Ingersoll 3012 User manual

Ingersoll

COMPACT

TRACTORS

3012,3014,3016,

3018,

3018PS

4016, 4020,

4020PS

Operator's

Manual

8-

59130

QUALITY IN

THE

AMERICAN TRADITION

Ingersoll

Equipment

Co., Inc. Winneconne, Wisconsin 54986-9576

IF

THIS

MACHINE

IS

USED

BY

AN

EMPLOYEE

OR

IS

LOANED

OR

RENTED,

MAKE

ABSOLUTELY

CERTAIN

TIL\T

THE

OPERATOR(S),

PRIOR

TO

OPERATING:

1.

IS

I:"JSTRUCTED

IN

SAFE

:\ND

PROPER

USE.

~.

REVIEWS

AND

UNDERSTANDS

THE

!Y1ANUAL(S)

PERT:\INING

TO

TIlE

:".1.\(,IIINE.

7':>

12

53

BEFORE

STARTING

ENGINE

STUDY

OPERATOR'S

MANUAL

SAFETY

MESSAGES

READ

ALL

SAFETY

SIGNS ON

MACHINE

CLEAR

THE

AREA

OF

OTHER

PERSONS

LEARN

&

PRACTICE

SAFE

USE

OF

CONTROLS

BEFORE

OPERATING

II

IS

YOUR

RE.SPONS,BIL

I , Y

10

UNLJ£

R S I

AND

AND

FOLLOW

MANUF

AC

1

uRE

R'S

INS

1

Rue'

IONS

O N

MACHINE.

O

PERATION,

S

ERVICE,

AND

10

OBSERVE.

PERTINE.NT

LAwS

AND

REGULAI.ION

S

OPERATOR

ANO

SERVICE

MANUAL

S

MAY

BE

OBTAINE.D

FROM

YOUR

E.QUIPME.NT

DE.ALER

/'

WARNING:

The engine

exhaust

from

this

product

contains

chemicals

known

to

the

State

of

California

to

cause cancer,

birth

defects

or

other

reproductive

harm.

TABLE OF CONTENTS

SAFETY MESSAGES . .

..

.

................................

II

-VII

TO THE OWNER . .

.. ..

.....

.

...

.

......

.

....................

2

PRODUCT IDENTIFICATION (PIN)

OR

SERIAL NUMBERS (SIN)

...

.

.....

3

OPERATING INSTRUCTIONS . .

...

.

........

.

....

.

......

.

..

...

4-12

Operating Controls and

Instruments

. .

.................

. . .

...

4-7

Prestarting Check List .

....

... ...

.........................

8

Break-in Procedure

........

..

......

.

......................

8

Starting

Procedure . .

..........

...

..

.

......

..

..

...

........

9

Stopping Procedure .

..

.

...

..

.....

.

....

.

.................

10

Operating Procedure

.......

.

................

..

........

11-12

TROUBLESHOOTING GUIDE

.....

..

............

..

.............

13

PREVENTIVE MAINTENANCE

..

.

...

.

.....

.

...........

.

.....

14-30

Maintenance

Chart

...

.

....

.

.....

..

..........

.

...........

15

Capacities

.....

.

......

.

...

.

..

.

....

..

...

..

......

"

...

.

...

15

Specifications

..............

.

...............

.

........

16-17

Over

All

Measurements

...

....

.....

.

..

...........

.

.......

17

Wiring Diagrams

.....................................

18-20

Storage

Battery

..

.

............

.

...

..

.........

.

.........

21

Jumper

Cables and Booster Battery

....

.

...........

.

...

.

.....

22

Headlights

....

.

..

.

...

.

..........

..

.....

.

..............

23

Fuse

...

.

............

.

...

.

.........

..

.....

.

..........

23

Attachment

Drive

Clutch

Break-in Procedure

......

.

............

23

Brake

........

.

..

.

.............

.

...

.

.........

.

........

24

Fuel

..........

..

.....

.

................

..

.............

25

Hydraulic Oil

...................................

.

.....

.

26

Hydraulic Oil Cooler .

....

.

..................

.

..

.

.........

27

Hydraulic Oil Filter

..

..

......................

..

..........

27

Seat

................

..

.........

....

.........

..

......

28

Transaxle . .

........

..

...

.

..

.

...

.

......

.

..

...

....

.

.....

28

Chassis Lubrication . .

.........

.

.........

...

.............

29

Steering

Adjustment

. .

.........

...

....

.

......

.

...

.

......

30

Toe-in

Adjustment

...........

..

........

..

. .

...

....

......

30

MANUAL

ORDERING PROCEDURE'

.............................

31

SAFETY

MESSAGES

CAUTION:

Disengage

The

first

twenty

-five safety messages

which

follow

power

to

attachment(s)

when

are provided

by

the American National Standards

transporting

or

not

in

use

.

Institute

*(ANSI)

.

Safety

rules

to

supplement those A ,

provided

by

ANSI

also appear

on

the

following

pages.

Study

these rules carefully before starting and

operating

your

Lawn and Garden Tractor.

A

Separate

Operator's

Manuals

are

provided

with

the

attach-

ments

purchased

with

your

tractor.

Refer

to

the

appro-

priate

attachment

operators

manual

for

specific

operating

instructions

and

safety

messages

that

apply

to

the

attachment.

A

CAUTION:

Know

the

controls

and

how

to

stop

quickly.

READ

THIS

OPERATOR'S

MANUAL

and

instructions

furnished

with

attachments.

A

CAUTION:

Do

not

allow

child-

ren

to

operate

the

machine.

Do

not

allow

adults

to

operate

it

without

proper

instruction.

A

CAUTION:

Do

not

carry

pas-

sengers.

Do

not

mow

when

children

and

others

are

around.

A

CAUTION:

Clear

the

work

area

of

objects

(wires,

rocks,

etc.)

that

might

be

picked

up

and

thrown.

A

CAUTION

:

Disengage

all

at-

tachment

clutches

and

shift

into

neutral

before

attempting

to

start

the

engine

(motor).

A

CAUTION

:

Disengage

power

to

attachment(s)

and

stop

the

engine

(motor)

before

leaving

the

operator's

position.

A

CAUTION

:

Disengage

power

to

attachment(s)

and

stop

the

engine

(motor)

before

making

any

repairs

or

adjustments.

A

A

A

A

A

A

CAUTION

:

Take

all

possible

precautions

when

leaving

the

vehicle

unattended,

such

as

disengaging

the

power

take-

off.

lowering

the

attachment

(s),

shifting

into

neutral,

setting

the

parking

brake.

stopping

the

engine,

and

re-

moving

the

key

.

CAUTION:

Do

not

stop

or

start

suddenly

when

going

up-

hill

or

downhill.

Mow

down

the

face

of

steep

slopes;

never

across

or

up

the

face.

(This

ANSI

rule

modified)

CAUTION:

Reduce

speed

and

exercise

extreme

caution

on

slopes

and

in

sharp

turns

to

prevent

tipping

or

loss

of

con-

trol.

Be

especially

cautious

when

changing

direction

on

slopes.

CAUTION:

Stay

alert

for

holes,

rocks,

and

roots

in

the

terrain

and

other

hidden

haz

-

ards.

Keep

away

from

drop-

offs.

CAUTION:

Use

care

when

pulling

loads

or

using

heavy

equipment.

a.

Use

only

approved

draw-

bar

hitch

points

.

b.

Limit

loads

to

those

you

can

safely

control.

c.

Do

not

turn

sharply

.

Use

care

when

backing.

d.

Use

counterweights

or

wheel

weights

when

suggested

in

this

oper-

ator's

manual.

CAUTION

:

Watch

out

for

traffic

when

crossing

or

near

roadways

.

