INNO Instrument M9 User manual

User's Manual

Version:V0.01

01

PAGE

User’s Manual

INNO Instrument, Inc.

Preface....................................................................................................................................4

Chapter1 Technical Parameters.................................................................................................5

Applicable Fiber Type....................................................................................................................5

Splice Loss....................................................................................................................................5

Splice Mode...................................................................................................................................5

Heat Oven.....................................................................................................................................5

Power Supply.................................................................................................................................5

Size and Weight.................................................................................................................6

Environmental Conditions.........................................................................................................6

Others............................................................................................................................................6

Battery precautions...................................................................................................................6

Chapter 2 Installation.....................................................................................................................7

Safety Warning and Precautions...................................................................................................7

Safety Warnings......................................................................................................................7

Maintenance and External Care Precautions........................................................................8

Transport and Storage Precautions..........................................................................................8

Installation upon Delivery............................................................................................................8

Unpacking the Splicer................................................................................................................8

Overview of External Parts ...........................................................................................................9

Power Supply Method............................................................................................................10

Loading or unloading Battery.......................................................................................................10

Charging..............................................................................................................................11

Battery Status..............................................................................................................................11

Battery Refresh Cycle............................................................................................................12

Heat Oven..............................................................................................................................12

Chapter 3 Basic Operation..........................................................................................................13

Turn On the Splicer......................................................................................................................13

Contents

02

PAGE

User’s Manual

INNO Instrument, Inc.

Adjust Monitor Angle...............................................................................................13

Adjust LCD Backlight Brightness............................................................................14

Preparing the Fiber..........................................................................................14

How to Make a Splice.............................................................................................15

Put the optical ber in..........................................................................................15

Inspecting the Fibers..........................................................................................15

Splicing............................................................................................................16

How to Protect the Splice.......................................................................................16

Steps for Heating....................................................................................................16

Chapter 4 Splice Mode..........................................................................................18

Displaying the Current Splice Mode........................................................................18

Selecting a Splice Mode..........................................................................................19

Steps of Normal Splicing Program........................................................................20

Pre-Fusion............................................................................................................20

Fusion.....................................................................................................................20

Splicing Process.....................................................................................................20

Parameters for Normal Splicing Process.................................................................21

Chapter 5 Splice Option..........................................................................................23

Splice Mode Setting..........................................................................................23

Chapter 6 Heater Mode..........................................................................................25

Select Heat Mode....................................................................................................25

Edit Heater Mode..........................................................................................26

Delete Heat Mode..........................................................................................27

Heater Mode Parameters........................................................................27

Chapter 7 Maintenance Menu...............................................................................28

Replace Electrodes..........................................................................................28

Replacement Procedure..........................................................................................28

Stabilize Electrodes..........................................................................................29

03

PAGE

User’s Manual

INNO Instrument, Inc.

Operation Procedure..........................................................................................29

Diagnostic Test........................................................................................................29

Operation Procedure..........................................................................................29

Dust Check............................................................................................................30

Operation Procedure..........................................................................................30

Motor Calibration..........................................................................................30

Operation Procedure..........................................................................................30

Arc Calibration........................................................................................................30

Operation procedure..........................................................................................31

Electrode Setting....................................................................................................31

Update Software..........................................................................................31

Chapter 8 Other Functions & Utilities.....................................................................32

Data Storage..........................................................................................................32

Display Splice Record..........................................................................................32

Delete Splice Record..............................................................................................32

Cancel Data Storage..........................................................................................32

System Setting.......................................................................................................32

Monitor Position......................................................................................................33

Power Save Option..........................................................................................34

System Information..........................................................................................34

Appendix I............................................................................................................35

Appendix II............................................................................................................37

Appendix III............................................................................................................40

04

PAGE

User’s Manual

INNO Instrument, Inc.

Thank you for choosing M9 Arc Fusion Splicer from INNO Instrument. M9 adopts

innovative product design and exquisite manufacturing technology so as to deliver

unprecedented splicing experience to customers.

The totally new technology greatly reduces splicing , and advanced estimation

method and alignment technique ensure the accuracy of splice loss estimation.

The simple-but-trendy product design, sophisticated internal structure and reliable

durability make the splicer be suitable for any operating environment. Dynamic

operation interface and automatic splice mode provide users great convenience.

