INHENERGY SI 50K User manual

INHENERGY CO., LTD.

User Manual

SI 50K, SI 60K, SI 70K, SI 80K

-1-

CONTENTS

1 NOTES ON THIS MANUAL.......................................................................................................- 3 -

1.1 VALIDITY.................................................................................................................................. - 3 -

1.2 SYMBOLS IN THIS DOCUMENT.........................................................................................- 3 -

2 OVERVIEW.....................................................................................................................................- 4 -

2.1 PRODUCT INTRODUCTION................................................................................................ - 4 -

2.2 APPEARANCE......................................................................................................................... - 5 -

3 INSTALLATION.............................................................................................................................- 6 -

3.1 CHECK FOR PHYSICAL DAMAGE...................................................................................... - 6 -

3.2 PACKING LIST......................................................................................................................... - 6 -

3.3 MOUNTING.............................................................................................................................- 7 -

3.4 SPACE REQUIREMENT..........................................................................................................- 9 -

3.5 MOUNTING STEPS................................................................................................................- 9 -

4 ELECTRICAL CONNECTION...................................................................................................- 10 -

4.1GRID CONNECTION............................................................................................................ - 10 -

4.2 PV CONNECTION................................................................................................................- 11 -

4.3 485 CONNECTION..............................................................................................................- 13 -

4.4 TURN-OFF THE INVERTER................................................................................................ - 14 -

5 POWERING ON THE SYSTEM...............................................................................................- 14 -

5.1 START-UP THE INVERTER................................................................................................. - 14 -

5.2 FIRST RUN TIME SETTING................................................................................................ - 14 -

6 LCD OPERATION....................................................................................................................... - 14 -

7 MAINTENANCE AND CLEANING....................................................................................... - 16 -

7.1 MAINTAIN PERIODICALLY................................................................................................ - 16 -

7.2 TROUBLE SHOOTING.........................................................................................................- 16 -

User Manual

-2-

8 DECOMMISSIONING...............................................................................................................- 16 -

8.1 REMOVE THE INVERTER....................................................................................................- 18 -

8.2 PACKAGING.......................................................................................................................... - 18 -

8.3 STORAGE AND TRANSPORTATION................................................................................- 18 -

9 TECHNICAL DATA.....................................................................................................................- 18 -

10 MANUFACTURER WARRANTY..........................................................................................- 18 -

11 CONTACT.................................................................................................................................. - 20 -

-3-

1 Notes on this manual

1.1 Validity

This manual describes the assembly, installation, commissioning and maintenance of

the following Inhenergy Inverter model:

SI 50K

SI 60K

SI 70K

SI 80K

Target Group

This manual is for qualified personnel. Qualified personnel have received training and

have demonstrated skills and knowledge in the construction and operation of this

device. Qualified Personnel are trained to deal with the dangers and hazards involved in

installing electric devices.

Additional information

Find further information on special topics in the download area at www.inhenergy.com

The manual and other documents must be stored in a convenient place and be available

at all times. We assume no liability for any damage caused by failure to observe these

instructions. For possible changes in this manual, Inhenergy Co., Ltd. accepts no

responsibilities to inform the users.

