Iniven PDR-2000 User manual

PDR-2000

DIGITAL TELEPROTECTION TERMINAL

INSTRINSTR

INSTRINSTR

INSTRUCTION MANUUCTION MANU

UCTION MANUUCTION MANU

UCTION MANUALAL

ALAL

AL

12.10.08

WARRANTY AGREEMENT

We hereby certify that the INIVEN product line carries a warranty for any part

whichfailsduringnormaloperationorservicefor12years. Adefectivepartshould

be returned to the factory after receiving a return material authorization number

(RMA),shippingchargesprepaid,forrepairf.o.b.Somerville,NewJersey. Incase

INIVEN cannot promptly return the unit to you it will endeavor to provide a loaner

until the repair or replacement is returned to you. Any unauthorized repairs or

modifications will void the warranty. In the case of parts not being commercially

available,INIVENreservestherightto replacetheunitwith afunctionallyequivalent

unit.

5 Columbia Road, Somerville, NJ 08876

i

SAFETY

Standard safety precautions must be followed at all times when installing, operating, servicing

and repairing this equipment. INIVEN assumes no liability for failure to observe safety

requirements or to operate this equipment for purposes other than intended.

GROUNDING

A suitable ground is required to reduce the hazard of shock. Refer to the enclosed module,

chassis,and/or cabinetwiring diagramfor groundconnection locations.

ENVIRONMENT

Operationofany electrical equipment inarea containing gases ormoisture is apotential safety hazard.

Necessary precautions should be taken.

MANUAL

Operators and maintenance personnel should read this manual before installing the equipment and

placing it in service. Only properly trained personnel with proper tools and equipment should operate,

maintain, repair or service this equipment.

SHOCK

Potentially dangerous electrical shock can occur when working on this product. Protective measures

and safety procedures should be observed at all times.

ii

Table of Contents

1. General

2. Digital Communications

3. On-Board Programming

4. Remote Programming (GUI)

5. Installation

6. System Tests

7. Event Recording

8. Specifications

9. Microprocessor Module

10. Communications Module (RS-422)

11. RS-232 Module

12. DC/DC Module

13. Status Relay Module

14. Trip In Module

15. Trip Out Module

16. Chassis

17. Option Modules

18. Maintenance

19. Glossary

20. Troubleshooting

Section 1 GENERAL

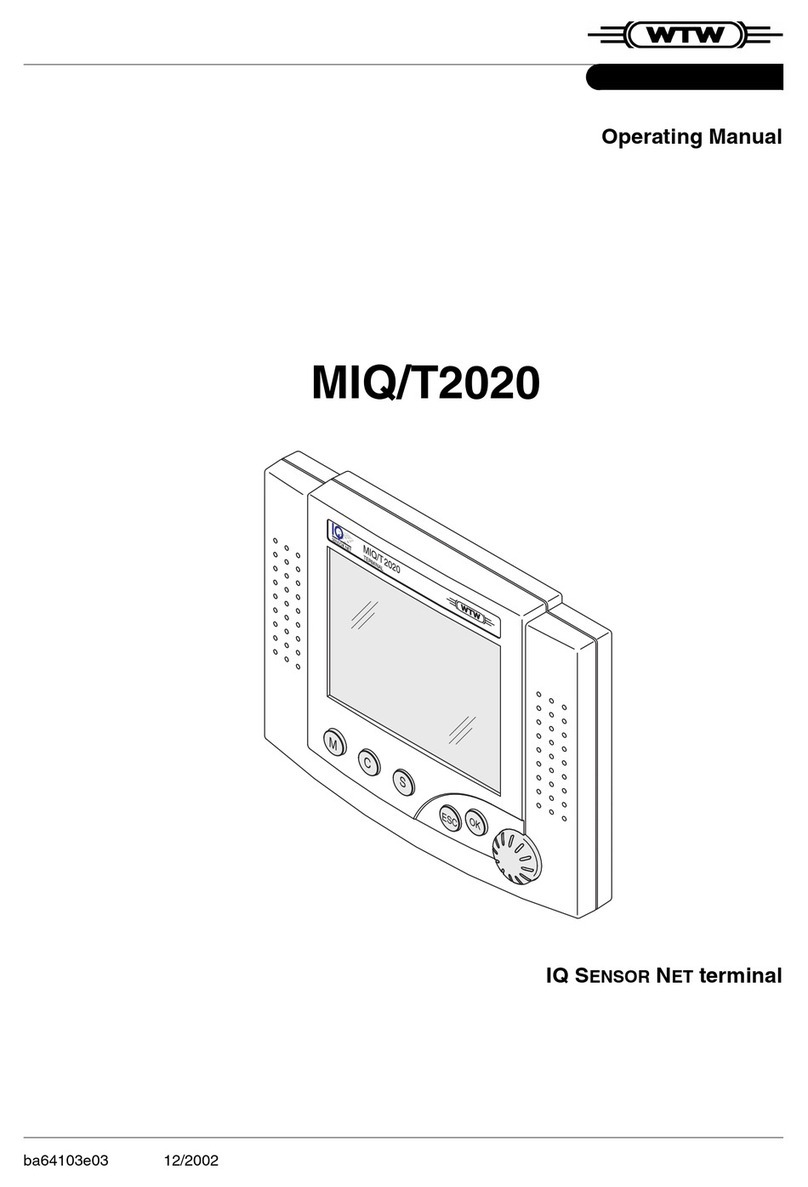

Figure1-1.PDR-2000

DESCRIPTION

ThePDR-2000isadigitalcommunicationssystem used for the protection of electrical power generation

and distribution equipment. A protection system consists of two or more PDR-2000 terminals

communicating with each other via a digital channel (i.e., 56/64 Kbps RS449, fiber optics or 64 Kbps

G.703). The PDR-2000 can also be used over a voice grade audio channel when equipped with an

Audio Communications module. Up to eight Trip commands can be inputted to the unit and up to

sixteen Trip outputs may be provided from a terminal.

