Ingco RS8008 User manual

EN

Reciprocating Saw

Reciprocating Saw

RS8008 URS8008 RS8008S

RS8008-4 RS8008-6

RS8008-8 RS8008M

ingcoglobal

INGCO GLOBAL

2|English

The symbols in instruction manual and the label on the tool

Double insulated for additional protection.

Read the instruction manual before using.

CE conformity.

Wear safety glasses, hearing protection and dust mask.

Waste electrical products should not be disposed of with household waste.

Please recycle where facilities exist. Check with your Local Authority or

retailer for recycling advice.

Safety alert.

Please only use the accessories supported by the manufacture.

3|English

follow the warnings and instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) Work area safety

a)

Keep work area clean and well lit.

Cluttered and dark areas invite

accidents.

b)

Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust.

Power tools

create sparks which may ignite the dust or fumes.

c)

Keep children and bystanders away while operating a power

tool.

Distractions can cause you to lose control.

2) Electrical safety

a)

Power tool plugs must match the outlet. Never modify the plug

in any way. Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

b)

Avoid body contact with earthed or grounded surfaces such as

pipes, radiators, ranges and refrigerators.

There is an increased

risk of electric shock if your body is earthed or grounded.

c)

Do not expose power tools to rain or wet conditions.

Water

entering a power tool will increase the risk of electric shock.

d)

Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool. Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or entangled cords

increase the risk of electric shock.

e)

When operating a power tool outdoors, use an extension cord

suitable for outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f)

If operating a power tools in a damp location is unavoidable, use

a residual current device (RCD) protected supply.

Use of an RCD

reduces the risk of electric shock.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING Read all safety warnings and all instructions

. Failure to

4|English

3)

Personal safety

a)

Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in

serious personal injury.

b)

Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

c)

Prevent unintentional starting. Ensure the switch is in the off-

position before connecting to power source and/or battery pack,

picking up or carrying the tool. Carrying power tools with your

finger on the switch or energizing power tools that have the switch on

invites accidents.

d)

Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the

power tool may result in personal injury.

e)

Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected

situations.

f)

Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

g)

If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used. Use of dust collection can reduce dust-relatedhazards.

4)

Power tool use and care

a)

Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at

the rate for which it was designed.

b)

Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c)

Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool accidentally.

5|English

d)

Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to

operate the power tool. Power tools are dangerous in the hands of

untrained users.

e)

Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained

power tools.

f)

Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

g)

Use the power tool, accessories and tool bits etc. in accordance

with these instructions, taking into account the working

conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous

situation.

5)

Service

a)

Have your power tool serviced by a qualified repair person using

only identical. This will ensure that the safety of the power tool is

maintained.

Additional SafetyWarnings

1)

Information on the correct use of the dust collection system, ifany

2)

Advice to wear a dust mask

Residual risks

Even when the power tool is used as prescribed it is not possible to

eliminate all residual risk factors. The following hazards may arise in

connection with the power tool’s construction and design:

a)

Health defects resulting from vibration emission if the power tool is being

used over longer period of time or not adequately managed and properly

maintained.

b)

Injuries and damage to property to due to broken accessories that are

suddenly dashed.

Warning! This power tool produces an electromagnetic field during

operation. This field may under some circumstances interfere with active or

passive medical implants. To reduce the risk of serious or fatal injury, we

recommend persons with medical implants to consult their physician and the

medical implant manufacturer before operating this power tool.

6|English

1

picture1

2

6

3

4

5

1

DESCRIPTION

1. Locking sleeve for saw blade 2. Adjustable footplate 3. Speed control

4. Lock-on button for ON/OFF switch 5. ON/OFF switch 6. Cord

TECHNICAL DATA

Number:

RS8008

RS8008-4

RS8008S

(SAA Plug)

RS8008-6

(ISRAEL Plug)

RS8008-8

(BS Plug)

RS8008M

URS8008

Rated voltage:

220-240V ~ 50/60Hz

110-120V ~ 50/60Hz

Rated power:

750W

750W

No-load speed:

900-3300/min

900-3300/min

Cutting capacity max.:Wood:

115mm

4-1/2˝

Alumin:

12mm

1/2˝

Steel:

8mm

5/16˝

PACKAGE CONTENTS

The package contains:

Reciprocating saws 1

Saw blade 2

Carbon brushes 1

Check fordamagetothetool,partsoraccessories

which may have occurred during transport.

Hex key

Instruction manual

1

Take the time to thoroughly read and understand

this manual prior to operation.

7|English

ELECTRICAL SAFETY

The electric motor has been designed for one

voltageonly.Alwayscheckthatthepowersupply

corresponds to the voltage on the rating plate.

YourINGCO toolisdoubleinsulatedin

accordance with EN 60745 ; therefore

no earth wire is required.