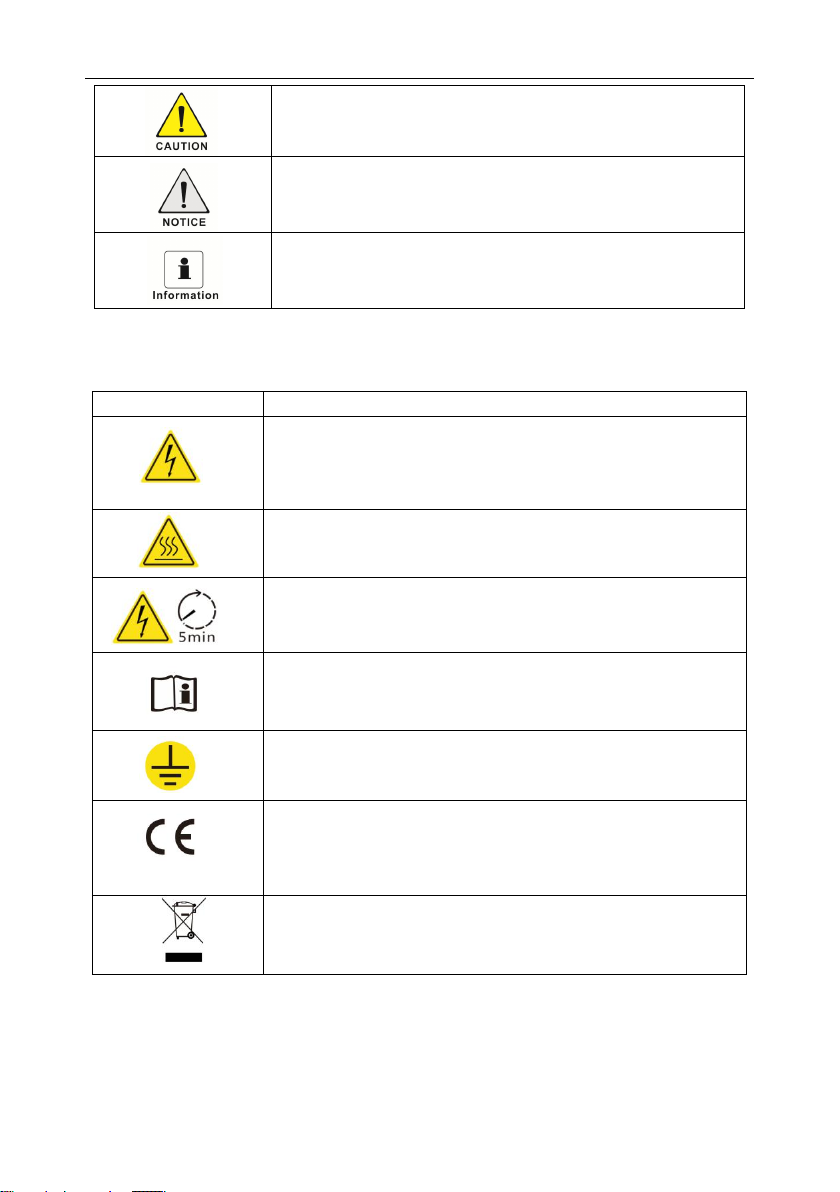

1.2 Symbols in this document

Please pay close attention to all the symbols for the purpose of avoiding possible personal

injury or equipment break down.

Symbol

description

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

User Manual

-4-

Markings on this product

2 Overview

2.1 Product Introduction

Function

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal

injury

Information that you must read and know to ensure

optimal operation of the system.

Symbol

Explanation

Caution,risk of electric shock

Caution,hot surface

Operation after 5 minutes

Read the manual

Point of connection for grounding protection

CE mark.

The inverter complies with the requirements of the

applicable CE guidelines.

The inverter must not be disposed of with the household

waste.

User Manual

-5-

The Inverters is a three-phase grid-tied PV string inverter that converts the DC power

generated by PV strings into AC power and feeds the power into the power grid.

