Ingco COS35568 User manual

EN

Cut Off Saw

COS35568 UCOS35568

COS35568-6 COS35568-8 COS35568-9

ingcoglobal

INGCO GLOBAL

2|English

Technical Specifications:

Model

COS35568

COS35568-6 COS35568-8 COS35568-9

UCOS35568

Input power:

2400W

2400W

Rated voltage:

220V-240V~50/60Hz

110V-120V~60Hz

Blade size:

355x25.4x3mm

14 x1 x1/8

No-load speed:

3900/min

3900/min

Max. cutting capacity:

in round pipe:

100mm

4

in square steel:

100X100mm

4 X4

in

:

120X100mm

4-3/4 X4

Max. cutting steel bar:

50mm

2

Specific Safety

Warnings

a)

Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by

hand.

b)

Do not work materials containing asbestos. Asbestos is consideredcarcinogenic.

c)

Take protective measures when dust can develop during working that is harmful to one’s health,

combustible or explosive.

Example: Some dusts are regarded as carcinogenic. Wear a dust mask and work with dust/chip extraction

when connectable.

d)

Keep your workplace clean. Blends of materials are particularly dangerous. Dust from light alloys can burn or

explode.

e)

Never leave the power tool before it has come to a complete stop. Cutting tools that are still running can

cause injuries.

f)

Do not use the power tool with a damaged cord. Do not touch the damaged cord and pull the plug from the

outlet when the cord is damaged

while working. Damaged cords increase the risk of an electric shock

g)

Connect power tools that are used in the open via a ground fault circuit interrupter.

h)

Never stand on the power tool. Serious injuries could occur when the power tool tips over or when

accidentally coming into contact with the cutting disc.

i)

Use the power tool only for dry cutting. Water penetrating into a power tool increases the risk of an electric

shock.

j)

Keep hands away from the cutting area while the machine is running. Danger of injury when coming into

contact with the cutting disc.

k)

Never remove cutting remainders, metal chips, etc. from the cutting area while the machine is running.

Always guide the tool arm back to the neutral position first and then switch the machine off.

l)

Guide the cutting disc against the workpiece only when the machine is switched on. Otherwise, there is

danger of kickback, when the cutting disc becomes wedged in theworkpiece.

m)

Operate the power tool only when the work area to the workpiece is clear of any adjusting tools, metal

chips, etc. Small pieces of metal or other objects that come in contact with the rotating cutting disc can strike the

operator with high speed.

n)

Always firmly clamp the workpiece. Do not cut workpieces that are too small to clamp. Otherwise, the

clearance of your hand to the rotating cutting disc is too small.

o)

Pay attention that persons are not put in danger by sparking. Remove any combustible materials in the

vicinity. Sparks develop when cutting metal.

p)

Use the cut off grinder only for cutting materials mentioned under “Intended Use”. Otherwise, the cut off

grinder can be subject to overload.

3|English

q)

Do not use damaged, out-of-center or vibrating cutting discs. Damaged cutting discs cause increased

friction, binding of the cutting disc and kickback.

r)

Always use cutting discs with correct size and shape (diamond versus round) of arbor holes. Cutting

discs that do not match the mounting hardware of the cut off grinder will run eccentrically, causing loss of

control.

s)

Do not touch the cutting disc after working before it has cooled. The cutting disc becomes very hot while

working.

Safety Warnings for Cut Off Saws with Retracting Blade Guard

Make sure that the blade guard operates properly and can move freely. Never clamp the blade guard in

place while retracted.

