Infranor SMT-BD1/t User manual

1

SMT-BD1/t

INFRANOR

®

UNWINDER/REWINDER

SERVO DRIVE WITH

PROFIBUS DP

INTERFACE

SMT-BD1/t

gb

2

SMT-BD1/t

WARNING

This is a general manual describing a series of servo amplifiers having output capability suitable for driving AC

brushless sinusoidal servo motors.

Instructions for storage, use after storage, commissioning as well as all technical details require the

MANDATORY reading of the manual before getting the amplifiers operational.

Maintenance procedures should be attempted only by highly skilled technicians having good knowledge

of electronics and servo systems with variable speed (EN 60204-1 standard) and using proper test

equipment.

The conformity with the standards and the "CE" approval is only valid if the items are installed according to the

recommendations of the amplifier manuals. Connections are the user's responsibility if recommendations and

drawings requirements are not met.

INFRANOR does not assume any responsibility for any physical or material damage due to improper handling or

wrong descriptions of the ordered items.

Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty.

Infranor reserves the right to change any information contained in this manual without notice.

©INFRANOR,June 2006. All rights reserved.

Issue:3.1

!

ELIMINATION

In order to comply with the 2002/96/EC directive of the European Parliament and of the Council of

27 January 2003 on waste electrical and electronic equipment (WEEE), all INFRANOR devices

have got a sticker symbolizing a crossed-out wheel dustbin as shown in Appendix IV of the

2002/96/EC Directive.

This symbol indicates that INFRANOR devices must be eliminated by selective disposal and not

with standard waste.

Any contact with electrical parts, even after power down, may involve physical damage.

Wait for at least 5 minutes after power down before handling the amplifiers (a residual voltage of several

hundreds of volts may remain during a few minutes).

ESD INFORMATION (ElectroStatic Discharge)

INFRANOR amplifiers are conceived to be best protected against electrostatic discharges. However,

some components are particularly sensitive and may be damaged if the amplifiers are not properly

stored and handled.

STORAGE

- The amplifiers must be stored in their original package.

- When taken out of their package, they must be stored positioned on one of their flat metal

surfaces and on a dissipating or electrostatically neutral support.

- Avoid any contact between the amplifier connectors and material with electrostatic potential

(plastic film, polyester, carpet…).

HANDLING

- If no protection equipment is available (dissipating shoes or bracelets), the amplifiers must

be handled via their metal housing.

- Never

g

et in contact with the connectors.

3

Contents

SMT-BD1/t

Contents

CONTENTS............................................................................................................................................. 3

CHAPTER 1 - GENERAL DESCRIPTION ............................................................................................. 6

1-INTRODUCTION............................................................................................................................ 6

2-GENERAL DESCRIPTION............................................................................................................. 6

3-REFERENCETO THESTANDARDS............................................................................................ 7

4-REFERENCETO OTHERDOCUMENTS...................................................................................... 7

CHAPTER 2 - SPECIFICATIONS........................................................................................................... 8

1-TECHNICAL SPECIFICATIONS.................................................................................................... 8

1.1 - Current ratings for the 220 VAC amplifier version.................................................................. 8

1.2 - Current ratings for the 400 VAC amplifier version.................................................................. 9

1.3 - Other specifications.............................................................................................................. 10

2-FUSE PROTECTION ................................................................................................................... 11

2.1 - Fuse protection for the 220 VAC amplifier version............................................................... 11

2.2 - Fuse protection for the 400 VAC amplifier version............................................................... 11

CHAPTER 3 - INPUTS / OUTPUTS ..................................................................................................... 12

1-CONNECTORSLOCATION ........................................................................................................ 12

1.1 - RACK connectors................................................................................................................. 12

1.2 - Amplifier connectors............................................................................................................. 12

2-LEDS............................................................................................................................................. 12

2.1 - Amplifier fault LEDs.............................................................................................................. 12

2.2 - Profibus communication LEDs ............................................................................................. 12

3-X1: RESOLVER CONNECTOR ................................................................................................... 13

4-X2: ENCODER CONNECTOR..................................................................................................... 13

5-X4: CONTROL CONNECTOR ..................................................................................................... 14

6-X6: PROFIBUS............................................................................................................................. 14

7-X5: RS-232CONNECTOR........................................................................................................... 14

8-X3: TEST CONNECTOR............................................................................................................. 15

9-LOGIC INPUTS-OUTPUTS SPECIFICATIONS........................................................................... 15

9.1 - Logic inputs: ENABLE, SEL1, SEL2, START, STOP........................................................... 15

9.2 - Logic inputs: TDI, Lin1.......................................................................................................... 15

9.3 - Logic outputs: TER, Lout1.................................................................................................... 16

CHAPTER 4 -CONNECTIONS ............................................................................................................ 17

1-CONNECTION DIAGRAMS......................................................................................................... 17

1.1 - Power supply and motor connections .................................................................................. 17

1.2 - AmplifierI/O connections ..................................................................................................... 17

2-RS-232SERIAL LINK CONNECTION.......................................................................................... 18

3-WIRING RECOMMENDATIONS.................................................................................................. 18

3.1 - GND wiring and ground connections.................................................................................... 18

3.2 - CONNECTORS SHIELD CONNECTION ............................................................................ 19

3.3 - MOTOR AND RESOLVER CABLES.................................................................................... 20

3.4 - SERIAL LINK CABLES........................................................................................................20

