Iniven PTR-1500 User manual

PTR-1500

AUDIO TONE TELEPROTECTION TERMINAL

5 Columbia Road, Somerville, NJ 08876

Phone: 908-722-3770 Toll Free: 800-526-3984 Fax: 908-722-5461

INSTRINSTR

INSTRINSTR

INSTRUCTION MANUUCTION MANU

UCTION MANUUCTION MANU

UCTION MANUALAL

ALAL

AL

PTR-1500

AUDIO TONE TELEPROTECTION TERMINAL

INSTRINSTR

INSTRINSTR

INSTRUCTION MANUUCTION MANU

UCTION MANUUCTION MANU

UCTION MANUALAL

ALAL

AL

3.1.03

i

WARRANTY AGREEMENT

We hereby certify that the INIVEN product line carries a warranty for any part

which fails during normal operation or service for 12 years. A defective part should

be returned to the factory after receiving a return material authorization number

(RMA), shipping charges prepaid, for repair f.o.b. Somerville, New Jersey. In case

INIVEN cannot promptly return the unit to you it will endeavor to provide a loaner

until the repair or replacement is returned to you. Any unauthorized repairs or

modifications will void the warranty. In the case of parts not being commercially

available, INIVEN reserves the right to replace the unit with a functionally equivalent

unit.

5 Columbia Road, Somerville, NJ 08876

ii

SAFETY

Standard safety precautions must be followed at all times when installing, operating, servicing

and repairing this equipment. INIVEN assumes no liability for failure to observe safety

requirements or to operate this equipment for purposes other than intended.

GROUNDING

A suitable ground is required to reduce the hazard of shock. Refer to the enclosed module,

chassis, and/or cabinet wiring diagram for ground connection locations.

ENVIRONMENT

Operation of any electrical equipment in area containing gas, fumes, wetness or dampness is a

potential safety hazard. Necessary precautions should be taken.

MANUAL

Operators and maintenance personnel should read this manual before installing the equipment

and placing it in service. Only properly trained personnel with proper tools and equipment should

operate, maintain, repair or service this equipment.

SHOCK

Potentially dangerous electrical shock can occur when working on this product. Protective

measures and safety procedures should be observed at all times.

iii

TABLE OF CONTENTS

Title Page - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ii

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Table of Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iv

Section 1. General

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Logic Mode Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Channel Frequencies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Trip Times - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

System Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

System Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Security Charts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

Dependability Charts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

Section 2. Installation

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Electrical Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Trip Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Trip & Guard Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Status Relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Audio Tone Lines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Power Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Initial Start-up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Wiring Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

Section 3. Specifications

Module Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

DIP Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

Transmitter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

Receiver - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Logic Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-8

Outline Drawing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-11

Section 4. Standard Modules

4-A. DC/DC Module

Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-A-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-A-1

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-A-1

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-A-2

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-A-3

Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-A-5

iv

4-B. Line Interface Module

Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-B-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-B-1

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-B-1

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-B-2

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-B-3

Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-B-5

4-C. Status Relay Module

Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-C-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-C-1

Relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-C-2

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-C-2

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-C-3

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-C-4

Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-C-5

4-D. Transmitter Module

Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-D-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-D-2

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-D-2

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-D-3

DIP Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-D-4

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-D-6

Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-D-9

Receiver Module

Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-E-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-E-2

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-E-2

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-E-2

DIP Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-E-3

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-E-5

Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-E-7

Logic Module

Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-F-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-F-1

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-F-2

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-F-3

DIP Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-F-4

SET/AutoSET - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-F-6

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-F-7

Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-F-9

v

4-G. Multi-Trip I/O Module

Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-G-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-G-2

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-G-2

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-G-2

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-G-3

Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-G-5

4-H. Hybrid Splitter Module

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-H-1

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-H-2

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-H-2

Jumper Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-H-3

Replaceable Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-H-4

Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-H-5

Section 5. Chassis

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Mother Board - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Interface Board - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Back Board - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Mother Board Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Interface Board Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Terminal Block Board Schematic - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5

