infrared industries IR-8400D User manual

IR-8400D

Continuous Gas Monitoring Analyzer

3

4

Table of Contents

UNPACKING AND VISUAL INSPECTION ..................................................................................................................................6

UNPACKING INSTRUCTIONS................................................................................................................................6

REPORTING DAMAGE ...........................................................................................................................................6

INTRODUCTION ...............................................................................................................................................................8

SPECIFICATIONS.............................................................................................................................................................10

TOOLS,EQUIPMENT,AND SUPPLIES ..................................................................................................................................12

Tools .....................................................................................................................................................................12

Electronic Test Equipment ................................................................................................................................12

Zero And Calibration Gases ..............................................................................................................................12

Gas Handling Equipment ..................................................................................................................................12

INSTALLATION...............................................................................................................................................................14

GENERAL ..............................................................................................................................................................14

PRECAUTIONS .....................................................................................................................................................14

MECHANICAL .......................................................................................................................................................14

ELECTRICAL.........................................................................................................................................................16

GAS CONNECTIONS .............................................................................................................................................17

CONFIGURING THE ANALYZER ..........................................................................................................................................18

STANDBY..............................................................................................................................................................18

IDENTIFYING ACTIONS WHEN PUMP IS On.....................................................................................................19

Menu 1..................................................................................................................................................................20

MENU 2.................................................................................................................................................................21

CALIBRATION AND OPERATION.........................................................................................................................................22

GENERAL OPERATION ........................................................................................................................................22

MEASURING GASES .............................................................................................................................................22

CALIBRATION ......................................................................................................................................................22

RECOMMENDED CALIBRATION SCHEDULE .....................................................................................................23

Auto Calibration .................................................................................................................................................23

IR SAMPLE CONDITIONER ...............................................................................................................................................28

IR1150/1151 SAMPLE CONDITIONER .............................................................................................................28

INSTALLATION ....................................................................................................................................................30

INITIAL SETUP.....................................................................................................................................................30

OPERATION .........................................................................................................................................................30

FILTER REPLACEMENT ......................................................................................................................................30

WARRANTY ..................................................................................................................................................................32

Warranty for Analyzers and Accessories .......................................................................................................32

WARRANTY EXCLUSIONS...................................................................................................................................32

LIMITATION OF DAMAGES.................................................................................................................................32

SERVICE.......................................................................................................................................................................34

INSTRUMENT IDENTIFICATION SHEET .................................................................................................................................36

5

6

Unpacking and Visual Inspection

U N P A C K I N G I N S T R U C T I O NS

Open the shipping container and carefully remove the analyzer from the container and packing materials.

Inspect the instrument for any signs of damage, such as a broken window or bent conduit. Unscrew the

explosion-proof window and remove it from the enclosure. Remove the display board from its

supporting brackets and lay it down outside of the enclosure.

Inspect the inside of the analyzer. Check all electrical connections, such as ribbon cables and connectors

for proper mating to the PC Boards. Check the gas sample lines from the bulkhead fittings to the optical

bench for integrity. If all internal components look proper, replace the display board and screw the front

window securely in place.

Remove the junction box cover. Inspect the fuse and terminal board. The cover can be left off for

installation purposes.

R E P O R T I N G D A M A G E

Should there be any apparent damage to the instrument inside or out, which has occurred due to

shipping and handling, notify both the shipper and Infrared Industries immediately. If there is any visual

damage to the shipping container or packing material these items should be saved for inspection by the

shipper.

7

8

Introduction

The gas analyzer operates by comparing the infrared transmission of two spectral bands through one

optical path. One spectral band is centered in one of the absorption bands of the gas being measured. The

other spectral band is of a reference wavelength in which there is no absorption by any of the gases

present in the sample stream. The difference in the transmittance of these two signals through the optical

path is a measure of the optical absorption of the gas being measured in the sample stream as sensed by

the infrared detector. The signal from the detector is electronically processed and used to derive a direct

measurement of the measured gas concentration in the sample gas.

