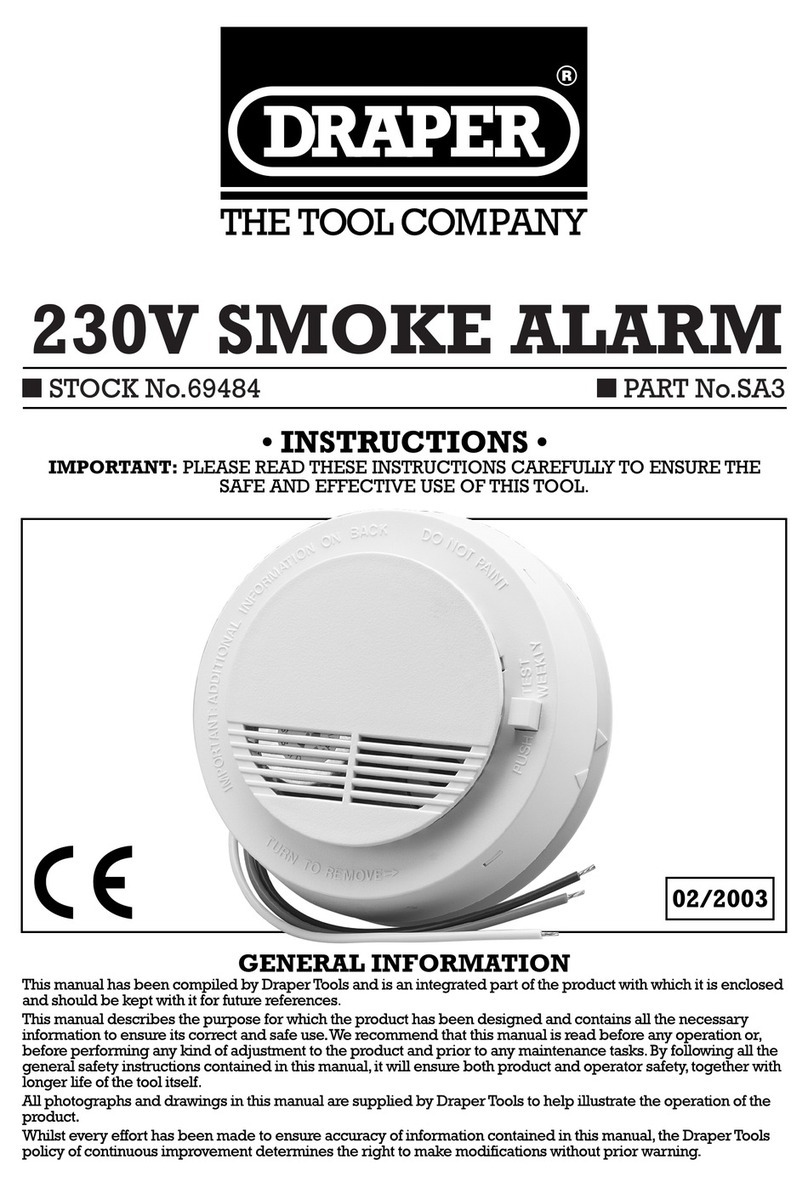

INIM ElectronicsV200 – Multicriteria smoke and temperature analogue addressable detector