For more information of M9, please visit our ofcial website at

www.innoinstrument.com

Standard accessory:

FH-40、FH-900、

FH-200/250S

This User Manual explains the use, performance characteristics, and cautions

about M9 fusion splicer and how to install and operate it. The primary goal of this

manual is to make the user as familiar with the splicer as possible.

Important!

INNO Instrument recommends all users to read this manual before operating M9

fusion splicer.

Preface

05

PAGE

User’s Manual

INNO Instrument, Inc.

* SM(ITU-T G.652&T G.657)/MM(ITU-T G.651)/DS(ITU- T G.653)/NZDS (ITU-T

G.655)

* Applicable fiber count; Single core

* Suitable indoor cable diameter: 0.25mm/0.9mm/2.0mm/2.4mm/3.0mm

* Cladding diameter: 80μm-150μ

Same ber is spliced, measured by cut-back method relevant to ITU-T standard.

The typical values of splice loss are:

*SM:0.03dB

*MM:0.02dB

*DS:0.05dB

*NZDS:0.05dB

*G.657:0.03dB

* 7 kinds of heat shrinking tubing: 10mm, 20mm, 30mm, 40mm, 50mm, 60mm,

s40mm(thin sleeve)

* Heating time: 20 to 900s optional.

* Typical heating time: 20s.

* Heating mode: 3 types of in-built heat modes available

* It can be preset 7 kinds of splice mode.

* It can store 10000 records of the latest splice results.

* Splice time: 12s

Chapter1 Technical Parameters

Applicable Fiber Type

Heat Oven

Splice Loss

Splice Mode

* Standard AC power voltage: AC 100 to 240V, 50 to 60Hz;

* Standard DC power voltage: DC 9 to14V

* Power supplied by the Lithium battery:DC 11.1V,3000mAh,Fully charged

time is approximately 2 to 3 hours

Power Supply

06

PAGE

User’s Manual

INNO Instrument, Inc.

* Size:136H x 114W x 125D (including rubber bumper)

* weight:1.67kg (including battery) / 1.43kg (without battery)

* Operating conditions: altitude: 0 to 5000m, relative humidity: 0 to 95%,

temperature: -10 to50 ℃ , the maximum wind velocity: 15m / s;

* Storage conditions: relative humidity: 0 to 95%, temperature: -20 to 60℃ ,

battery: -20 to 30 ℃ for long-term storage

* Observation and display: Two cameras (orthogonally view), 4.3-inch color LCD

display(There's high-strength and impact resistant protective layer on the surface

of the LCD).

* 300X magnification, 400X partial magnification

* Tension test: 1.96 to 2.25N.

* Terminals: Mini USB

1) Do not touch or hit battery with pointed or sharp items.

2) Do not transport or store the battery together with metals.

3) Do not throw, drop, impact, or bend battery, or any knock or stomp on the battery is

forbidden.

4) Do not connect the anode and cathode terminals of the battery with metals such as

electric wire for fear of short circuit trouble.

5) Do not allow battery’s anode or cathode terminal to touch with the aluminum layer

of package made from aluminum laminated plastic film material for fear of short-circuit.

6) In no case the battery cell can be dismantled.

7) Do not immerse the battery into water or seawater, because the battery cell cannot

bear moist environment.

8) Do not place or use the battery beside or near the heat source such as fire or heater.

9) Do not heat battery or throw it into water.

10) Do not directly solder the battery.

11) Do not charge battery near or beside the fire or in a very hot environment.

12) Do not place the battery into microwave oven or any high pressure vessel.

13) Do not allow the battery work or place it in hot temperatures such as in strong

sunshine or hot environment in car for a long time, for fear that battery might be

overheated, on fire, weakened functionally, or shortened in life.

14) Any usage of the damaged battery is forbidden. The battery should be kept away

from fire source when electrolyte leakage occurs or the battery emits electrolyte smell

for fear battery might catch on fire or explode.

Size and Weight

Environmental Conditions

Other

Battery precautions

07

PAGE

User’s Manual

INNO Instrument, Inc.