CHAPTER 5 - ADJUSTABLE FUNCTIONS ........................................................................................ 21

1-HARDWARE ADJUSTMENTS..................................................................................................... 21

2-ADJUSTABLE PARAMETERS .................................................................................................... 23

CHAPTER 6 - COMMISSIONING......................................................................................................... 24

1-AMPLIFIER HARDWARECONFIGURATION ............................................................................. 25

1.1 - Standard configuration ......................................................................................................... 25

1.2 - Motor thermal sensor configuration...................................................................................... 25

1.3 - Current loops adjustments ................................................................................................... 26

2-PUTTING INTO OPERATION...................................................................................................... 27

3-MOTOR ADJUSTMENT............................................................................................................... 28

4 Contents

SMT-BD1/t

3.1 - Motor parameter setting........................................................................................................ 28

3.2 - Adjustment to a new motor................................................................................................... 28

4-SPEED CONTROLLOOP ADJUSTMENT................................................................................... 29

4.1 - Regulator parameters adjustment ........................................................................................ 29

4.2 - Enabling................................................................................................................................ 29

4.3 - Brake control......................................................................................................................... 29

4.4 - Jogcontrol ............................................................................................................................ 29

5-UNWINDER/REWINDER CONFIGURATION.............................................................................. 30

5.1 - Rotation direction.................................................................................................................. 30

5.2 - Gearing ratio adjustment ...................................................................................................... 30

5.3 - Diameter sensor calibration.................................................................................................. 30

5.4 - Encoder ratio calibration....................................................................................................... 31

5.5 - Tension measurement calibration ........................................................................................ 31

5.6 - PID loop adjustment for tension control................................................................................ 32

5.7 - Parameters setting for tension control.................................................................................. 33

6-PROFIBUS ADDRESS................................................................................................................. 33

7-PARAMETERS SAVING .............................................................................................................. 33

8-PROFIBUS OR STAND ALONE MODE SELECTION.................................................................. 33

CHAPTER 7 - PROGRAMMING........................................................................................................... 34

1-GENERAL DESCRIPTION........................................................................................................... 34

2-CONTROL SEQUENCE PARAMETERS ..................................................................................... 34

3-SEQUENCE SET POINT SELECTION ........................................................................................ 35

4-VARIABLE DIAMETER OPERATION .......................................................................................... 35

4.1 - Speed gearing ratio adaptation ............................................................................................35

4.2 - Torque set point ratio adaptation.......................................................................................... 36

4.3 - Servo loop gains adaptation................................................................................................. 36

5-EDITION OF ACONTROLSEQUENCE ...................................................................................... 37

5.1 - Tension control sequence..................................................................................................... 37

5.2 - Gearing ratio initialization sequence.....................................................................................39

5.3 - Speed 1 control sequence.................................................................................................... 40

5.4 - Speed 2 control sequence.................................................................................................... 41

5.5 - Torque control sequence...................................................................................................... 42

6-SEQUENCES CHAINING............................................................................................................. 44

6.1 - Sequence control.................................................................................................................. 44

6.2 - Logicinputs........................................................................................................................... 45

6.3 - Logicoutputs ........................................................................................................................ 46

CHAPTER 8 - OPERATION WITH PROFIBUS.................................................................................... 47

1-PROFIBUS COMMUNICATION................................................................................................... 47

1.1 - PPO message....................................................................................................................... 47

1.2 - Configuration ........................................................................................................................ 49

1.3 - Parameter setting (PKW)...................................................................................................... 49

1.4 - Global control........................................................................................................................ 50

2-CONTROL VIA PROFIBUS.......................................................................................................... 51

2.1 - Control word ......................................................................................................................... 51

2.2 - Input command..................................................................................................................... 51

2.3 - Status.................................................................................................................................... 52

2.4 - Feedback.............................................................................................................................. 52

3-OPERATIONDIAGRAM............................................................................................................... 53

3.1 - Amplifier control process ...................................................................................................... 53

3.2 - Unwind/rewind mode ............................................................................................................ 54

4-DRIVING OF THE UNWINDER/REWINDER ............................................................................... 55

4.1 - Enabling/disabling................................................................................................................. 55

4.2 - Starting a sequence.............................................................................................................. 55

4.3 - Other movements ................................................................................................................. 55

4.4 - All-speed control................................................................................................................... 55

CHAPTER 9 - PARAMETER SETTING BY PROFIBUS...................................................................... 56

1-PARAMETER LIST....................................................................................................................... 56

5

Contents

SMT-BD1/t

2-PARAMETERS DESCRIPTION................................................................................................... 57

2.1 - Motor parameters ................................................................................................................. 57

2.2 - Current parameters .............................................................................................................. 58

2.3 - Speed regulator parameters................................................................................................. 59

2.4 - Application parameters......................................................................................................... 60

2.5 - Unwinder/rewinder parameters ............................................................................................ 62

2.6 - Encoder output ..................................................................................................................... 63

2.7 - Manual jog parameters......................................................................................................... 64

2.8 - PID loop parameters............................................................................................................. 64

2.9 - Gearing ratio calibration parameters.................................................................................... 65

2.10 - Tension control parameters................................................................................................ 66

2.11 - Torque control parameters................................................................................................. 67

2.12 - SequenceReading/Writing.................................................................................................68

CHAPTER 10 - TROUBLESHOOTING................................................................................................ 72

1-DIAGNOSTICS............................................................................................................................. 72

1.1 - SMT-BD1/t fault display........................................................................................................ 72

