Ingenium MECing Owner's manual

Mechanical Control

MECing

Programming manual

V1.0

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

2 de 58

Index

1.

MECING ...........................................................................................................................................3

1.1.

GENERAL DESCRIPTION..............................................................................................................3

1.2.

TECHNICAL DESCRIPTION...........................................................................................................3

1.3.

OPERATION MODE.........................................................................................................................4

1.4.

PROGRAMMING THE DEVICE.......................................................................................................4

1.4.1.

AssistedProgramming

.......................................................................................................13

1.4.2.

Programming by Scripts

....................................................................................................38

1.5.

DEVICE DIAGNOSTIC

...............................................................................................................47

1.6.

REGISTERS ADMITTED

.............................................................................................................48

1.6.1.

RAM

...................................................................................................................................48

1.6.2.

EEPROM

...........................................................................................................................52

1.7.

UPLOADING DATA TO THE DEVICE

..........................................................................................53

1.8.

WIRELESS DEVICE:MECINGW:

..............................................................................................54

1.9.

WIRING

...................................................................................................................................56

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

3 de 58

1.

MECing:

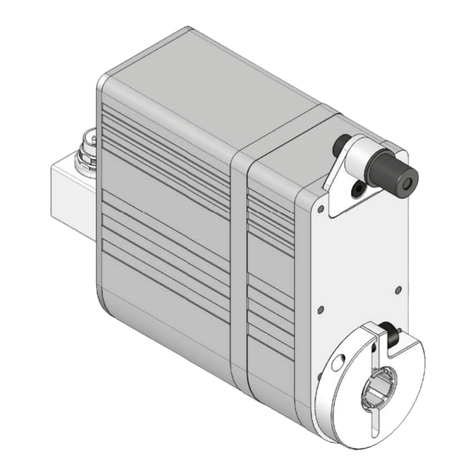

1.1. General Description:

Converts common mechanisms into smart mechanisms.

Enables digital signals to be entered in the bus, sensor or detector signals.

Its main function is to store events.

It has 3 low voltage (SELV) digital outputs , referred to the bus ground.

The MECing is designed to distribute the installation and installed behind

mechanisms in mechanism boxes.

This device is included in the following KITS:

KI1-6, KI1-10

Ki1-D6

KP1-6, KP1-D6

KR1, KR1-D300

KR2, KR2-D300

1.2. Technical Description:

Supply at 12Vdc

Consumption at 12Vdc: 40mA

3 potential free inputs.

Size: 45x45x10mm to install in universal mechanism box.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

4 de 58

1.3. Operation Mode:

The MECing converts common mechanisms (switches and pushbuttons) to

smart mechanisms.

Its operation mode is very simple, you only need to press on the switch or

pushbutton connected to the MECing to execute programmed events.

1.4. Programming the Device:

As seen in the description of the Installation Modules, program the MECing by

double clicking on it (or select and right-click on it Edit Properties).

Steps to follow:

Double click on the MECing or, right-click on the MECing and select the

following option: Edit Properties:

NB: If you add a lighting KIT, the MECing is called a MECKI1.

If you add a blinds KIT, the MECing is called a MECKP1.

If you add a dimmer KIT, the MECing is called a MECKR1.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

5 de 58

Once this has been done, the MECing programming window appears.

NB: The MECing operates according to the KIT included and how it is

programmed; see the corresponding KIT Help Manual.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

6 de 58

The node address for the MECing is given as shown on the right, in red,

(address 40 in the image). You can use this address later to check the state of

the MECing in the Diagnostics tab after the project has been finished.

There are two buttons at the top of the screen:

New Program: Not applicable in the KITS Development System

Software.

Check Program: When you change a program it checks that what has

been programmed is correct. This command is executed by default when

new data is uploaded to devices.

In the MECing Working Modes section, you can configure it as a pushbutton or

as a switch.

The execution of programmed events is carried out by pressing the switch, or

the pushbutton connected to the MECing.

The MECing Working Modes appear on the right-hand side. They can be:

Pushbutton: This option configures the three inputs as pushbuttons, i.e.,

they respond when an up flank and another down flank are produced. In

this example, the Scripts in the top programming box correspond to the

first time you press the button and the Scripts in the bottom programming

box of each input correspond to the second time you press the button.

Switch: This option configures the three inputs as switches, i.e., they

respond when a single flank is produced. In this example, the Scripts in

the top programming box correspond to the up flank and the Scripts in

the bottom programming box for each input correspond to the down

flank.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

7 de 58

Autorepeat: This option configures the three inputs as pushbuttons in

repetition mode. In this example, when one input is short-circuited to

Reference (closed contact), it consecutively and repeatedly sends the

programming which appears in the top and bottom boxes. In other words,

it sends the programming in the top box and then the programming in the

bottom box. While the input remains closed it will repeat this process.

Special: This mode allows the user to configure each input independently

as a pushbutton, switch or repetition.

The programmed events are executed when the switch or pushbutton

connected to the MECing is pressed and are organised as follows:

There are 3 switches (2 positions for each switch) or 3 pushbuttons.

Switch Mode: Each position of the switch executes the corresponding event.