Section 6. Option Modules

Section 7. Maintenance

Preventative Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Module Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Module Replacement - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

vi

Section 1 GENERAL

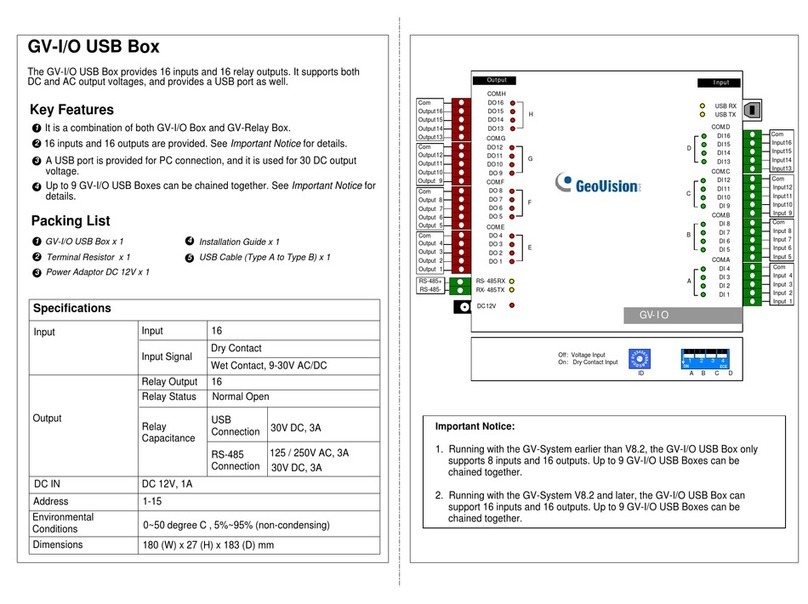

Figure 1-1. PTR-1500

DESCRIPTION

The PTR-1500 is a communications system used for the protection of electric power generation and

distribution equipment. A protection system consists of two PTR-1500 units that communicate with each

other via voice-grade telecommunication lines (i.e., carrier, wire line or metallic pairs, fiber optics, and

microwave). The basic operation consists of a unit receiving a voltage from a closed contact (Trip input)

from a relay into the transmitting terminal and having it communicate to the receiving terminal, which

provides a closed contact and a externally sourced voltage output (Trip output).

FEATURES

DESIGN: The PTR-1500 has been optimized for high speed, high Dependability, and high Security. Single

and Dual Channel FSK modulation techniques are used in conjunction with digital differential Guard/Trip

energy sensing. These methods have a proven record of accomplishment for high reliability in the tone

protection relaying applications.

PROGRAMMABILITY: Operating characteristics of the PTR-1500 are controlled by firmware. The majority

of parameter changes are accomplished by changing DIP switch settings. A few logic changes are made

by PROM/EPROM replacement. Frequencies, channel bandwidths, communications protocols, and logic

modes are all programmable.

COMPATIBILTY: The PTR-1500 is compatible with other INIVEN PTR equipment as well as certain other

manufacturer’s audio tone protection equipment, depending on their configuration.

STABLE OPERATION: The Digital Signal Processing (DSP) technology used to generate the transmitter

frequency, establish receiver frequency discrimination, and manage all channel filtering, is crystal controlled.

This design provides a high level of stability, which overcomes the drift with temperature and age problem

encountered with analog methods.

1-1

LOGIC MODE OPTIONS

The PTR-1500 is designed as a four channel communications system that can operate in three different

modes depending on how the Logic module is programmed

1. DUAL CHANNEL – two frequencies are always generated by the Transmitter, either two Guard

tones or two Trip tones, one from Sub-Channel A and one from Sub-Channel B, from the selected

frequency Group (see Table 1-1) chosen by the customer. The Guard frequencies, one from each

Sub-Channel, are transmitted during normal, non-Trip, operation. When a Trip input is received by

the PTR-1500, the Transmitter will output both Trip frequencies, one from each Sub-Channel. The

PTR-1500 connected to the other end of the communication line will only allow a Trip output to the

receiving end’s relay when it has received both Trip signals simultaneously. The use of two frequencies

for Guard and Trip signals dramatically increases the Security (see Security charts later in this

section) of the system.

2. SINGLE CHANNEL – one frequency is generated by the Transmitter, either a Guard or Trip tone.

The frequencies will be either Sub-Channel A or B, but not both, of the selected frequency Group

(see Table 1-1) chosen by the customer. The Guard frequency is transmitted during normal, non-

Trip, operation. When a Trip input is received by the PTR-1500, the Transmitter will output the Trip

frequency and the PTR-1500 connected to the other end of the communication line will allow a Trip

output.

3. DUAL INDEPENDENT – two frequencies are generated by the Transmitter. The system operates

as two Single Channel units simultaneously. In this configuration, two separate Trip inputs are

received by the PTR-1500. Trip input 1 will be transmitted using a single frequency, Sub-Channel A

of a frequency Group (see Table 1-1) chosen by the customer. During normal, non-Trip, operation

the Transmitter will output the Sub-Channel A Guard tone. When a Trip input is received by the PTR-

1500 from Trip input 1, the Transmitter will output the Sub-Channel A Trip tone and the PTR-1500

connected to the other end of the communications line will allow a Trip 1 output. Trip input 2 will

cause the system to operate the Guard and Trip tones of Sub-Channel B in the same manner as

described for Trip input 1. Each Trip input will operate independently of the other.