II

CAUTION:

'

When

using

any

A

CAUTION:

Do

not

change

attachments

,

never

direct

dis-

the

engine

governor

settings

charge

of

material

toward

by-

or

overspeed

the

engine

.

standers

nor

allow

anyone

near

the

vehicle

while

in

oper-

A

A

ation.

CAUTION:

Handle

gasoline

with

care

-

it

is

highly

flam-

mable.

a.

Use

approved

gasoline

container.

b.

Never

remove

the

fuel

cap

of,

or

add

gasoline

to,

a

running

or

hot

engine

or

an

engine

that

has

not

been

allowed

to

cool

for

several

minutes

after

running.

Never

fill

the

tank

indoors

and

always

clean

up

spilled

gasoline.

c.

Open

doors

if

the

engine

is

run

in

the

garage

-

ex-

haust

fumes

are

danger

-

ous.

Do

not

run

the

en-

gine

indoors.

CAUTION:

Keep

the

vehicle

and

attachments

in

good

operating

condition,

and

keep

safety

devices

in

place

and

in

working

condition.

CAUTION:

Keep

all

nuts,

bolts,

and

screws

tight

to

be

sure

the

equipment

is

in

safe

working

condition.

CAUTION:

Never

store

the

equipment

with

gasoline

in

the

tank

inside

a

building

where

fumes

may

reach

an

open

flame

or

spark

.

Allow

the

engine

to

cool

before

storing

in

any

enclosure.

CAUTION:

To

reduce

fire

hazard,

keep

the

engine

free

of

grass,

leaves,

or

excessive

grease.

CAUTION:

The

vehicle

and

attachments

should

be

A

A

CAUTION:

When

using

the

vehicle

with

mower,

proceed

as

follows:

11)

Mow

only

in

daylight

or

in

good

artificial

light.

12)

Never

make

a

cutting

height

adjustment

while

the

engine

(motor)

is

running

if

the

operator

must

dismount

to

do

so.

13)

Shut

the

engine

(motor)

off

when

removing

the

grass

catcher

or

unclogg-

ing

chute.

(4)

Check

the

blade

mounting

bolts

for

proper

tightness

at

frequent

intervals.

CAUTION:

Under

normal

usage,

the

grass

catcher

bag

material

is

subject

to

deterior-

ation

and

wear.

Check

bag

frequently

for

deterioration

and

wear

and

replace

worn

bags.

Check

that

replacement

bags

comply

with

the

original

manufacturer's

recommend-

ations

or

specifications.

CAUTION:

Disengage

power

to

mower

before

backing

up

.

Do

not

mow

in

reverse

unless

absolutely

necessary

and

then

only

after

observation

of

the

entire

area

behind

the

mower.

CAUTION:

Do

not

wear

loose

clothing

which

may

catch

in

moving

parts.

CAUTION:

Do

not

smoke

when

working

near

fuel.

A

stopped

and

inspected

for

damage

after

striking

a

foreign

object,

and

the

CAUTION:

Drive

at

a

speed

slow

enough

to

insure

safety

damage

should

be

repaired

before

restarting

and

and

complete

control

at

all

times.

operating

the

equipment

.

III

A

CAUTION:

Highway

travel

should

be

avoided.

If

nec-

essary,

use

SMV

safety

emblem

and

lights

for

adequate

warning

to

the

operators

of

other

vehicles.

Check

local

government

reg

-

ulations.

A

WARNING:

Improper

operation

of

your

tractor

on

hillsides

and

slopes

can

be

dangerous.

Avoid

improper

operation!

Read

and

follow

the

instructions

given

in

the

section

titled

"Hi"side

Operation"

in

this

manual

A

A

CAUTION:

Read

operator's

manuals.

Know

location

and

function

of

all

controls.

Keep

all

shields

and

safety

switches

functional.

Before

starting

engine:

disengage

attachment

drive

and

place

travel

control

in

neutral.

Remove

objects

from

the

terrain

that

could

be

thrown

by

the

attachment

.

Keep

people

and

pets

a

safe

distance

away.

Never

carry

passengers.

Always

look

behind

tractor

before

backing.

On

any

incline

that

the

tractor

can

be

safely

operated

use

low

range/gear.

Front

end

tip

over

can

occur

when

operating

on

loading

ramps

or

hills,

back

up

ramps

or

hills.

Drive

forward

going

down

ramps

or

hills.

To

park

tractor:

place

travel

control

in

neutral,

set

parking

brake,

disengage

attachment

drive,

shut

engine

off

and

re-

move

key.

Park

tractor

before

ser-

vicing

or

making

adjustments

to

tractor

or

attachments.

Failure

to

observe

these

precautions

could

result

in

serious

injury

or

death.

CAUTION:

Place

the

transmission

in

neutral,

set

the

parking

brake

and

stop

the

engine

before

standing

between

the

tractor

and

attachment

when

hitching.

A

A

A

A

before

opera~ing

your

tractor.

CAUTION:

If

necessary

to

move

tractor

on

a

trailer,

al-

ways

back

up

onto

the

trailer

and

drive

off

of

trailer.

CAUTION:

Hydraulic

sys-

tems

are

highly

pressurized.

Escaping

hydraulic

oil,

even

an

invisible

pinhole

leak,

can

penetrate

body

tissues

causing

serious

injury.

Use

a

piece

of

wood

or

cardboard

when

looking

for

leaks

-

never

use

the

hands

or

other

parts

of

the

body.

Relieve

hydraulic

pressure

before

disconnecting

circuits.

When

reassembling,

make

absolutely

certain

that

all

con-

nections

are

tight.

If

injured

by

hydraulic

oil

escaping

under

pressure,

see

a

doctor

immediately.

Serious

complicaitons

may

arise

if

medical

attention

is

not

given

at

once.

CAUTION:

When

adjusting

steering

wheel

free

play

make

certain

that

some

free

play

remains

between

the

sector

gear

and

pinion

gear,

since

a

tight

fit,

with

no

clearance

be-

tween

the

two

gears

may

cause

binding

and

tooth

fail

-

ure.

CAUTION:

When

removing

a

battery,

always

disconnect

the

1-)

negative

ground

cable

first

.

When

installing

the

battery,

always

connect

the

1-)

negative

ground

cable

last.

CAUTION:

Storage

areas

for

Become

thoroughly

familiar

batteries

must

be

well

ventil

-

with

all

tractor

and

attach-

ated

to

prevent

accumulation

ment

controls

before

of

hydrogen

gas

from

newly

operating.

recharged

batteries.

A A

IV

DANGER:

Batteries

produce

explosive

charges.

Keep

sparks,

flame

and

cigarettes

away.

Ventilate

when

charg-

ing

or

using

in

enclosed

space.

Always

shield

eyes

when

working

near

batteries.

CAUTION:

When

working

around

storage

batteries,

re-

member

that

all

of

the

ex-

posed

metal

parts

are

"live".

Never

lay

a

metal

object

across

the

terminals

as

a

spark

or

short

circuit

may

result.

Sparks,

lighted

matches

and

exposed

flames

must

be

kept

away

from

the

battery

due

to

the

presence

of

explosive

gas

in

the

battery.

The

liquid

in

the

batteries

is

acid.

Use

care

not

to

spill

it

on

hands

or

clothing.

POISON:

Batteries

contain

sulfuric

acid

which

can

cause

severe

burns.

Avoid

contact

with

skin,

eyes

or

clothing.

Antidote:

EXTERNAL,

flush

with

water;

INTERNAL,

drink

large

quantities

of

water

or

milk.

Follow

with

milk

of

magnesia,

beaten

egg

or

veg

-

etable

oil.