As M9 is designed for fusion splicing silica glass optical fibers, it is very important

that the splicer should not be used for any other purposes. The splicer is a precision

instrument and must be handled with caution. Therefore, you must read the following

safety rules and general precautions in this manual regarding the use and handling of

M9 at any time. Any behaviors that do not follow the warnings and cautions will break

the safety standard about design, manufacture, and usage of the fusion splicer. INNO

Instrument will not take the responsibility for those consequences caused by misuse!

① DO NOT use the splicer in places where there is a risk of explosion.

② DO NOT touch the electrodes when the splicer is switched on.

Note: The fusion splicer can only use the specied electrodes. Please

choose the electrode replacement option on maintenance menu or turn

off the power before you replace the electrode. Do not discharge the

battery before you install a pair of electrodes.

Chapter 2 - Installation

Safety Warnings and Cautions

Safety Warnings

③ DO NOT disassemble or modify any components of the splicer without approval, except for

the permitted-to-disassemble / modify components or parts by users stated in this manual.

Component replacement and its internal adjustment must be implemented by INNO or its

authorized technicians or engineers.

④ Handle the main supply cable carefully. Pull out the cable from the electrical socket by

holding only the wall plug and not by pulling the cable. Always ensure this cable to be in good

condition. Otherwise, there is a risk of fire or electrical shock.

⑤ To prevent any fire or electrical shock, do not expose the splicer to rain or damp conditions.

⑥ Safety glasses should always be worn during fiber preparation and splicing operation. Fiber

fragments can be extremely dangerous if they come into contact with the eye, skin, or are

ingested.

⑦ Disconnect the AC power cord from the AC adapter inlet or the wall socket (outlet)

immediately if user observes the following or if the splicer receives the following faults::

· Fumes, bad smell, abnormal noise or over heat.

· Liquid or other matter falls into cabinet

· The splicer is damaged or dropped.

If any of these faults occurs, please contact our service center immediately. Leaving the splicer

in a damaged state without any prompt measures may cause equipment failure, electric

shock, or fire and may result in injury or death.

⑧ Do not use compressed gas or canned air to clean the splicer. They may contain

flammable materials that could ignite during the electrical discharge.

⑨ Use the supplied AC power adapter of M9. Use of an improper cord or a damaged cord

may cause fuming, electric shock, or equipment damage and may result in injury, death, or

fire.

⑩ Use the supplied AC power cord of M9. Do not place heavy objects on the AC power

cord. Do not heat or modify the cord. Use of an improper cord or a damaged cord may cause

fuming, electric shock, or equipment damage and may result in injury, death, or fire.

08

PAGE

User’s Manual

INNO Instrument, Inc.

Maintenance and External Care Precautions

Transport and Storage Precautions

Unpacking the Splicer

① Always avoid using hard objects to clean V-grooves and electrodes.

② Always avoid using acetone, thinner, benzol or alcohol when cleaning any part of

the splicer, except for the places advised.

③ Use a dry cloth to remove dust and dirt from the splicer.

④ If the outside of the splicer is dirty, plunge a soft cloth into diluted neutral

washing up liquid, wring out the cloth and clean. Dry the splicer with a dry cloth but

DO NOT use furniture polish or other cleaning agents.

⑤ Always follow the maintenance instructions in this manual.

① When the splicer is moved from cold to warm environment, you should allow the

splicer to warm up gradually. Otherwise, the condensation generated inside will

bring harmful effects to the splicer.

② Pack the fusion splicer well for long time storage.

③ Keep the splicer clean and dry.

④ The splicer is precision adjusted and aligned. Always keep the splicer in its

carrying case to protect from damage and dirt. Put cushion package outside the

carrying case for long distance transportation.

⑤ Always avoid leaving the splicer in direct sunlight or expose to excessive heat.

⑥ DO NOT store the splicer in dusty or humid environment. This may result in

electric shock, splicer malfunction or poor splicing performance.

⑦ Keep the humidity to a minimum level where the splicer is stored. The humidity

must not exceed 95%.