Because the PTR-1500 is a four channel unit, it can operate 2 of the above logic schemes independently in

the same unit. The 2 “halves” of the unit need not be the same. For example, a PTR-1500 can be ordered

with 2 Dual Channels, a Dual Channel and a Single Channel, a Dual Independent and a Single Channel,

etc….

The PTR-1500 can also be ordered as a single direction or as the standard bi-direction. A single direction

unit can only transmit or receive while a bi-directional unit can do both. These options may also be combined

with the different logic configurations.

FSK MODULATION

340Hz Channel Spacing: ± 75 Hz

680Hz Channel Spacing: ±150 Hz

1-2

CHANNEL FREQUENCIES

TABLE 1-1. Standard Frequency Groups

TYPICAL TRIP TIMES

Channel speed is measured with back-to-back terminals and does not include delays inherent in the

communication media. For those units equipped with the optional Trip Relays, add approximately 3ms to

the times indicated below.

EDOMGNICAPSLENNAHC

zH043zH086

YTIRUCESHGIHsm21sm8

DEEPSHGIHsm9sm6

TABLE 1-2. Trip Speed

1-3

SEICNEUQERFENOTDEDNEMMOCER

HTDIWDNABLANIMONzH071-GNICAPSLENNAHC-BUSzH043

PUORGLENNAHC-BUSEDOM&YCNEUQERFYCNEUQERFRETNECLENNAHC-BUS

1A

B

068

0101

0021

0531

pirT

drauG

drauG

pirT

zH539

zH5721

2A

B

0021

0531

0451

0961

pirT

drauG

drauG

pirT

zH5721

zH5161

*3 A

B

0451

0961

0881

0302

pirT

drauG

drauG

pirT

zH5161

zH5591

*4 A

B

0881

0302

0222

0732

pirT

drauG

drauG

pirT

zH5591

zH5922

*5 A

B

0222

0732

0652

0172

pirT

drauG

drauG

pirT

zH5922

zH5362

6A

B

0652

0172

0092

0503

pirT

drauG

drauG

pirT

zH5362

zH5792

7A

B

0092

0503

0423

0933

pirT

drauG

drauG

pirT

zH5792

zH5133

HTDIWDNABLANIMONzH043-GNICAPSLENNAHC-BUSzH086

8A

B

587

5801

5641

5671

pirT

drauG

drauG

pirT

zH539

zH5161

*9 A

B

5641

5671

5412

5442

pirT

drauG

drauG

pirT

zH5161

zH5922

01 A

B

5412

5442

5282

5213

pirT

drauG

drauG

pirT

zH5922

zH5792

.lennahcnoitacinummocfodnereppurorewoltaffo-llordiovaotdnaesionmuminimrofspuorGderreferP*

