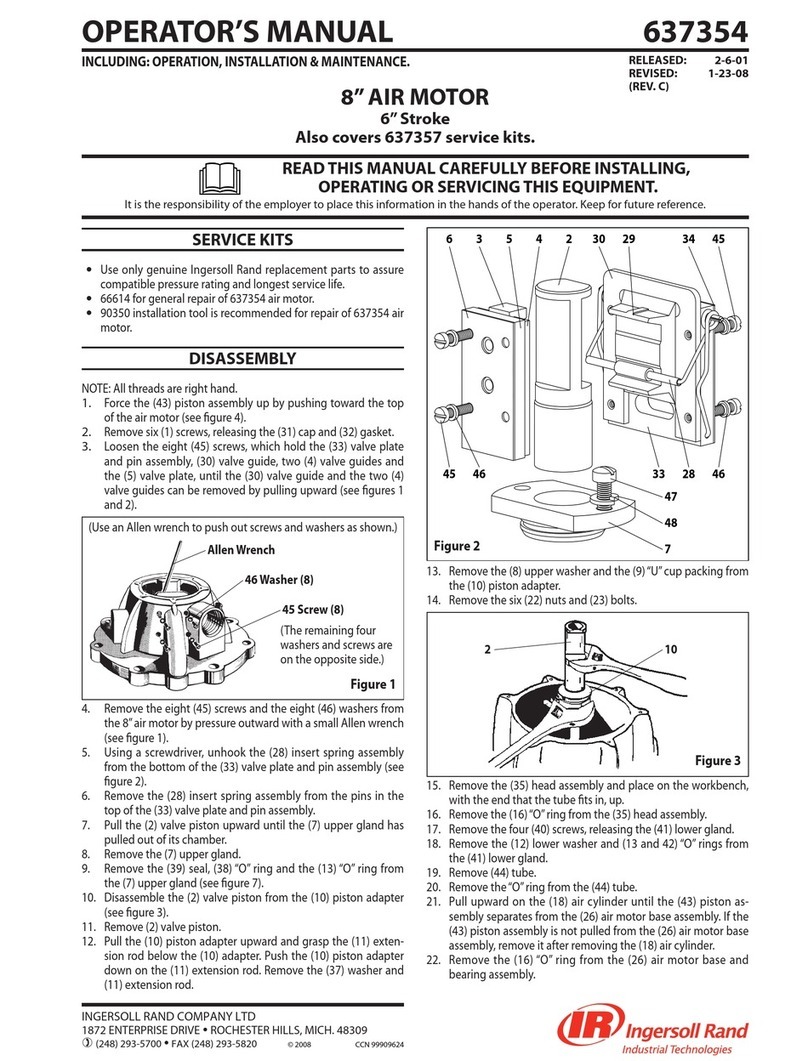

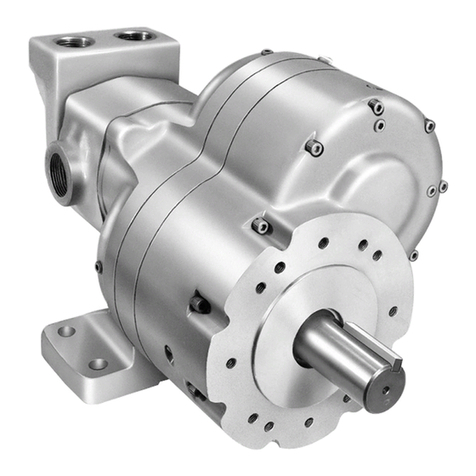

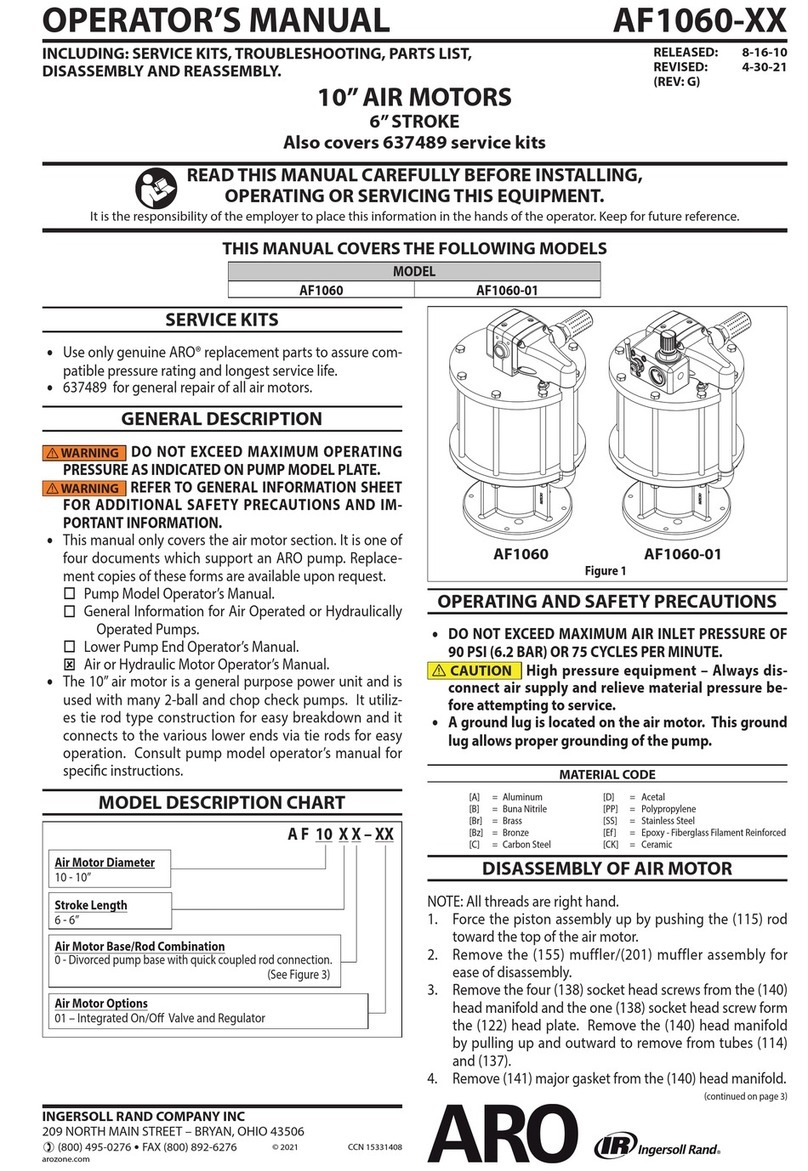

Disassembly of the Motor

1. Clamp a large adjustable wrench in vise jaws with the

adjustable opening upward.

2. Adjust the jaw of the wrench to clear the body of the

Gear Case (14).

3. Roll the motor in the wrench jaw until it stops against

the Gear Case Grease Screw (15) and, using a wrench

on the flats of the Coupling Nut (33) at the flange end

of the Gear Case, loosen the Coupling Nut.

4. Roll the motor in the opposite direction until it stops

against the Gear Case Grease Screw and, using a

wrench on the flats of the Coupling Nut at the flange

end of the Gear Case, loosen the Coupling Nut.

5. Holding the motor horizontally over a workbench,

unscrew the Coupling Nut at the motor end of the

Gear Case and pull the motor from the Gear Case.

Do not lose the Flange Key (42).

6.

For Models with Square Drive Adapter (27A),

using a hex wrench, unscrew and remove the two

Adapter Screws (27B).

7. Unscrew the Coupling Nut and pull the Flange As-

sembly and the Spindle (27) out the of Gear Case.

Once the Spindle is removed from the Gear Case, the

entire gear train must be disassembled to install the

Spindle Planet Gears (28) or the Spindle Planet Gear

Assemblies (30) on the opposite end of the Spindle.

Do not lose the Flange Key.

8.

For Models with Square Drive Adapters,

carefully

grasp the Spindle in copper--covered vise jaws and

using a wrench on the square drive, unscrew and re-

move the Adapter.

9. Push the Spindle out the gear end of the Flange As-

sembly.

10. Remove the Spindle Seal (41) and Flange Seal (40)

from the inside of the Flange (39).

11. Using snap ring pliers, remove the Spindle Retaining

Ring (37) and pull the two Spindle Bearings (35) and

the Spindle Bearing Spacer (36) from the shaft of the

Spindle. Remove the second Spindle Retaining Ring.