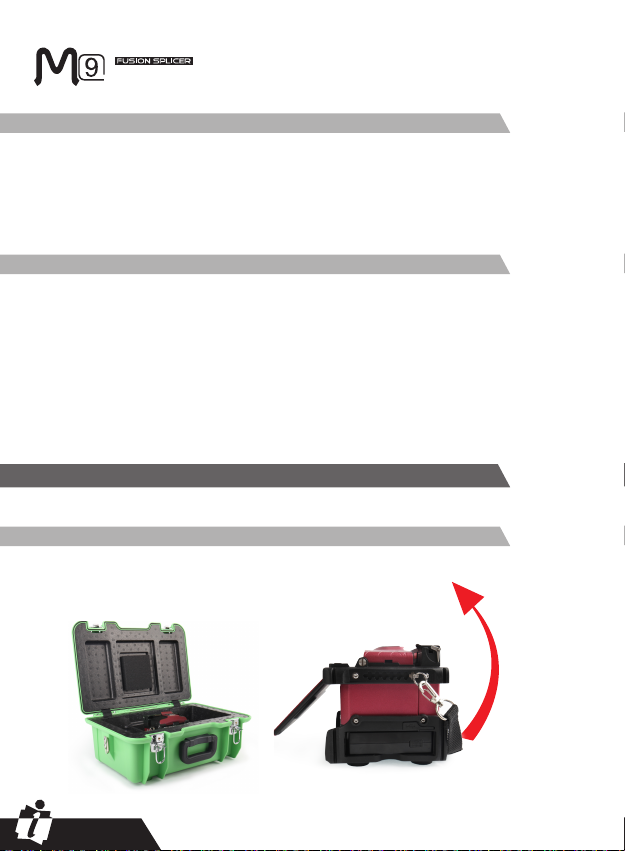

Raise the handle upwards and with a rm grip, lifting the splicer upward and out of

the carrying case. As shown below.

Important!

Please carefully follow the instructions below.

Installation upon Delivery

09

PAGE

User’s Manual

INNO Instrument, Inc.

Overview of External Parts

heat oven

display battery

handle

on/off button Set/Reset keys for operation

Battery charger interface

Mini USB Interface

10

PAGE

User’s Manual

INNO Instrument, Inc.

1. Following is the way of installing a battery.

Power Supply Method

Loading or unloading Battery

Shut off fusion splicer. Press on

release button at lateral, drawing

the battery out of the fusion

splicer.

Place the battery into power unit

slot until you push it into the right

place.

Draw the battery

11

PAGE

User’s Manual

INNO Instrument, Inc.

*When power supply unit is loaded on M9 fusion splicer.

*When power supply unit is detached from M9 fusion splicer.

During charging, the battery indicators will blink.

When battery charge completed, all of the indicators will be on steadily.

Loaded

There are 2 ways for viewing battery level.

① If the battery is connected to the slicer, then battery level will be displayed on the

upper right side of the screen.

② Battery level is indicated by battery LED indicator. You can press “PUSH” to

view the battery level. As shown below:

BATTERY

INDICATOR

Charging

Battery Status

Detached

Note: 1. Before fusion splicing, please check if the remaining battery capacity is

over 20% to prevent battery capacity damage. When fusion splicing or heating

is needed but battery level is lower than 20%, please detach the battery but you

can use power adapter to support operation. 2. The temperature of battery will

increase during charging. So please do not charge for the adapter together with

battery or charge when fusion splicer is still in the carrying case.

12

PAGE

User’s Manual

INNO Instrument, Inc.

How to Install Cleaving Table

When adapter is used for power supply, a power supply indicator will be displayed

at the upper right side on the screen of fusion splicer. As shown below:

The battery should be refreshed or activated periodically for fear

of aging caused by battery memory effect. The method is as

follows:

Keep the splicer in power-on status to discharge until the splicer

switched off automatically due to completely discharging. Then

go on to charge until fully charging completes. Battery refreshing

process completes.

BATTERY

INDICATOR

Battery Refresh Cycle

Heat Oven

Open heat oven lid

cooling tray

13

PAGE

User’s Manual

INNO Instrument, Inc.