.tseuqernoelbaliavaeragnicapsdnaseicneuqerfTTICC

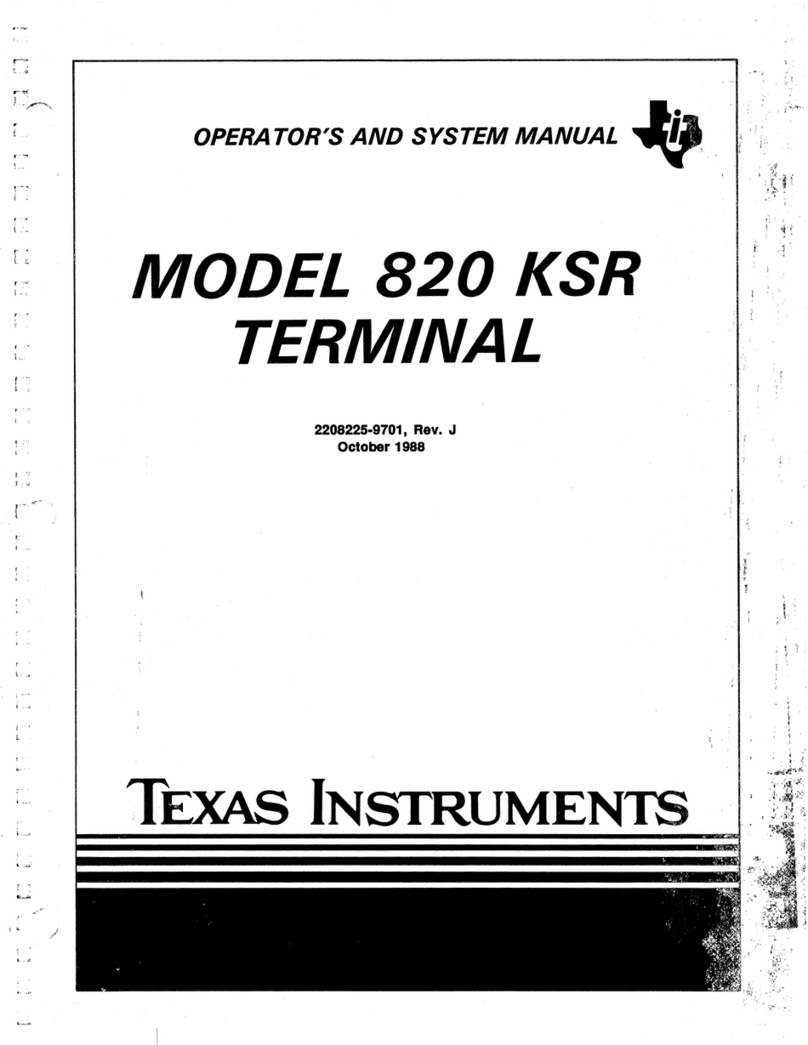

SYSTEM OPERATION

The following is a brief description of the standard modules that comprise a typical terminal. For detailed

descriptions, schematics and parts lists, refer to the individual module’s section in this manual.

POWER SUPPLY: Accepts the station battery voltage from the Line Interface module and produces a

regulated +5V output. It also isolates the rest of the PTR 1500 from the station battery.

LOSS OF POWER ALARM RELAY: A SPDT relay will be located on the Interface board, the wiring

connections are a 3 terminal board strip next to the power supply.

STATUS RELAY MODULE: Contains 8 relays that indicate problems with the communications system: 2-

Alarm, 2-Block, 4-LOS (Loss of Signal).

DC/DC MODULE: Contains overvoltage and undervoltage detectors that will disable the PTR-1500 Trip

circuits if the supply voltage is out of limit. The card produces ±12VDC outputs.

LOGIC MODULE: The PTR-1500 requires two Logic modules for quad channel operation. The Logic

module monitors all Trip inputs, furnishes all instructions to the tone Transmitter, analyzes the tone Receiver

outputs, and controls the Trip output drivers for one Dual Channel. The module also controls the Status

Relay module and monitors the DC/DC module. The Logic module utilizes a Z80 processor as its CPU.

LINE INTERFACE MODULE: Contains power supply filters, ON/OFF switch, and fuses. It also couples the

communication lines using four transformers.

MULTI-TRIP I/O MODULE: Contains five Trip input optical isolators and eight solid state outputs optically

isolated (4 - Trip and 4 - Guard).

TRANSMITTER MODULE: The PTR-1500 requires one Transmitter module (Quad-tone plus two pilot

tones). Utilizing the TMS320C16 DSP, the Transmitter performs calculations necessary to synthesize

required tone frequencies and to execute required control functions.

RECEIVER MODULE: The PTR-1500 requires two Receiver modules (two channels per Receiver module)

for quad channel operation. The Receiver utilizes the TMS320C16 DSP, which performs all calculations

necessary for tone filtering, control functions, and noise detection.