1.2 - Fault reset............................................................................................................................. 72

2-FAULT FINDING .......................................................................................................................... 73

2.1 - System fault.......................................................................................................................... 73

2.2 - Non stored faults .................................................................................................................. 73

2.3 - Stored faults ......................................................................................................................... 73

3-OPERATINGPROBLEMS ........................................................................................................... 75

3.1 - Motor does not move............................................................................................................ 75

3.2 - Motor supplied but no torque................................................................................................ 75

3.3 - Shaft locked, eraticoscillations or rotation at maximum speed ........................................... 75

3.4 - Discontinuous motor rotation with zero torque positions...................................................... 75

3.5 - Loud crackling noise in the motor at standstill ..................................................................... 75

3.6 - Loud noise in the motor at standstill and when running....................................................... 75

3.7 - Sequence not executed........................................................................................................ 75

4-SERVICE AND MAINTENANCE.................................................................................................. 75

CHAPTER 11 - APPENDIX .................................................................................................................. 76

1-USE OF THEPOSITIVE &NEGATIVE LOGIC INPUTS .............................................................. 76

2-USE OF THE"AMP. READY" &"POWER READY"OUTPUTS................................................... 76

3-SPEED FOLLOWING ERRORPROTECTION ............................................................................ 77

4-I2TPROTECTION......................................................................................................................... 77

4.1 - Current limitation in Fusing mode.........................................................................................77

4.2 - Current limitation in Limiting mode.......................................................................................78

5-MASTER/SLAVE CONFIGURATION........................................................................................... 79

5.1 - Reversible master/slavegearing operation with two SMT-BD1/t amplifiers ........................ 79

5.2 - Configurable master/slave gearing operation with more than two SMT-BD1/t amplifiers.... 80

6-COGGING TORQUE COMPENSATION ..................................................................................... 81

7-AMPLIFIER TYPES...................................................................................................................... 81

6 CHAPTER 1 – General description

SMT-BD1/t

Chapter 1 - General description

1 - INTRODUCTION

Series SMT-BD1/t servo modules are PWM servo amplifiers that provide current and speed control for AC

sinusoidal motors (brushless) with transmitter resolver.

The SMT-BD1/t servo drive is 220 VAC or 400 VAC mains operated. The SMT-BD1 plug-in system with 220 VAC

power supply is available as a single-axis block version or as a multiaxis version that can receive up to six axes in

a standard 19" rack including the power supply. The SMT-BD1/t plug-in system with 400 VAC power supply is

available as a multiaxis version that can receive up to three axes in a standard 19" rack including the power

supply.

2 - GENERAL DESCRIPTION

Series SMT-BD1 amplifiers have their own DC/DC converter to provide the appropriate supply voltage (+5 V,

+/-15V). The source supply voltage for the control board is the auxiliary 310 VDC supply voltage. The auxiliary

supply voltage allows to have the amplifier control board still active when the power supply voltage is turned off.

Each module is packaged as a 6 U "double Eurocard":

- one power board with IGBT transistors

- one control board with DSP (Digital Signal Processing).

The SMT-BD1/t servo amplifiers are suited for unwind/rewind and tension control applications. Up to 64 control

sequences including tension control, speed control and torque control can be programmed and combined in order

to solve various unwind/rewind and tension control applications. The sequence chaining capability allows to

define macro-sequences for complex applications: several control sequences can be linked together in order to

be automatically executed one after the other. The control sequences are pre-programmed. So, the application

programming simply consists in initializing the sequences parameters with the desired values.

The SMT-BD1/t servo amplifier most typical unwind/rewind and tension control applications are listed below :

•Material unwind/rewind force control based on diameter sensor feedback

•Material unwind/rewind line speed control based on diameter sensor feedback

•Material unwind/rewind force control based on line encoder feedback

•Material unwind/rewind line speed control based on line encoder feedback

•Accumulator control for material unwinder based on diameter and accumulator sensors feedback

•Material unwind/rewind tension control based on line encoder and dancer feedback

•Material unwind/rewind tension control based on diameter sensor and dancer feedback

The SMT-BD1/t servo amplifier operates with a PROFIBUS DP interface. The servo amplifier control and the

parameter setting can both be made via the PROFIBUS DP connection. The servo amplifier control via

PROFIBUS DP connection simply consists in selecting one of the amplifier pre-programmed control sequences

and start its execution.

The SMT-BD1/t servo amplifier can also operate with the RS-232 serial link for the parameters setting and the

sequences programming. The INFRANOR BPCW parameter setting software which is IBM-PC compatible makes

the amplifier commissioning and the application programming easier.

The SMT-BD1/t servo amplifier can also run in stand-alone mode without the PROFIBUS DP connection. In this

configuration, a pre-programmed control sequence is selected via the SEL1 and SEL2 logic inputs and its

execution is started by using the START logic input. However, in this case only the sequence numbers 0 to 3 can

be selected by the SEL1 and SEL2 logic inputs activation.

7

CHAPTER 1 – General description

SMT-BD1/t

3 - REFERENCE TO THE STANDARDS

The 220 VAC version of the SMT-BD1/t amplifiers operating in the BF rack, which is equipped with the mains

filter BF-35 or 70, has been approved for its compliance with the Electromagnetic Compatibility standards:

•EN 55011, Group 1, Class A regarding conducted and radiated radioelectric disturbances,

•CEI 801 - 2 - 3 - 4 regarding immunity.

