Ingenieurbüro Mencke & Tegtmeyer Si-RS485TC-T-MT User manual

Ingenieurbüro Mencke & Tegtmeyer GmbH • Schwarzer Weg 43A • 31789 Hameln • Germany • www.ib-mut.de

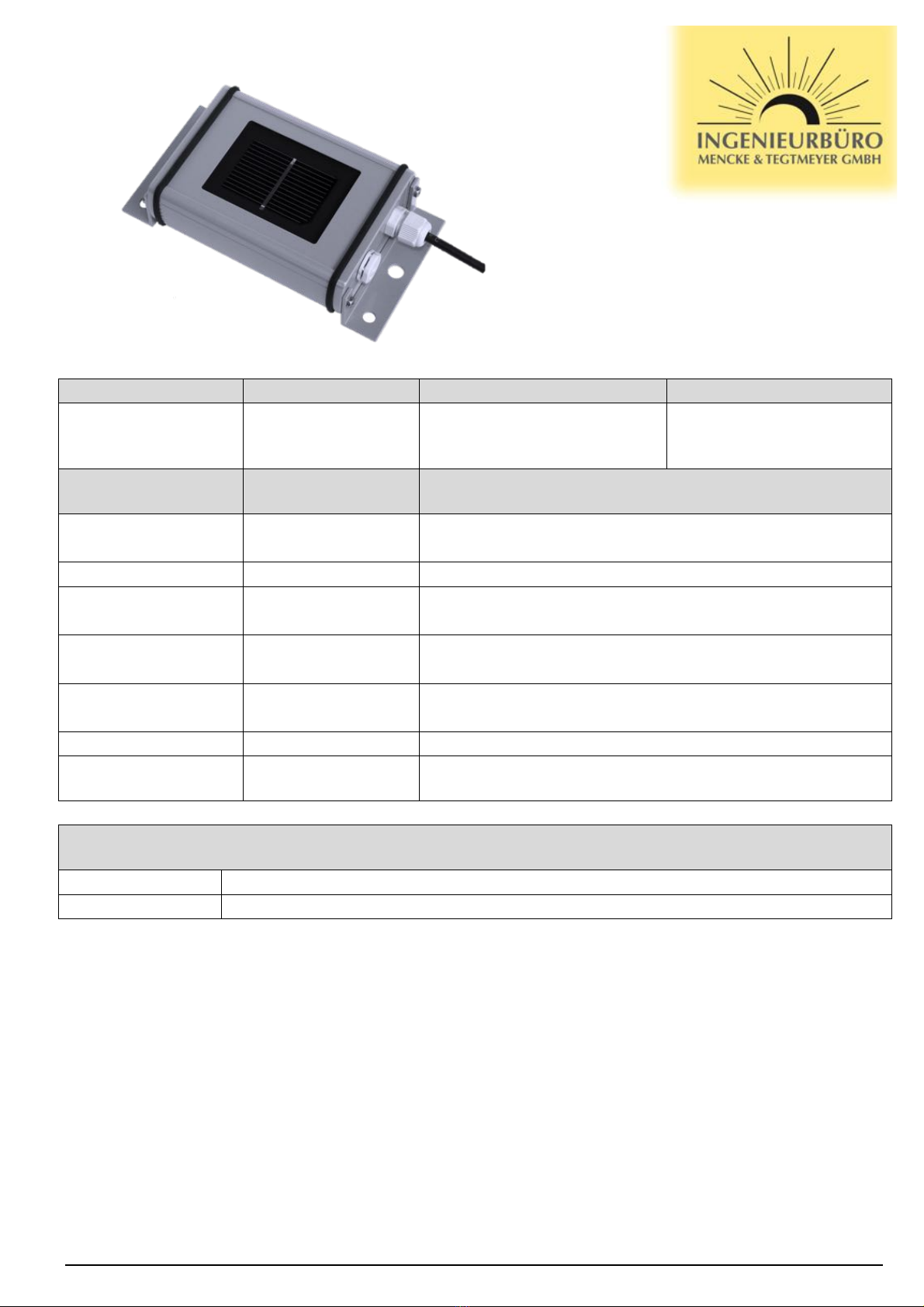

Types

Type

Voltage supply

Measuring range irradiance

Protocol

All sensors

12 to 28 VDC

0 to 1500 W/m2

MB: Modbus (RTU)

MT: M&T protocol

CANopen (CiA437)

Type

Measuring

temperature solar cell

Note

Si-RS485TC-T-MT

Si-RS485TC-T-MB

-40 to +90°C

./.