FEATURES

DESIGN: The PDR-2000 has been designed for ease of setup, use and field modification. The units

modularity allows for quick diagnostics, module replacement and addition of optional modules by the

user. Multiple communication ports, up to eight Trip inputs and up to sixteen Trip outputs make the

PDR-2000 extremely efficient.

PROGRAMMABILITY: The settings of the PDR-2000 are completely programmable both on-board

and remotely via local or remote RS-232 ports. Firmware changes can be loaded using the GUI

(Graphical User Interface) allowing software upgrades to be made easily in the field.

UNIT ID: Unit ID is a software selectable feature that requires the receive logic to confirm the Unit ID

number that is transmitted on every packet to increase security and prevent accidental tripping. The

UnitID permits the terminalto uploadthe statusand settings ofa remoteunit andretrieve datafrom it’s

Event Recorder. Unit ID in combination with two communication ports allows the unit to offer a feature

called Packet Forwarding.

PACKET FORWARDING: A PDR-2000 uses Packet Forwarding to communicate beyond a unit it is

directly connected to via the digital communications channel. Since the PDR-2000 has two

communications ports and is capable of transmitting information to two units simultaneously, with the

useofPacket Forwarding, multiple units maybe arranged ina string or aloop. Packet Forwarding may

1-1

be used for Trip commands by turning the feature On in the software settings. Other information such

as events, unit status and settings use Packet Forwarding automatically. Packet Forwarding is not

used for audio applications.

EVENTRECORDING: The PDR-2000 has a built in sequence of eventsrecorder. ThisEvent Recorder

time stamps all activity that takes place in the unit. Events include all Trip and Guard inputs and

outputs,statusrelayactivation,passwordaccess,and initial power on, see Section 7, Event Recording,

for a complete list.

Up to 40,000 events are stored in nonvolatile memory before the process of overwriting the events

begins. Eventsmaybe viewed oneatatimeon the frontpanel orupto1000events may bedownloaded

and sorted using the PDR-2000’s Windows® based GUI.

COMMUNICATIONS: The PDR-2000 is equipped with two communication ports regardless of which

type is supplied (RS-449, Fiber Optic, G.703, or Audio). Two communication ports makes the PDR-

2000 extremely flexible. They may be used independently, allowing the unit to communicate with two

units (or more with Packet Forwarding) simultaneously or they can both be used to communicate to

one unit creating a redundant path for added security.

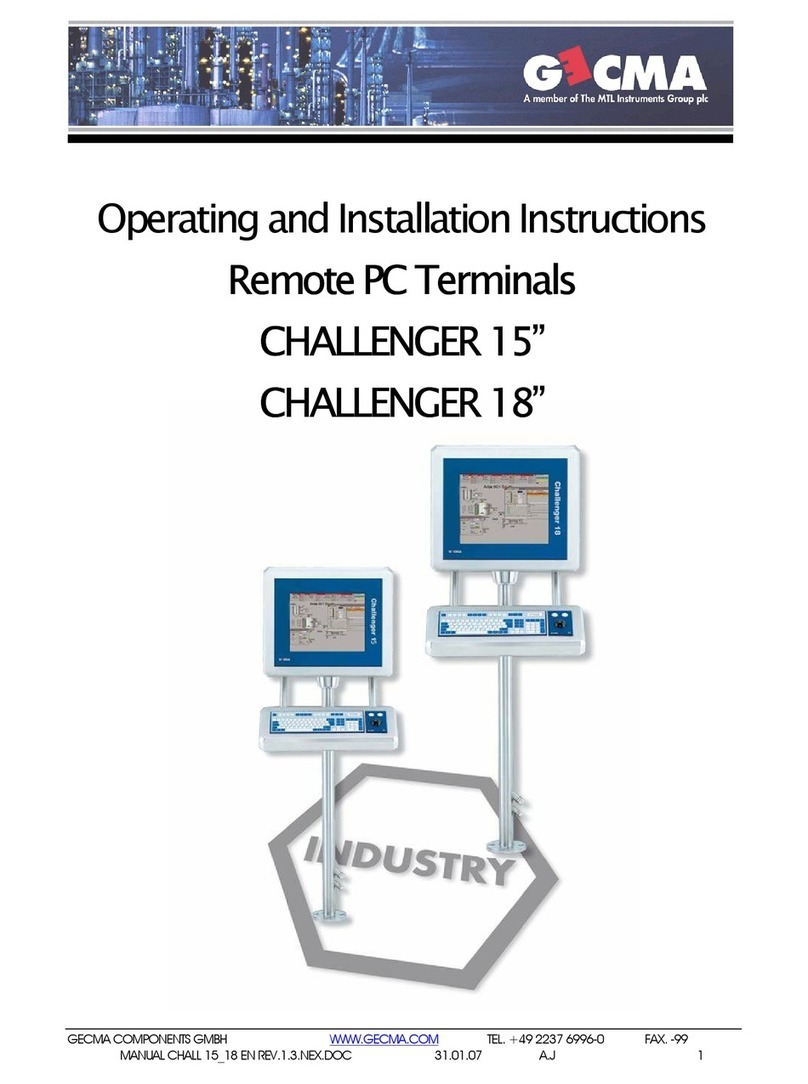

SPEED: The PDR-2000 is a high speed communications terminal. Trip times average approximately