1-4

Figure 1-2. PTR-1500 Block Diagram

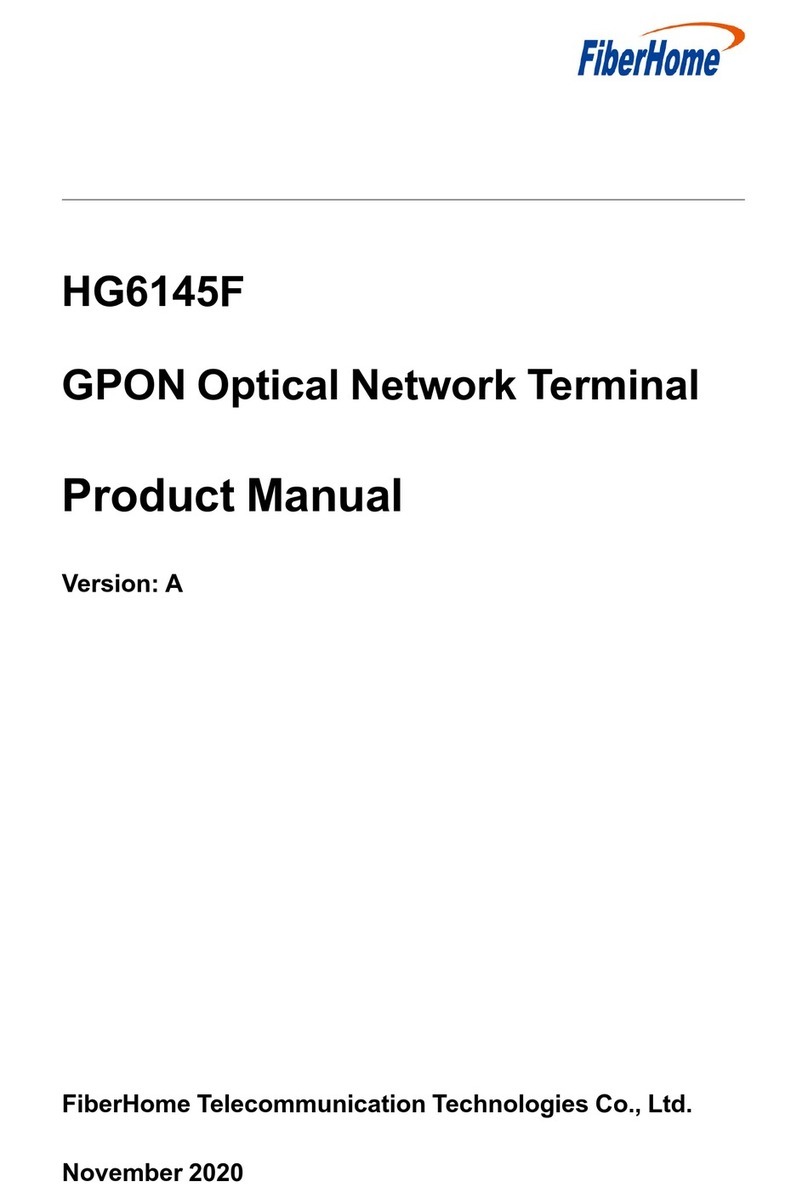

SECURITY CHARTS

Security charts showing the PTR-1500’s ability not to false Trip in the presence of noise.

STANDARD SECURITY

0

100000

200000

300000

400000

500000

600000

700000

800000

900000

1000000

NOISE

BURSTS

(per Trip)

-12 -11 -10 -9 -8 -7 -6

S/N LEVEL

SECURITY

GRP.3 Standard Dual Logic

0

1000000

2000000

3000000

4000000

5000000

6000000

7000000

8000000

9000000

10000000

NOISE

BURSTS

(per Trip)