The 220 VAC version of the SMT-BD1/t amplifiers operating in the single-axis racks BM 20 A – BMM 05F – BMM

05A, which are equipped with the appropriate mains filter (FN 612-20/06 or FN 356-16/06 or BF-35), has been

approved for its compliance with the Electromagnetic Compatibility standards:

•EN 55011, Group 1, Class A regarding conducted and radiated radioelectric disturbances,

•CEI 801 - 2 - 3 - 4 regarding immunity.

The 400 VAC version of the SMT-BD1/t amplifiers operating in the BF-400 rack, which is equipped with the mains

filter BF400-35 or 70, has been approved for its compliance with the Electromagnetic Compatibility standards:

•EN 55011, Group 1, Class A regarding conducted and radiated radioelectric disturbances,

•CEI 801 - 2 - 3 - 4 regarding immunity.

Standard to be applied to the electrical equipments of industrial machines: EN 60204.1.

The SMT-BD1 amplifiers have been "CE" marked since year 1995.

4 - REFERENCE TO OTHER DOCUMENTS

♦BF-400 rack –for the use of the 400 VAC amplifier versionin a multiaxis rack.

♦BF rack – for the use of the 220VAC amplifier version in a multiaxis rack.

♦BM20A/BMM05F/05AF single-axis rack – for the use of the 220 VAC amplifier version in a single-axis rack.

8 CHAPTER 2 – Specifications

SMT-BD1/t

Chapter 2 - Specifications

1 - TECHNICAL SPECIFICATIONS

1.1 - Current ratings for the 220 VAC amplifier version

Operating voltage DC bus 310 VDC (270 VDC < DC bus < 340 VDC max.)

Auxiliary supply voltage 310 VDC ( 200 VDC < Uaux < 340 VDC max.)

Motor terminal to terminal output voltage 200 Vrms for 310 VDC bus

Authorized output currents for current pulse mode operation (I2t protection in fusing mode)

AMPLIFIER

U rated

Imax (A rms)

Max. authorized rated current (Arms)

of the amplifier

(Vrms) 1 s WITHOUT

FAN*

FAN TYPE

1*

FAN TYPE

2*

SMT-BD1/t - 220/04 240 4,4 2

SMT-BD1/t - 220/08 240 8,8 4

SMT-BD1/t - 220/12 240 13,8 6

SMT-BD1/t - 220/17 240 17,7 8,5

SMT-BD1/t - 220/30 240 30,8 10 12 15

SMT-BD1/t - 220/30r 240 30,8 10 15

SMT-BD1/t - 220/45 240 48,6 10 15 20

SMT-BD1/t - 220/45r 240 48,6 10 20 23

SMT-BD1/t - 220/60 240 61 10 19 25

SMT-BD1/t - 220/60r 240 61 12 26 30

SMT-BD1/t - 220/70 240 70 25 30 35

SMT-BD1/t - 220/100 240 100 25 30 35

Authorized output currents for continuous current mode operation (I2t protection in limiting mode)

AMPLIFIER TYPE

U rated

Imax (A rms)

Max. authorized continuous current (Arms) of

the amplifier

(Vrms) 1 s WITHOUT

FAN*

FAN TYPE

1*

FAN TYPE

2*

SMT-BD1/t - 220/04 240 4,4 2

SMT-BD1/t - 220/08 240 8,8 4

SMT-BD1/t - 220/12 240 13,8 6

SMT-BD1/t - 220/17 240 17,7 8,5 8,5

SMT-BD1/t - 220/30 240 30,8 8,5 12 15

SMT-BD1/t - 220/30r 240 30,8 10 15

SMT-BD1/t - 220/45 240 48,6 8,5 15 18

SMT-BD1/t - 220/45r 240 48,6 10 20 23

SMT-BD1/t - 220/60 240 61 8,5 17 20

SMT-BD1/t - 220/60r 240 61 12 26 30

SMT-BD1/t - 220/70 240 70 17 30 35

SMT-BD1/t - 220/100 240 100 25 30 35

* Maximum ambient temperature = + 40° C, fan 1 = 56 l/s, fan 2 = 90 l/s.

Note: The SMT-BD1/t-X/Xr amplifier types are equipped with an additional heatsink in order to improve the heat

dissipation and increase their rated current. The width of these amplifier types is then 18 TE instead of 12 TE.

9

CHAPTER 2 – Specifications

SMT-BD1/t

Minimum inductance between phases 1 mH

Conformity with the standards: CE approval - EMC standards

with multiaxis power supply configuration Immunity: CEI standards 801- 2 - 3 - 4

BF rack with mains filter BF-35 or 70, Conducted and radiated disturbances: EN 55011,

or SMTB.M 20 A / BMM05F/AF single-axis rack Group 1, class A

with filters FN 612-20/06 or FN 356-16/06 or BF-35. - Electrical standards for industrial machines:

360° shields; equipotentiality according to the wiring rules. EN 60204.1: - Insulator: 1500 VAC/1 min.

- Leakage current > 3 mA

(EMI filters)

Temperature range * storage - 20°C to + 70°C

* operation 5°C to +40°C

From 40°C on, the rated currents

must be reduced of 3 %/°C.

Max. temperature: 50°C

1.2 - Current ratings for the 400 VAC amplifier version

Operating voltage DC bus 565 VDC (480 VDC < DC bus < 685 VDC

max.)

Auxiliary supply voltage 310 VDC ( 200 VDC < Uaux < 340 VDC max.)