3 ms for digital interfaces and 14 ms for the audio interface. Due to the size of the PDR-2000

communication packets and the delays inherent to multiplexed digital communications, times vary,

see Section 2, Digital Communications, for more information on packets. For those units equipped

with optional dry contact Trip relays, add approximately 3 ms to the Trip time for 10 amp relays and

approximately 1 ms for 30 amp relays. In-serviceTrip times can be determined by using the Ping Test,

which is initiated on the front panel or GUI, see Section 6, System Tests, for more details.

Channel speed is measured with two back-to-back terminals and does not include channel delays.

Figure 1-2. Digital Trip Times

1-2

0

10

20

30

40

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

TRIP THROUGH TIME (msec)

PERCENTAG

E

SYSTEM SUMMARY

The following is a brief description of the standard modules that comprise a typical terminal. For

detaileddescriptions,schematicsandparts lists,refertotheindividualmodule’ssection inthismanual,

Sections 9 through 17.

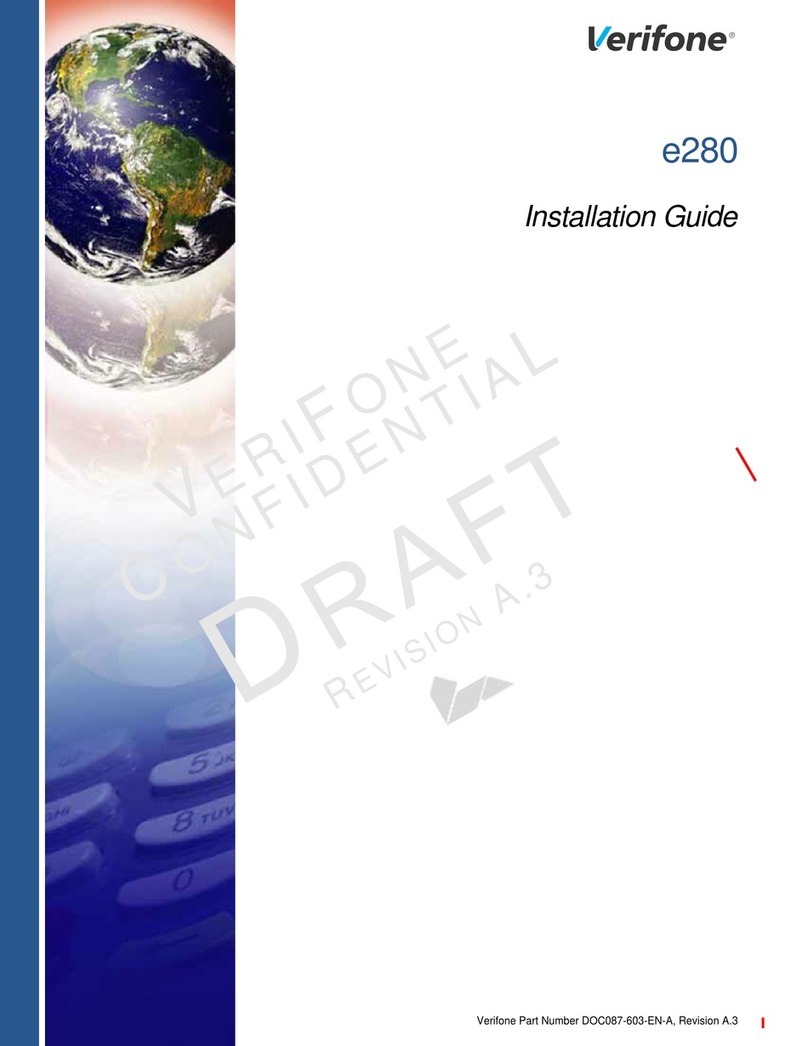

MICROPROCESSOR MODULE: This module, located behind the Display module, controls all of the

functions of the PDR-2000. The Microprocessor module (uP module) monitors and controls all Trip

inputs and outputs and system status. All event recording, communications and programming are

also controlled by the uP module. The Display module is directly connected to the uP module. A

proprietarysoft-core processorresidingin anAlteraFPGAandFLASHmemoryarethemaincomponents

that run the module. A real time clock with battery backup is also on this module. The PDR-2000

requires one uP module, but an optional second module can be installed for redundancy.

DISPLAYMODULE: The Display module ismade upof a 4X 20 characterVacuum Florescent Display

(VFD)and a fourteen key keypad. Thekeypad has fourfunction keysand ten alphanumerickeys. The

VFD is used to display Channel status, time and in conjunction with the keypad can be used to

programtheunit, perform tests and view events. TheVFD and keypad areconnected directly to theuP

modulevia ribbon cables. This module ishinged onthe left andswings outof the wayto accessthe uP

module(s) and the Communications module.

COMMUNICATIONSMODULE: Locatedbehindthe Displaymoduleandto therightofthe uPmodule(s),

this card converts the communications coming from the uP module to the format used in the system,

i.e.RS-422,G.703,fiber optic or audio. The COM module(Communications module) differsdepending

on the type of communications supplied with the unit.