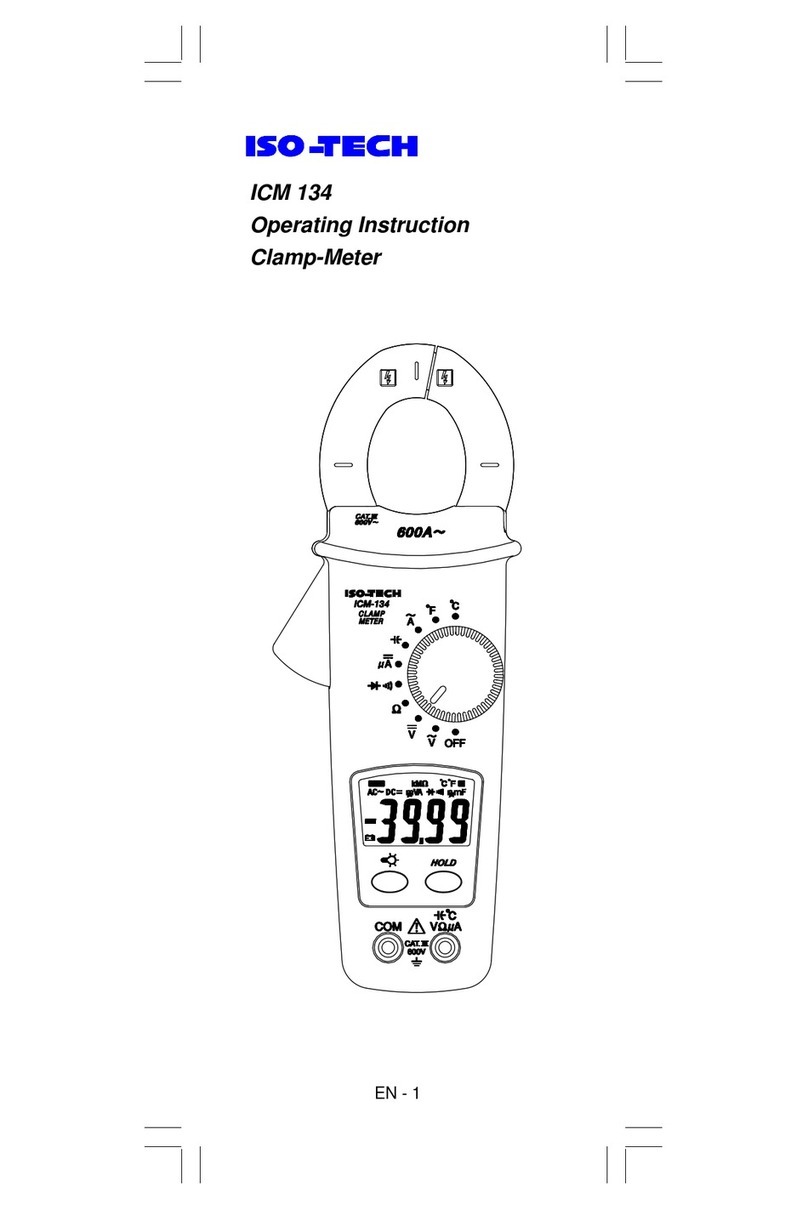

Figure 1: IR8400D

The Infrared Industries 8400D series models are non-dispersive infrared (NDIR) gas analyzers, capable

of continuously monitoring various gases in a sample stream for extended periods of time. The IR-8400D

is designed specifically for the measurement of Hydrocarbons, Carbon Dioxide, Carbon Monoxide,

Oxygen, and Oxides of Nitrogen. Other non-standard gases are possible. Contact your IRI representative

for further details. The ranges for the IR-8400D are specified by the end users requirements. The

instrument is designed specifically for enhanced oil recovery applications as well as refineries and

petroleum transfer station. The analyzers are temperature and pressure compensated to achieve

9

excellent long-term stability and negate the need for frequent calibrations. Built to withstand hostile

temperature and weather environments, the analyzers provide as standard, an LCD display, digital

RS232 output, analog output, and an isolated linear 4-20 mA current output.

Features include a solid-state detector, a direct-reading display, a low-energy infrared source, a sample

cell that is easy to remove and clean, and many field-serviceable components.

10

Specifications

Measured gases (optional): HC, CO, CO2, O2, NOx, Butane, Methane, Propane (See

identification sheet for specified gas configuration)

Measurement range: See Identification Sheet

Accuracy: ± 2% of reading or ± 0.5% F.S.

Repeatability: ± 1% of reading or ± 0.5% F.S.

Stability: 24 Hour Period

± 0.5% F.S. zero drift (Maximum)

± 1% F.S. span drift (Maximum)

90 Day Period

± 1% F.S. zero drift (typical)

± 2% F.S. span drift (typical)

Suggested calibration: 6 - 12 Month Intervals

Display (0.7" high-visibility LCD): Range: 0-110% of full scale standard

Accuracy: ± 1 least significant digit

Output range (linear): 0-100 mV standard. 0-1V, 0-5 V, or 0-10 Vdc optional.

4-20 mA (isolated)

RS232 Bi-directional Digital Communication

Fault indication: Zero signal fault indications standard

Output noise (RMS): Less than 0.5% F.S.

Output response time (0 - 90%): Less than 10 seconds (electronic).