Call

physician

im-

mediately;

EYES,

flush

with

water

for

15

minutes

and

get

prompt

medical

attention.

Keep

out

of

reach

of

children

.

Remember,

a

careful

operator

is

always

the

best

insurance

against

an

accident.

Give

complete

and

undivided

at-

tention

to

the

job

at

hand.

CAUTION:

Set

parking

brake,

shut

off

engine,

remove

key,

and

wait

until

all

engine

and

attachment

motion

has

stopped

before

dismounting

from

the

operator's

seat.

WARNING:

To

jump

start

this

machine,

connect

pos-

itive

jumper

cable

to

battery

terminal

on

starter

solenoid

and

connect

negative

jumper

cable

to

good

engine

ground

.

Start

engine

only

when

seated

in

operator's

seat.

Stop

en-

gine

before

leaving

machine.

Disconnect

jumper

cables

.

Any

other

method

could

result

in

uncontrolled

machine

movement.

CAUTION:

Never

wear

rings

or

metal

watch

bands

when

working

.

with

the

tractor

electrical

system

or

battery

as

you

may

ground

a

live

circuit.

CAUTION:

Too

much

air

pressure

in

the

tires

can

cause

tire

or

rim

failure

.

Never

put

more

air

pressure

in

a

tire

than

specified

in

the

operator's

manual

or

on

the

sidewall

of

the

tire.

If

the

tire

or

rim

explode

because

of

too

much

pressure,

injury

can

result.

CAUTION

:

Before

attempt-

ing

to

service

the

attachment

Drive

Clutch,

be

sure

to

remove

tractor

key

and

spark

plug

wire(s).

CAUTION:

Only

operate

controls

from

the

operator's

seat

to

prevent

injury.

IMPORTANT:

Always

install

new

decals

whenever

the

old

decals

are

destroyed,

lost,

painted

over

or

illegible.

When

individual

parts

are

replaced

that

have

decals

attached,

be

sure

to

install

a

new

decal

with

the

new

part.

Replacement

decals

are

available

from

your

dealer.

CAUTION:

Do

not

operate

machine

while

under

the

influence

of

alcohol

or

drugs

.

v

HILLSIDE (SLOPE)

OPERATION

Read,

Understand,

Obey:

WARNING:

Improper

opera-

tion

of

your

tractor

on

hill-

A

sides

and

slopes

can

be

dan-

gerous.

Avoid

improper

oper-

ation!

Read

and

follow

the

in-

structions

given

in

the

section

titled

"Hillside

Operation"

in

this

manual

before

operating

you

r

tractor.

Avoid operating tractor on hillsides and slopes.

To

minimize the possibility

of

accidents while operating

on hills

and/or

rough terrain, obey a combination

of

rules, practices and good

common

sense.

These include:

1.

Reading, understanding, and obeying all written

safety messages appearing

on

decals

on

the ma-

chine and in operator's manuals.

2.

Learning from your operator's manual and careful-

ly from EXPERIENCE

how

to

operate your tractor

correctly.

Know

your tractor's limitations.

3. Knowing the terrain on

which

you

are operating

your

tractor. There are terrain conditions on which

your tractor cannot

be

operated!

4. Learning

to

expect changes in operating condi-

tions. Adding or removing attachments or weight

to

your tractor will make your tractor perform dif-

ferently. Rain, snow, loose gravel,

wet

grass, etc.,

change the tractive conditions

of

the terrain re-

quiring changes in your operating technique or

not

to

operate on that terrain.

The following paragraphs will cover these practices

one at a time. Read and study them. The examples

provided are

not

all inclusive

but

will give you a firm

understanding

of

the requirements

for

avoiding acci-

dents while operating your tractor.

Ingersoll Lawn and Garden Tractors are designed and

built

to

comply

with

the Voluntary Standard

ANSI

(American National Standards Institute).

THE OPERATOR

IS

THE SOLE JUDGE

AS

TO THE

DEGREE

OF

SLOPE ON

WHICH

THIS TRACTOR

CAN

BE

SAFELY OPERATED. IF

IN

DOUBT

THAT

THIS TRACTOR CAN

BE

SAFELY OPERATED ON A

PARTICULAR SLOPE,

DO

NOT OPERATE ON

THAT

SLOPE! COMMON SENSE

MUST

PREVAIL.

VI

Safety messages are found on the tractor and in the

operator's manuals. These must be understood by the

tractor operator

to

be

of

value.

Be

sure that these mes-

sages are studied before starting

and/or

operating the

tractor by

an

operator not familiar

with

this particular

tractor.

learn

to

Operate:

Learn your tractor's controls

from

decals on the trac-

tor and from instructions in

the

operator's manual.

Practice

how

to

properly manipulate these controls.

Practice must be done in a flat area, clear

of

obstacles

and bystanders. Learn your tractor's operating charac-

teristics and limitations. These include:

a.

amount

of

engine power available

b. engine governor response

c. tractive ability

d. steering characteristics

e.

braking characteristics

f.

movement of.travel lever

g. forward and reverse ground speeds

h. speed

of

attachment

lift

i. and others

Attempting

any operation

which

approaches or ex-

ceeds the tractor's limitation is risking

an

accident.

Know

the

Terrain:

Know

the terrain on which you are working. Find hid-

den obstacles

by

walking through and inspecting the

area prior

to

operating your tractor on it. Mark ob-

stacles, such as, rocks, ruts or holes

with

a 6 ft. long

pole and red flag and stay well clear

of

these obstacles

when operating.

Operate your tractor at a ground speed

slow

enough

to

insure complete control at all times.

Place the transmission in

low

gear and regulate the

throttle control lever slowly and

smoothly

to

maintain

this safe speed. Do

not

stop on a hill or slope

to

change gears.

-

Always drive in a

forward

direction

when

proceeding

downhill. Never drive

up

a hill. If necessary, back up a

hill

to

the desired position. Always back up loading

ramps and tilt bed trailers. If necessary

to

turn

while

on

a hill, always turn

downward

.

Your judgement, based on operating experience is

the

final

word

in deciding

if

you should negotiate

any

given hill or slope. If you are in

doubt

about safety,

STAY OFF THE SLOPE.

Under no circumstances should an inexperienced

op

-

erator

attempt

to

use

your

tractor

on

slopes

or

hill-

sides.

You may encounter some terrain on

which

your

trac-

tor

cannot be operated even

if

a

different

piece

of

equipment has operated there in the past.

Learn

to

Compensate

for

Changes

in

Operating

Conditions

:

Adding

or

removing attachments

or

ballast (such as

wheel

weights

or fluid) change the

weight

and

weight

distribution

of

your

tractor

and, therefore, changes

your

tractor's

operating characteristics.

Be

alert

to

these changes. Practice operating

the

trac-

tor

after each change has been made.

Adding

an attachment (weight) to the rear

of

the trac-

tor reduces the

weight

on

the

front

axle.

Adding

an

at-

tachment

(weight)

to

the

front

of

the

tractor

reduces

weight

on

the rear

of

the

tractor

. You

must

add coun-

terweight

to

the

front

if

a rear

mounted

attachment is

installed. You

must

add

counterweight

to

the rear if a

front

mounted

attachment

is installed.

Tractive conditions will vary

with

weather

and terrain

and equipment.

Areas

wet

with

dew

or

rain will be

more

slippery than

when

dry

. Areas covered

with

loose gravel are more

slippery than firm

dry

ground.

Greater stopping dis-

tances are required

in

these slippery areas.

Spinning

rear wheels tend

to

move

the

tractor side-

ways. The addition

of

tire chains will provide more

traction

to

the

rear wheels in the forward-reverse di-

rection

but

less stability in the si

deways

direction.