RS-232 MODULE (Data module): The RS-232 module contains two main circuits. The first contains

the RS-232 circuits for the front (DCE) and rear (DTE) RS-232 communication ports and electrically

isolates them from the uP module. The second contains the IRIG-B circuitry that coverts the GPS

clock input for the uP module. This module may be replaced for optional protocols.

DC/DC MODULE: The standard redundant DC module converts, handles, and monitors the power in

the PDR-2000. External power coming into the unit is fused and passed into the DC convertors

located on the board and is fused again coming out of the DC convertors. Power is then distributed

throughout the rest of the unit. The power is also monitored and is clamped if it goes high and then

reset. The module is capable of handling up to two DC inputs that can be the same or different

voltages. The DC module has two status relays whose contacts close in case of power failure.

STATUS RELAY MODULE: This module contains eight form A/B relays and LED indicators on the

frontpanel. Conditionsthat will result in an alarminclude: a uP modulefailure, loss of communications,

masteralarm, unitidentificationdisabled, orcommunicationblock. Twooutputsmayalsobe programmed

to indicate one of seven events, Trip In, Trip Out, invalid Unit ID received, loss of communication of

indirectlyconnectedunits,biterrorsoneitherComport,or a Ping test failure that can indicate excessive

propagationdelay.

TRIP IN MODULE: Up to eight trips can be input into the PDR-2000, these are handled by the Trip In

module. Thismodulecontains optical isolators and communicates detected trips withthe uP module.

TRIP OUT MODULE: The Trip Out module has eight optically isolated solid state Trip output circuits.

Trip outputs can be programmed by the uPmodule. The Trip Out module can also be used to drive up

to 8 optional dry contact relays. A redundant Trip Out module is available that increases the total Trip

out circuits to sixteen.

1-3

Figure 1-3. PDR-2000 System Block Diagram

1-4

VERSIONS

HARDWARE: The PDR-2000 may be configured with different hardware arrangements. Items that

differ are battery voltages, the number and type of Trip out circuits, redundant circuits and modules,

and methods of communication. The part numbering system for the PDR-2000 is explained in

Table1-1. Thepartnumber covers all standard configurations. Any option module not listed is assigned

a number that is placed in the last field (Special).

Table 1-1. PDR-2000 Configuration Menu

Anyrevisionmadeto an individual module changes the dashnumber of the modules “CC” partnumber.

EXAMPLE: The Trip Out module’s part number is CC2245-00. If a change were made to the module

it would be assigned the number CC2245-01.

Changes to a CC number are made only when modifications have been made to the hardware of the

module. Typically, a new dash number will replace the old version and when ordering a PDR-2000

dash numbers do not need to be specified.

SOFTWARE:There are two typesof software that relate tothe PDR-2000. The GUIis run ona PC and

does not directly affect the operational parameters. The GUI is used to change settings, review the

status of a unit, view events, and download firmware. Firmware is the software that performs all the

functionality of uP module and resides in the microprocessor module. Both types of software are

independent of each other and maintain their own version numbers.

1-5

PDR-2000

- - - - - - -125 00A11X

X

24

Power Supply Voltage

24 - 24VDC

48 - 48VDC

125 - 125VDC

250 - 250VDC

Redundant

Power Supply Voltage

24 - 24VDC

48 - 48VDC

125 - 125VDC

250 - 250VDC

Dry Contact Trip

Relay Options

00 - No Optional Relays

01 - 1 Universal Relay Module

02 - 2 Universal Relay Modules

10 - 1 Heavy Duty Relay Module

20 - 2 Heavy Duty Relay Modules

11 - 1 Univ & 1 HD Relay Module

1 - 1 Trip Out Module (STD)

2 - 2 Trip Out Modules

Trip Out Module

1 - No Redundant

Logic Module

2 - Redundant

Logic Module

Redundant

Logic Module

Special

Consult Factory

for Dash Number

A

- 56/64Kbps, RS-449

B - 64Kpbs, G.703

C - C37.94 Fiber 2Tx 2Rx

D - Audio

For Other Fiber Optics

Communications Options

F -X X X

5 - 1550nm, sm

3 - 1300nm, sm

1 - 1300nm, mm

8 - 850nm, mm

1 - 1Tx 1Rx

2 - 2Tx 2Rx

S - Laser

D - LED

TheGUIversion number is PDR2000 GUI 1.1. Thenumber at the end(1.1) is the versionnumber. The

version number is part of the name of the GUI that is located on the Desktop or in the INIVEN folder as

part of the Start menu. The date the software was created may be found on the lower right hand side

of the System Configuration Screen.

The Firmware version number is found one of two ways. Using the Keypad and Display and going to

the Diagnostics menu or by using the Get Settings feature in the GUI. See Section 3, On-Board

Programming and Section 4, Remote Programming for more details on using the Keypad and Display,

and the GUI. A sample Firmware version number is: PTG-0025 10/10/03. The date at the end of the

numberiswhenthe version was created and can beusedalongwiththeprefixtokeeptrackof revisions.

The features of the GUI and Firmware described in this manual are written for the version numbers

indicated on the first page of this manual.