Motor terminal to terminal output voltage 380Vrms for 565 VDC bus

Authorized output currents for current pulse mode operation (I2t protection in fusing mode)

AMPLIFIER

U rated

Imax (A rms)

Max. authorized rated current

(Arms) of the amplifier

(Vrms) 1 s WITHOUT

FAN*

FAN TYPE

2*

SMT-BD1/t - 400/15 400 15.5 5 7.5

SMT-BD1/t - 400/30 400 30 8 15

SMT-BD1/t - 400/45 400 48 10 19

SMT-BD1/t - 400/60 400 60 not used 28

SMT-BD1/t - 400/100 400 100 not used 35

Authorized output currents for continuous current mode operation (I2t protection in limiting mode)

AMPLIFIER TYPE

U rated

Imax (A rms)

Max. authorized continuous

current (Arms) of the amplifier

(Vrms) 1 s WITHOUT

FAN*

FAN TYPE

2*

SMT-BD1/t - 400/15 400 15.5 not used 5

SMT-BD1/t - 400/30 400 30 not used 10

SMT-BD1/t - 400/45 400 48 not used 15

SMT-BD1/t - 400/60 400 60 not used 23

SMT-BD1/t - 400/100 400 100 not used 28

* Maximum ambient temperature = + 40° C, fan 2 = 90 l/s.

Minimum inductance between phases 2 mH

Conformity with the standards: CE approval - EMC standards

with multiaxis power supply configuration Immunity: CEI standards 801- 2 - 3 - 4

BF-400 rack and mains filter F400-35 or 70. Conducted and radiated disturbances: EN 55011,

360° shields; equipotentiality according to the Group 1, class A

wiring rules. - Electrical standards for industrial machines:

EN 60204.1: - Insulator: 2500 VAC/1 min.

- Leakage current > 3 mA

(EMI filters without condensators)

Temperature range * storage - 20°C to + 70°C

* operation 5°C to +40°C

From 40°C on, the rated currents

must be reduced of 3 %/°C.

Max. temperature: 50°C

10 CHAPTER 2 – Specifications

SMT-BD1/t

1.3 - Other specifications

PWM switching frequency 8 kHz

Current regulator (PI) Adjusted to the motor

Current loop bandwidth Cut-off frequency for 45° phase shift > 1 kHz

Internal current limitation Imax: 20 % to 100 % and Irated: 20 % to 50 %

Imax duration = 1 second

Speed regulator (PI) Sampling period = 0,5 ms

Adjustable digital gains

Tension regulator (PID) Sampling period = 1 ms

Adjustable digital gains

Speed loop bandwidth Selectable cut-off frequency for 45° phase shift: 50 Hz,

75 Hz or 100 Hz

Max. motor speed Adjustable from 100 rpm to 14 000 rpm

Encoder position output Two channels A and B in quadrature + n marker pulses per

revolution.

RS 422 line driver

Programmable resolution:

max. 8 192 ppr up to 900 rpm

max. 4 096 ppr up to 3 600 rpm

max. 1 024 ppr up to 14 000 rpm

Accuracy: 8 arc minutes + ¼ point

(optional: 2 arc minutes + ¼ point)

Note: The total position accuracy must take into account the

accuracy of the motor resolver

Master encoder input Two channels A and B in quadrature + Z marker pulse

RS 422 line receiver.

Maximum pulses frequency: 250 kHz

Analog outputs (monitor) Speed input command (CV): ±10 V for ± max speed

Speed monitor (GT): ±8 V for ±14 000 rpm, linearity: 10%

Current input command (IDC): ±10 V for ± current rating,

DACout1 resolution = 8 bits

Current monitor (Imes): ±10 V for ± current rating,

DACout2 resolution = 8 bits

Analog inputs (control) ANin1 +/- 10V resolution = 12 bit standard (16 bit optional)

Torque or Speed reference

Dancer or Load cell tension measurement

ANin2 0V to 10V resolution = 12 bit standard (16 bit optional)

Diameter sensor measurement

Dedicated logic inputs Positive logic or negative logic:

- Amplifier enabling: ENABLE

- Sequence selection: SEL1, SEL2 (stand alone operation)

- Sequence start : START (stand alone operation)

- Motor stop: STOP

- Fault reset: RAZ

Optocoupled:

- Tension control disable: TDI

Dedicated logic outputs Open collector: Umax = 24V

Imax = 5 mA

« Tension error »: active if tension OK, inactive if tension

error

11

CHAPTER 2 – Specifications

SMT-BD1/t

Relay outputs Relay contact: Umax = 60 V

Imax = 200 mA, Pmax = 10 W

« Amp ready »: closed if amplifier OK, open if fault

« Power ready »: closed if power OK, open if fault

« Brake control » : closed for disabling the motor brake

General purpose I/Os Programmable input: Lin1 (Optocoupled)

Programmable output: Lout1 (Open collector)

PROFIBUS link PPO-1 or PPO-2 or PPO-3 or PPO-4.

Fault display LEDs on front panel and diagnostic by serial link RS232 +

diagnostic by PROFIBUS.

Motor and application parameter setting Serial link RS232 or Profibus DP link

Automatic functions Amplifier adjustment to the motor (AUTO-PHASING)

Automatic regulator tuning (AUTO-TUNING)

Altitude 1000 m

Moisture < 50% to 40° C and < 90% to 20° C: EN 60204-1 standard

Cooling Natural convection or forced air according to the rated

current

2 - FUSE PROTECTION

2.1 - Fuse protection for the 220 VAC amplifier version

F1 : Control of the average DC current of the power board supply (see Hardware adjustments in chapter 5).