Chains will cause more

abrupt

starting and stopping.

The final

word

in safe

tractor

operation rests on

your

judgement.

If

in

doubt

of

your

safety,

STAY

OFF THE SLOPE.

VII

FIGURE

1

" 1 "

TO

THE

OWNER

The Maintenance you give

your

new

tractor is impor-

tant. Use this manual

as

your

guide.

Follow

these

instructions and tips

to

make sure your

tractor

oper-

ates

efficiently

for

many years.

We

are a

factory

authorized dealer.

We

have replace-

ment parts

which

are the same

as

the original equip-

ment.

If you need additional aid or information,

contact

us.

CY()tMt

~

9eak

NOTE: Ingersoll Equipment Co., Inc. reserves the

right

to

make improvements in design

or

changes in specifications at any

time

without

incurring any obligation

to

install

them

on

units

previously sold.

IMPORTANT

This

manual

covers

many

different

NOTE:

model

tractors.

The

illustrations

us-

ed in

this

manual

may

not

be

of

your

tractor.

NOTICE

A spark arrester

or

spark arrester muffler

must

be used

on some machines. Check the laws in

your

area.

Some states have regulations

for

the use

of

this ma-

chine in agriculture, forestry and construction. These

laws control the maintenance

of

spark arrester equip-

ment. These laws also control

the

installation

of

spark

arrester

equipment

on the exhaust system

of

naturally

aspirated engines (engines

without

a turbocharger).

RADIO

INTERFERENCE

REGULATIONS

OF

CANADA

Tractors taken

into

Canada after September

1,

1976

must have resistor spark plugs,

Resistor spark plugs and resistor wires

for

the

spark

plug

must

be

used

for

replacement.

Printed in U.S.A. 10-96-RP-1000-119

-

-------

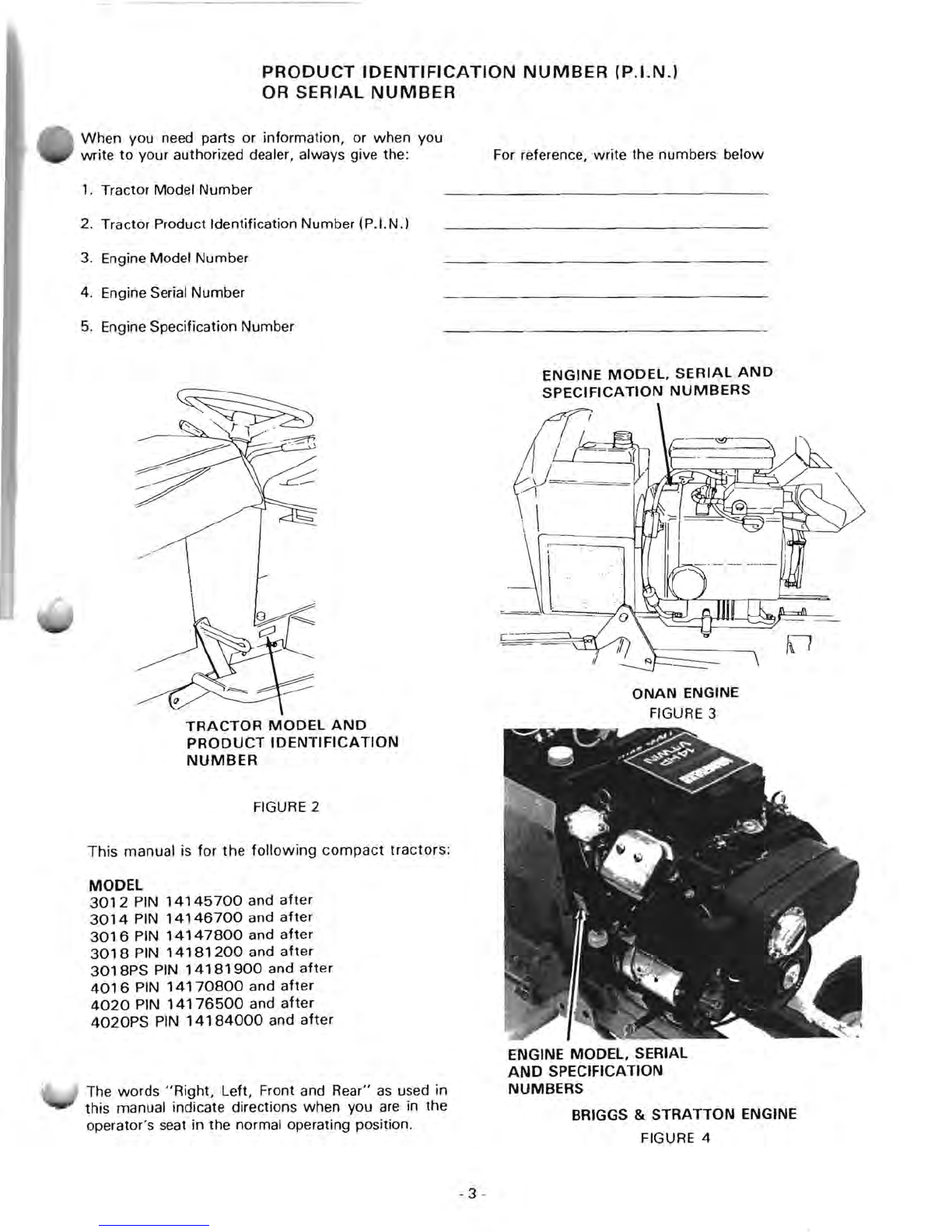

PRODUCT

IDENTIFICATION

NUMBER

(P.I.N.)

OR

SERIAL

NUMBER

When

you need parts or information, or when you

write

to

your authorized dealer, always give the: For reference, write the numbers below

1.

Tractor Model Number

2. Tractor Product Identification Number

(P.1.

N.)

3. Engine Model Number

4. Engine Serial Number

5.

Engine Specification Number

ENGINE

MODEl,

SERIAL

AND

SPECIFICATION

NUMBERS

ONAN

ENGINE

FIGURE 3

TRACTOR

MODEl

AND

PRODUCT

IDENTIFICATION

NUMBER

FIGURE 2

This

manual

is

for

the

following

compact

tractors:

MODEl

3012

PIN

14145700

and

after

3014

PIN

14146700

and

after

3016

PIN

14147800

and

after

3018

PIN

14181200

and

after

3018PS

PIN

14181900

and

after

4016

PIN

14170800

and

after

4020

PIN

14176500

and

after

4020PS

PIN

14184000

and

after

The

words

"Right,

Left, Front and Rear"

as

used in

this manual indicate directions

when

you are in the

operator's seat in the normal operating position.