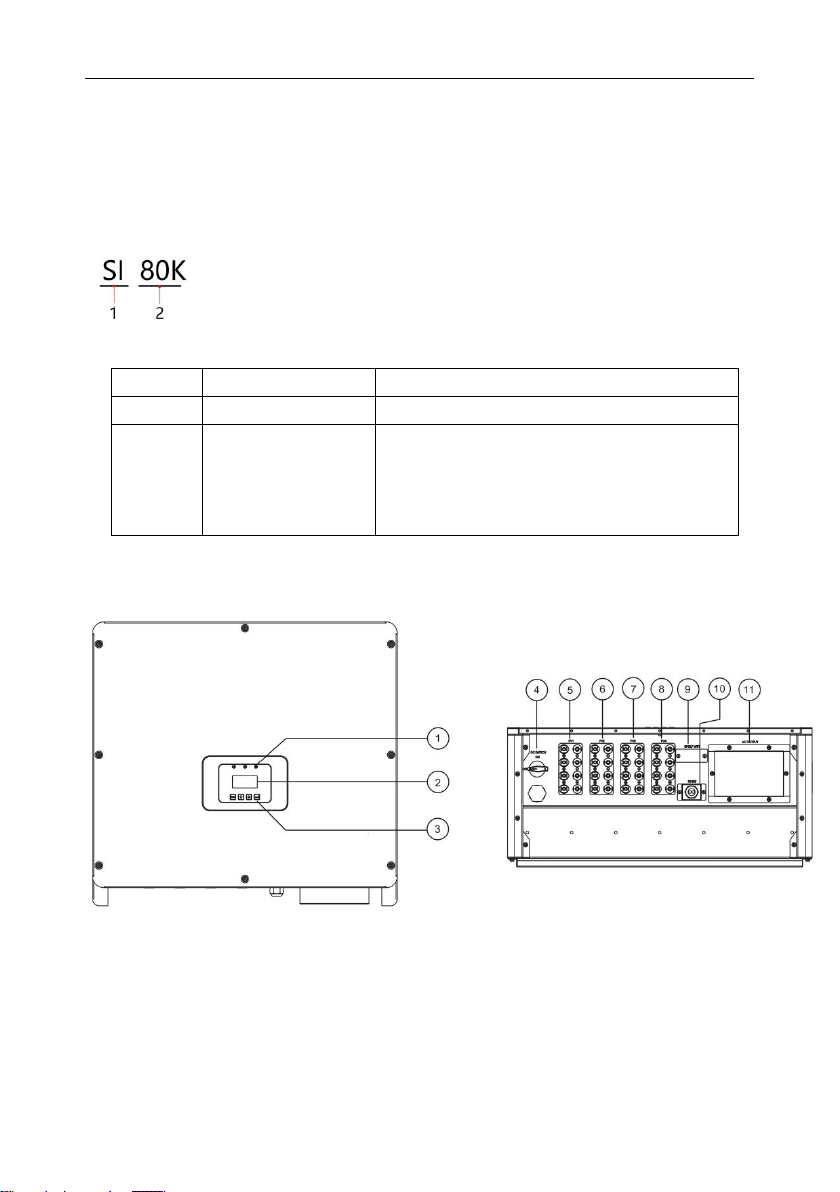

Models

This document involves the following product models:

SI 50K,SI 60,SI 70K,SI 80K;

Model description (,SI 80K is used as an example)

Model description

2.2 Appearance

1.LED indicator 2. LCD display 3. Function button 4. DC switch

5.DC input terminals (PV1) 6. DC input terminals (PV2) 7. DC input terminals (PV3)

8. DC input terminals (PV4) 9. GPRS/WIFI output port 10.Communication port (RS485)

11. AC output port

Icon

Meaning

Description

1

Product

the grid-tied PV string inverter

2

Power level

50K :The rated power is 50 kW.

60K :The rated power is 60 kW.

70K :The rated power is 70 kW.

80K :The rated power is 70 kW.

User Manual

-6-

LED indicator description

Function button description

3 Installation

3.1 Check for Physical Damage

Make sure the inverter is intact during transportation. If there is any visible damage,

such as cracks, please contact your dealer immediately.

3.2 Packing List

Open the package and take out the product, please check the accessories first.

The packing list shown as below.

Category

Status

Meaning

Blinking green at short intervals

waiting status

Blinking green at long intervals

Self-check

Steady green

normal status

Steady yellow

Alarm

Off

No alarm

Blinking red at short intervals

Fault

Off

faultless

Category

Description

ESC button: Return from current interface or function.

Down button: Move cursor to downside or decrease

value

Up button: Move cursor to upside or increase value.

OK button: Confirm the selection.

User Manual

-7-

*C : SI 50K PV connectors (9*positive,9*negative);

SI 60K /70K PV connectors (12*positive,12*negative);

SI 80K PV connectors (16*positive,16*negative);

*D: SI 50K PV pin connectors (5*positive,5*negative);

SI 60K /70K PV pin connectors (12*positive,12*negative);

SI80K PV connectors (16*positive,16*negative);