V200

ANALOGUE ADDRESSABLE

MULTICRITERIA

SMOKE+TEMPERATURE

DETECTOR

GENRAL DESCRIPTION

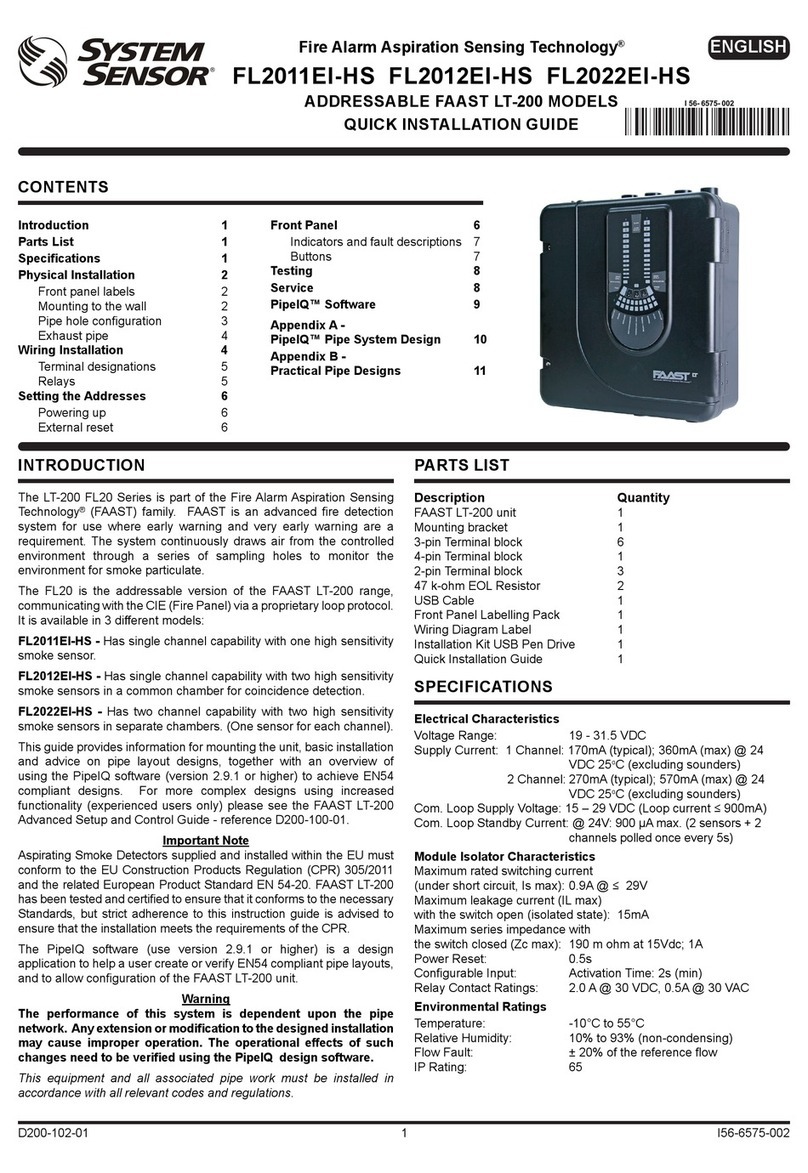

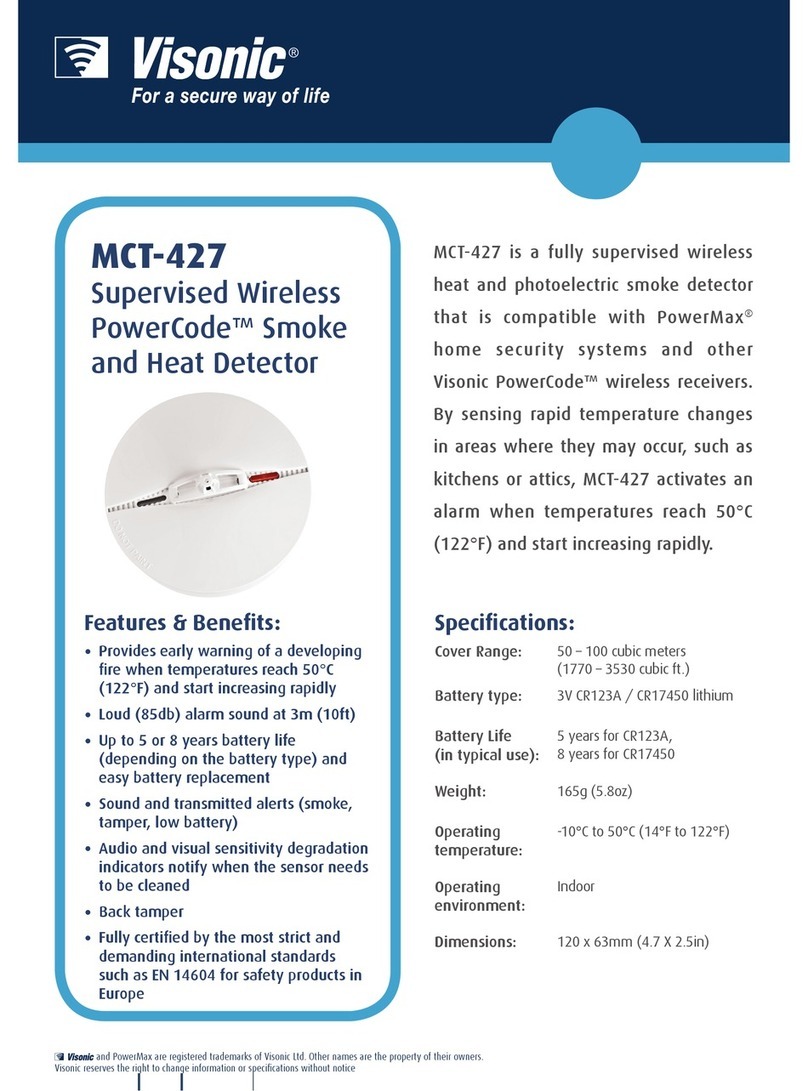

V200 is a multicrteria Analog addressable

detector which combine an optical smoke

detector based on Tyndall effect and a

temperature detector. The combination of

these two principle make the detector suitable

also for that fire risk where Smoke detector

are not normally used (i.e. fires with high

flames but low smoke emission etc.) The

innovative design of the baffle which the air

flow has to pass trough before enter in the

sampling chamber guarantee an high

immunity to environmental dust and a long

period between two consecutive cleaning of

the chamber. Each detector is equipped with a

Loop short circuit isolator.