F2 : Control of the average DC current of the logic board supply (see Hardware adjustments in chapter 5).

AMPLIFIER TYPE F1 F2

Power Logic

SMT-BD1/t -220/04 to 12 10 AT 1 A

SMT-BD1/t -220/17 and 30 15 AT 1 A

SMT-BD1/t -220/45 20 AT 1 A

SMT-BD1/t -220/60 20 AT 1 A

SMT-BD1/t -220/70 - 1 A

SMT-BD1/t -220/100 - 1 A

2.2 - Fuse protection for the 400 VAC amplifier version

F2 : Control of the average DC current of the logic board supply (see Hardware adjustments in chapter 5).

AMPLIFIER TYPE F2

Logic

SMT-BD1/t - 400/15 1 A

SMT-BD1/t - 400/30 1 A

SMT-BD1/t - 400/45 1 A

SMT-BD1/t - 400/60 1 A

SMT-BD1/t - 400/100 1 A

12 CHAPTER 3 – Inputs/Outputs

SMT-BD1/t

Chapter 3 - Inputs / Outputs

1 - CONNECTORS LOCATION

1.1 - RACK connectors

For the 400 VAC amplifier version, see BF-400 RACK manual.

For the 220 VAC amplifier version, see SMTB.M 20 A SINGLE-AXIS RACK manual or BF RACK manual.

1.2 - Amplifier connectors

X1

X5

X2

X4

X6

X6

on/sys LEDs

error display LEDs

X1 Resolver

X5 Serial link

X2 Encoder input / output

X4 Command

X3 Test

Offset push button

Diag LED

Run LED

X6 Profibus

2 - LEDs

2.1 - Amplifier fault LEDs

Location: above the resolver connector X1

ON (green) : power supply

SYS (red) : system fault

2.2 - Profibus communication LEDs

Location: above the Profibus connector X6

ON SYS

Amplifier faults (red)

DIAG Diagnostic of the PROFIBUS interface (green)

RUN Communication OK (green)

13

CHAPTER 3 – Inputs/Outputs

SMT-BD1/t

3 - X1: RESOLVER CONNECTOR

Sub D 9 pins female.

PIN FUNCTION NOTE

1 TC (motor thermal sensor) pin H sensor connector for MAVILOR motor

6 Shield connection If no « 360° » connection on the connector

2 TC (motor thermal sensor) pin I sensor connector for MAVILOR motor

7 S1 (+sin resolver) pin C sensor connector for MAVILOR motor

3 S3 (-sin resolver) pin D sensor connector for MAVILOR motor

8 S4 (+cos resolver) pin B sensor connector for MAVILOR motor

4 S2 (-cos resolver) pin A sensor connector for MAVILOR motor

9 R2 (+ref resolver) pin F sensor connector for MAVILOR motor

5 R1 (-ref resolver) pin E sensor connector for MAVILOR motor

4 - X2: ENCODER CONNECTOR

Sub D 25 pins female.

PIN SIGNAL I/O DESCRIPTION

1 /CZ O Differential output of the encoder marker pulse /Z (5 V, 20 mA max.)

Recommended line receiver: 26LS32

2 CZ O Differential output of the encoder marker pulse Z (5 V, 20 mA max.)

Recommended line receiver: 26LS32

3 /CA O Differential output of the encoder channel /A (5 V, 20 mA max.)

Recommended line receiver: 26LS32

4 CA O Differential output of the encoder channel A (5 V, 20 mA max.)

Recommended line receiver: 26LS32

5 /CB O Differential output of the encoder channel /B (5 V, 20 mA max.)

Recommended line receiver: 26LS32

6 CB O Differential output of the encoder channel B (5 V, 20 mA max.)

Recommended line receiver: 26LS32

7, 10, 11 0 V

12 /IA I Input of the master encoder channel /A (5 V, 2 mA)

Recommended line driver: 26LS31

13 IA I Input of the master encoder channel A (5 V, 2 mA)

Recommended line driver: 26LS31

14 /IB I Input of the master encoder channel /B (5 V, 2 mA)

Recommended line driver: 26LS31

15 IB I Input of the master encoder channel B (5 V, 2 mA)

Recommended line driver: 26LS31

21 Lin1 I Programmable input (Optocoupled, 5 V to 24 V)

22 TDI I Tension disabled (Optocoupled, 5 V to 24 V)

8 Lout1 O Programmable output (open collector: 24 V max, 5 mA max)

18 TER O Tension error (open collector: 24 V max, 5 mA max)

23 0V logic I/Os O

24 +5V O Master encoder supply: 5 V +/-5 %, 300 mA, with 5 V jumper closed

25 GND

other pins reserved

14 CHAPTER 3 – Inputs/Outputs

SMT-BD1/t

5 - X4: CONTROL CONNECTOR

Sub D 25 pins male.