Specific safety rules

a)

Maintain labels and nameplates on the Cut-Off Saw. These carry important information. If unreadable or

missing, contact our company for a replacement.

b)

Keep hands and fingers away from cutting area and Grind Wheel. Keep one hand on the handle and

your second hand on the motor housing. If both hands are holding the saw, your hands and fingers cannot

be cut by the Grind Wheel.

c)

Do not reach under the Base of the Cut-Off Saw. The Upper Guard can not protect you from the Grind

Wheel below the base.

d)

Check Upper Guard for proper closing before each use. Do not operate the Saw if the Upper Guard

does not move freely and close instantly. Never clamp or tie the Upper Guard into the open position. If

the Saw is accidentally dropped, the Upper Guard may be bent. Raise the Upper Guard and make sure it

moves freely and does not touch the Grind Wheel or any other part, in all depths of cut.

e)

The Upper Guard should be retracted manually only for special cuts such as "Pocket Cuts" and

"Compound Cuts". Raise the Swing Guard only enough to begin the cut. As soon as the Grind Wheel

enters the material, the Upper Guard must be released. For all other sawing, the Upper Guard should

allowed to operate automatically.

f)

The Saw is not to be used for any cutting operation in the locked down position. The Saw should be in

the locked down position only for carrying and storage.

g)

Always use Grind Wheels with a 355mm Diameter,25.4mm round arbor hole, and rated at a minimum of

3900/min. Grind Wheels that do not match the mounting hardware of the Saw or that are rated at less than

the saw’s maximum RPM may fly off the Saw or may run eccentrically , causing loss of control.

h)

Never use damaged or incorrect Grind Wheel washers or bolts. The Grind Wheel’s washers and bolt were

specially designed for your Saw, for optimum performance and safety of operation.

i)

Do not use the included Grind Wheel to cut aluminum, copper, brass, or other non-ferrous metals. The

included Grind Wheel is designed to cut only ferrous (iron containing) metals such as steel alloys and cast

iron. If using other Grind Wheels, only use them on materials that the manufacturer recommends.

j)

To avoid accidental injury, always wear heavy duty work gloves and work bib when changing a Grind

Wheel.

k)

Before using the Cut-Off Saw, make sure the Grind Wheel is properly mounted on the Saw Spindle.

Make sure the Grind Wheel is balanced, and is not cracked or bent.

l)

The Grind Wheel will become hot while cutting. Allow the Grind Wheel to completely cool before touching.

m)

Allow the Grind Wheel to spin up to full speed before feeding it into the workpiece, When turning off the

Saw, allow the Grind Wheel to spin down and stop on its own. Do not press against the Grind Wheel to stop it.

n)

Do not force the Grind Wheel into the workpiece when cutting. Apply moderate pressure, allowing the

Grind Wheel to cut without being forced.

o)

Always turn off the Cut-Off Saw and unplug the Cord from its electrical outlet before changing

accessories or performing any inspection, maintenance, or cleaningprocedures.

p)

Use the right tool or attachment for the right job. Do not attempt to force a small tool or attachment to do

the work of a larger industrial tool or attachment. There are certain applications for which this product was