-12 -11 -10 -9 -8 -7 -6

S/N LEVEL

SECURITY

GRP.3 Standard Dual Logic

mBdN/SBdpirTrep

4-21-0000001

5-11-0000001

6-01-000061

7-9-00009

8-8-000211

9-7-0000001

01-6-0000001

(-) 16 Signal Level

Figure 1-3. Security Chart, Group 3, Standard Security, Dual Channel Logic

HIGH SECURITY

mBdN/SBdpirTrep

4-21-00000001

5-11-00000001

6-01-0000001

7-9-000053

8-8-0000011

9-7-00000001

01-6-00000001

(-) 16 Signal Level

Figure 1-4. Security Chart, Group 3, High Security, Dual Channel Logic

1-5

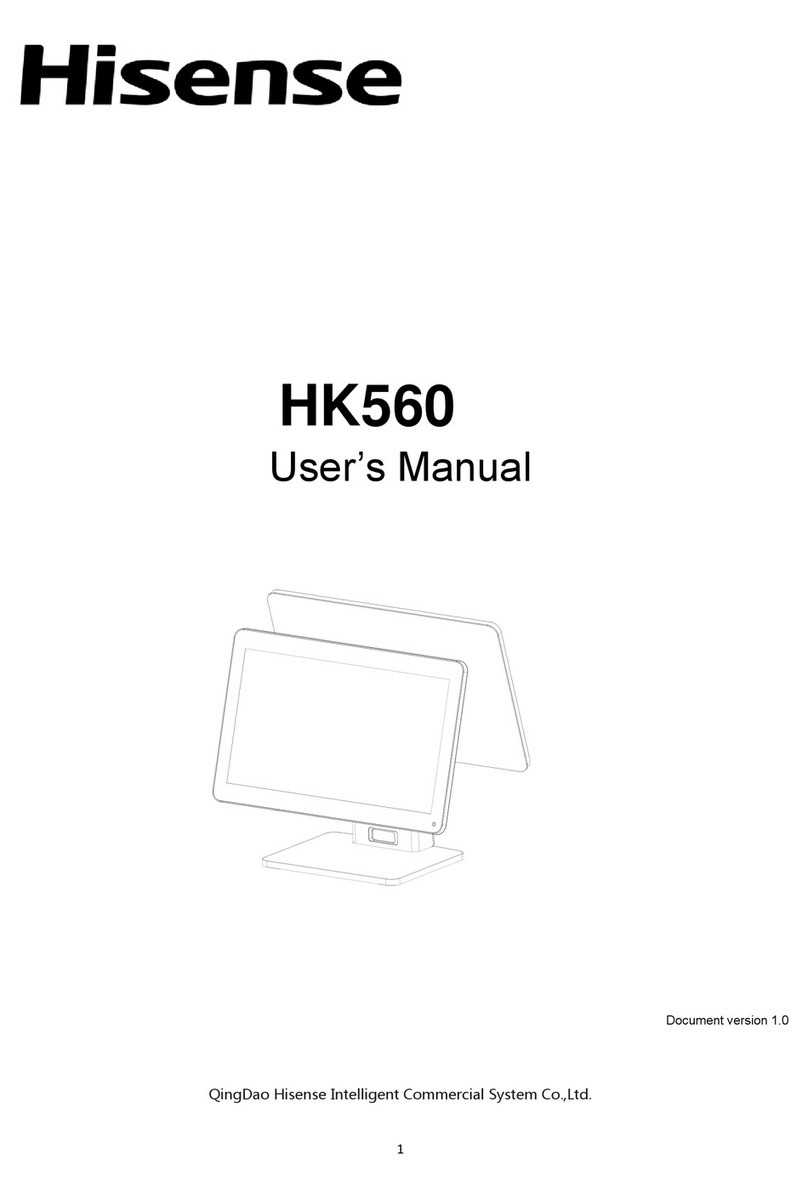

DEPENDABILITY CHARTS

Dependability charts showing the PTR-1500’s ability to provide an output in the presence of noise.

STANDARD SECURITY

DEPENDABILITY

GRP.3 Standard Dual Logic

0

10

20

30

40

50

60

70

80

90

100

-8-7-6-5-4-12345

S/N in dB

Percentage of Trips

Received

DEPENDABILITY

GRP.3 Standard Dual Logic

0

10

20

30

40

50

60

70

80

90

100

-8-7-6-5-4-12345

S/N in dB

Percentage of Trips

Received

mBdN/SBd%

01-8-0

11-7-3

21-6-5

31-5-81

41-4-72

71-1-58

02-2001

12-3001

22-4001

32-5001

(-) 18 Signal Level

mBdN/SBd%

01-8-0

11-7-0

21-6-2

31-5-01

41-4-51

71-1-54

02-277

12-319

22-4001

32-5001

HIGH SECURITY

Figure 1-5. Dependability Chart, Group 3, Standard Security, Dual Channel Logic

Figure 1-6. Dependability Chart, Group 3, High Security, Dual Channel Logic

(-) 18 Signal Level

1-6

Section 2 INSTALLATION

This section of the manual covers installation, unpacking, mounting and interconnect wiring instructions.

UNPACKING

Various forms of the PTR-1500 may be supplied. The unit may be supplied as an individual chassis,

stacked interconnected chassis, or mounted in a rack or cabinet. Follow the procedure for the type of

system supplied.

INDIVIDUAL CHASSIS: An individual chassis will be packed in its own shipping carton. Inspect the carton

for possible damage in transit. Open each carton carefully and remove the chassis. Inspect the equipment

for possible damage. Verify all items of value have been removed from the carton prior to discarding the

packing material.

NOTE: It is suggested the carton be retained for possible onward shipment.

INTERCONNECTED CHASSIS: An interconnected chassis or equipment mounted in racks or cabinets

will be shipped either in special boxes (wood crates or via air-ride van without any case). Inspect the crate

or other packaging for possible damage in transit. Carefully remove the equipment from the container and

inspect it for damage. Verify all items of value have been removed from the crate prior to discarding any

packing material and refer to above note.

Should transit damage be found, please notify INIVEN immediately.

MOUNTING

INDIVIDUAL CHASSIS: Two screws are required per mounting bracket (four total per chassis) and are not

supplied with the unit. Install the chassis in the desired location and securely tighten all four screws.

Spacing of the mounting holes is compliant with EIA and DIN standards.

SYSTEMS: Systems provided in a rack or cabinet from the factory must be secured to the floor or wall as

required. Mounting hardware is not supplied due to the various surfaces and mounting methods.

CAUTION: EQUIPMENT MOUNTED IN SWING RACK TYPE CABINETS MUST BE SECURED TO

THE MOUNTING SURFACE PRIOR TO OPENING THE SWING RACK TO PREVENT THE CABINET

FROM FALLING.