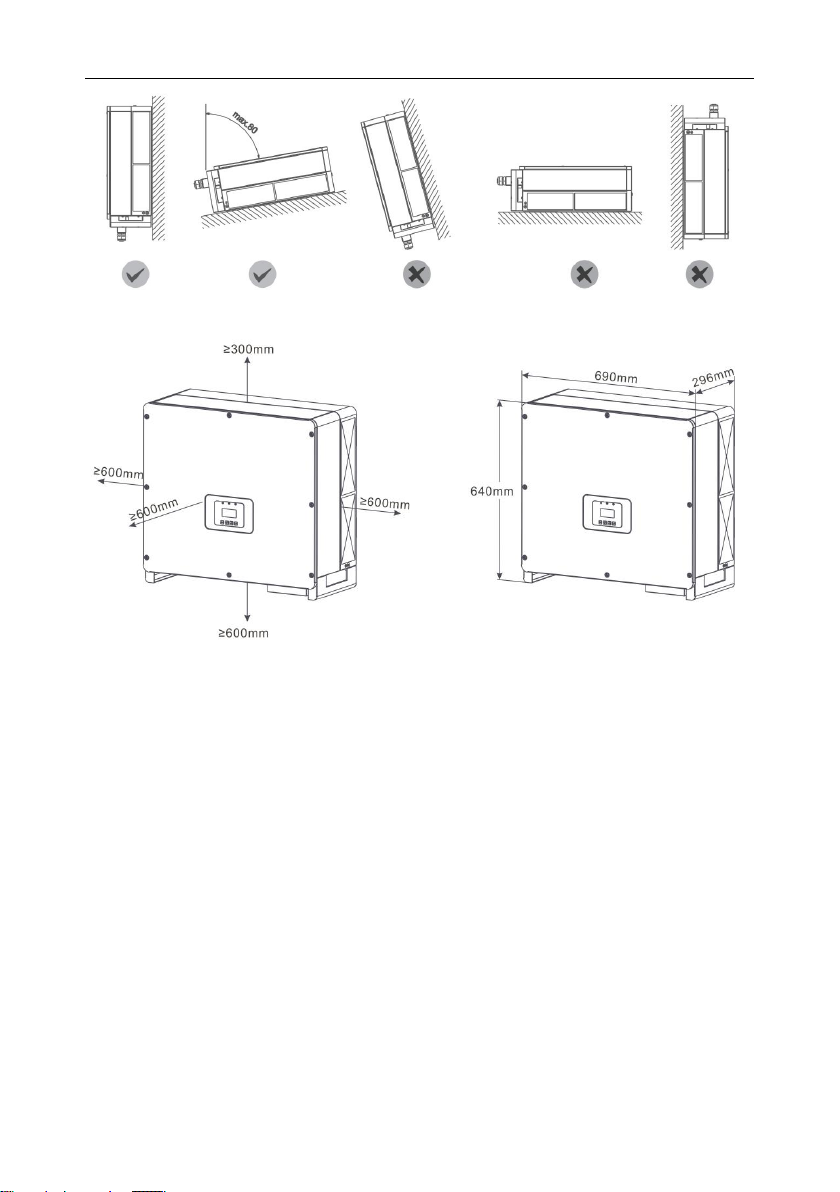

3.3 Mounting

Installation Precaution

SI 80K series inverter is designed for outdoor installation (IP 65).

Make sure the installation site meets the following conditions:

Object

Description

Quantity

A

Inverter

1

B

Bracket

1

*C

PV connectors (16*positive,16*negative)

16/16

*D

PV pin connectors (16*positive, 16*negative)

16/16

E

Ring terminal

6

F

User manual

1

G

Expansion screws

5

H

Set screw( for mounting,external enclosure grounding)

3

I

Cable gland for AC connection

1

J

RS485 terminal (optional)

1

K

Wifi module (optional)

1

User Manual

-8-

◆ Not in direct sunlight.

◆ Not in areas where highly flammable materials are stored.

◆ Not in potential explosive areas.

◆ Not in the cool air directly.

◆ Not in environment of precipitation or humidity (>95%).

◆ Under good ventilation condition.

◆ The ambient temperature in the range of -20℃ to +60℃.

◆ The wall hanging the inverter should meet conditions below:

1.Solid brick/concrete, or strength equivalent mounting surface;

2.Inverter must be supported or strengthened if the wall’s strength isn’t enough(such

as wooden wall, the wall covered by thick layer of decoration).

Please avoide direct sunlight, rain exposure, snow laying up during.

◆ The slope of the wall should be within 80°.

User Manual

-9-

3.4 Space Requirement

3.5 Mounting Steps

1.Use the wall bracket as a template to mark the position of the 5holes on the wall.

2.Drill holes with driller, make sure the holes are deep enough (at least 75mm) for

installation, and then tighten the expansion tubes.

3. Install the expansion tubes in the holes, and tighten them. Then install the wall

bracket by using the expansion screws.(Φ10 driller, torque: 2.5±0.2Nm)

4. Hang the inverter over the bracket, move the inverter close to it, slightly lay down the

inverter, and make sure the 4 mounting bars on the back are fixed well with the 4

grooves on the bracket.

