INNO Instrument IFS-10 User manual

1

Please read this manual before operating your

fusion splicer, and keep it for future reference.

2013/06 Rev.1.0

ARC Fusion Splicer

IFS-10 User Manual

1

IFS-10

User Manual

2

3

Contents

Introduction

Scope and purpose of the manual

The reader

IFS-10 Arc fusion splicer

Chapter 1: Installation

Safety warnings and precautions

Operational safety warnings

Maintenance and external care precautions

Transport and storage precautions

Installation upon delivery

Unpacking the splicer

The IFS-10 splicer standard

Optional accessories for IFS-10

Overview of external parts

The power connection

General

Mounting the power source

The power supply

General

Charging the battery

Power source and battery status

The heat oven

Chapter 2: Basic Operation

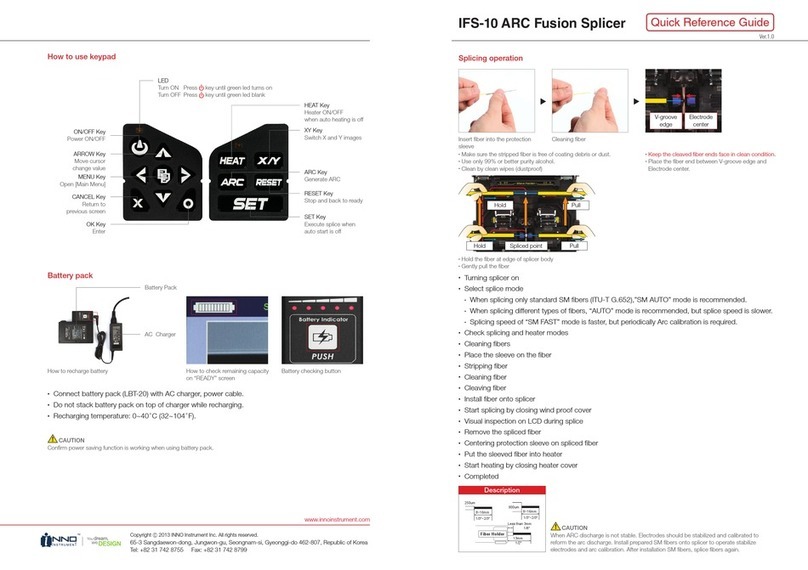

Quick guide

Preparing the splicer

Connecting the power supply

Cleaning V-grooves

Replace electrodes

7

7

7

7

8

8

9

9

9

10

10

10

11

12

13

13

13

13

13

14

15

16

17

17

18

18

18

18

4

Preparing the ber

How to strip the ber

How to clean the ber

How to cleave the ber

How to make a splice

Inserting the bers

Inspecting the bers

Splicing

How to protect the splice

Prepare to move ber from the splicer to the oven

Moving the ber to the heat oven

Shrinking

Resetting the ber movement motors

Chapter 3: Splice Programs

General

Displaying the active splice program

Selecting a splice program

Editing a splice program

Copying a splice program

The steps of the normal splicing process

Pre-fusion

Fusion

Summary

Splice program parameters, normal splicing process

Chapter 4: Other Functions & Utilities

General

Heater mode

Selecting heater mode

Referring or editing heater mode

Splice option

Data storage

System setting

18

19

19

20

21

21

21

22

22

22

23

24

24

25

25

26

26

26

27

27

27

28

28

28

31

31

32

32

33

34

35

36

Contents

5

Monitor position

Power save

Maintenance menu

Replace electrodes

Stabilizing electrodes

Diagnostic test

Dust check

Motor calibration

Arc calibration

Operation procedure

System information

Troubleshooting

Power supply

Splicing operation

Tube-heating operation

Supervising

Other functions

37

37

38

38

39

40

41

41

42

42

43

44

44

45

47

47

48

Contents

6

Important: INNO Instrument strictly recommends all users to read this manual

before operating IFS-10 splicer.

This manual is valid for the following software version:

7

Introduction

Scope and purpose of the manual

This User Manual explains how to install and operate IFS-10 fusion splicer. The

primary aim of this manual is to make the user as familiar with the splicer as

possible. Basic maintenance procedures are also described in Chapter 6

“Maintenance” to enable the user to keep the IFS-10 in excellent working

condition.

The reader

Inexperienced users can learn how to carry out basic splicing with IFS-10 as

described in Chapter 2 ‘Basic operation’. Experienced users will be able to extend

their knowledge by learning how to change parameters, implement utilities, etc.

Once the main routines and procedures have been learned, “Quick guide” in

Chapter 2 serves as a fast reminder of how to use IFS-10.

IFS-10 Arc fusion splicer

The most advanced eld fusion splicer from INNO Instrument, the IFS-10

delivers ultra fast splicing time and has an incredibly short shrinking time. The

prole alignment technique is combined with extremely accurate splice loss

estimation to ensure a precise alignment process. A new shrinking technology

means that the shrink time is greatly reduced, thus resulting in an extremely fast

total cycle time. The splicer is designed to withstand harsh environmental

conditions. Its lightweight, yet robust, compact and ergonomic design allows

users to easily carry or move. IFS-10 has a menu-driven user interface with

dynamic function buttons and a fully automatic splice process. For more product

information, contact your local distributor or visit our website at

www.innoinstrument.com

8

Installation

Scope and purpose of the manual

This chapter contains the following information:

•Safety warnings and precautions

•Operational safety warnings

•Maintenance and external care precautions

•Transport and storage precautions

•Installation upon delivery

•Unpacking the splicer

•Removing the cover

•IFS-10 splicer standard delivery kit

•Optional accessories

•Tool set

•Overview of external parts

•Power connection

•Mounting the power source

•Power supply

•Battery

•Charging the battery

•Power source and battery status

•Heat oven

•Mounting the heat oven

Safety warnings and precautions

As IFS-10 is designed for fusion splicing silica glass optical bers, it is very

important that the splicer should not be used for any other purpose. The splicer

is a precision instrument and must be handled with caution. Therefore, you must

observe the following safety rules and general precautions regarding the use and

handling of IFS-10 at any time.