REPLACING/

INSERTING THE SAW

BLADE

When mounting the saw blade,

wearprotectivegloves. Dangerof

injury when touching the saw blade.

When changing the saw blade,

take care that the saw blade

holderisfreeofmaterialresidue,

e. g. wood or metal shavings.

INSERTING THE SAW BLADE

•

Turn the locking sleeve 4 approx. 90° in the

direction ofthe arrow and hold. Push the saw

blade into the saw blade holder. Release the

locking sleeve 4 again.

CHECK THE TIGHT SEATING OF THE SAW

BLADE.

•

loose saw blade can fall out and lead to injuries.

Forcertainwork, thesaw blade canalso be turned

through180°(withthe teethpointedupwards)and

re-inserted again.

REMOVING THE SAW BLADE

•

Turn the locking sleeve 4 approx. 90°in the

directionofthe arrow and hold. Removethesaw

blade .

DUST/CHIP EXTRACTION

•

Dusts from materials such as lead-containing

coatings, some wood types, minerals and metal

can be harmful to one’s health.Touching or

breathing-in the dusts can cause allergic reactions

and/orlead torespiratory infectionsof the useror

bystanders.

•

Certain dusts, such as oak or beech dust,

are considered as carcinogenic, especially in

connection with wood-treatment additives

(chromate, wood preservative). Materials

containingasbestosmay onlybe worked by

specialists.

---Provideforgoodventilation oftheworking

place.

--- It isrecommended to wear a P2filter-class

respirator.

Observe the relevant regulations in your country

for the materials to be worked.

•

Prevent dust accumulation at the

workplace.

Dusts can easily ignite.

INSTRUCTIONS FOR

USE

Always observe the safety

instructions and applicable

regulations.

Observe correct mainsvoltage!The

voltage of the power source must

agreewiththevoltagespecifiedon

the nameplate of the machine.

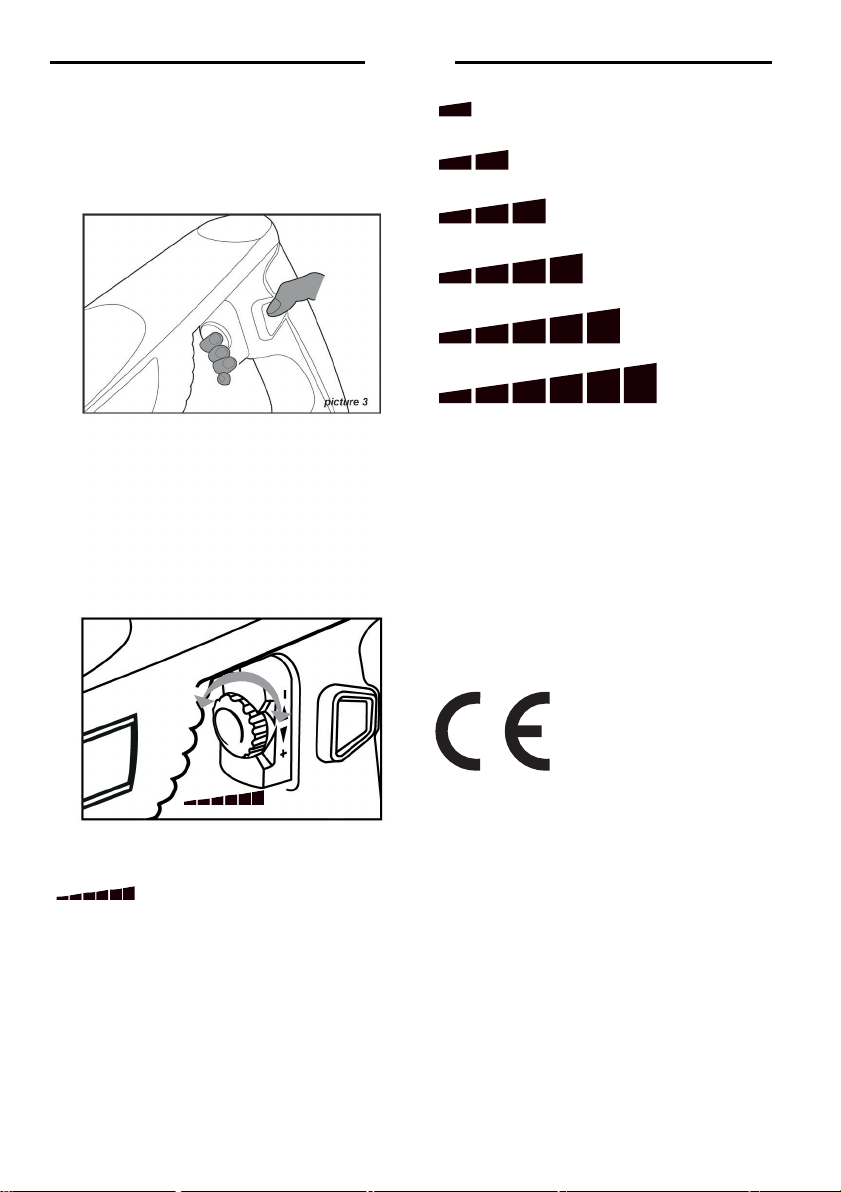

PIVOTING AND RETRACTABLE FOOTPLATE

• Due to its movability, the adjustable footplate

adapts to the required angular position of the

surface.