- 3 -

ENGINE

MODEL,

SERIAL

AND

SPECIFICATION

NUMBERS

BRIGGS &

STRATTON

ENGINE

FIGURE 4

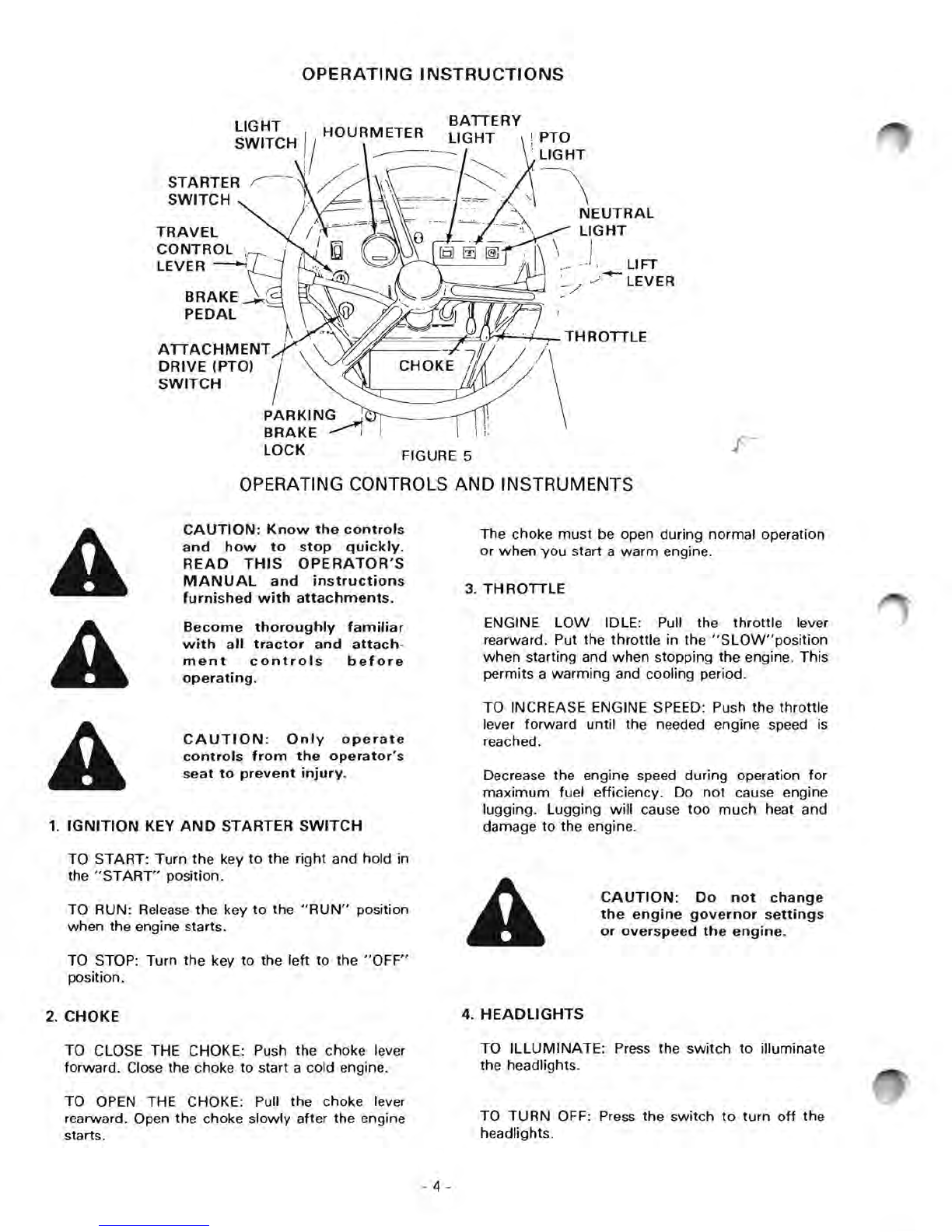

OPERATING

INSTRUCTIONS

NEUTRAL

THROTTLE

1\

PARKING

' r<

BRAKE

~

\

'

I'

\,

LOCK

F

FIGURE 5

OPERATING CONTROLS

AND

INSTRUMENTS

A

CAUTION:

Know

the

controls

The choke

must

be open during normal operation

and

how

to

stop

quickly.

or

when

you

start a

warm

engine.

READ

THIS

OPERATOR'S

MANUAL

and

instructions

3.

THROTTLE

furnished

with

attachments.

A ENGINE

LOW

IDLE: Pull the

throttle

lever

Become

thoroughly

familiar

rearward. Put the

throttle

in the

"SLOW"position

with

all

tractor

and

attach-

when

starting and

when

stopping

the

engine. This

ment

controls

before

permits a

warming

and cooling period.

operating.

TO INCREASE ENGINE SPEED: Push

the

throttle

A lever

forward

until the needed engine speed is

CAUTION:

Only

operate

reached.

controls

from

the

operator's

seat

to

prevent

injury.

Decrease the engine speed during operation

for

maximum

fuel efficiency. Do

not

cause engine

lugging. Lugging

will

cause

too

much

heat and

1.

IGNITION

KEY

AND

STARTER

SWITCH

damage

to

the engine.

TO START: Turn

the

key

to

the right and hold in

the

"START"

position.

CAUTION:

Do

not

change

TO RUN: Release

the

key

to

the "

RUN"

position

the

engine

governor

settings

when the engine starts.

or

overspeed

the

engine.

A

TO STOP: Turn

the

key

to

the

left

to

the

"OFF"

position.

2.

CHOKE

4.

HEADLIGHTS

TO CLOSE THE CHOKE: Push the choke lever TO

ILLUMINATE:

Press the

switch

to

illuminate

forward. Close the choke

to

start a cold engine. the headlights.

TO OPEN THE CHOKE: Pull

the

choke lever

rearward. Open the choke slowly after the engine TO

TURN

OFF: Press

the

switch

to

turn

off

the

starts. headlights.

- 4 -

5.

BATTERY

VOLTAGE

INDICATOR

LIGHT

The battery voltage indicator light will illuminate

when the battery voltage is

low

and

will

go

out

when the

battery

voltage

is

acceptable.

It is normal

for

the

light

to

illuminate when the

tractor

is

first started after a period

of

non-use and

to

glow

when the tractor engine is operated at

low

idle speed.

Stop

the engine and have the problem corrected

if

the indicator light does

not

go

out

after running

the engine at normal operating speed

after

a

few

minutes

of

operation.

It is normal

for

the Battery Voltage Indicator

light

to

remain

out

if

the engine is stopped

when

the

battery is fully charged and the ignition key is

turned to the

"run"

position.

6.

HOUR

METER

The electric hourmeter records hours

of

operation

whenever

the

key

is

in the

"RUN"

position.

Utilize the hourmeter

to

meet the required

maintenance schedule.

7.

BRAKE

PEDAL

TO ACTUATE THE BRAKE: Push the brake pedal

fully

down.

This action will return the travel control

to

the

"NEUTRAL"

position.

The tractor will come

to

a

quick

stop.

NOTE: Do

not

use the above method

if

possible.

Stop

the

tractor

with

the travel control lever.

The tractor can be stopped

smoothly

by

slowly

returning

the

travel

control

lever

to

the

"NEUTRAL"

position.

Actuate

the brake fully

if

you can

not

stop

the trac-

tor

with

the travel control lever.

See

the Operating Procedure Section

of

this manual

for

a more complete description

of

stopping travel.

8.

PARKING

BRAKE

LOCK

TO ENGAGE: Push the brake pedal fully

down.

Push

down

on the parking brake lock.

TO DISENGAGE: Push the brake pedal a small

amount

and release.

A spring will disengage the parking brake lock.

9.

HYDRAULIC

ATTACHMENT

LIFT LEVER

TO LIFT: Run the engine

Pull the lever rearward.

Release the lever when

the

needed height is

reached.

TO LOWER: Run the engine.

Push the lever forward a small amount.

Release the lever when

the

needed height

is

reached.

When

you release this lever, a spring will auto-

matically return the lever

to

the

"NEUTRAL"

position.

THE

"FLOAT"

POSITON: Push the lever fully for-

ward

.

A detent holds the lever in the

"FLOAT"

position.

The lever must

be

manually returned

to

the

"NEUTRAL"

position

from

the

"FLOAT"

position.

The

"FLOAT"

position prevents hydraulic

down

pressure

on

the attachment.

See the instructions included

with

each attachment

for

correct attachment

lift

lever use.

10.

ATTACHMENT

DRIVE

(PTO)

SWITCH

TO ENGAGE: Pull

switch

toggle

out

and push up-

ward.