Power required: Standard: 100-240 VAC maximum, 117 Vrms ± 10%, 50-60

Hz, Maximum draw –2.5 Amps (Optional: 12 VDC / 24 VDC)

Warm-up time for specified performances: Less than 1 hour.

Sample flow rate: 1 scfh (1/2 sipm) recommended; 2 scfh (1 sipm) maximum,

exhaust to ambient

Environmental temperature range: -40° to 122°F (-40° to 50°C)

Materials of construction (wetted): 316 Stainless Steel, Sapphire, Teflon, Viton, and Polypropylene

(typical)

Enclosure: 10.25 x 10.25 x 8.5 inch enclosure with display window and

attached 3.50 dia. x 2.50 inch junction box.(See Figure 1)

Enclosure Rating: NEMA 4 / NEMA 7 (Group C, D, E, Div 1, 2)

Gas Connections: 1/4" compression fitting, sample inlet; 3/8" or 1/4"

compression fitting, sample outlet.

Weight: 28 lbs (12.7 kg)

The specifications as stated above are based on a sample stream that is free of particulates and

condensable vapors, and regulated to a flow of 1 scfh (1/2 liter per minute).

11

12

Tools, Equipment, and Supplies

The procedure for calibration and field service of the gas analyzer require the following tools, test

equipment, and expendable supplies:

T O O L S

Screwdrivers, standard (medium and small); and Phillips (medium and small).

Adjustable wrench.

Low-power soldering iron.

E L E C T R O N I C T E S T E Q U I P M E N T

Oscilloscope, Tektronix Model 912B or equivalent.

Digital Voltmeter, Fluke Model 8000A or equivalent.

Z E R O A N D C A L I B R A T I O N G A S E S

Nitrogen in a pressurized cylinder (zero gas).

Calibration gas, near full-scale concentration, with a nitrogen balance, in a pressurized,

certified cylinder.

G A S H A N D L I N G E Q U I P M E N T

Pressure regulators for zero and span gas cylinders.

Teflon TM* gas tubing or equivalent, 1/4 inch OD, 10 feet.

An IR-1151 sampling conditioner or equivalent.

*Teflon TM is a trademark of E. I. DuPont

13

14

Installation

G E N E R A L

The size of the analyzer allows for ease of installation and service. The analyzer was built to be robust

and to handle rugged environmental conditions. The instructions below are for a typical installation. If

you have any doubts or questions regarding a particular installation, consult our applications engineer at

the factory at (800) 344-0321.

CAUTION: APPROPRIATE SAFETY PRECAUTIONS SHOULD BE OBSERVED

WHEN INSTALLING IN A POTENTIALLY HAZARDOUS AREA.

P R E C A U T I O N S

To insure accurate operation of the instrument, the following precautions must be taken. The instrument

should be shaded from mid-day sun conditions. Direct radiant sun energy on a hot day can cause

overheating. Internal temperatures over 140°F (60°C) must be avoided. A sunshade, as discussed later,

should be utilized.

Line voltage surge protectors are provided. Infrared Industries may include additional protection

devices at the time of installation, if deemed necessary.

M E C H A N I C A L

This analyzer is designed to be mounted vertically on a wall or panel (see Figure 2: IR-8400D Series

Outline Dimensions).

You must provide room for access to the instrument on both the bottom and right-hand side (as viewed

from facing the front panel). This allows for connections to the gas sample inlet and outlet, and to the

electrical junction box on the bottom.

A sunshade is required to protect the instrument from excessive radiant heating. Requirements for the

sunshade will vary with geographical location. The primary consideration is shielding from the warmest

or mid-day sun. Internal analyzer temperatures must not exceed 140°F (60°C).

15

Figure 2: IR-8400D Outlying Dimensions

16

E L E C T R I C A L

All electrical interconnections are brought out to a convenient junction box for easy installation. The

junction box has a cover, which is easily unscrewed for access to the internal terminals. Two conduits are

provided: one for the AC power and the second for the output signals (see Figure 3 for details).

CAUTION: ALL ELECTRICAL WIRING SHOULD COMPLY WITH THE NEC AND

ANY LOCAL STANDARDS.

Figure 3: Junction Box Wiring

A switch or circuit breaker marked as the disconnecting device must be included in the building

installation. This device should be in close proximity to the equipment and within easy reach of the

operator.

A single-phase power source is required to operate the instrument. The standard instrument requires

100 to 240 volts AC. The hot, neutral, and ground leads should be connected to the appropriate line

power inputs using the insulated terminals provided with the instrument (p/n 11002-001). The junction

box contains a 2 Amp fuse for the AC power. Replacement parts for the fuses are available from Infrared

Industries, Inc. (p/n 11428-001). The outputs available from the junction box include the standard 4-20

mA isolated output and serial communication.