4|English

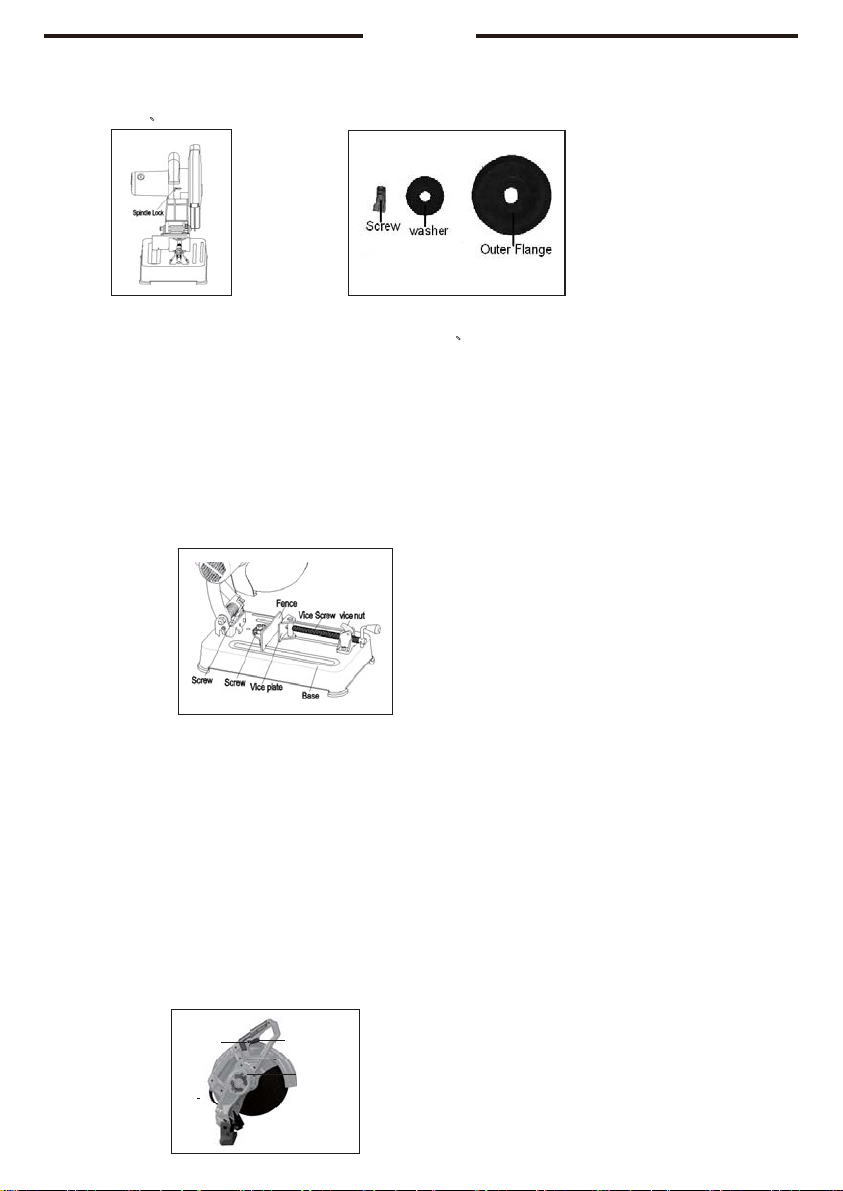

Upper Guard

Stopper Knob

Knurled Screw

designed. It will do the job better and more safely at the rate for which it was intended. Do not modity this

product, and do not use this product for a purpose for which it was not intended.

People with pacemakers should consult their physician(s) before using this product. Operation of

electrical equipment in close proximity to a heart pacemaker could cause interference or failure of the

pacemaker.

The warnings, precautions, and instructions discussed in this manual cannot cover all possible

conditions and situations that may occur. The operator must understand that common sense and caution are

factors which cannot be built into this product, but must be supplied by the operator.

For additional references to the parts listed in the following pages, refer to the

Prior to performing any assembly procedures, make sure the Cord of the Cut-Off Saw is unplugged

from its electrical outlet. Also, make sure the Cut-Off Wheel has completely cooled and wear work gloves

while replacing the Wheel.

Place the Cut-Off Saw in its fully raised position. To do so, turn the Stopper knob lock wise while pushing down

on the Handle.

Unscrew and remove the Knurled Screw.

Remove the Upper Guard. Then, set the Upper Guard aside, making sure not to allow it to be bent or damaged;

that can interfere with proper guard operation.

To keep the Grind Wheel from turning: Depress the Spindle Lock and turn the Grind Wheel until the Spindle

Lock clicks into place.

Use the Spanner to remove the Screw. NOTE: Make sure to turn the Screw counterclockwise to remove.

Remove the washer. Then, remove the Outer Flange.

Remove the old Grind Wheel, and replace it with a new Grind Wheel.

Grind Wheels that do not match the mounting hardware of the Saw

that are rated at less than the saw’s maximum RPM may fly off the Saw or may run eccentrically,

causing loss of control.

5|English

9.

Reinstall the Outer Flange (with the concave side facing the Wheel), washer, andScrew.

NOTE: Make sure to firmly tighten the Screw in al clockwise direction while depressing the Spindle Lock. (See

Figures G 、H)

Figure F Figure H

10.