5.After confirming the inverter is fixed reliably, fasten two M5 safety-lock sockets head

cap screws on the right or left side firmly to prevent the inverter from being lifted off the

bracket (torque: 2.0±0.2Nm)

User Manual

- 10 -

4 Electrical Connection

4.1Grid Connection

SI 80K series inverter are designed for three-phase grid. Voltage is 400V, frequency is

50/60Hz. Other technical requests should comply with the requirement of the local

public grid.Micro-breaker should be installed between inverter and grid, any load

should not be connected with inverter directly.

Table 3 Cable recommended

Model

Copper Cable

Conductor crosssection

SI 50K/SI 60K

Five-core cable

(L/N/PE)

2 AWG

SI 70K/SI 80K

Five-core cable

(L/N/PE)

1 AWG

User Manual

- 11 -

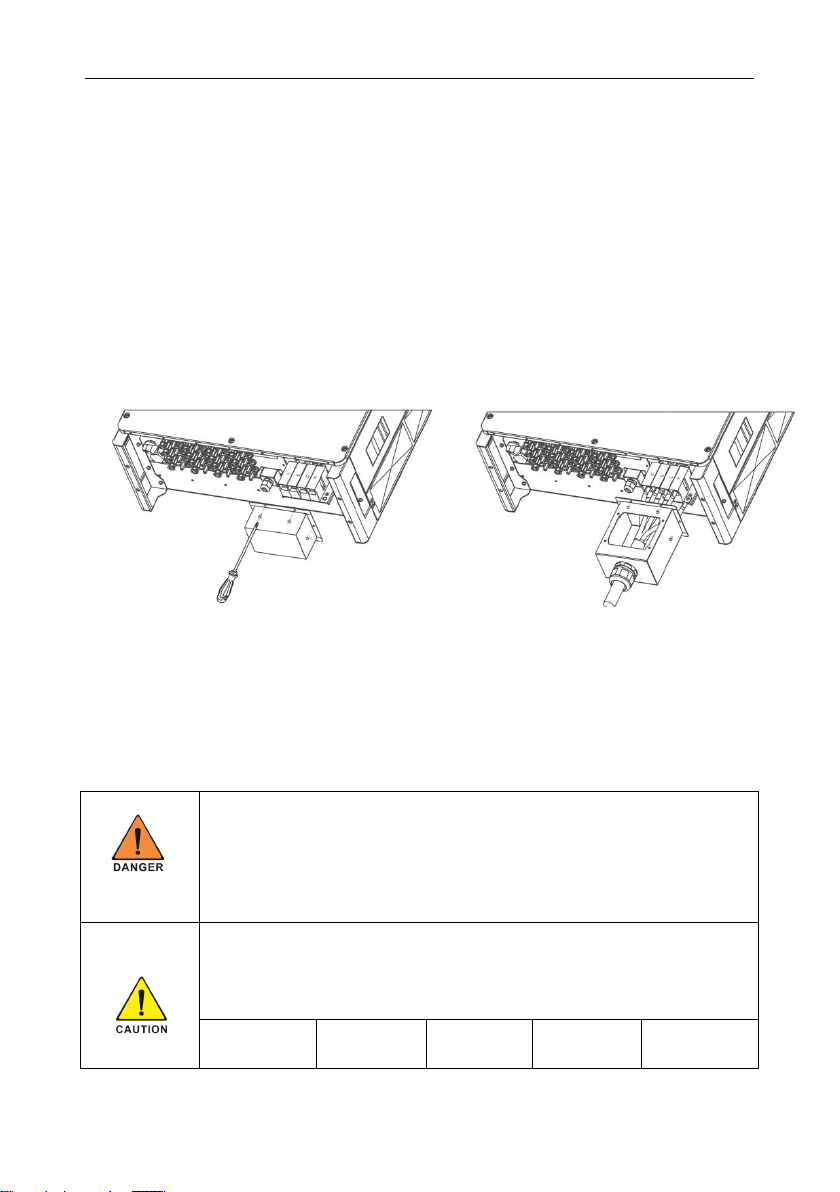

Connection Steps

1. Choose the appropriate wire(Cable size: refer to Table3).

2.Remove 10mm of insulation from the end of wire.

3.Insert stripped wires into AC terminal and ensure that all conductor strands are

captured in the AC terminal.Compress the terminal head by using a crimping pliers .

4. Remove the protection shell onto the bottom of the inverter

5.Insert AC cable into port through screw cap and then tighten the screw cap.