17

This output can accommodate up to an 600 Ohm loop. Also available is a 0-100 mV dc output. Several

optional ranges, such as 0-1, 0-5, or 0-10 Vdc, are available. This output appears at the recorder plus and

minus terminals. This signal should feed an input impedance of 1 mega-ohm or greater to prevent

loading of the signal. A fault indicator circuit is used to monitor the analyzer. In the event of an

instrument failure, this will result in a zero signal output condition, where the display and output signals

out will go to zero, indicating an instrument fault.

As an option, the analyzer can be outfitted at any time (field modification) with set point alarms. These

contain relay closure outputs with a maximum rating of 10 watts at 28 volts DC.

G A S C O N N E C T I O N S

Unless calibrated specifically for other pressures, the analyzer requires a feed of clean and dry sample gas

at atmospheric pressure for analysis. The sample flow rate should not exceed 2 SCFH (1 SIMP). Since the

analyzer is usually calibrated with the sample cell at atmospheric pressure, pressurized gases must be

reduced ahead of the analyzer. A typical gas handling system would include a pressure regulator, a

coalescing particulate filter, a multiple inlet valve for introduction of calibration gases, and a flow meter

with metering valve. A prepackaged sample system, such as the Infrared Industries IR-1150 series, may

be provided. The conditioner and analyzer are usually mounted on the same plate.

The inlet gas connection on the analyzer is a 1/4" compression fitting. The standard outlet gas connection

is 3/8" compression. It is recommended that the outlet be vented away from the instrument to ambient

air. The tubing length and number of bends should be minimized in the vent line to reduce the

backpressure in the analyzer sample cell.

CAUTION: VENTED GAS MAY BE HAZARDOUS (EXPLOSIVE) AND SHOULD BE

TREATED ACCORDINGLY.

18

Configuring the Analyzer

After plugging in the 8400D the Power Indicator will be illuminated confirming that there is power to the

analyzer - the power supply is properly attached or the unit’s battery is charged. Press the On/Off button

to activate the analyzer. During the initial power-up, the pump will come on briefly and there will be a

status bar at the bottom of the screen to indicate the calibration of O2. When this is complete, the Standby

Screen will appear. The operator MUST zero the analyzer using the corresponding soft key before

exhaust gas testing. Refer to Chapter 3 “Display Features” if you are not sure which button to use.

S T A N D B Y

The 8400D will return to this screen after exiting the

menu selection. It is possible to customize the display

screen settings by going to Display Settings in Menu 2.

This allows the operator to select one or as many as all

of the values to be displayed on the screen.

M E A S U R E –Allows manual on/off operation of the pump. This function can also be used to purge gas

from the analyzer. For more detailed information, please refer to the section “Identifying Actions When

Pump Is On”.

Z E R O –Zeros the analyzer for approximately 1 minute. The pump is automatically controlled during

this phase.

P L A Y –Plays back recorded data. Choose Pause/Continue to control the play function or Exit to return

to the Standby screen.

M E N U –Use this button to access Menu 1

19

I D E N T I F Y I N G A C T I O N S W H E N P U M P I S O N

The 8400D will display this screen when Measure is

selected from the Standby screen. It is possible to

customize the display screen settings by going to

Display Settings in Menu 2. This allows the operator to

select any or all of the values shown to be displayed on

the screen.

M E A S U R E –Selecting MEASURE allows the operator to turn the pump on and off. When the pump

is off, the display will return to the Standby screen. To start pump when the measurement of a specific

gas concentration is desired simply press the MEASURE button. Once the pump has been turned on the

screen menu will change from MEASURE, ZERO, PLAY, and MENU, to MEASURE, PRINT, HOLD, and

RECORD. Pressing the MEASURE key once more while the pump is running will stop the pump and

return you to the standby menu.

P R I N T –Prints data to a printer connected to the serial port located in the Junction Box.

H O L D / R E S U M E –Selecting the HOLD key will lock the display values to capture that moment in

time. Once the HOLD key has been initiated the HOLD enunciator will change from HOLD to RESUME.

To return to normal operation press the RESUME key and return to a live display.

R E C O R D –The analyzer has the ability to store data by selecting RECORD. The recorded

information will remain in memory until it’s erased. To erase the data in memory enter into the Menu 1

options and select Erase Data. Once you have selected this option you will be asked if you wish to erase

stored data. Select YES to erase data or NO and return to the standby screen.

Table of contents

Other infrared industries Measuring Instrument manuals