Reinstall the Upper Guard, and secure it in place with the Knurled Screw. Make sure to tighten the Screw in

thescre w holereferredto inFigure D.(SeeFiguresD

The quick lock vise:

E、)

1.

The Quick Lock Vise allows for the angle of cut to be adjusted from 0 to 45 degrees to the left and 0 to 30

degrees to the right. To adjust the angle of cut, loosen the two Screws. Move the Fence to the desired angle as

indicated by the line on the Base of the Cut-Off Saw. Then, retighten the two Screws. ( See Figure I )

2.

The Quick Lock Vise features a vice nut which slows the operator to quickly release from the Vise the

workpiece being cut. To use the vice nut, pull the lever rearward to disengage the threads. Slide the clamp

forward until it contacts the workpiece. Lower the release lever, then tighten by turning the handle clockwise. To

remove the workpiece, loosen the Vice Screw slightly. Raise the vice nut and pull back on the Vice Screw. ( See

Figure I )

Figure I

To adjust the depth of cut:

The depth of cut may be adjusted, using the Screw. To cut shallower: Turn the Screw counterclockwise. Then,

tighten the Hex Nut. To cut deeper: Loosen the Hex Nut and turn the Screw clockwise. Then, tighten the Hex

Nut. (See FigureI)

To operate the Cut-Off Saw:

1.

To operate the Cut-Off Saw, first make sure the Cutting Arm is in it's the upright position with the Stopper knob

disengaged. (See Figure D)

2.

If necessary, adjust the angle of cut. Then, secure the workpiece in the vice nut. (See Figure I)

3.

Plug the Cord into the nearest 230 volt, grounded, electrical outlet .

Operation of Switch (see Figure J)

Start: press down the switch .

Keep running: press down the switch then depress the Switch button with your thumb. Stop: press down the

switch . Then, release the Switch..

Figure J

Brush Holder Cap

Carbon Brush

Brush holder

Cord

Switch

Switch button

6|English

4.

Allow the Grind Wheel to spin up to full speed. Then, slowly lower the Grind Wheel into the workpiece. (See

Figure D, and J )

5.

If the Grind Wheel does not pass completely through the workpiece, Raise the Saw Arm, turn off and unplug

the Saw, and wait until it comes to a complete stop. Remove stock being cut. Then, lower the Grind Wheel,

following the instructions on page10. (See Figure I)

6.

After adjusting the Screw (44), press down on the Cut-Off Saw and make sure the Grind Wheel does not

contact the bottom of the Base or any other part of the Base. (See Figure I)

7.

If the Grind Wheel touches the Base or any other part of the Base, raise the Grind Wheel until it clears,

following the instructions on page 7. (See Figure I)

8.

Plug the Cut-Off Saw back into its electrical outlet, and finish making the cut following Steps #3 and #4 above.

9.

Once the cut is completed, turn off the Cut-Off Saw by releasing the Switch. This allows the Switch button to

return to the “OFF” position. ( See Figure J )

10.

Unplug the Cut-Off Saw from its electrical outlet, and make sure to wait until the Saw has come to a complete

stop before removing the workpiece.

11.

Lock down the Saw with Stopper knob and store the Saw in a dry, safelocation.

Inspection, maintenance and cleaning

1. WARNING

!

Always

make

sure

the

Switch

is

in

its

“OFF”

position,

and

unplug

the

Cord

from

its

230

volt

electrical outlet before performing any inspection, adjustments, maintenance, or cleaning.

2.

Before each use, inspect the general condition of the Cut-Off Saw. Check for loose screws, misalignment or

binding of moving parts, cracked or broken parts, damaged electrical wiring, loose, cracked, or bent Grind

Wheel, and any other condition that may affect its safe operation. If abnormal noise or vibration occurs, have

the problem corrected before further use. Do not use damaged equipment.

3.

Daily: With a soft brush, cloth, or vacuum, remove all dust and debris from the Cut-Off Saw. Then, use a

premium quality, lightweight machine oil to lubricate all moving parts, except the Grind Wheel itself.