Si-CANopenTC-T

-25 to 75°C

./.

Si-RS485TC-2T-MT

Si-RS485TC-2T-MB

-40 to +90°C

Hard-wired external ambient temperature sensor

(-40 to 90°C)

Si-RS485TC-T-Tm-MT

Si-RS485TC-T-Tm -MB

-40 to +90°C

Hard-wired external module temperature sensor

(-40 to 90°C)

Si-RS485TC-2T-v-MT

Si-RS485TC-2T-v-MB

-40 to +90°C

Female connectors for optional external temperature sensor

(-40 to 90°C) and wind speed sensor (0 to 80 m/s)

Si-CANopenTC-2T

-25 to 75°C

Hard-wired external ambient temperature sensor (-25 to 75°C)

Si-CANopenTC-2T-v

-25 to 75°C

Female connectors for optional external temperature sensor

(-25 to 75°C) and wind speed sensor (0 to 80 m/s)

Measurement uncertainty over all,

according to GUM (Guide to the Expression of Uncertainty in Measurement), k = 2

Irradiance

±5 W/m²± 2.5 % of MV valid perpendicular incidence of the light, spectrum AM 1.5

Cell temperature

1.0 K Range -35 to 80°C

User information

The guarantee is for 1 year from the date of the invoice for the intended use. M&T does not accept any liability

for possible losses or damage due to the incorrect usage of the sensor. Liability for consequential damages is

excluded.

Special note: The housing for the Si sensors is not allowed to be opened by the installer or user because, as a

consequence, the housing will no longer be sealed after it is closed. If the housing is opened, the

manufacturer's warranty will be rendered void.

Maintenance

Scope of the regularly check (at least every 2 years): Cleaning of solar cell, external damage, mechanical

fastening, cable laying and any damage to the cable.

In the report IEA-PVPS T13-03:2014 "Analytical Monitoring of Grid-connected Photovoltaic Systems" an

interval of 1 to 2 weeks is recommended.

Should damage be found that degrades the function or safety, the sensor is to be replaced.

A recalibration is recommended at least every 3 years.

Quick Reference Guide

digital Silicon Irradiance Sensor

Main data

Irradiance measurement: up to 1500 W/m2

Cell temperature measurement: RS485: -40 to +90°C

CANopen: -25 to +75°C

Working temperature: -35 to 80°C

Weight: appr. 0.4 kg

Ing.-Büro Mencke & Tegtmeyer GmbH, Hameln Quick reference guide digital Silicon Irradiance Sensor