6.Fasten the protection shell onto the bottom of the inverter, make sure the four screws

aretightened

4.2 PV connection

◆ Conditions for DC Connection

The inverter has 4 independent input : PV1\PV2\ PV3\PV4. Notice that the connectors

are in paired (male and female connectors). The connectors for PV arrays and inverters

are H4 connectors;

The solar modules connected to the inverter must conform to the

Class A requirements of the IEC 61730 standard.

If the inverter is not equipped with a DC switch but this is mandatory in the

country of installation, install an external DC switch.The following limit values at

the DC input of the inverter must not be

exceeded:

Model

Max current

PV1

Max current

PV2

Max current

PV3

Max current

PV4

User Manual

- 12 -

◆ Connecting the PV Array

Connection Steps:

1.Choose the 12 AWG wire to connect with the cold-pressed terminal.

2.Remove 7mm of insulation from the end of wire.

3.Insert the insulation into pin contact and use crimping plier to clamp it.

4.Insert pin contact through the cable nut to assemble into back of the male or female

plug. When you feel or heard a “click” sound the pin contact assembly is seated

correctly.

5. Plug the PV conntector into the corresponding PV connector on inverter.

SI 50K

SI 60K

SI 70K

SI 80K

33A

44A

33A

44A

33A

44A

33A

44A

33A

44A

33A

44A

/

/

33A

44A

Danger to life due to lethal voltages!

◆ PV array supplies d.c voltage to inverter when exposed to

light,before connecting the PV array, cover some light screens above

PV arrays,ensure that the DC switch and AC breaker are disconnect

from the inverter. NEVER connect or disconnect the DC connectors

under load.

◆ Make sure the maximum open circuit voltage(Voc) of each PV

string is less than the maximum input voltage of the inverter.

◆ Check the design of the PV plant. The Max. open circuit voltage,

which can occur at solar panels temperature of -10℃, must not

exceed the Max. input voltage of the inverter.

◆ Improper operation during the wiring process can cause fatal

injury to operator or unrecoverable damage to the inverter. Only

qualified personnel can perform the wiring work.

◆ Please don’t connect PV array positive or negative pole to the

ground, it couldcause serious damages to the inverter

◆ Check the connection cables of the PV modules for correct polarity

and make sure that the maximum input voltage of the inverter is not

exceeded

User Manual

- 13 -

4.3 485 Connection(Optional)

◆ 485 is provided the function of remote control that allows external control device to

make the inverters remote cluster control through 485 port on the inverter.

Connection Steps:

1.Uninstall the parts of the connection plug from the accessory bag.

2.Prepare communication cable,trip the insulation from the communication cable.

3.Let the communication cable pass though the waterproof connector , then insert it

into the connector following the PIN definition rule.

4.Fasten the protection shell onto the bottom of the inverter, make sure the four

screws are tightened, the completed appearance is like the below figure.

◆ When routing the signal cable, ensure that it is separate from the

power cable and away from interfering sources to prevent

communication from being affected.

◆ The protection layer of the cable is in the connector. Cut off surplus

core wires from the protection layer. Ensure that the core wires are

completely inserted into the cable holes, and that the cable is securely

connected.

User Manual

- 14 -

4.4 Turn-off the Inverter

Turn-off the inverter step:

1.Disconect the line circuit breaker from single-phases grid and prevent it from being

reactivated.

2.Turn off the dc switch.

3.Check the inverter operating status.

4.Waiting until LED, OLED have go out, the inverter is shut down.

5 Powering On the System

5.1 Start-Up the inverter

1.Turn on the AC switch between the inverter and the power grid.

2. If there is a DC switch between the PV string and the inverter, turn on the DC switch.

3. Turn on the DC switch at the bottom of the inverter.

4. Observe the LEDs to check the operating status of the inverter.

5.2 First run time setting

6 LCD Operation

The main interface is the default interface, the inverter will automatically jump to this

interface when the system started up successfully or not operated for a period of time.

Menu interface

Do not disconnect the DC connectors under load.

Before turning on the AC switch between the inverter and

the power grid, use a multimeter set to the AC position to

check that the AC voltage is within the specified range.

User Manual

- 15 -

User Manual

- 16 -

7 Maintenance and Cleaning

7.1 Maintain Periodically

1.Checking Heat Dissipation

If the inverter regularly reduces its output power due to high temperature, please

improve the heat dissipation condition. Maybe you need to clean the heat sink.