See

Attachment

Drive Clutch Break-in pro-

cedure in maintenance section in this manual

before operating your attachment.

The center dash panel indicator

light

will

illuminate

when

the attachment drive

switch

is

on

.

TO DISENGAGE: Push

switch

down.

The center dash panel indicator light will

go

out

when the attachment drive

switch

is

off.

NOTE: The

attachment

drive

switch

must

be

off

before

you

can

start

the

engine

.

- 5 -

--- -

TRAVEl

~

CONTROL

LEVER

DUAL

RANGE

TRANSAXLE

BRAKE

\

L

~

=

~

PEDA~

~

~

FIGURE 6

EARLY STYLE RANGE

SHIFT

,"~=/J<L=_)Jk

I!~~

i

I

~

HYDRAULIC

: ,

DUAL

RANGE

f:~~?

~~EVER

>1~J/

TRANSAXLE

FIGURE

6A

CURRENT STYLE RANGE SHIFT

11.

DUAL

RANGE

TRANSAXLE

(EARLY STYLE)

TO SELECT

LOW

RANGE: Put the travel control

lever in the

"NEUTRAL"

position.

Stop the tractor.

Pull the lever forward a small

amount

to

go over the

neutral locating pin.

Pull the lever up beyond the neutral locating pin and

release.

TO SELECT NEUTRAL: Put the travel control lever

in the

"NEUTRAL"

position.

Stop the tractor.

Pull the lever forward a small

amount

to

go over the

neutral locating pin.

Align the hole in the lever

with

the neutral locating

pin and release the lever.

TO SELECT HIGH RANGE: Put the travel control

lever in the

"NEUTRAL"

position.

Stop

the tractor.

Pull the lever forward a small

amount

to

go over the

neutral locating pin.

Push the lever

down

beyond the neutral locating

pin and release.

If the range

shift

does

not

move easily, rotate the

gears.

To rotate the gears:

1.

move the travel control lever a small amount

into

the

"FORWARD"

position.

2. return the travel

control

lever

to

the

"NEUTRAL"

position.

IMPORTANT:

The range

shift

lever

must

be beyond

the neutral locating pin while in

"LOW"

or

"HIGH"

range. If the lever

is

not

in the correct position, damage

to the gears will result.

DUAL

RANGE

TRANSAXLE

(CURRENT STYLE)

TO SELECT

LOW

RANGE: Put

travel

control

lever in

"NEUTRAL"

position

.

Stop

tractor.

Push lever

down

and

to

left.

Release lever

up

into

"LOW

RANGE"

notch.

TO

SELECT NEUTRAL: Put

travel

control

lever in

"NEUTRAL"

POSITION.

Stop

tractor

.

Push lever

down

and

move

lever

to

align

with

"NEUTRAL"

notch

and release.

TO

SELECT HIGH RANGE: Put

trave

l

control

lever

in

"NEUTRAL"

position

.

Stop

tracto

r.

Push lever

down

and

to

right.

Release lever

up

into

"HIGH

RANGE"

notch.

- 6 .

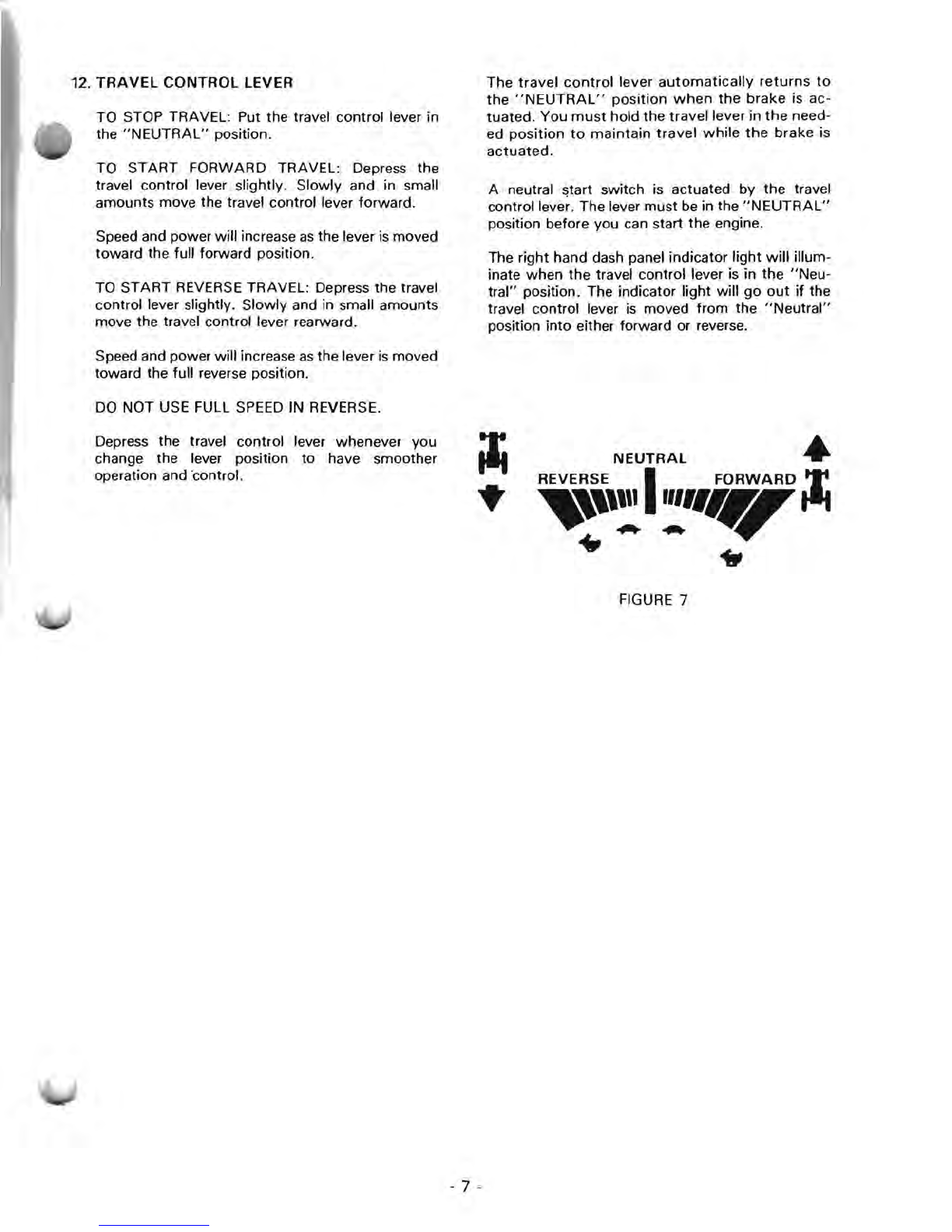

12.

TRAVEL

CONTROL

LEVER

TO STOP TRAVEL: Put

the

travel

control

lever in

the

"NEUTRAL"

position.

TO

START

FORWARD TRAVEL: Depress the

travel control lever slightly.

Slowly

and in small

amounts move the travel control lever

forward.

Speed and power will increase

as

the lever

is

moved

toward

the full forward position.

TO

START

REVERSE TRAVEL: Depress

the

travel

contro

l lever slightly.

Slowly

and in small amounts

move the travel control lever rearward.

Speed and power

will

increase

as

the lever

is

moved

toward the full reverse position.

DO

NOT USE FULL SPEED IN REVERSE.

Depress the travel control lever whenever

you

change the lever position

to

have smoother

operation and ·control.

The

travel

control

lever

automatically

returns

to

the

"NEUTRAL"

position

when

the

brake

is

ac-

tuated.

You

must

hold

the

travel

lever in

the

need-

ed

position

to

maintain

travel

while

the

brake

is

actuated.