Page 2 of 4 Date: September 2017 All rights reserved

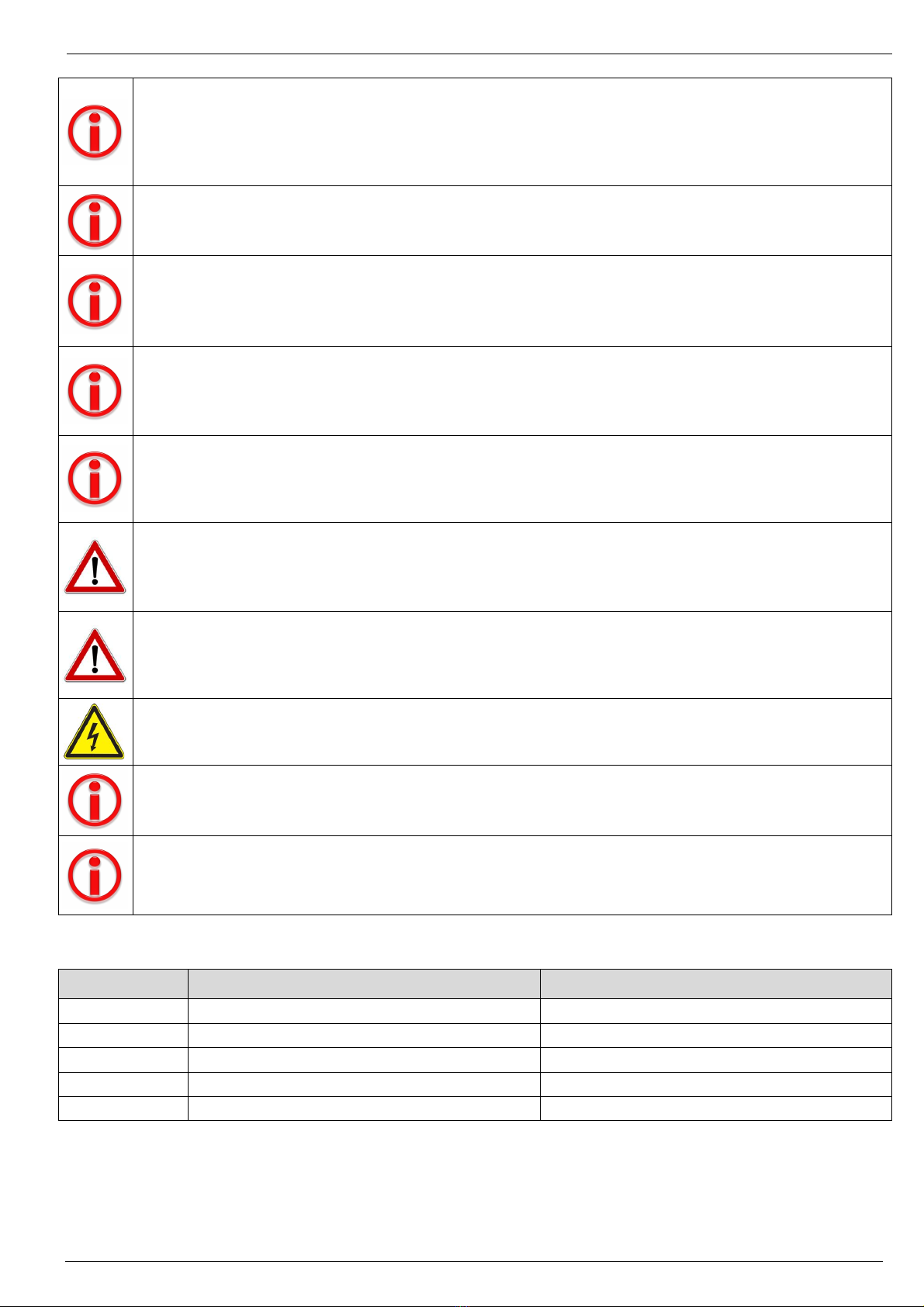

Si sensors that are used for monitoring PV installations must be installed with the same alignment

and inclination as the PV generator. The mounting location should be free of shading as far as

possible.

To facilitate maintenance and cleaning of the Si sensor, the Si sensor should be mounted in an easily

accessible place (e.g. near roof windows or skylights).

The mounting location at a PV generator must be selected such that snow cannot jeopardise the Si

sensor as it slides off. For this reason do not mount along the drip edge on the PV generator.

The connecting cable should always be laid separated from, e.g. main DC cables or AC cables.

The connecting cable is to be laid so it is fixed.

The minimum bending radius of 15 x cable diameter (ø approx. 5 mm) is to be observed.

The voltage drop at the cable has to be considered when calculating the maximum cable length.

The pressure equalisation element must not be damaged.

The cable gland is not allowed to be undone or tightened by the user.

It is not necessary for the installer or user to open the Si sensor. If the housing is nevertheless

opened, no liability for the sealing can be accepted.

The surge protection concept must be adapted to the specific local situation. This means, for

instance, that the measuring cables must be equipped with a separate surge arrester at the entry to a

building.

The sensor must be integrated into the lightning protection concept.

The sensors are designed for safety extra-low voltage (SELV) operation.

Reversing the polarity or mixing up the connections on the Si sensor may cause irreversible damage

to the sensor.

The cable shield is to be connected to PE during installation.

The installation and assembly of electrical equipment must be carried out by electrically qualified

persons.

The sensor may not be used with equipment whose direct or indirect purpose is to prevent human

death or injury, or whose operation poses a risk to humans, animals or property.

Mortal danger due to electrical power

On the connection of the Si sensor to an inverter, dangerous voltages are present on the inverter

(disconnection, secure against switching, follow inverter manual).

Should it be necessary to clean the Si sensor, a soft cotton cloth, water and a mild cleaning agent

can be used for this purpose.

A terminating resistor is usually not required for the RS485 sensors (MB and MT).

In principle a terminating resistor of 120 Ωat both ends of the CANopen bus is required for the

CANopen sensors.

Wire colour

Wire colour

All RS485 sensors

All CANopen sensors

Orange

RS485 Data- / B

CAN high

Brown

RS485 Data+ / A

CAN low

Black

Supply (negative)

Supply (negative)

Red

Supply (positive)

Supply (positive)

Black (thick)

Shield

Shield

Items supplied:

-Si sensor incl. pre-assembled connecting cable or suitable male connector

-Data sheet

-Calibration record

Ing.-Büro Mencke & Tegtmeyer GmbH, Hameln Quick reference guide digital Silicon Irradiance Sensor

Errors and omission excepted Date: September 2017 Page 3 of 4

A

B

C

D

E

FF

E

D

C

B

A

Drawing No.