PIN SIGNAL I/O REMARK

1 SEL1 I Positive logic or negative logic (stand alone operation only)

14 SEL2 I Positive logic or negative logic (stand alone operation only)

4 START I Positive logic or negative logic (stand alone operation only)

7 STOP I Positive logic or negative logic

23,24,25 0 V logic input

20 ENABLE I Positive logic or negative logic

23 0 V ENABLE I

13 RAZ I Fault reset via 0 Volt (contact between pins 13 and 12)

12 0 V RAZ I

3 ANin2 I 0 V to 10 V resolution = 12 bits, Diameter sensor measurement

17

16

ANin1 +

ANin1 -

I

I

+/- 10V resolution = 12 bits, Torque or Speed reference,

Dancer or Load cell tension measurement

15 0 Volt analog inputs I

10 Speed monitor output O GT: ±8 V for ±14 000 rpm, linearity: 10%

2 Current monitor output O DACout2: ±10 V for ± current rating, resolution = 8 bits

11 0 Volt analog output O

18,19 Amp ready O Relay contact: closed when amplifier OK

Pmax = 10 W with Umax = 60 V or Imax = 200 mA

8, 9 Brake control output O Relay contact

Pmax = 10 W with Umax = 60 V or Imax = 200 mA

21 +15 Volts O Max. 50 mA

22 -15 Volts O Max. 50 mA

5, 6 non connected

6 - X6: PROFIBUS

Sub D 9 pins female.

PIN SIGNAL DESCRIPTION

1 Shield Shield

2

3 RxD/TxD-P Data reception/transmission (Plus)

4 CNTR-P Control signal

5 DGND 0 V

6 VP Supply for termination resistor

7

8 RxD/TxD-N Data reception/transmission (Minus)

9

7 - X5: RS-232 CONNECTOR

Sub D 9 pins male.

PIN FUNCTION NOTE

5 0 Volt GND (shield connection if no « 360° » connection on the connector)

3 TXD Transmit data RS-232

2 RXD Receive data RS-232

6 TXH Transmit data RS-422

7 TXL Transmit data RS-422

8 RXL Receive data RS-422

9 RXH Receive data RS-422

15

CHAPTER 3 – Inputs/Outputs

SMT-BD1/t

8 - X3: TEST CONNECTOR

PIN FUNCTION NOTE

1 - 6 0 Volt

2 Current input command IDC ± 10 V; resolution: 8 bits, linearity: 10 % (DACout1)*

4 Speed monitor GT ± 8 V for ± 14000 rpm

5 Current monitor Imes ± 10 V; resolution: 8 bits, linearity: 10 % (DACout2)*

3 Reserved

* : 10 V for amplifier current rating.

9 - LOGIC INPUTS-OUTPUTS SPECIFICATIONS

9.1 - Logic inputs: ENABLE, SEL1, SEL2, START, STOP

Log+ Log-

+5V

47 Kohm

47 nF

4,7 Kohm

4,7 V

0 V

SMT-BD1/t

ENABLE

SEL1, SEL2,

START, STOP

These inputs can be configurated in positive or negative logic by means of jumpers.

9.2 - Logic inputs: TDI, Lin1

100 nF

TLP281

SMT-BD1/t

TDI1 Lin1

4,1 Kohm

100 Kohm

0 V I/Os

These inputs are opto-isolated from the amplifier 0V reference.

16 CHAPTER 3 – Inputs/Outputs

SMT-BD1/t

9.3 - Logic outputs: TER, Lout1

TLP281

SMT-BD1/t

TER, Lout1

max. current = 5 m

A

max. voltage = 24 V

0 V I/Os

These outputs are opto-isolated from the amplifier 0V reference.

17

CHAPTER 4 – Connections

SMT-BD1/t

Chapter 4 - Connections

1 - CONNECTION DIAGRAMS

1.1 - Power supply and motor connections

For the 400 VAC amplifier version, see BF-400 RACK manual.

For the 220 VAC amplifier version, see SMTB.M 20 A SINGLE-AXIS RACK manual or BF RACK manual.

1.2 - Amplifier I/O connections

1.2.1 - AMPLIFIER CONNECTION WITH MASTER ENCODER

1

2

7

13

12

15

3

4

8

5

9

14

24

25

17

16

15

3

15

U

V

W

U

V

W

GND

SMT-BD1/t

X2 X1

X4

L1

L2

L3

A

A/

B

B/

+5 V

TER 18

23

24 V

0 V

V+

V+

20

7

4

0 V

+24 V

8

18

9

19

0 V

13

12

S1

S3

S2

S4

R1

R2

25

GND

MOTOR

RESOLVER

RACK

GND

POWER

SUPPLY

DANCER / LOAD CELL

GND

DIAMETER SENSOR

GND

ENABLE

STOP

START

+24 V (positive logic)

or

0 V (negative logic)

AOK

Brake

Reset

T° motor

T° motor

MASTER ENCODER

GND

18 CHAPTER 4 – Connections

SMT-BD1/t

1.2.2 - MASTER / SLAVE AMPLIFIER CONNECTION

13 IA

12 /IA

15 IB

14 /IB

CA 4

/CA 3

CB 6

/CB 5

X2 X2

GND 7 7 GND

SMT-BD1/t MASTER SMT-BD1/t SLAVE

An SMT-BD1/t master amplifier can supply up to 10 SMT-BD1/t slave amplifiers.

2 - RS-232 SERIAL LINK CONNECTION

3 - WIRING RECOMMENDATIONS

3.1 - GND wiring and ground connections

A shield has no effect if it is not connected:

- to a reference potential,

- by a connection as short as possible (a few centimeters; 10 centimeters is prohibited),

- by a "360°" shield connection. This means that the whole circumference of the shield sleeve must be

connected to the reference conductor via a metal collar.