INTERCONNECTED CHASSIS: Interconnected chassis’ or equipment mounted on shipping rails will be

mounted similarly to a single chassis. When shipping rails are provided, the equipment is to be placed near

the desired location. Remove the screws holding the shipping rails and remove them. Slide the equipment

into the rack or cabinet and secure it with the proper screws for mating hardware being used. Tighten all

screws.

NOTE: Adequate ventilation is required for reliable operation of electronic equipment. Temperatures within

the equipment room should be kept within specifications to assure reliable operation.

2-1

ELECTRICAL CONNECTIONS

User connections are made on the rear of the chassis through barrier and screw terminal blocks, fiber optic

connectors and the IRIG-B BNC connector, depending on the unit’s configuration. Not all types of connectors

are supplied on all PTR-1500 models. Refer to the end of this section or to the drawings that come with the

unit for specific wiring details.

References made to terminal blocks are via terminal block numbers. Terminal block TB-1 terminal 1 is

refered to as TB1-1. Terminal block TB-1 terminal 2 is refered to as TB1-2 and so on.

CAUTION: FOR SAFETY REASONS, ELECTRICAL POWER ON THE LEADS BEING CONNECTED

TO THE UNIT SHOULD BE DE-ENERGIZED DURING INSTALLATION.

Various methods of making the connections to the terminal blocks may be used and are based on local

practice. Lugs or bare wire may be used. Make sure to tighten all connections and insure exposed wires

and/or lugs do not touch each other or the chassis.

To reduce the possibility of induced currents on the Trip input leads, it is recommended that shielded

twisted pair wires are used with the shield grounded at the PTR-1500 end only. The Trip input leads and the

communication cables should be bundled separately from each other and the other leads.

TRIP INPUT: The Trip input current is limited to 10 ma. A resistor in series with the optical isolator on each

of the Trip inputs is used to limit the current. To produce a Trip, the battery voltage must be within 50% of the

input battery voltage.

TRIP & GUARD OUTPUT: Eight independent (Trip and Guard) outputs are provided with the standard

software. Outputs can be used singularly or can be used in parallel.

When an optional relay module is added, the interface board (see Section 5) may need to be modified.

Please consult the factory when changes to a PTR-1500’s factory configuration are being made.

STATUS RELAYS: There are eight status relay alarms each with a single set of SPDT (form C) contacts.

See Section 4-C. Status Relay, for status relay alarm functionality. All of the status relays are energized

during normal operation. Contacts are closed in their de-energized state.

AUDIO TONE LINES: The basic unit is supplied for four-wire operation. However, the Hybrid/Splitter module

(or similarly functioning module) can be configured for applications requiring two-wire communications.

GROUNDING THE EQUIPMENT IS IMPORTANT FOR BOTH SAFETY REASONS AND RELIABLE

OPERATION. Connect a 16 AWG or larger wire between chassis ground and earth ground utilizing the

shortest path to keep resistance and inductance to a minimum.

POWER CONNECTIONS: Verify the battery voltage matches the input power requirements of the

units.

WARNING: Double-check all connections for tightness and correctness, including polarity

as applicable. Replace all protective covers supplied.

2-2

INITIAL START-UP

Each unit is checked and adjusted at the factory. Verify the electrical connections as described earlier in this

section. The following procedure will check the unit for proper operation and set transmit and receive levels.

This procedure can be performed at any time to verify proper operation.

The following tools and equipment are required:

Digital multimeter with dBm readout function or rms. Fluke or equivalent.

Flat-blade-screwdriver with 1/4-inch wide tip.

Flat-blade-screwdriver with 1/8-inch wide tip or potentiometer adjustment tool.

Input and output level adjustment.

Unless otherwise directed, follow the steps in the order presented. Comments and typical results will

appear in italic.

1. Verify that the MAIN POWER switch, located on the front of the LINE INT module, is OFF.

2. Using a flat-blade screwdriver, loosen the two captive screws securing the TRANS module to the

chassis.

3. Remove TRANS module from chassis by pulling on the handle.

4. Set DIP switch SW1 for desired frequency of Channel 1A (see DIP switch settings, Section 3).

5. Set DIP switch SW2 for desired frequency of Channel 1B (see DIP switch settings, Section 3).

6. Set DIP switch SW2 for desired frequency of Channel 2A (see DIP switch settings, Section 3).

7. Set DIP switch SW4 for desired frequency of Channel 2B (see DIP switch settings, Section 3).

8. Set DIP switch SW5 for desired bandwidth of all channels (see DIP switch settings, Section 3).

9. Set DIP switch SW6 for desired Trip boost level of Channel 1A & 1B (see DIP switch settings,

Section 3).

10. Set DIP-switch SW7 for desired Trip boost level of Channel 2A & 2B (see DIP switch settings,

Section 3).