Page:

12345678

A

B

C

D

E

FF

E

D

C

B

A

Drawing name:

12345678

Scale: none

A

B

C

D

E

FF

E

D

C

B

A

Projekt:

Si - Series

of 1 pages

1

12345678

Silicon Irradiance Sensor

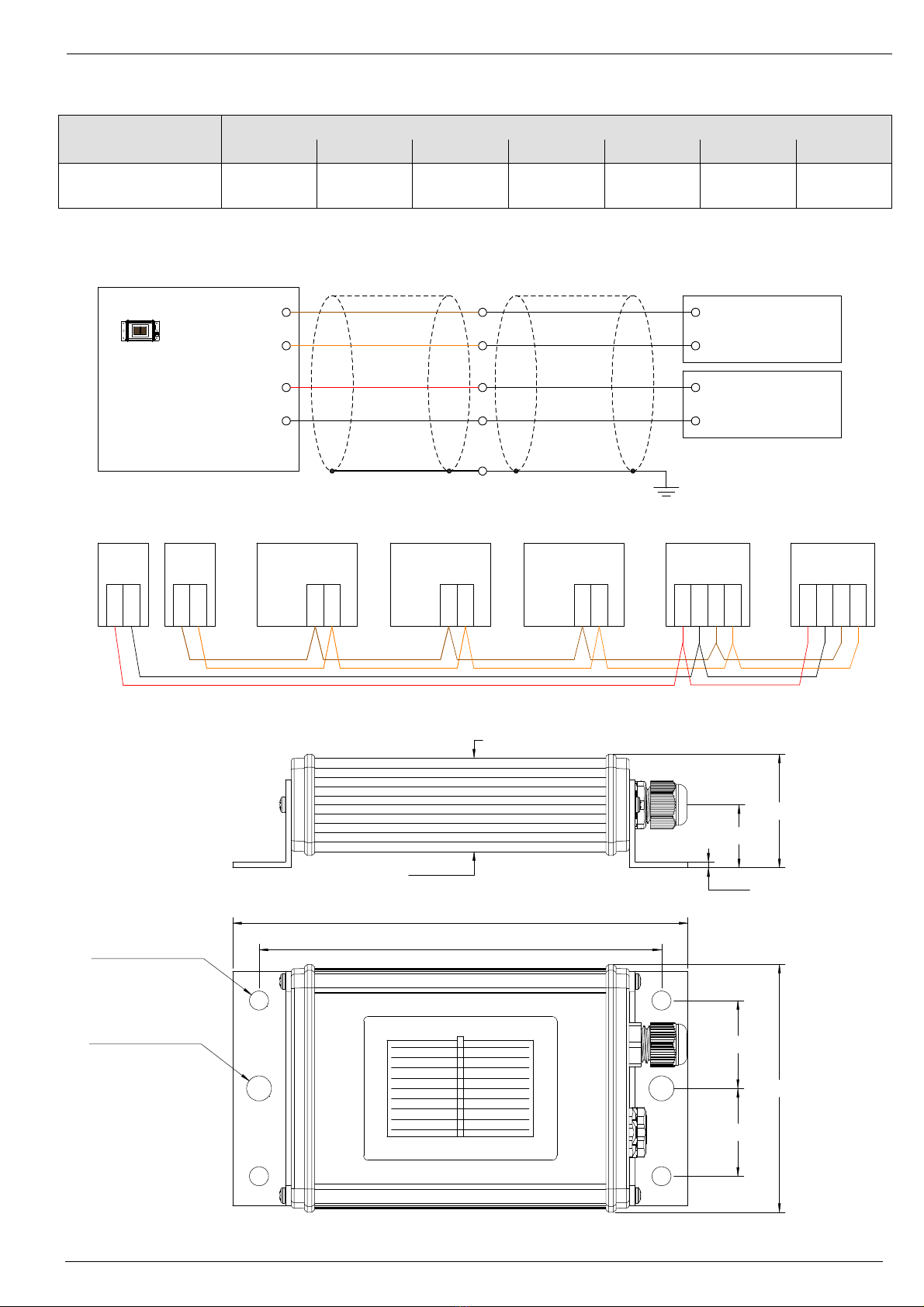

155±1.0 mm

137±1.0 mm

85 mm

30 mm

30 mm

39 mm

2 mm

85 mm

Ø 8.5 mm - 2x

Ø 6.5 mm - 4x

32 mm

22 mm

Maximum additional cable length of Si sensors with 3 m connection cable

at voltage supply of 24 VDC / 12 VDC

Sensor type

Cable diameter

0,14 mm2

0,25 mm2

0,34 mm2

0,5 mm2

0,75 mm2

1,0 mm2

1,5 mm2

Si-RS485TC-XXX

300 m /

50 m

600 m /

100m

800 m /

150m

1.000 m /

200 m

1.000 m /

300m

1.000 m /

400m

1.000 m /

650m

Wiring diagram of digital Si sensors

Bus topology

Dimension

Data +

Data -

Plus

Minus

Data +

Power Supply Plus

Power Supply Minus

Data -

Data +

Data -

Data +

Data -

Data +

Data -

Data +

Data -

Types

Si-RS485TC-X

Inverter

Datal-

ogger Inverter Si-Sensor

RS 485

Inverter

PE

Datalogger

Power Supply

Cable Shield

Optional

Te mp e r at u r e

Irradiance

Power Supply

Plus

Power Supply

Minus

Types

Si-01TC(-T)

Si-13TC(-T)

Si-420TC(-T)

SiS-01TC(-T)

SiS-13TC(-T)

SiS-420TC(-T)

Si(S)-Sensor

brown

orange

red

black

black (thick)

AIN 1+

AIN 2+

AIN 1-

AIN 2-

V+

V-

Data +

Data-

Plus

Minus

Power-

Supply

RS 485 RS 485 RS 485 RS 485

Cable Shield

PE

Cable Shield

brown

orange

red

black

black (thick)

Cable Shield

Datalogger

Power Supply

V+

V-

Si-Sensor

Plus

Minus

Data +

Data -

Si-Sensor

RS 485

Data +

Power Supply Plus

Power Supply Minus

Data -

Types

SiS-RS485TC-X

Data +

Data-

PE

Cable Shield

brown

orange

red

black

yellow

Cable Shield

Datalogger

Power Supply

V+

V-

SiS-Sensor

Data +

Data -

Plus

Minus

Data +

Power Supply Plus

Power Supply Minus

Data -

Data +

Data -

Data +

Data -

Data +

Data -

Data +

Data -

Types

Si-RS485TC-X

Inverter

Data-

logger Inverter Si-Sensor

RS 485

Inverter

PE

Datalogger

Power Supply

Cable Shield

Optional

Te mp e r at u r e