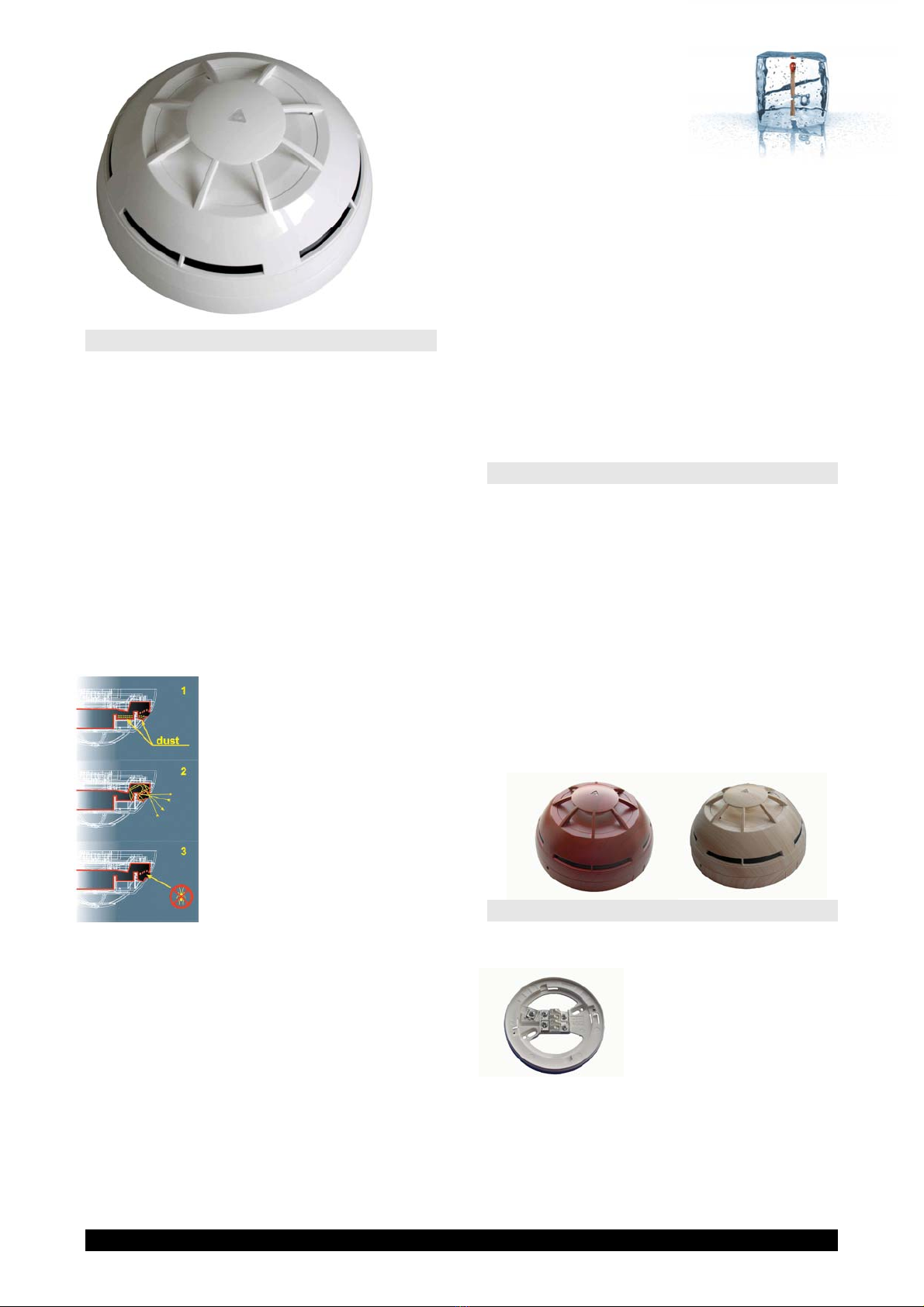

The centrally positioned

status LED provides full

360° visibility. The LED can

signal an alarm condition

(red), a fault condition or

loop short circuit condition

(yellow). The led can also be

manually switched on from

control panel (green) for an

easy identification of the