2. Cleaning the Inverter

If the inverter is dirty, turn-off the AC breaker and DC switch ,waiting the inverter shut

down ,then clean the enclosure lid, the display, and the LEDs using only a wet cloth. Do

not use any cleaning agents (e.g. solvents or abrasives)

3. Checking the DC switch

Check for externally visible damage and discoloration of the DC switch and the cables at

regular intervals.If there is any visible damage to the DC switch, or visible discoloration

or damage to the cables, contact the installer.

7.2 Trouble shooting

Our quality control program assures that every inverter is manufactured to accurate

specifications and is thoroughly tested before leaving our factory. If you have difficulty

in the operation of your inverter, please read through the following information to

correct the problem.

Alarm ID

Alarm Name

Suggestion

Alarm ID

Alarm Name

Suggestion

E00

Grid Volt Low

Check the AC

voltage range

E16

Remote Off

Check

background

instructions

E01

Grid Volt High

E18

SPI Error

Contact the

manufacturer

E02

Grid Freq Low

E20

GFCI High

E03

Grid Freq High

E21

GFCI Chk Error

E04

Bus Volt Low

Please switch off

DC switch.

Restart the invert

E22

Vol Not Same

E05

Bus Volt High

E23

Curr Not Same

E06

Bus Imbalance

E26

Soft start erro

User Manual

- 17 -

E07

ISO Low

Check PV

impedance to

ground

E27

PV Voltage

High

Check the PV

panel

configuration

E08

DC Curr High

Check the PV

panel

configuration

E32

DSP Comm.

Error

Please switch

off DC switch.

Restart the

invert

E09

Hw Invert High

Contact the

manufacturer

E10

Invert I High

E11

Invert DCI High

E12

Env T High

E13

Radiator Heat

E14

AC Contactor

E15

PV Voltage Low

Check the PV

panel

configuration

Alarm ID

Alarm Name

Suggestion

Alarm

ID

Alarm Name

Suggestion

W16

Clock Warn

Replace the

internal button

pool

W05

Fan 1 Speed Low

Check the

external fan

W03

Active 0

Warn

Normal

shutdown at

low power

W06

Fan2 Speed Low

W04

Array Warn

Check the PV

panel

W07

Fan 3 Speed Low

W21

Arrester

Warn

Check the

lightning

arresters

W08

Fan 4 Speed Low

User Manual

- 18 -

8 Decommissioning

8.1 Remove the Inverter

◆ Disconnect the inverter from DC Input and AC output.

◆ Wait for 5 minutes for de-energizing.

◆ Disconnect communication and optional connection wirings.

◆ Remove the inverter from the bracket.

◆ Remove the bracket if necessary.

8.2 Packaging

◆ Please pack the inverter with the original packaging.

◆ If the original package is no longer available, you can also use an equivalent carton

that meets the following requirements.

8.3 Storage and Transportation

◆ Store the inverter in a dry environment where ambient temperature keep always

between -20 °C - +60 °C. Take care of the inverter during the storage and

transportation,keep less than 4 cartons in one stack.

◆ When the inverter or other related components need to be disposed. Have it carried

out according to local waste handling regulations. Please be sure to deliver wasted

inverters and packing materials to certain site, where can assist relevant department

to dispose and recycle.