•

Dependingonthesaw blade being used andthe

application, thefootplate can bemoved inlength

way direction in three steps. Press the release

button for the footplate and slide the footplate

8|English

to the required position. Release the footplate

release button and check that the footplate is

firmly latched. Slide the footplate as required until

it is firmly latched.

SWITCHING ON AND OFF

Stainless steel

Plastics

Aluminum

Mild steel

Autoclaved lightweight

concrete

Wood

NOTE:

•

If the tool is operated continuously at low

speedsfor alongperiod of time, theoperation

life of the motor will be reduced.

•

Thespeed adjustingdialcanbeturnedonly as

far as full speed and lowest speed. Do not force

it past full speed or lowest speed, or the speed

adjusting function may no longer work.

EC-DECLARATION OF

CONFORMITY

•

Thestrokes perminutecanbeadjustedjust

by turning the adjusting dial.This can be done

evenwhilethetool is running.Thedial ismarked

lowest speed to full speed.Turn the

adjusting dial without positive stops between

lowest speed and full speed according to your

work.

•

Refer to the table toselectthe proper speed for

the workpiece to be cut. However, the appropriate

speed may differ with the type or thickness of the

workpieces. In general, higher speed will allow

youtocut workpieces fasterbut theservicelife of

the blade will bereduced.

INGCO declares that these power tools

have been designed in compliance with:

2006/42/EC , 2004/108/EC,

EN60745-1,

EN60745-2-11,

EN55014-1,

EN55014-2,

EN61000-3-2,

EN61000-3-3.

•

To start the machine, press the On/Off switch

and

keep it pressed.To lock the pressed

On/Off

switch,

press thelock-on button.

•

To switch off the machine, release the On/

Off

switch or when it is locked with the lock-on

button,

brieflypresstheOn/Offswitch and

then

release

it.

SPEED ADJUSTING DIAL

picture4

9|English

RS8008,URS8008,RS8008-4,RS8008-6,RS8008-8,RS8008S,RS8008M

10|English

RS8008,URS8008,RS8008-4,RS8008-6,RS8008-8,RS8008S,RS8008M

No.

Description

Qty

No.

Description

Qty

1

Power cord

1

29

Bearing

1

2

Cord sleeve

1

30

Gear cover

1

3

Capacitor

1

31

Reciprocating shaft

1

4

Switch

1

32

Guide plate

1

5

O-ring

1

33

Screw with washer

4

6

Inductor

2

34

Screw (Nylon)

2

7

Carbon brush

2

35

Flat washer

2

8

Spring

1

36

Screw

1

9

Brush holder

1

37

Support board lock

1

10

Screw

2

38

Screw

2

11

Cord clamp

1

39

Screw

2

12

Brush holder

1

40

Pin

1

13

Spring

1

41

Inner collar

1

14

Stator

1

42

Circlips for shaft

1

15

Bearing

1

43

Outer collar

1

16

Rotor

1

44

Spring

1

17

Circlip

1

45

Steel ball

2

18

Washer

1

46

Plastic sheath

1

19

Bearing

2

47

Circlips for shaft

1

20

Nut

1

48

Cover

1

21

O-ring

1

49

Dustproof ring

1

22

Bearing

1

50

Bearing

1

23

Spacer bush

1

51

Screw

12

24

Circlip for hole

1

52

Right Housing

1

25

Gear box

1

53

Lable

1

26

Shaft

1

54

Left Housing

1

27

Gear

1

55

inner hexagon spanner

1

28

Pin

1

56

Blade

2

This manual suits for next models

6

Table of contents

Other Ingco Saw manuals

Popular Saw manuals by other brands

Ryobi

Ryobi ETS-1526AL Owner's operation manual

Sovereign

Sovereign J1X-HZ02-210K Original instruction manual

Dexter Power

Dexter Power J1G-ZP28-255A-EU Assembly, Use, Maintenance Manual

HIKOKI

HIKOKI C8FSHE Handling instructions

Chicago Electric

Chicago Electric ITEM 69684 Owner's manual & safety instructions

Chicago Electric

Chicago Electric 61608 owner's manual