12. Remove the Motor Clamp Washer (13) from the Gear

Case.

13.

For Models with 000 ratios,

pull the Spindle Drive

Plate (32) from the Gear Case.

For Models with 006 ratios,

pull the three Spindle

Planet Gear Assemblies (30) from the Gear Case.

For Models with 004 ratios,

pull the Rotor Pinion

(16) and the three Spindle Planet Gear Assemblies

(30) from the Gear Case.

For Models with 011 ratios,

pull the Rotor Pinion

(16), three Gear Head Planet Gears (18), three Planet

Gear Bearings (19), Gear Head (17), Gear Head

Spacer (26), three Spindle Planet Gears (28) and three

Spindle Planet Gear Bearings (29) from the Gear

Case.

For Models with 015 ratios,

pull the Rotor Pinion

(16), three Gear Head Planet Gear Assemblies (20),

Gear Head (17), Gear Head Spacer (26) and three

Spindle Planet Gear Assemblies (30) from the Gear

Head.

For Models with 023 ratios,

pull the three Gear

Head Planet Gear Assemblies (20), Gear Head (17),

Gear Head Spacer (26), four Spindle Planet Gears

(28) and four Spindle Planet Gear Bearings (29) from

the Gear Case.

For Models with 033 ratios,

pull the three Gear

Head Planet Gear Assemblies (20), Gear Head (17),

Gear Head Spacer(26) and three Spindle Planet Gear

Assemblies (30) from the Gear Case.

For Models with 050 ratios,

pull the Rotor Pinion

(16), three Gear Head Planet Gear Assemblies (20),

Gear Head (17), Gear Head Spacer (22), three Inter-

mediate Gear Head Planet Gear Assemblies (24),

Intermediate Gear Head (23), Gear Head Spacer (26),

three Spindle Planet Gears (28) and three Spindle

Planet Gear Bearings (29) from the Gear Case.

For Models with 083 ratios,

pull the three Gear

Head Planet Gear Assemblies (20), Gear Head (17),

Gear Head Spacer (22), three Intermediate Gear Head

Planet Gear Assemblies (24), Intermediate Gear Head

(23), Gear Head Spacer (26), three Spindle Planet

Gears (28) and three Spindle Planet Gear Bearings

(29) from the Gear Case.