Chapter 3 - Basic Operation

Turn On the Splicer

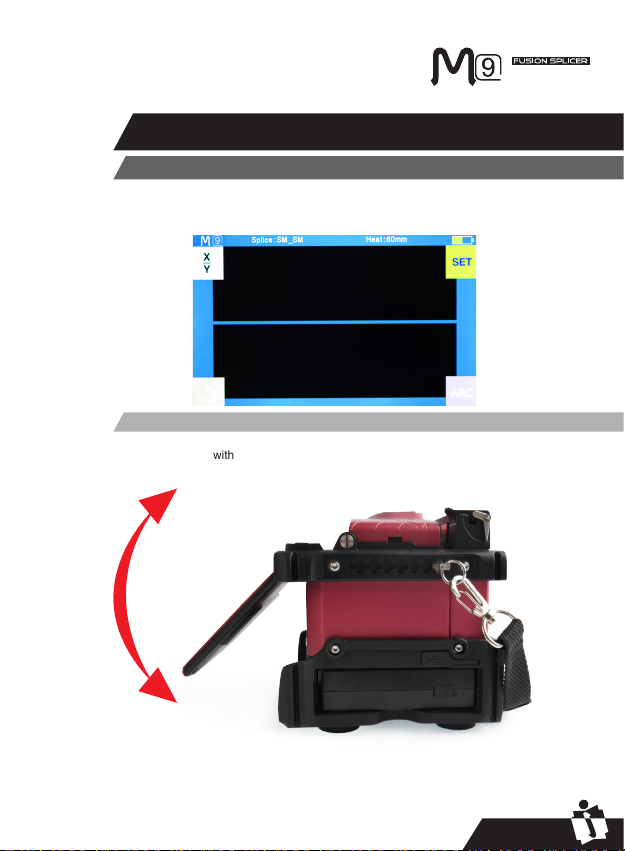

Adjust the monitor with a best angle for your convenient observation and operation

Press the “ON/OFF” button on the top left of the front operating panel of the

splicer. The READY screen of working menu (workbench) will be displayed after

startup, as shown in the following picture:

Adjust Monitor Angle

14

PAGE

User’s Manual

INNO Instrument, Inc.

In the original operating interface (workbench), press the confirmation button then

adjust LCD backlight brightness by tapping the two brightness icons on the LCD

monitor, as the following picture shows:

There are three basic preparatory steps to be completed before the fibers can be

placed in the splicer.

1) Stripping

Remove the sleeve and retain at least 50mm length of coating of optical fiber (valid

for both tight and loose tube optical fiber) with an appropriate stripper. Remove

approximately 30 to 40mm length of primary coating with an appropriate stripper.

2) Clean bare fibers with lint-free cotton tissue soaked in Alcohol.

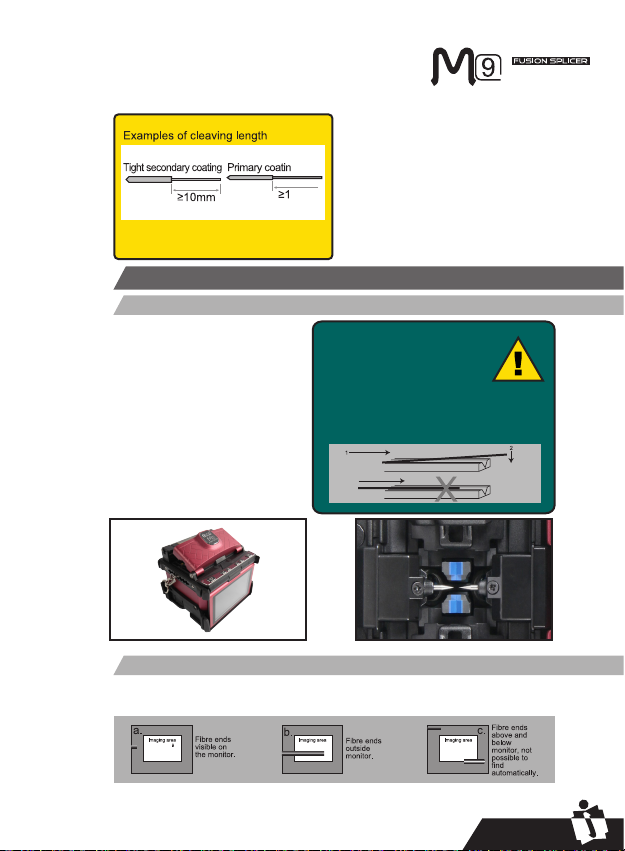

3) How to cleave the fiber

Cleave the fibers by using a high precision cleaving tool.

To ensure good splicing, you should cleave the fibers by using a high precision

cleaver such as the cleaver of INNO V series and you should strictly control the

cleaved length well, as shown in the following picture.