detector. Detectors are

equipped with an output for

remote signalling (FI100). Detector sensitivity

can be adjusted directly from control panel,

by means of a magnet the detector can be

inducted in alarm state for test pourpose.

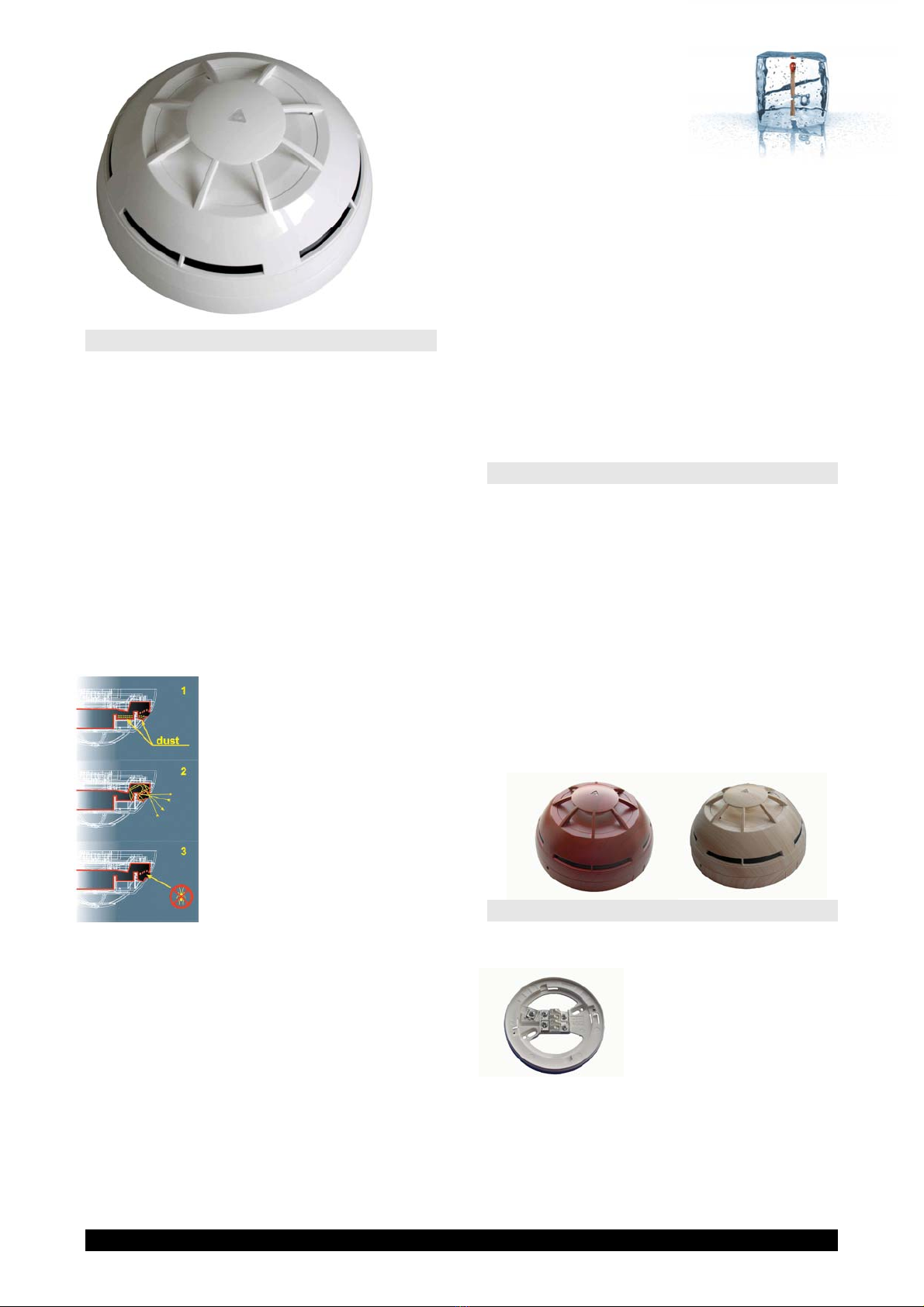

The detector can be fitted in the following

mounting bases:

•VB100 (standard base)

•VDBS100 (deep base)

•BLR100 (relay base)

•VBS100 (siren base)

V200 detectors can be used with the control

panels:

•SMARTLoop

•SMARTLight

Detector address (from 1 to 240) can be

selected:

•By means of VPU100 programmer

•Using the control panel self addressing

feature

MAIN FEATURES

•Approved according to EN54-7 ed

EN54-5 Standards by BSI (N°

KM96628)

•Approved accordin European

Construction Products Directive

(CPD) : 0086-CPD-504706

•Hi noise immunity

•Fast response

•3 Colour led located in the detector

center

•Output for remote LED driving

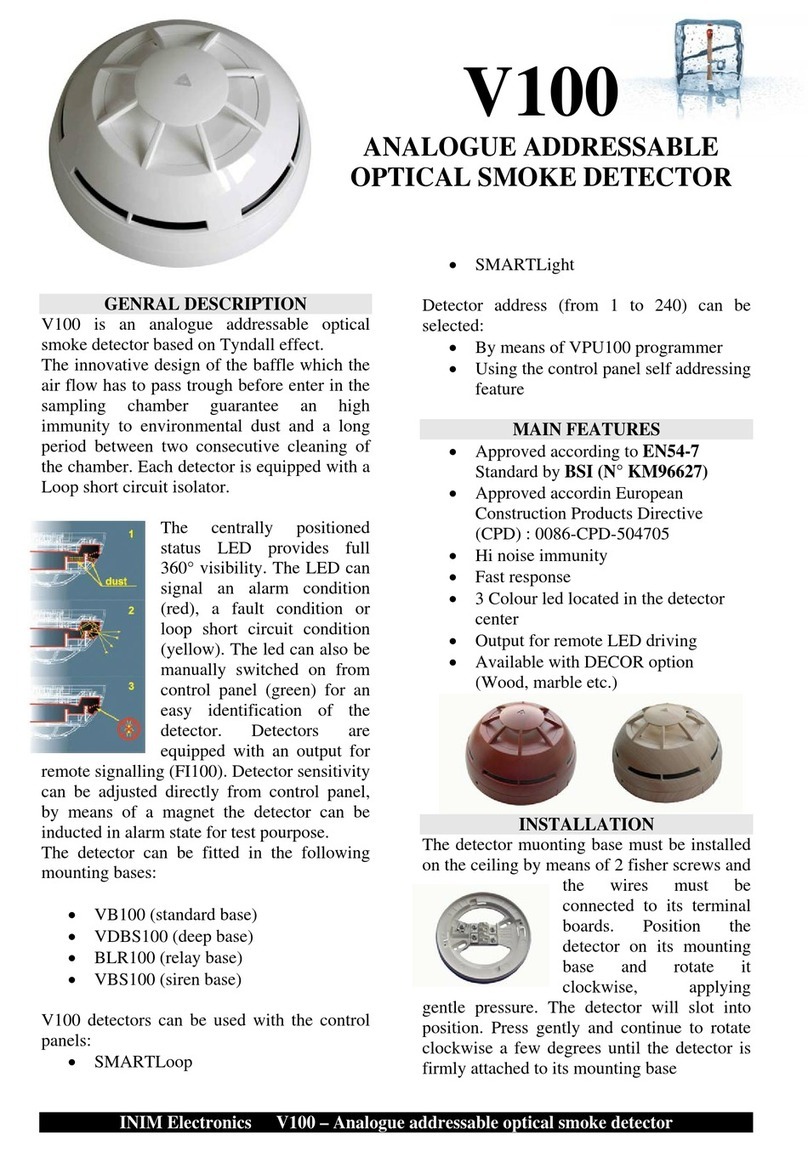

•Available with DECOR option

(Wood, marble etc.)