11. Set all the DIP switches on SW9 in the “OFF” position to turn off the pilot tone function.

12. Reinsert the TRANS module into the chassis and secure it in place by tightening the two

captive screws with a flat-blade screwdriver.

13. Place the MAIN POWER switch, on the front of the LINE INT module, to the ON position.

14. Set the multimeter for dBm measurement.

15. Connect the positive multimeter lead to the TX OUT 1 test point on the front of the TRANS module,

and connect the negative lead to the COMMON test point.

2-3

16. Note the indication on the multimeter. This is the output of Channel 1. Set to +2dBm (this will result

in 0dBm at the output).

17. Connect the positive multimeter lead to the TX OUT 2 test point on the front of the TRANS module,

and connect the negative lead to the COMMON test point.

18. Note the indication on the multimeter. This is the output of Channel 2. Set to +2dBm (this will result

in 0dBm at the output).

19. Disconnect the multimeter test leads from the TRANS module.

20. Place the MAIN POWER switch, on the front of the LINE INT module, to the OFF position.

21. Using a flat-blade screwdriver, loosen the two captive screws securing one of the REC modules to

the chassis.

22. Remove the module from the chassis by pulling on the handle.

23. Set the REC module to Low-gain (High-gain A & B, Low-gain B & C (see Section 4-E, Receiver,

for description of Gain setting)).

24. Set DIP switch SW3 for desired frequency of Channel A (see DIP switch settings, Section 3).

25. Set DIP switch SW2 for desired frequency of Channel B (see DIP switch settings, Section 3).

26. Set DIP switch SW4 for desired bandwidth of all channels (see DIP switch settings, Section 3).

27. Reinsert the REC module into the chassis and secure it in place by tightening the two captive

screws with a flat-blade screwdriver.

28. Place the MAIN POWER switch, on the front of the LINE INT module, to the ON position.

29. Connect the positive multimeter lead to the REC OUT test jack on the front of the REC module that

was removed from chassis during step 22. Connect the negative lead to the COMMON test point on

the same card. The meter will read the incoming signal.

30. Verify that the unit is receiving a steady incoming Guard signal (no Trip or line noise).

31. Press and hold SENS SET switch on the REC module front panel.

32. Using a small screwdriver or potentiometer adjustment wand, slowly turn SENS potentiometer

counterclockwise until the GUARD LO indicator begins to flicker.

33. Release the SENS SET switch.

34. Repeat steps 20 through 33 for the other REC module.

The above procedure will set your Receivers for a 20db dynamic range.

35. Refer to Section 4-F, Logic, for programming the options available on the Logic module. If the

Logic module’s programming is to be changed, go to step 36, if not, skip to the end of this section.

2-4

36. Place the MAIN POWER switch, on the front of the LINE INT module, to the OFF position.

37. Using a flat-blade screwdriver, loosen the two captive screws securing the LOGIC module to the

chassis.

38. Remove the module from the chassis by pulling on the handle.

39. Set DIP switch S1 to program: Single or Dual channel, Trip Boost, the Pre-Trip timer, the Transmit

Flasher, the Trip Hold timer, and the Guard before Trip options (see Section 4-F, Logic, for DIP switch

settings and descriptions).

40. Set DIP switch S2 for desired Mode and Bandwidth if SET/AutoSET is not an option on the Logic

module (see Section 4-F, Logic, for DIP switch settings). If the Logic module has SET/AutoSET, set DIP

switch S2 for those options (see Section 4-F, Logic, for DIP switch settings and descriptions).

41. Reinsert the LOGIC module into the chassis and secure it in place by tightening the two captive screws

with a flat-blade screwdriver.

42. Place the MAIN POWER switch, on the front of the LINE INT module, to the ON position.

If the above procedure was successfully completed, the terminal is working properly. If the procedure could

not be completed, or if a malfunction is suspected, refer to the maintenance information in Section 7 and

the information on the individual cards in Section 4 to determine the source of the problem. Once the

problem is located and corrected, repeat the initial startup procedure to assure that the unit is functioning

properly.

2-5

2-6

Table of contents

Other Iniven Touch Terminal manuals

Popular Touch Terminal manuals by other brands

Ericsson

Ericsson W25 quick guide

Immarsat

Immarsat Wideye FX 250 installation manual

Thrane&Thrane

Thrane&Thrane Explorer 727 user manual

Festo

Festo VTSA-ASI 4E4A-Z Series Brief description

Sperry instrument

Sperry instrument UTS 30 System installation

Allen-Bradley

Allen-Bradley PanelView 600 installation instructions