Irradiance

Power Supply

Plus

Power Supply

Minus

Types

Si-01TC(-T)

Si-13TC(-T)

Si-420TC(-T)

SiS-01TC(-T)

SiS-13TC(-T)

SiS-420TC(-T)

Si(S)-Sensor

brown

orange

red

black

black (thick)

AIN 1+

AIN 2+

AIN 1-

AIN 2-

V+

V-

Data +

Data-

Plus

Minus

Power-

Supply

RS 485 RS 485 RS 485 RS 485

Cable Shield

PE

Cable Shield

brown

orange

red

black

black (thick)

Cable Shield

Datalogger

Power Supply

V+

V-

Si-Sensor

Plus

Minus

Data +

Data -

Si-Sensor

RS 485

Data +

Power Supply Plus

Power Supply Minus

Data -

Types

SiS-RS485TC-X

Data +

Data-

PE

Cable Shield

brown

orange

red

black

yellow

Cable Shield

Datalogger

Power Supply

V+

V-

SiS-Sensor

Ing.-Büro Mencke & Tegtmeyer GmbH, Hameln Quick reference guide digital Silicon Irradiance Sensor

Page 4 of 4 Date: September 2017 All rights reserved

Mounting instruction

Technical data

General data

Solar cell

Monocrystalline silicon; 50 mm x 33 mm

Housing Material

Powder-coated aluminium

Dimension / Weight

155 mm x 85 mm x 39 mm / appr. 350 to 470 g

Degree of protection

IP 65

Operating temperature

-35 to +80°C

Supply voltage

24 VDC (12 ... 28 VDC)

Current consumption

Typical 35 mA at 24 VDC

Sensor cable

LiYC11Y 4x0.14mm2UL20233; length typical 3m

Maximum cable length for RS485

1000 m

Maximum cable length for CANopen

200 m (at 125 kBaud)

Customs tariffs number

85 41 40 90

Protocol

Settings (standard)

Note

Modbus (RTU)

Address: 1

Transmission rate: 9600 baud

Format: 8N1

Address can be set (e.g. using software "Si

Modbus Configurator")

Max. transmission rate 38400 baud

MT

Address: last two digits of serial number

Transmission rate: 9600 baud

Format: 8N1

Cannot be changed

CANopen

Transmission rate: 125 kbaud

Protocol to CiA 437

Max. transmission rate 250 kbaud

Note for configuration with software "Si Modbus Configurator“: Required are a computer, a voltage supply

and an USB to RS485 interface converter. We recommend as a converter the ICPCON I-7561 or DIGITUS,

type DA-70157.