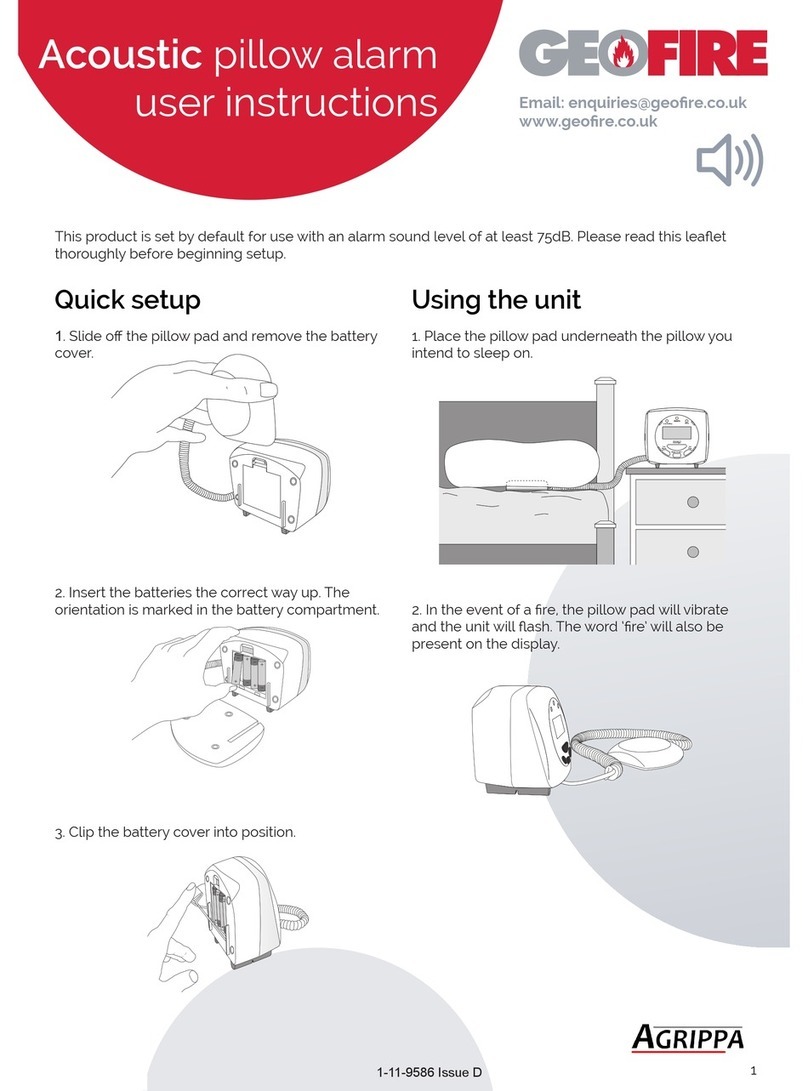

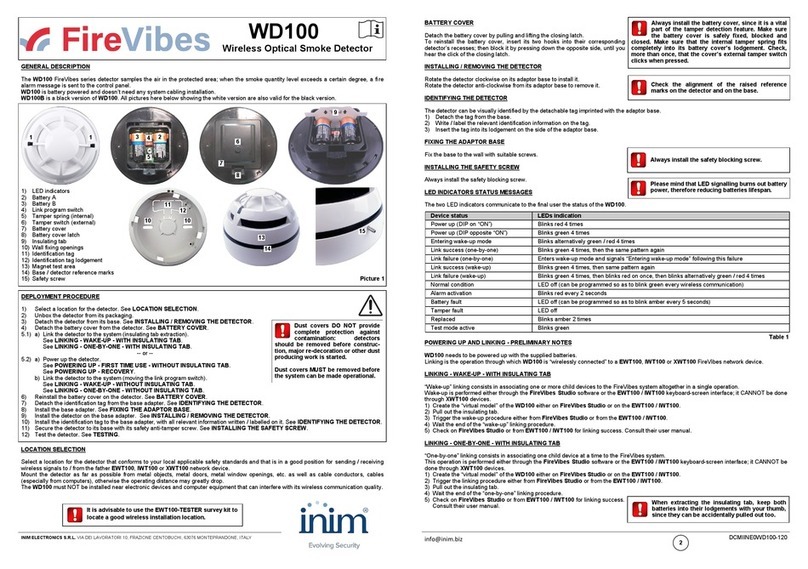

INSTALLATION

The detector muonting base must be installed

on the ceiling by means of 2 fisher screws and

the wires must be

connected to its terminal

boards. Position the

detector on its mounting

base and rotate it

clockwise, applying

gentle pressure. The detector will slot into

position. Press gently and continue to rotate

clockwise a few degrees until the detector is

firmly attached to its mounting base