1-6

Section 2 DIGITAL COMMUNICATIONS

The PDR-2000 uses two types of digital communications. The first is the main unit to unit

communications that passes through the Com ports on the back of the chassis. The Com ports may

be 64 Kbps RS-422 (using a RS-449 connector), point to point fiber optic, short haul fiber optic (ANSI

C37.94), or G.703. The type of unit to unit communications is determined by the type of Com module

installed. The second type of communications is the asynchronous communications from the two 9

pin RS-232 ports located on the front and rear panels. If a protocol other then RS-232 is supplied with

the unit, its function is described in Section 17, Option Modules.

COMMUNICATION PORTS

The unit to unit communications involves three modules; the microprocessor module (uP module), the

communications module (Com module), and the communication port module (Com port module).

COM PORT MODULE

The Com port module is a physical interface that allows for different types of connectors to be used

with the PDR-2000. Two screws attach this module to the rear of the chassis. It mates to a connector

located on the Interface board, see Section 16, Chassis for more information. The Com Port module

comeswithtwocompleteinterfacesofwhichevertypeissuppliedwiththeunit. Forfiberopticinterfaces

this includes two transmit and two receive heads. This allows the PDR-2000 to communicate over

two different paths to two units simultaneously. The two Com ports transmit the same packets but

receiveindependently. Programmingthereceivelogic allowsaunitto discriminate whichTripcommands

to respond to (see Section 5, Installation or Section 4, Remote Programming for more details on

setting receive logic and programming Com ports).

The available connectors are: RS-449 D-sub, single mode fiber (1550 and 1300 nm), multimode fiber

(1300and 850 nm), G.703D-sub,and voice grade audioterminal blocks. TheCom portmodule isfield

changeable,but requiresthematchingCom moduletohandlethedifferenttypesof digitalcommunication

protocols. Electrical connectors are isolated to at least 5000 V.

COMMODULE

The Com module is located in the third slot from the left behind the keypad and display. This module

takesthedigital communications packet fromthe uP module andconverts it tothe appropriate protocol

forthe type ofcommunications beingused: 64Kbps (RS-449),point topointfiber optic, short haulfiber

optic (C37.94), G.703, or Audio. This module matches the Com port module’s connector type on the

rear of the chassis.

uP MODULE

The uP module creates the communications packets that are converted by the Com module to a

particular protocol, i.e. RS-422. The uP module is capable of synchronous and asynchronous

communications. Synchronous communications are used by all unit to unit communications.

Asynchronous communications are used by the RS-232 ports or other protocol used for unit to PC

communications.

The uP module also controls the output of the Com ports. The Com ports can be turned On or Off

individually in the settings software.

2-1

DIGITAL PACKETS

The communications packet created by the uP module varies in length depending on the information

being transmitted. The minimum packet length is 40 bits (forTrip and Guard communications) and the

maximum length is 152 bits (for communicating settings).

ThePDR-2000iscapable,aslisted previously, of communicating more thenjustTrip andGuard inputs.

By using the PDR-2000 GUI (Graphical User Interface), a local unit can be used to get the status, get

the settings, get the events, send new settings, and send an erase events command to a remote unit.

Packets can travel from unit to unit, PC to unit, and unit to PC. Trip/Guard commands are sent from

unit to unit. Sending information regarding status, current settings, and events are sent from a unit to

a PC. A request for information (including status, settings and events), an erase events command,

anda download of settingsor firmwareoriginate fromthe PCand aresent toa unit. Allinformation can

be forwarded, other than firmware. Firmware must only be downloaded from a PC directly to a unit.

DIGITALPACKETSTRUCTURES

There are several types of packets that are used by the PDR-2000.

TYPEA

Trip/Guard Commands

Byte 1 Sync word

Byte 2 Unit ID number

Byte 3 Trip input status (Guard - 0, Trip - 1)

Bytes 4 and 5 CRC code

TypeApackets always have priority over all other packet types. Other packet types are sent when the

Trip inputs are not changing state. Type A packets are transmitted between the packets of another

type when they are in a string, even if there is not a change of state for theTrip inputs. TypeApackets

can only be generated and received by a PDR-2000. The packet size is always 40 bits.

2-2

TYPE B

Ping Tests

Byte 1 Sync word

Byte 2 Second sync word

Byte 3 Packet size

Byte 4 UnitID to

Byte 5 Command

Byte 6 Unit ID from

Bytes 7 and 8 CRC code

Type B packets are used only when executing a Ping test, see Section 6 for more information on Ping

tests. All types of Ping tests (manual, automatic, GUI generated, and keypad generated) use similar

packet structures.

TYPE C

Get Status, Get Settings, Get Events, Get Inputs, Erase Events

Byte 1 Sync word

Byte 2 Second sync word

Byte 3 Packet size

Byte 4 UnitID to

Byte 5 Command

Byte 6 Sub-command

Bytes 7 and 8 CRC code

Bytes 9 and 10 Footer

Type C packetsare all generated from thea PC usingthe GUI. All ofthese packetsare requestsfor the

unit to perform a function, whether it is to return data to the PC or to erase events in the Flash memory.

These packets can be forwarded along the Com link connecting units until the PDR-2000 addressed

by the GUI is reached.

2-3

TYPE DAND E

Type D packets are used for a unit to send responses to the PC in reply for a request for information.

Uploading settings, status and events are three types of information sent. Type D packets are also

used to download settings and firmware to the unit from the PC. Type D packets vary in length but

never exceed 152 bits in length. These longer packets are required to accommodate the amount of

information that needs to be sent. All type D packets use similar structures to type C packets but vary

in construction as the steps of transferring data take place. After a type D packet has been sent, the

sender, whether the unitor GUI, requiresa typeE packetas a response before itwill sendanother type

D packet.