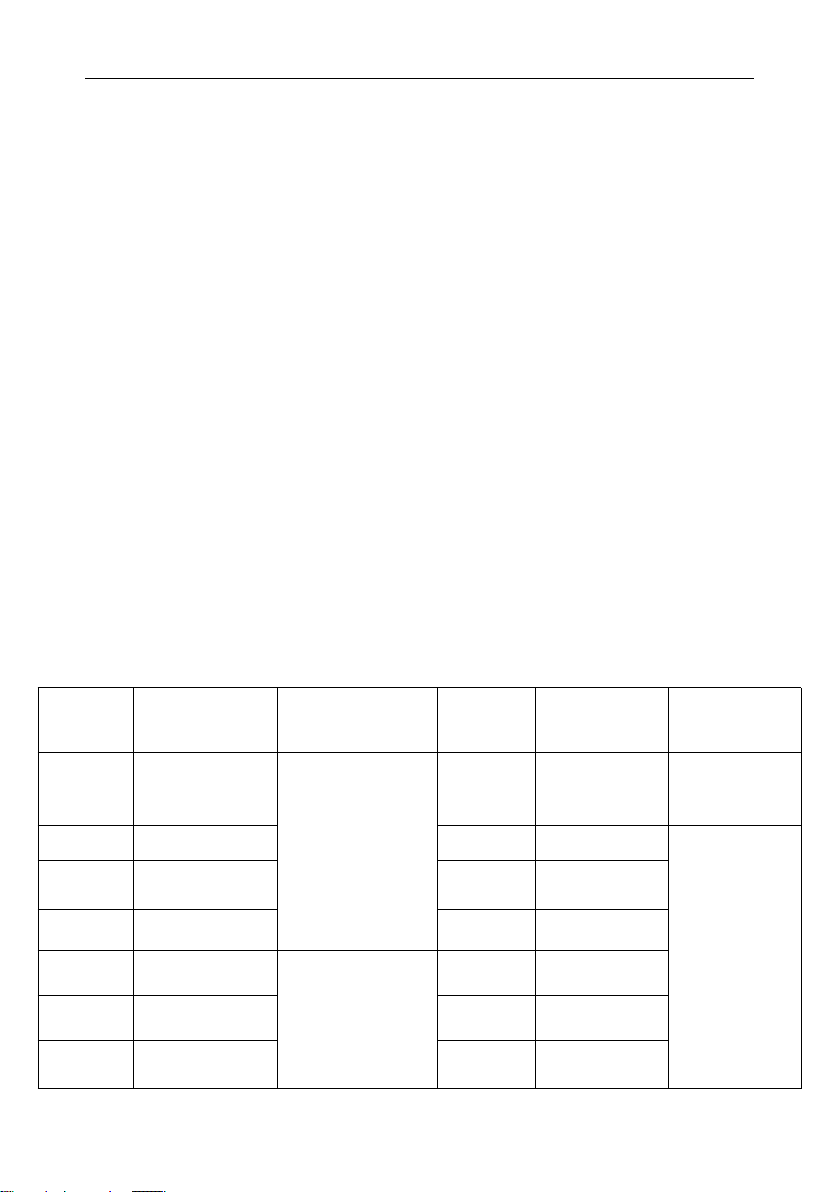

9 Technical Data

Model

SI 50K

SI 60K

SI 70K

SI 80K

Input Data

Max. DC input power

60KW

75KW

85KW

100KW

Max. DC input voltage

1100V

Operation voltage range

200V-1000V

Number of independent

MPPT/strings per MPPT

3/3

3/4

4/3

4/4

MPPT max. current

33A*3

44A*3

33A*4

44A*4

User Manual

- 19 -

AC Output Data

Rated output power

50KW

60KW

70KW

80KW

Max. output power

55KW

66KW

77KW

88KW

Rated output voltage

400V ±20%

Rated output frequency

50 /60 Hz± 5 Hz

Rated output current

72A

87A

101A

115A

Max. output current

80A

95A

111A

128A

Power factor

+-0.8

THDi

<3%

Grid system pattern

3W+N+PE

Efficiency

Max. efficiency

99%

Europe efficiency

98.5%

General Data

Dimensions(W/L/H)in mm

690/640/296

690/640/296

Weight

≤60kg

≤68kg

Operation temperature

range

–25 °C ... +60 °C

Noise

≤60dB

Heat dissipation mode

Smart cooling

IP Class

IP65

Features

LCD display

yes

Communication interface

WiFi/GPRS/RS485

This manual suits for next models

3

Table of contents

Other INHENERGY Inverter manuals

Popular Inverter manuals by other brands

ECO-WORTHY

ECO-WORTHY 3000W user manual

CyberPower

CyberPower CPS1000AI user guide

Generac Power Systems

Generac Power Systems 005261-0 owner's manual

Omnik

Omnik Omniksol-1k-TL2 user manual

Mitsubishi

Mitsubishi FR-A740-00023-EC instruction manual

Generac Power Systems

Generac Power Systems SD100 Specifications

Mitsubishi Electric

Mitsubishi Electric FR-A760 Series instruction manual

Sungrow

Sungrow SG2K-S user manual

Mitsubishi Electric

Mitsubishi Electric FR-E720-0.1K(SC) instruction manual

AirMan

AirMan SDG60S-7A6 instruction manual

Victron energy

Victron energy EasySolar 12/1600/70 manual

SMA

SMA SUNNY BOY STORAGE 2.5 Quick reference guide