Please read also the installation and operating instruction (newest version on www.ib-mut.de).

See technical data for

maximum cable length

Fastening with at least

one screw per wall

bracket

Ø 6.5 mm

Ø 8.5 mm

Ø 6.5 mm

Not allowed for

Si-RS485TC-2T-v

and

Si-RS485TC-2T

This manual suits for next models

10

Other Ingenieurbüro Mencke & Tegtmeyer Accessories manuals

Popular Accessories manuals by other brands

Pil Sensoren

Pil Sensoren P41-200-I-CM12 quick start guide

Samsung

Samsung SmartThings STS-PRS-250 quick start guide

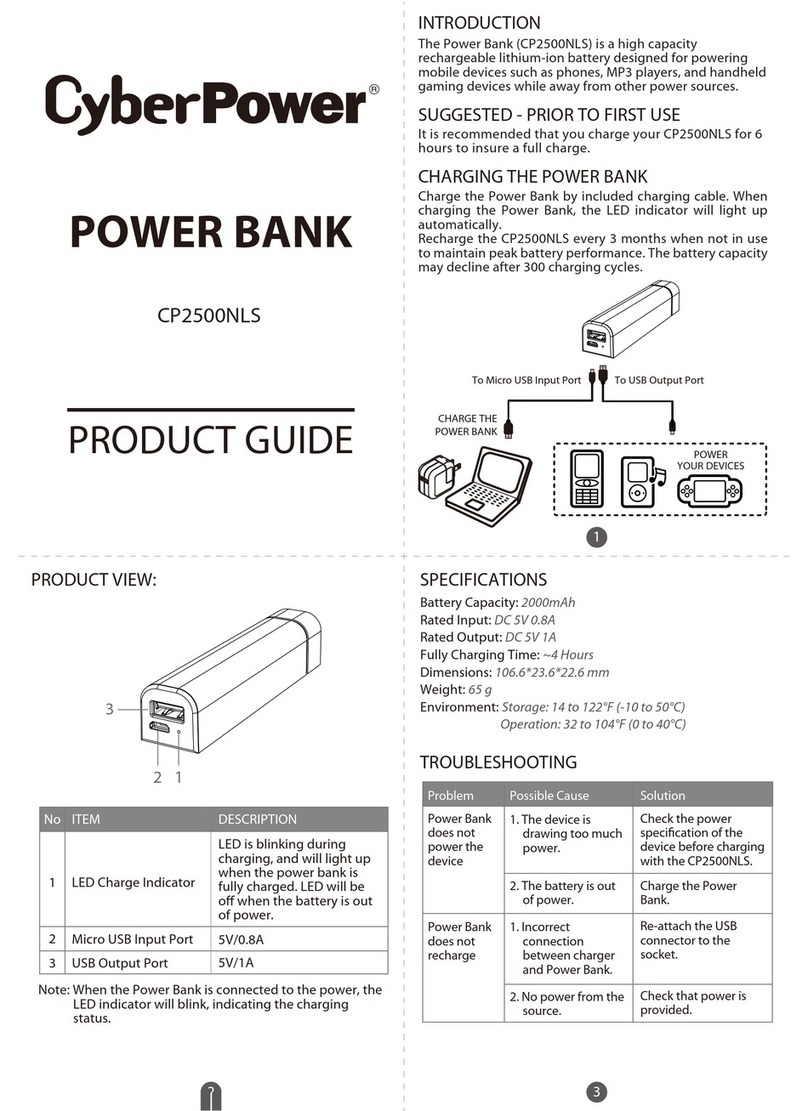

CyberPower

CyberPower CP2500NLS Product guide

Baumer

Baumer OADM 20U5440/S14C manual

Tronic

Tronic QI TPBQ 10000 A1 Operation and safety notes

Invacare

Invacare Personal Seat VF Installation and operating instructions