A type E packet is a simple 7 byte packet that tells the sending unit that the previous packet was

received successfully or not. If the sending unit receives a type E packet that indicates the previous

packet was received successfully, it sends the next type D packet. If the sending unit receives a type

E packet that indicates the previous packet was not received successfully, it re-sends the previous

packet, at which time it waits for the next response in the form of a type E packet and will repeat the

message again if necessary. This process is to ensure that all data is received accurately and to

prevent the unit or GUI from locking up do to faulty communications. Firmware must be downloaded

from a PC directly to the unit being updated. All other information can be forwarded automatically to

indirectly connected units.

2-4

CRC

The packets are checked using the CRC code (Cyclic Redundancy Check). The PDR-2000 uses the

CRC-CCITT polynomial for the CRC with the formula: x16 + x12 + x5 + 1. If a packet fails the CRC, the

datain the packetis disregarded. Theunitstarts counting thenext 999packetsand writes tothe event

recorder the percentage of bad packets received over the 1000 packets. This process is not initiated

again until a packet with a CRC error is received. If the Status Relay module is programmed for a bit

error alarm, the LED and relay will be activated for the duration programmed, see Section 3 (On-Board

Programming) or Section 4 (Remote Programming), for instructions on programming Status Alarm

relays. 100ms of bit errors will cause a loss of communications alarm on the Com port(s) with the bit

errors. One error free packet is required to reset the communications channel.

TheuPmodulealsochecksforcommunicationsfailure. Ifno recognizable communications are sensed

on the input of the Com port, a communications failure alarm will close and a time stamped event will

be logged for the Com port from which the communications failed.

Thedifferenttypesofpacketsareprioritized. ATrip/Guardpacketalwayshaspriorityoverother packets.

Whendatapacketsother thenTrip/Guardpacketsaresent, they are interlaced withTrip/Guardpackets

in order to maintain the fastest Trip times possible. When the state of the Trip inputs and outputs is

stable, the other packet types are again transmitted.

UNITID

A Unit ID number is included in every packet. This is the number assigned to each unit to differentiate

it from other units on the same communications system (see Section 3, On-Board Programming, to

program Unit ID). The Unit ID number is used in two ways. First, the Unit ID number allows the GUI to

program locally or remotely a unit, get the status, events and settings. This is stored in the unit and is

used to respond to queries addressed, with the Unit ID number, for that unit. The other use of the Unit

ID number is for acceptance of Trip commands. When a packet is received, if the receiving unit has

the Unit ID feature turned On, the Unit ID number in the packet must agree with the receive logic in

order to accept the Trip command, increasing security.

The PDR-2000 continually updates the status of theTrip outputs based on the packets being received.

The status of an output (Trip/Guard) is maintained until a new packet is received with different (Trip/

Guard) commands.

The PDR-2000 does not use the Unit ID number to address to a particular unit. It is used as an

address from a unit. The receive logic determines if the Unit ID number as well as the Trip/Guard data

containedinthereceivedpackethave the requirements to output aTrip. Thisallowstheunitto be more

flexible and does not require direct connections between units to allow tripping.

Ifcommunications were tocease, theUnitID number allowsthe unittoblock individualTrip outputs. In

cases where one of the two Com ports is still operating, the PDR-2000 blocks the outputs that are

programmedwith the Unit IDnumbers that areno longerbeing received. Depending onhow theunit is

programmed, the output will block in 500 ms or less, see Section 3 (On-Board Programming) or

Section 4 (Remote Programming) for alarm programming.

Unit ID should always be used for increased security, but can be turned Off for loop back testing or

other applications. Unit ID must be On when using Packet Forwarding or any other application that

requires both Com ports.

2-5

PACKET FORWARDING

Packet Forwarding is used by the Trip commands and the GUI communications. When the unit is

programmed with the Packet Forwarding feature turned On, all Type A packets are retransmitted.

When a packet is retransmitted, it is received on one Com port and transmitted on the other port.

Packets are not forwarded on the same Com port they are received on.

EXAMPLE: IfUnit10 has Packet Forwarding Onand receives aTypeATrip/Guardpacketon Com port

1, Unit 10 will look at the data for its own operation and retransmit the entire packet out of Com port 2.

A packet with a CRC error will not be retransmitted. The packet will no longer be forwarded when it

reachesthepacket’soriginatingunit,aunitwithonlyone activeComport, oraunitwithPacketForwarding

turned Off.

Packet Forwarding is also used to transmit data and requests for data such as settings or events.

Data packets (all packets other then Type A packets) are forwarded automatically. These packets

forward until the addressed unit or PC are located regardless of whether Packet Forwarding is on or

off. Packets that forward automatically are stopped when they reach their destination, the originating

unit, or a unit with only one active Com port.

EXAMPLE: If a PC is connected to Unit 10 and the Get Status button (see Section 4, Remote

Programming for instructions to operate the GUI) is clicked for Unit 30, Unit 10 will forward the query

out of all active Com ports. If unit 20 receives the query from Unit 10, it will forward the query out the

other Com port (if the other Com port is On) and this process will continue until Unit 30 is found. The

process will reverse itself with Unit 30’s response until it makes it back to Unit 10 and to the PC.