A neutral start

switch

is actuated by

the

travel

controlleve~.

The lever

must

be in the

"NEUTRAL

"

position before you can start the engine.

The right hand dash panel indicator

light

will

illum-

inate

when

the

travel control lever

is

in

the

"Neu-

tral"

position. The indicator

light

will

go

out

if

the

travel control lever is moved

from

the

"Neutral"

position

into

either forward or reverse.

NEUTRAL

""".1

If"~,.

iii

...~

...

"

...

FIGURE 7

- 7 -

PRESTARTING CHECK LIST

A

A

A

CAUTION

:

Read

operator's

manuals.

Know

location

and

function

of

all

controls.

Keep

all

shields

and

safety

switches

functional.

Before

starting

engine:

dis-

engage

attachment

drive

and

place

travel

control

in

neutral.

Remove

objects

from

the

terrain

that

could

be

thrown

by

the

attachment

.

Keep

people

and

pets

a

safe

distance

away.

Never

carry

passengers.

Always

look

behind

tractor

before

backing.

On

any

incline

that

the

trac-

tor

can

be

safely

operated

use

low

range/gear.

Front

end

tip

over

can

occur

when

operating

on

loading

ramps

or

hills,

back

up

ramps

or

hills.

Drive

forward

going

down

ramps

or

hills

.

To

park

tractor:

place

travel

control

in

neutral,

set

parking

brake,

disengage

attachment

drive.

shut

engine

off

and

re-

move

key.

Park

tractor

before

servic-

ing

or

making

adjustments

to

tractor

or

attachments.

Failure

to

observe

these

precautions

could

result

in

serious

injury

or

death.

CAUTION:

Do

not

wear

loose

clothing

which

may

catch

in

moving

parts.

CAUTION:

Disengage

power

to

attachmentls)

and

stop

the

engine

(motor)

before

making

any

repairs

or

adjustments.

1.

Use

only

clean fuel, oil, container and funnel.

2.

Apply

oil

or

grease

to

all

the

specified

points

shown

in the Lubrication Chart.

3. Check

the

oil level in the engine

and

add oil

as

re-

quired.

4. Check the engine air cleaner and air intake screen

for

dirt

or

obstructions

. Clean

as

required.

CAUTION:

Handle

gasoline

with

care

-

it

is

highly

flam-

mable.

a.

Use

approved

gasoline

container

.

A b.

Never

remove

the

fuel

cap

of.

or

add

gasoline

to,

a

running

or

hot

engine

or

an

engine

that

has

not

been

allowed

to

cool

for

several

minutes

after

running.

Never

fill

the

tank

indoors

and

always

clean

up

spilled

gasoline.

c.

Open

doors

if

the

engine

is

run

in

the

garage

-

ex-

haust

fumes

are

danger-

ous.

Do

not

run

the

en

-

gine

indoors.

A

CAUTION:

Do

not

smoke

when

working

near

fuel.

5.

Fill the fuel tank

with

clean fuel. Clean the area

around

the

fuel cap before you remove the cap.

The requirements are listed in

the

Fuel Specifica-

tions

Section

of

this manual.

6. Check the ventilation hole in fuel tank cap and

clean

as

required.

7. Check all operating

controls

and

instruments

for

correct

function

before using

the

tractor

.

BREAK-IN

PROCEDURE

Controlled

break-in

is

the

ideal

fitting

of

all

internal

moving

metal

parts.

Using

the

proper

oil

and

apply-

ing

a

conscientious

maintenance

program

during

this

period

helps

assure

satisfactory

service

from

your

engine

.

Maintain the

proper

cooling

and lubrication

during

break-in. Run

the

engine at half load

for

the

first three

- 8 -

hours

with

intermittent

periods

of

full

load

to

control

engine break-in.

Check

the

oil level at least every five operating

hours

.

Add

oil

to

keep it at

the

proper

level,

but

never overfill

as

overfilling

may

cause the oil

to

foam

and enter

the

breather system, resulting in high oil

consumption

and

oil

accumulation

in air cleaner

housing

.

STARTING PROCEDURE (Operating the Tractor)

CAUTION:

Only

operate

con·

6.

Pull the choke lever rearward

slowly

after the

trois

from

the

operator's

seat

engine starts running.

to

prevent

injury.

7. Permit the engine

to

warm

before applying a load.

CAUTION:

Do

not

wear

NOTE:

The hydraulic system

must

be

warm

before

loose

clothing

which

may

you

use the

tractor

when

air temperatures are

catch

in

moving

parts.

less than 32°F (O°C). Use the

following

pro-

cedure:

NOTICE:

Your

new

tractor

is

equipped

with

a

switch

under

the

seaL

a.

Set the

throttle

1/3

of

the

way

between the

The

tractor

engine

will

stop

if

you

get

off

the

seat

"SLOW"

and

"FAST"

position.

when

the

attachment

drive

clutch

is in

the

"ON"

position, or

the

travel

control

lever is in

"FORWARD"

b. Select the

"NEUTRAL"

position

of

the dual

or

"REVERSE"

position.

range transaxle.

c.

Move

the travel

control

lever

to

the full

1-

Put

the

travel control lever in the

"NEUTRAL"

"FORWARD"

position.

position.

d. Run

for

several

minutes

before operating the

2. Put the attachment drive

switch

in

the

"Off"

posi-

tractor.

A noise can occur

when

the

hydraulic

tion. system is cold.

CAUTION:

Disengage

all

at-

tachment

clutches

and

shift

into

neutral

before

attempting

to

start

the

engine

(motor).

IMPORTANT:

DO

NOT

TRY

TO

START

THE TRAC-

TOR BY PUSHING OR

TOWING.

3. Push the choke lever forward to close the choke. SERIOUS

DAMAGE

WILL

RESULT

TO THE DRIVE

SYSTEM.

The choke setting will change according

to

the air

temperature, engine temperature, and grade

of

fuel.

Separate

Operator's

Manuals

are

provided

with

the

attach-

4. Push the

throttle

lever forward approximately

1/3

ments

purchased

with

your

of

the

way

between the

"SLOW"

and

"FAST'

tractor.

Refer

to

the

apprq-

positions.

priate

attachment

operators

manual

for

specific

operating

CAUTION:

Do

not

allow

child-

instructions

and

safety

ren

to

operate

the

machine.

messages

that

apply

to

the

Do

not

allow

adults

to

operate

attachment.

it

without

proper

instruction.

Remember,

a

careful

operator

CAUTION:

Do

not

carry

pas-

is

always

the

best

insurance

sengers.

Do

not

mow

when

against·

an

accident.

Give

children

and

others

are

complete

and

undivided

at-

around.

tention

to

the

job

at

hand.

5.

Turn

the ignition key

to

the right and hold in the

"START"

position. Release the key

to

the

"RUN"

position

when

the engine starts running.

NOTE:

Release the key immediately

when

the engine

starts. If you hold the key in the

"START'

position after the engine is

running

damage

can occur. Release the key after 30 seconds

if

the engine does

not

start running.

Wait

3

minutes before you

try

again.

- 9 -

STOPPING PROCEDURE (OPERATING THE TRACTOR)

START

SWITCH

...........

TRAVEl

~

.-

CONTROL~'

-

lEVER

.

BRAKE

,~

/

THROTTLE

PEDAL

FIGURE 8

A

CAUTION:

Know

the

controls

6.

Turn the key

to

the left

to

the

"OFF"

position.

and

how

to

st<:>p

quickly.

READ

THIS

OPERATOR'S

MANUAL

and

instructions

furnished

with

attachments

.

NOTE:

Muffler

after bang can

be

prevented by

closing

the

choke at the same time the key

switch is turned

to

the

"OFF"

position. This

action prevents the entry

of

air

into

the

1.

