4 Instruction Manual 332004

Table of Contents

Introduction & Safety Notices

Receiving Inspection............................................................................................................... 6

International Shipment........................................................................................................... 6

Limited Warranty..................................................................................................................... 6

Explosive Gases ...................................................................................................................... 7

Implosion / Explosion ............................................................................................................. 7

Safety/Warning Notices ......................................................................................................... 8

Grounding................................................................................................................................ 8

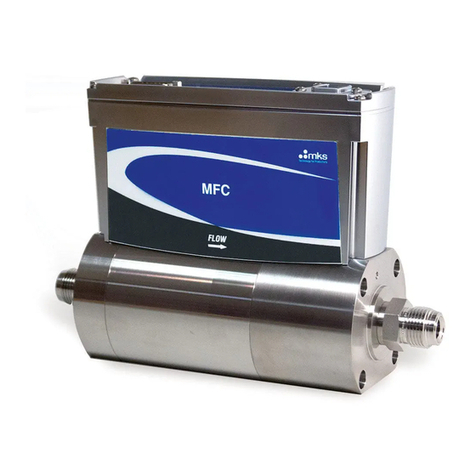

1.1 General Description ........................................................................................................ 9

Available Options ............................................................................................................. 9

Convectron Gauge Option ..................................................................................... 9

1.2 Installation....................................................................................................................... 9

Mounting Configurations................................................................................................. 9

Ionization Gauge Types and Installation ......................................................................10

Ion Gauge Cable Connections ......................................................................................11

System Ground Test Procedure....................................................................................12

1.3 Operation .......................................................................................................................14

Ion Gauge Theory of Operation.....................................................................................14

Emission Current Adjustment .......................................................................................15

Table 1-1...............................................................................................................15

Example 1.............................................................................................................15

Example 2.............................................................................................................15

Example 3.............................................................................................................15

Analog Output.......................................................................................................16

Overpressure Shutdown ......................................................................................19

Degas....................................................................................................................19

1.4 Calibration ......................................................................................................................19

Electrometer Zero..........................................................................................................19

Electrometer Log Amplifier............................................................................................19

Summary ........................................................................................................................20

1.5 Specifications ................................................................................................................20

2.1 General Description ......................................................................................................23

2.2 Safety Instructions ........................................................................................................23

Explosive Gases ...................................................................................................23

Limitation of Use of Compression Mounts .........................................................23

Convectron Gauge Mounting Position ................................................................23

Overpressure Conditions .....................................................................................23

High Indicated Pressure ......................................................................................24

Chemicals .............................................................................................................24

Sensor Failure ......................................................................................................24

Tube Contamination ............................................................................................24

2-3 Convectron Gauge Theory of Operation ......................................................................24

2.4 Convectron Gauge Installation......................................................................................25

Important Precautions for Gauge Installation....................................................25

Convectron Gauge Orientation............................................................................26