The Switch Mode can distinguish between high and low levels. In high level

(position 1 in the switch) for example, each one of the three switches execute

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

8 de 58

the events programmed in the top boxes and in low level (position 2 in the

switch) it executes the events programmed in the bottom box.

Pushbutton Mode: In this mode, there are two flanks:

One up flank (top box in the same column): If you press once (if it is a

pushbutton, and if it is a switch when you put it in one position), an up

flank is made and the events programmed in the top box are executed.

A down flank (bottom box in this column): When you release (for

pushbuttons) or you change position (for switches), a down flank is

produced and the events programmed in the bottom box are executed.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

9 de 58

Summary:

Mode

Device

pushbutton

switch

pushbutton

The first time you press,

the events in programming

box 1 are executed, and

the second time the

pushbutton is pressed it

executes the events in

programming box 2.

In box 1 and 2 you can

have different events.

No more than 6 events

The first time you press the

pushbutton, it executes the

events in programming

box1 and on releasing it,

those in programming box

2.

In programming box 2 you

should have the same

Scripts as in box 1, or none

at all.

No more than 3 events.

switch

When the top part of the

switch is pressed, the

events programmed in box

1 are executed and when

the bottom part is pressed

it does nothing. When the

top part of the switch is

pressed again, the events

in programming box 2 are

executed. When the bottom

part is pressed, it does

nothing.

This combination is not

admitted.

When the top part of the

switch is pressed, the

events programmed in box

1 are executed and when

the bottom part is pressed it

executes the events in

programming box 2.

No more than 6 events.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

10 de 58

As mentioned before, when events are executed they are done so in pairs per

column: 1 and 2, 3 and 4, 5 and 6. Following the explication given in this table,

this is completely valid for boxes 1 and 2, for 3 and 4 and/or 5 and 6.

SWITCH IN SWITCH MODE

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

11 de 58

PUSHBUTTON IN PUSHBUTTON MODE

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

12 de 58

PUSHBUTTON IN SWITCH MODE

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

13 de 58

SWITCH IN PUSHBUTTON MODE

You can program each box in two different ways:

Assisted programming (not valid for KA, which

is programmed by

Scripts).

Programming by Scripts.

1.4.1. AssistedProgramming.

Programming events in different programming boxes is all done in the same

way, as described below:

Double click on a programming box to assign the event you want.

Once done, the Node Selection window appears as shown below.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

14 de 58

All the devices that have been added to the project appear in this window, but

you can only select devices that belong to the group of actuators. (If you try to

select a different device type, the Development System Software will not

respond). In other words, if you click on a device that does not belong to the

group of actuators (KI, KP, KR, KA...) like a MECBUS, CGBUS, MECing,

LDRBUS, the system will not respond.

Double click on the actuators to access their outputs.

NB: The KI, KP, KR are programmed by default (see the KI, KP and KR

Help Manuals). To avoid confusion, the default programming has been

erased in the examples given in this manual.

If you select…

KI1-KI8:

The following window appears:

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

15 de 58

NB: Outputs Z1 to Z6 correspond exactly to the arrows shown in the image

above.

You can modify these outputs.

On the right side of the screen you have the following sections:

Discrete switches: You can select an output to activate (on the left column) or

deactivate (right column). The on/off of an output does not affect the rest of the

device outputs. In other words, when you select Circuit1ON, it activates output

Z1 and the remaining outputs continue as they were, whether on or off (lights

on/off) and represented as grey circles in the image.

Example: You want to activate the lights associated to outputs Z1, Z5 and Z6

and leave the rest as they were (on or off):

Double click on this programming box.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

16 de 58

NB: Remember that all default programming has been erased, hence the

boxes are empty.

Double click on the corresponding actuator, for example, KI1.

Then, click on each output you want to activate (this action is not applied to the

remaining outputs you do not select).

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

17 de 58

Click on Close to generate the following Script:

Double click again on the same programming box and activate Z5:

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

18 de 58

Click on Close to generate the following Script:

Repeat the same steps for Z6.

Toggle an output ( or single switch):

Toggles a selected output, i.e., the output state is changed: if its state is shown

as activated then when it is pressed it will deactivate and vice versa (the control

device is a MECing in this example). A blue circle is shown in the window as

shown below:

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

19 de 58

Figure: the circles indicate specific on/off executed by the device. If the circle is

red, the output is deactivated (relay open, lights connected to this output are

off); if it is green, the output is activated (relay closed, lights connected to this

output are on).

Clicking on the circles changes its state (red/green) enabling you to program the

device as you require. Example: to activate the lights associated to outputs Z1,

Z5 and Z6 while deactivating the rest (Z2, Z3 and Z4), click on the circles that

correspond to those outputs only.

PROGRAMMING MANUAL

MECING -V1.0

Mechanical Control

20 de 58

Once you have done this, click on Close to generate a Script which is the same

as that generated by clicking on the circles as shown below:

To create a new event, double click again on the corresponding programming

box.

The previous example can also be done as follows:

Double click on the selected programming box and select KI1; double click on it:

Table of contents

Other Ingenium Controllers manuals