There are two types of schemes that Packet Forwarding can be used, a string or a loop. When used

in a string, trip speeds are not severely impacted because they are moving in one direction. The PDR-

2000determinesautomatically that itisinaloop configuration whenalltheunitshavePacket Forwarding

On. It realizes that a loop exists when packets containing it’s own Unit ID number are being received

on both Com ports. When the unit is in a loop, the spacing between packets is increased to allow for

the additional data that is required on the same bandwidth. Change of state of the Trip inputs causes

theassociated packet to be acceleratedand notwait for thelonger spacebetween packets. In general

trip times will be slower then for units not in a loop.

When requesting data from remote units or changing settings using the GUI when the system is in a

loop, whether or not Packet Forwarding is On, or is being queried by two computers simultaneously,

the unit can only respond to one request at a time. Once the first request for information or attempt to

downloadsettings appears on a Comport, all otherrequests or downloadsare rejected bythe unituntil

the first process is finished or if the first process is interrupted for one second. If a request is made to

a “busy” unit, a message is posted that stating that there is no communications with the unit. If this

happens, wait a few seconds and try again.

It is recommended that no more then four consecutive units in a string or loop have Packet Forwarding

On. When excessive packets exist on a system, some are discarded when timing and bandwidth do

not allow for all packets to be transmitted. This may slow trip times.

2-6

AUDIO PACKETS

When equipped with an Audio Communications module, the PDR-2000 sends the digital information

over a voice grade audio circuit, 300 to 3380 Hz. The audio module uses a unique set of data when

compared to the digital I/O modules.

The Audio Communications module generates 22 tightly spaced sub-channels with a bandwidth of

approximately140Hz each. Twenty of the sub-channelscarry digital data,twoofthe sub-channels are

pilot channels that synchronize both ends of the PDR-2000 communication channel. Of the 20 data

sub-channels, each sub-channel transmits 2 bits for a total of 40 bits. The 40 data bits are made up of

thefollowing:

2 bits for Unit ID and determining packet type

8 bits contain the data (trip/guard) or (settings, status, etc...)

10 bits for CRC error detection

20 bits are a Reed-Solomon bit error correction code

Using a large bit error correction code increases dependability by correcting the most common bit

errors caused by noise. The CRC will reject almost all uncorrectable errors avoiding false trips. Only

packets that can not be corrected are flagged by the event recorder as a bit error.

When Type B, C, D, or E packets need to be sent using theAudio Communications module, they are

sent in their entirety. The packets are broken into 8 bit bytes and transmitted in the 8 bit data field as

described above. Trip/guard packets are alternated with these packets as to not adversely delay trip

functionality. The result is slow transmission of Type B, C, D, or E packets when compared to fully

digital systems.

PACKET FORWARDING

Packet Forwarding must be turned Off when using theAudio Communications module.

The delays and bandwidth restrictions associated with audio communications make Packet

Forwardingslow andimpractical.

UNITID

The Unit ID numbers available when using the Audio Communications module are limited due to the

bandwidth restrictions of an audio line. Only Unit ID numbers 1, 2, or 3 may be used. Do not use any

other Unit ID numbers as they will not be recognized by the communication module. Since Packet

Forwarding does not work with the Audio Communications module, more then 3 Unit ID numbers are

notrequired.

PINGTESTS

When Ping tests are used with the Audio Communication module, the results of the throughput time

will not be accurate. This is due to the parceling of the Ping Test packet as described above. Use of

the Ping test Fail alarm will have to be adjusted to accommodate the length of the test, see Section 6,

System Tests for more details on Ping tests and see Section 13, Status Relay module for more details

on the Ping Test alarm

2-7

2-8

RS-232 COMMUNICATIONS

The RS-232 ports use asynchronous communications to communicate from a PC (using the GUI) to

a PDR-2000. The purpose of this communication is for programming and retrieving information.

HARDWARE

The PDR-2000 comes with two RS-232 ports. A 9 pin DCE port is located in the front of the chassis

and a 9 pin DTE port is located on the rear of the chassis.

The DCE is designed to be directly connected to a serial port of a PC via a straight (not a null modem)

M/F extension cable. The rate on this port is 115200 baud.

The DTE port on the rear of the chassis is designed for remote access via a modem or similar device.

The PDR-2000 GUI provides for connection options including modem driver software, see Section 4

Remote Programming for instructions.

These ports are run from the RS-232 module located next to the keypad and display and has the DCE

portlocatedon its front panel. This module alsocontains the circuitryfor the IRIG-B input. TheRS-232

module provides an isolation of 5000 V between the connector and the unit. This module converts the

asynchronous signal from the uP module to the RS-232 electrical standard.

The GUI is capable of downloading settings, downloading firmware, erasing events, getting events,

getting status, getting settings from the unit it is directly communicating with, and can do all of the

above, except download firmware, using Packet Forwarding.

IRIG-B

The PDR-2000 has the ability to update the internal clock (used for sequence of events recording)

using a standard modulated IRIG-B input from a GPS clock. The standard modulated signal does not

include the year so it must be entered manually (see Section 7, Event Recording for programming

instructions). The uP module uses crystal oscillator to maintain the internal clock. The internal clock

is updated using the IRIG-B signal to maintain a 1 ms accuracy. The internal clock maintains the time

whenthere is noIRIG-Bsignal. If power islost, abatterylocated on theuP modulepowersthe internal

clock. Theinternal clock automatically tries toupdate fromthe IRIG-B signalat Power On. Thebattery

is only used for maintaining the internal clock when the power is turned off. If the battery dies or is

removed, the clock must be set manually or by the IRIG-B input every time the power is turned on.