Slowly

move

the

travel control lever

to

the muffler

as

the engine comes

to

a stop and

"NEUTRAL"

position. therefore prevents combustion

within

the

muffler.

2. Completely

stop

the tractor.

Actuate

the brake

pedal

if

necessary.

7.

Remove the ignition key.

3. Engage the parking brake lock.

4.

Pull the

throttle

lever rearward

to

the

"SLOW"

CAUTION

:

Take

all

possible

A

position.

precautions

when

leaving

the

vehicle

unattended,

such

as

5. Permit the engine

to

cool. Run the engine

at

idle

for

disengaging

the

power

take-

several minutes

if

the

work

load was severe.

off.

lowering

the

attachment

Is1.

shifting

into

neutral,

setting

the

parking

brake,

stopping

the

engine.

and

re-

CAUTION:

Set

parking

brake,

moving

the

key

.

A

shut

off

engine.

remove

key

and

wait

until

all

engine

and

attachment

motion

has

stop-

CAUTION

:

Disengage

ped

before

dismounting

from

power

to

attachment!s)

when

the

operator's

seat.

transporting

or

not

in

use

.

A

-

10

-

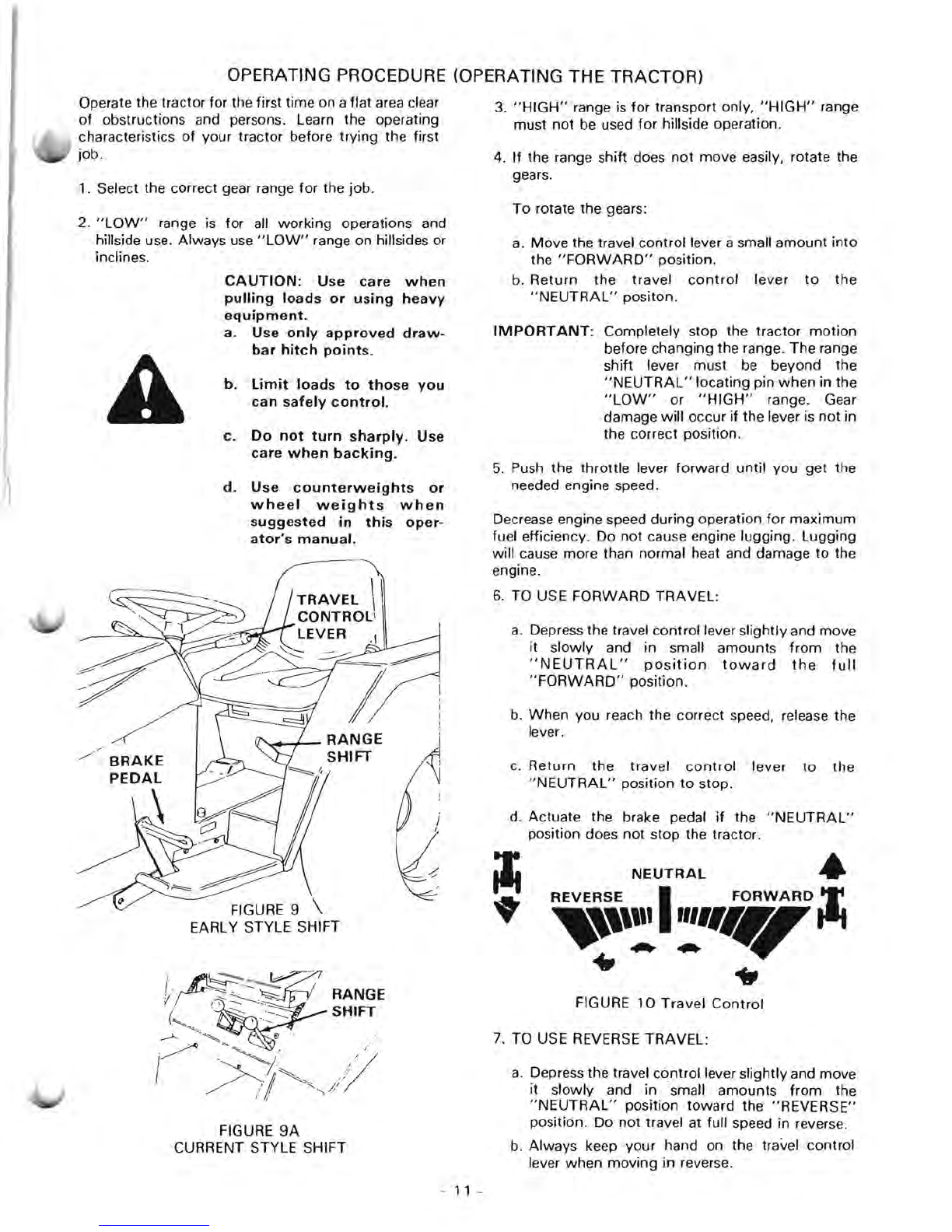

OPERATING PROCEDURE (OPERATING THE TRACTOR)

Operate the tractor for the first time on a flat area clear

of obstructions and persons. Learn the operating

characteristics

of

your tractor before trying the first

job.

1.

Select the correct gear range for the job.

2.

"LOW"

range

is

for all working operations and

hillside use. Always use

"LOW"

range on hillsides or

inclines.

CAUTION:

Use

care

when

pulling

loads

or

using

heavy

equipment.

a.

Use

only

approved

draw-

bar

hitch

points.

b.

limit

loads

to

those

you

can

safely

control.

c.

Do

not

turn

sharply.

Use

care

when

backing.

d.

Use

counterweights

or

wheel

weights

when

suggested

in

this

oper-

ator's

manual.

~......,._RANGE

SHIFT

FIGURE 9 \

EARLY STYLE SHIFT

FIGURE

9A

CURRENT STYLE SHIFT

3.

"HIGH"

range

is

for

transport only,

"HIGH"

range

must

not

be used

for

hillside operation.

4.

If the range shift does

not

move easily, rotate the

gears.

To

rotate the gears:

a. Move the travel control lever a small

amount

into

the

"FORWARD"

position.

b. Return the

travel

control

lever

to

the

"NEUTRAL"

positon.

IMPORTANT:

Completely stop the tractor

motion

before changing the range. The range

shift lever must

be

beyond the

"NEUTRAL"

locating pin

when

in the

"LOW"

or

"HIGH"

range. Gear

damage will occur

if

the lever is

not

in

the correct position.

5.

Push the

throttle

lever

forward

until you get the

needed engine speed.

Decrease engine speed during operation for maximum

fuel eHiciency. Do not cause engine lugging. Lugging

will cause more than normal heat and damage

to

the

engine.

6.

TO USE FORWARD TRAVEL:

a. Depress the travel

control

lever slightly and move

it

slowly and in small amounts

from

the

"NEUTRAL"

position

toward

the

full

"FORWARD"

position.

b.

When

you reach the correct speed, release the

lever.

c.

Return

the

travel

control

lever

to

the

"NEUTRAL"

position

to

stop.

d. Actuate the brake pedal

if

the

"NEUTRAL"

position does not stop the tractor.

NEUTRAL

~

."'"I

JI'.~

FORWARD

jIf

...

~

--

FIGURE

10

Travel

Control

7. TO USE REVERSE TRAVEL:

a.

Depress the travel control lever slightly and move

it

slowly and in .small amounts from the

"NEUTRAL"

position

toward

the "REVERSE"

position. Do not travel at full speed in reverse.

b. Always keep your hand on the travel control

lever

when

moving in reverse.

-11 -

This manual suits for next models

6

Table of contents

Other Ingersoll Tractor manuals