4.

To replace the Motor Carbon Brushes: It may become necessary at sometime to replace the two Carbon

Brushes when the Motor performance decreases, or stops working completely. The Carbon Brushes are

located on each side of the Housing. To do so, use a standard screwdriver (not included) to remove the two

Brush holder Caps. Then, remove the two Carbon Brushes from the Brush holders. If the Carbon Brushes are

worn down more than 1/2 of the original size, replace both Carbon Brushes. If however, the Carbon Brushes

are just dirty they may be cleaned by rubbing them with a pencil eraser. When installing the Carbon Brushes,

make sure the carbon portion of the Carbon Brushes contact the Motor Armature, and that the springs face

away from the Motor. Also, make sure the springs operate freely. After cleaning or replacement, replace the

Carbon Brush Caps with a screwdriver and tighten firmly.

NOTE: New Carbon Brushes tend to arc or spark when first used until

They wear and conform to the Motor's Armature. ( See Figure J )

Please read the following carefully

The manufacturer and/or distributor has provided the parts list and assembly diagram in this manual as a

reference tool only. Neither the manufacturer or distributor makes any representation or warranty of any kind to

the buyer that he or she is qualified to make any repairs to the product, or that he or she is qualified to replace any

parts of the product. In fact, the manufacturer and/or distributor expressly states that all repairs and parts

replacements should be undertaken by certified and licensed technicians, and not by the buyer. The buyer

assumes all risk and liability arising out of his or her repairs to the original product or replacement parts thereto, or

arising out of his or her installation of replacement parts thereto.

Symbols

he rating plate on your tool may show symbols. These represent important information about the product or

instructions on its use.

7|English

Wear hearing protection. Double insulated for

additional protection

Wear eye protection. Read the instruction manual

Danger area! Keep hands, fingers or arms

away from this area.

Environmental Protection and Guarantee

ENVIRONMENT PROTECTION

Waste electrical products should not be disposed of with household waste. Please recycle where

facilities exist. Check with your local Authority or retailer for recycling advice.