The connectors used for the compliance with the CEI 801 standard must be metal or metallized connectors and

must allow the 360° shield connections.

Reference potential connections (especially with the ground) are recommended only if these connections have a

very low impedance (< 0,1 Ω). Any shield that is used as a conductor can be connected at both ends with the

condition to be connected over 360° at both ends by means of metal links in order to ensure the shield continuity.

The preferred reference potiential is the ground.

Cables with low potential should never run in the proximity of power lines.

SMT-BD1/t

X5

PC

SERIAL PORT

360° shield connection

Sub D 9 pts female Sub D 9 pts female

RxD 2

TxD 3

GND 5 5 GND

2 RxD

3 TxD

CAUTION

Each potential conducting element must be shielded. Several potential conductors in the same sleeve must

be twisted and shielded.

19

CHAPTER 4 – Connections

SMT-BD1/t

If there is a potential reference, i.e. a main chassis or cabinet with a low impedance between its various elements,

it should be used to connect ALL reference to it and also being grounded itself.

3.2 - CONNECTORS SHIELD CONNECTION

RULE

The shield should never be interrupted or corrupted over the whole cable length.

X

X

W

V

U

L1 L2 U WN

V

UV W

Self-sticking copper ribbon if necessary,

for increasing the shield diameter in order

to get it correctly tightened

under the clamp

Motor connector for

resolver and motor BF RACK

Ground

The cable can be soldered on the shield

because the connector box is metallic.

This solution does not exactly meet

the EMC requirements but

it is acceptable.

Motor connector box

Metallic or metal plated plastic

SUB-D pin package

360° shield ensured by

the tightening clamp

The fastening screws must

be tightened in order to ensure

the shield continuity on the

amplifier housing

INFRANOR

amplifier

SUB-D connectors

Ground

U

V

W

As short as possible

SMT.AS / M.AS

SMT-BM 20 A

GND

NOTE

When the 360° shield connection is made by means of a collar, it is not necessary to connect a cable on the

appropriate pin of the SUB-D connector.

20 CHAPTER 4 – Connections

SMT-BD1/t

3.3 - MOTOR AND RESOLVER CABLES

Motors and resolvers are grounded via their housing.

Cable inputs should be made by means of metal connectors with collars allowing the 360° shield connection.

The resolver cable must be pair twisted and shielded (sin, cos, ref.). Motor cables MUST also be shielded.

3.4 - SERIAL LINK CABLES

The serial link cable must also be shielded according to the above mentioned shield connection

recommendations.

CAUTION

Command cables (resolver, serial link, Profibus) as well as the power lines must be connected and

disconnected with amplifier OFF.

Table of contents

Popular Recording Equipment manuals by other brands

Sony

Sony PMW50 brochure

Avid Technology

Avid Technology MediaCentral Command Installation and configuration guide

SpinCore Technologies

SpinCore Technologies USB-PTS owner's manual

Panasonic

Panasonic SC-HG1 Series Reference manual

DuTCH audio

DuTCH audio IM2.3 manual

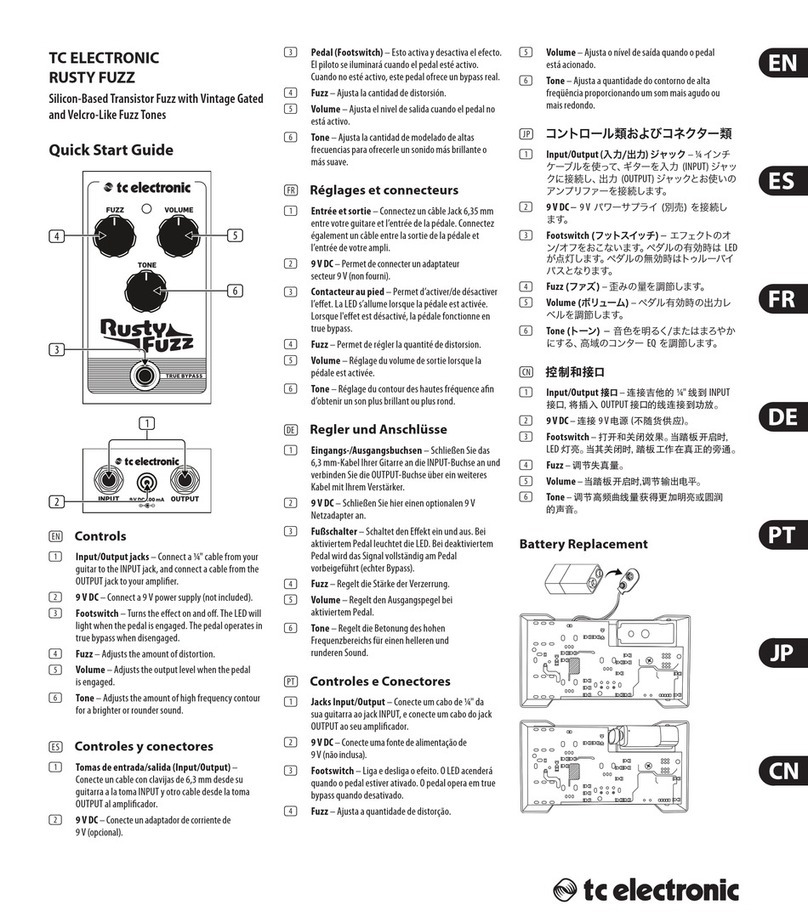

TC Electronic

TC Electronic Rusty Fuzz quick start guide