Adjust LCD Backlight Brightness

Note: The LCD monitor is a precise instrument of the splicer and

it is produced in the factory under strict quality control. But there

may be dots of various colors on the screen. The brightness of

the LCD monitor depends on the monitor angle. These symptoms

are not defects of the LCD display but a natural phenomenon.

Preparing the Fiber

Note: always remember to slip a

heat-shrinkable sleeve onto either

end of the fibers at the beginning

of each fiber preparations.

15

PAGE

User’s Manual

INNO Instrument, Inc.

Important!

You must ensure to keep the fibers

clean.

- Avoid putting them down on a dusty

working surface

- Avoid waving them around in the air

- Check if the V-grooves are clean; if

not, wipe them clean with cotton swab

immersed into alcohol.

- Check whether the clamps are clean;

if not, wipe them clean with cotton swab

immersed into alcohol.

use blue V-grooves

(Clamping on bare fiber)

① Open the safety shield.

② Raise the fiber clamps.

③ Position the fibers into

V-grooves. Make sure the fiber

ends are between the V-groove

edges and the electrode tip.

④ Clamp the fiber in position by

lowering both sets of fiber clamps.

⑤ Close the safety shield.

Before continuing with splicing, you should visually check the fibers in the monitor

to make sure they are clean and well-cleaved.

How to Make a Splice

Put the optical ber in

Inspecting the Fibers

Note: Be careful not to slide the

fibers along V-grooves. When

fiber is placed into V-groove,

the fiber end should exceed

V-groove but it can’t surpass

the location of the electrode tips.

(as the following picture shows)

16

PAGE

User’s Manual

INNO Instrument, Inc.

If any defect exists in

the optical fiber, please

take out the optical fiber

carefully and prepare it

again.

① Select any desired

splice mode.

② Splice the fibers by

pressing: “SET”.

After splicing, press the key of “HEAT” to activate “shrink” process after

you have put the optical fiber sleeved with a heat shrinkable sleeve into the

heating oven, heating the heat shrinkable sleeve for purpose of strengthening and

protecting the spliced joint.

① Open the heat oven lid

② Raise left and right fiber clamps on the splicer. Hold the heat-shrink tube, lift the

spliced fibers and hold them taut, move the heat-shrink tube so that it is centered

over the splice point.

③ Move both the fibers and the heat-shrink tube over to the heat oven and place

them in the oven clamps.

④ Press the “HEAT” key to begin heating, when the heating process is finished,

the heating indicator will be turned off automatically and companied by prompt

sound of the buzzer.

Lip

Note:The fibers are checked automatically

when you press Splice button. The splicer

automatically focuses the fibers and checks

for damage or dust particles.

Note: The splicer always starts as “Auto

mode”. The splicing starts once the safety

shield is covered.

Splicing

Steps for Heating

How to Protect the Splice

17

PAGE

User’s Manual

INNO Instrument, Inc.

Heat key

Moving the ber into heat oven

position of splices

Opening the heater lid

Heating Indicator

18

PAGE

User’s Manual

INNO Instrument, Inc.

M9 fusion splicer has a concise and clear menu of splice mode, easy to be

operated. Splice modes define arc currents, splice times as well as various

parameters used when performing a splice. Therefore, it is essential to select the

correct splice mode in accordance with the type of ber you want to splice.

There is a numeric value of “pre-defined” splice modes for common fiber

combinations. However, it is also easy to either modify new splice modes to further

optimize the parameters for more unusual ber combinations.