8|English

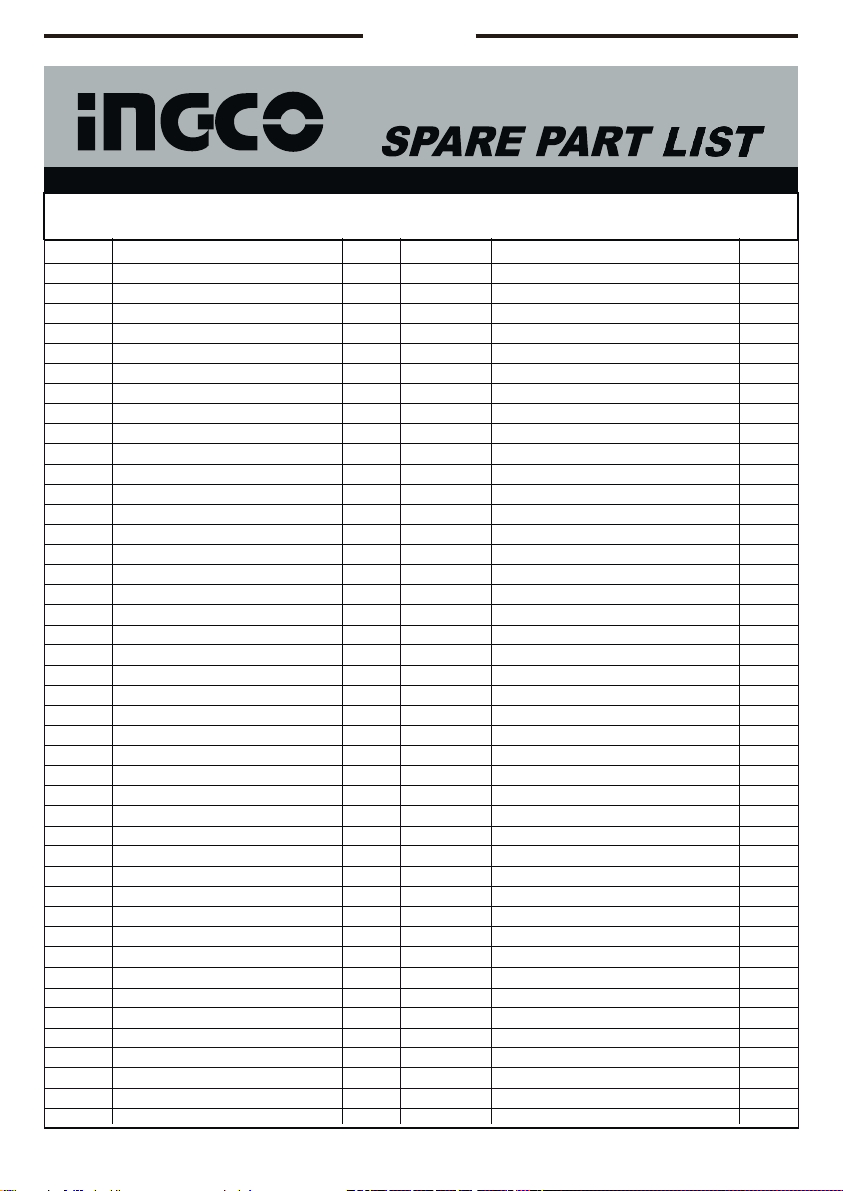

COS35568,UCOS35568,COS35568-6,COS35568-8,COS35568-9

83

82

84

85

9|English

COS35568,UCOS35568,COS35568-6,COS35568-8,COS35568-9

NO.

Part Description

Qty

NO.

Part Description

Qty

1

Brush cover

2

44

square key

1

2

Carbon brush

2

45

Bearing(6204-2z)

1

3

Brush hold

2

46

Hex nut

4

4

Pan head screw

4

47

Fixed guard

1

5

Spring washer

4

48

Cover

1

6

Flat washer

4

49

Gear

1

7

Motor housing

1

50

Bearing(6000-2z)

1

8

Stator

1

51

external criclips

1

9

plain washer

2

52

Hollow shaft

1

10 Spring washer

2

53

Hex nut

1

11 Screw

2

54

Screw

1

12 Bearing sleeve

1

55

Torsion spring

1

13 Bearing(6000-2z)

1

56

Dust cover

1

14 Washer

1

57

Flat washer

1

15 Armature

1

58

Spring washer

1

16 Bearing(6202-2RS)

1

59 Screw

1

17 Baffle

1

60 Screw

2

18 Pin

1

61 Spring washer

2

19 Rubber pin

1

62 Flat washer

2

20 Screw

8

63 Vice B

1

21 Right handle

1

64 Base

1

22 Screw

1

65 Flat washer

2

23 Switch

1

66 Pin

1

24 Cable 2*1.5 2m

1

67 Spring round pin

1

25 sheath

1

68 Vice nut

1

26 Screw

2

69 Pin

1

27 tension disc

1

70 Support bracke

1

28 Left handle

1

71 Screw rod

1

29 Hex nut

1

72 Screw rod handle

1

30 Screw

1

73 Handle sleeve

1

31 Cutting arm

1

74 Washer

1

32 Screw

1

75 Spring retainer

1

33 Lock pin

1

76 Screw

2

34 Spring

1

77 Spring washer

2

35 round-headed screw

2

78 Vice A

1

36

rubber rails

3

79 Flat washer

1

37

satfey guard

1

80 Hex nut

1

38 Hex nut

1

81 shock absorbing foot cover

4

39

Clamp sheet

1

82 six angle locknut

2

40

Outer flange

1

83 bracket O washer

1

41 Cutting wheel

1

84 wrench

1

42

Inner flange

1

85 non-slip mat

1

43

Spindle

1

This manual suits for next models

4

Table of contents

Other Ingco Saw manuals