Section 3 ON-BOARD PROGRAMMING

This section describes all the processes available to program the PDR-2000 without the use of any

external equipment (see Section 5, Installation for step by step installation instructions). There are up

to four ways to program the unit; the Display module on the front panel, a PC using the RS-232 port on

the front panel, a computer using a RS-232 port (or other communication port depending on unit

configuration) on the rear terminal block board, or a computer connected to another PDR-2000.

Programming using the Display Module is described in this section. Chart 3-1, located at the end of

this section, is a flow chart for all the screens available through the Display module.

Downloading new settings does not take the PDR-2000 out of service. When programming

using the Display Module, settings are changed instantaneously when the OK is pressed (as

described later in this section). Unlike using the Graphical User Interface (GUI), On-board

programming is done step by step. It may be recommended in some circumstances to take the

PDR-2000 off-line before making significant changes to the settings using the Display Module.

PASSWORD: No matter which method is used, programming the unit requires it’s password. The

PDR-2000 comes with the default password, 1234, and may be changed to any four digit number.

Iniven retains a manufacturer’s password in case a unit’s password is changed and/or forgotten.

PRIORITY: If a user is programming a PDR-2000 using the Display module, other programming

methods are disabled. As long as the display module is not being used to program the unit, the other

threemethodshave no priority andwill not conflictsince all programminginformation is downloadedall

at once with the click of a mouse. The last changes downloaded are the ones that will be retained and

used by the unit.

TRIP IN/OUT & CHANNELS: Since the Trip outputs can be programmed to operate with different

channels, to avoid confusion, when programming the PDR-2000 Trip Inputs and Trip Outputs are

referred to as 1 through 8. The eight communication sub-channels are referred to as A through H.

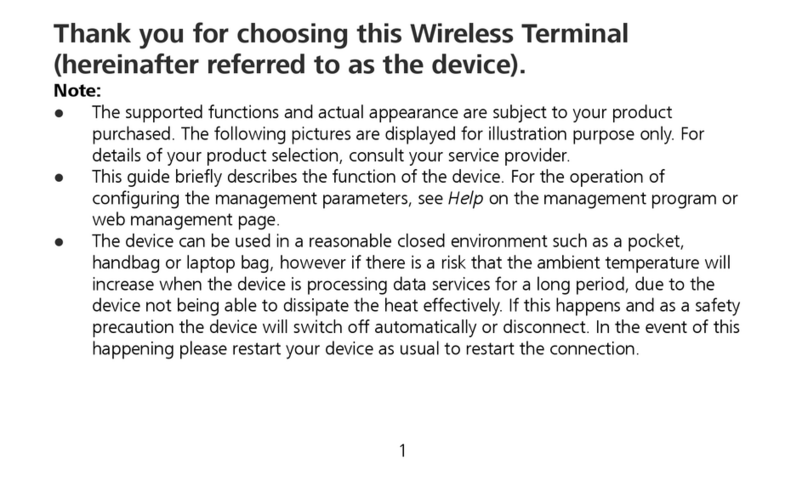

DISPLAY MODULE

3-1

F1 F2 F3 F4

1-A 2-B 3-C 4-D 5-E

6-F 7-G 8-H 9 0

Figure3-1.DisplayModule

The display module uses a Vacuum Florescent Display (VFD) and a keypad to program the PDR-

2000. All the program settings can be made and reviewed by using the Display module. The Display

module is menu driven and controlled by a combination of function keys and alphanumeric entries.

The VFD has 4 lines of 20 characters each. With the exception of the default screen, where the time

isalso shown, the bottomline isonlyused as function keycommands. The topthree linesare used as

menu selection and information display.

Note: If left untouched for approximately two minutes, no matter what screen is presently on the VFD,

the Display module will abort the screen and return to the default display. If a task is left uncompleted,

the system will not be updated. When not in use the display dims to extend it’s longevity.

DEFAULTDISPLAY: Duringnormal operation and whilenot beingqueriedor programmed the Display

module has the following screen:

Figure 3-2. Default Display

TheAthrough H on the first line of the display are the eight communication channels of the unit. To the

left, is a two digit number. This is the Unit ID number assigned to this unit. The next line is the status

of the eight communication channels that are being transmitted. The display will show a G for Guard,

or T for Trip. The third line of the display is the state of the eight receive channels, again using G, Tor

B for Block. The bottom line has the commands for the function keys (F keys) and the time being used

by the Event Recorder.

FUNCTION KEYS: There are four function keys F1 through F4. These keys perform the function

described directly above it on the bottom line of the display.

PROGRAMMING

To program the PDR-2000 press the F1 key to enter the SETUP menu. The next screen will ask you

for the unit’s four digit password. You must enter the correct password before any settings can be

changed. The password when the unit leaves the factory is 1234.

3-2

Figure 3-3. Password Screen

Use the alphanumeric keys to enter the password and press F1 for OK if correct. Press F3 to clear the

entry and F4 to return to the default display.

If the password is entered incorrectly the following screen will allow you to return to the password

screen or exit back to the default display.

0 1 A B C D E F G H

TXGGGGGGGG

RXGGGGGGGG

S E T U P D I A G 1 2 : 4 9 P M

E N T E R P A S S W O R D

____

O K C L R E X I T

Table of contents

Other Iniven Touch Terminal manuals