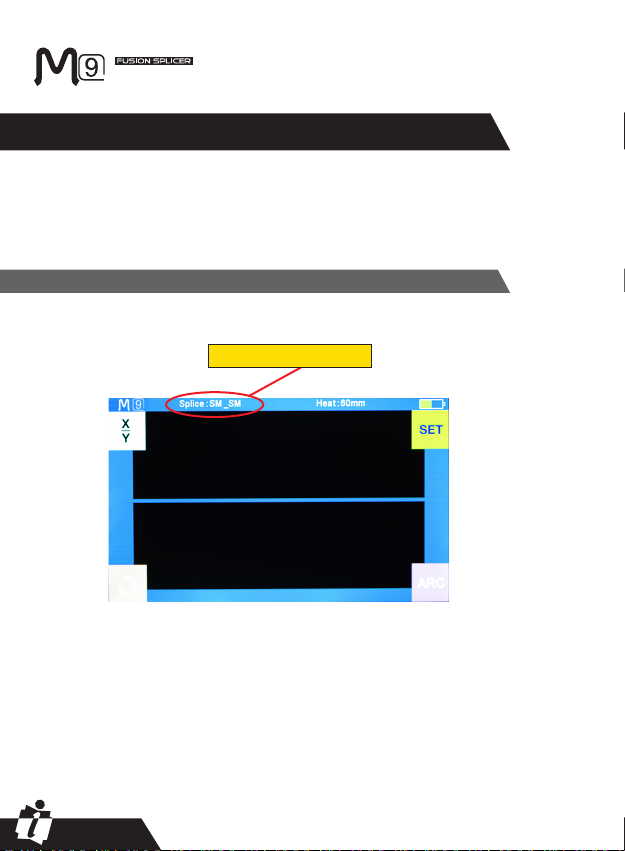

Displaying the Current Splice Mode

The active splice mode in progress at the moment is always displayed at the top of

the screen (as the picture shows).

Active splice mode currently

Chapter 4 Splice Mode

19

PAGE

User’s Manual

INNO Instrument, Inc.

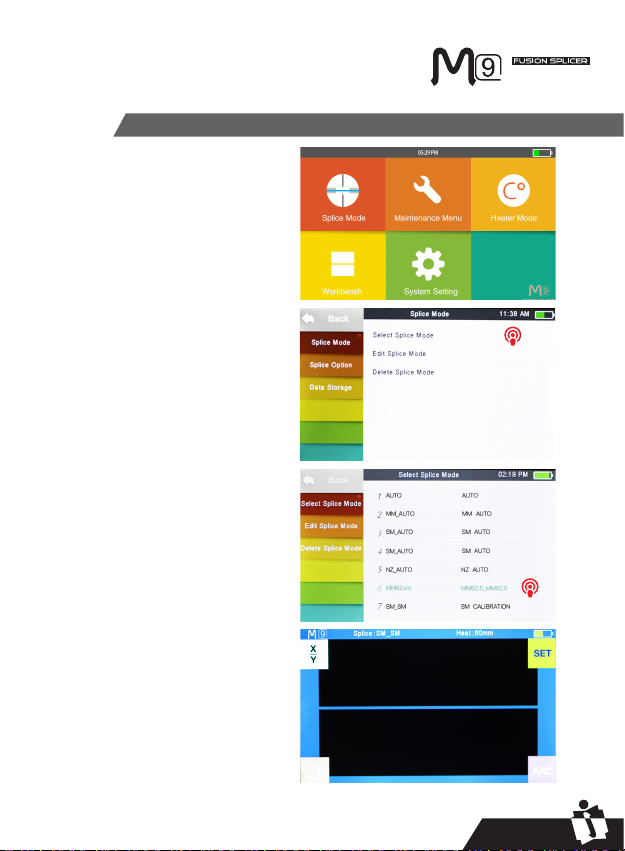

①Enter main menu.

②Click “Splice Mode” for

entry.

③ Click “Select Splice

Mode” before you can

select the splice mode that

you need.

④After viewing and

selecting the splice mode,

you can press the button

of “Reset” to go back to

initial interface.

Selecting a Splice Mode

Table of contents

Other INNO Instrument Welding System manuals

Popular Welding System manuals by other brands

Miller Electric

Miller Electric SCP-200C owner's manual

Climax

Climax AUTOBOREWELDER BW3000 operating manual

Hypertherm

Hypertherm Powermax30 AIR Operator's manual

Air Liquide

Air Liquide OERLIKON CITOMIG 300 XP Safety instruction for use and maintenance

MAC TOOLS

MAC TOOLS MW13O owner's manual

Linde

Linde BOC Smoothcut 100A operating manual

GF Piping Systems

GF Piping Systems TM 160 ECO instruction manual

SincoSald

SincoSald EVOLUTION SP3-C instruction manual

Hypertherm

Hypertherm powermax1000 Service manual

Lincoln Electric

Lincoln Electric statiflex 200-m Operator's manual

DuroStar

DuroStar DS4000WGE owner's manual

Miller

Miller GW-55C owner's manual