1

9

Operational safety warnings

•Do not use the splicer in places where there is a risk of explosion.

•Do not touch the electrodes when the splicer is switched on.

•To avoid an electric shock, Do not open the back of the splicer or the power

supply. There are no user-serviceable parts inside the splicer, so refer any service

of the splicer to qualied personnel.

•Handle the main supply cable carefully. Pull out the cable from the electrical

socket by holding only the wall plug and not by pulling the cable. Always ensure

this cable to be in good condition. Otherwise, there is a risk of re or electrical

shock.

•To prevent any re or electrical shock, Do not expose the splicer to rain or damp

conditions.

•Be cautious when handling ammable solvents - always read the manufacturer’s

instructions.

Maintenance and more care precautions

•Always avoid using hard objects to clean V-grooves and electrodes.

•Always avoid using acetone, thinner, benzol or alcohol when cleaning any part

of the splicer, except for the places advised.

•Use a dry cloth to remove dust and dirt from the splicer.

•If the outside of the splicer is very dirty, plunge a soft cloth into diluted neutral

washing up liquid, wring out the cloth and clean. Dry the splicer with a dry cloth

but Do not use furniture polish or other cleaning agents.

•Always follow the maintenance instructions in this manual.

Transport and storage precautions

•When the splicer is moved from cold to warm environment, you should allow

about an hour for acclimatization. By this time, any condensation should

disappear.

•Put the cover on the splicer when it is not in operation.

•Keep the splicer clean and dry.

•Always keep the splicer in its carrying case to protect from damage and dirt.

•Always avoid leaving the splicer in direct sunlight or expose to excessive heat.

•Keep the humidity to a minimum level where the splicer is stored. The humidity

must not exceed 95%.

Chapter 1 Installation

10

Installation upon delivery

Important: Follow these instructions carefully.

Unpacking the splicer

Raise the handle upwards and with a rm grip, lift the splicer upward and out of

the carrying case. Place the handle of the splicer downwards.

IFS-10 splicer standard kit

IFS-10 is delivered in a portable case together with a basic set of tools and this

manual.

①IFS-10 Splicer

②High Precision Cleaver

③Cleaver Pouch

④Battery Pack

⑤CD

⑥Shoulder Strap

⑦Carrying Case

⑧Carrying Case Key

⑨Cooling Tray

⑩Cigarette Lighter Cable

⑪Extra Eletrodes

⑫RS-232 Cable

⑬Power Cable

⑭AC Charger

Chapter 1 Installation

11

Documents (not shown)

•User manual

•Supplier’s declaration of conformity

•Test protocol

Optional accessories for IFS-10

•AC adapter pack

Note: AC adapter pack should also be mentioned as standard or optional

accessories

Chapter 1 Installation

12

Overview of external parts

Heat oven

On / Off button

Control buttons

Display

USB Terminal

Serial port

Connector for charging battery

Safety shield

Power supply / Battery

Splicer handle

Chapter 1 Installation

13

Power connection

General

The splicer can be powered from the power supply connected to the main outlet,

or from the battery. In either case, the power source is mounted underneath the

splicer.

Mounting the power source

Battery charger

General

The battery charger connects to a main outlet through a standard power cable.

A green LED, located is lit when the power supply is in operation.

Insert the Battery unit into the power unit dock until it clicks into place.

Insert

Release button

Draw power supply module out

Chapter 1 Installation

14

Charging the battery

Charging progress is indicated by ve red LEDs continuously sweeping from 20%

to 100% on the battery indicator. As charging proceeds, one LED is lit when 20%

charged. When it’s fully charged, all ve LEDs are lit (i.e. 100%)

Battery indicator

It is available to charge the battery in three different ways. When the battery is

detached from the splicer, it can be charged with AC charger.

Chapter 1 Installation

15

Charging the battery

The splicer can be charged in two different ways (see step1 and 2 below). The

power source which is used to charge the splicer is indicated by a special icon on

the bottom right-hand corner of the monitor (see below) If the battery is connected

to the slicer, then its charging level appears. If the battery is being used to charge

the splicer by the power supply, the charging level will appear in green color.

However, if the charge level drops under 20%, then the light will appear in red.

5%

10%

30%

50%

70%

100%

Step 1 Step 2

Chapter 1 Installation

16

Heat oven

Heat oven - Lid open Cooling tray

Chapter 1 Installation

17

Basic Operation

Scope and purpose of the manual

This chapter contains the following basic information:

•Quick guide

•Preparing the splicer

•Preparing the ber

•How to make a splice

•How to check the splice strength

•How to protect the splice

Quick guide

2

•Preparing the splicer

•Connecting the power supply

•Cleaning V-grooves

•Cleaning electrodes

•Preparing the ber

•How to strip the ber

•How to clean the ber

•How to cleave the ber

•How to splice

•Inserting the bers

•Inspecting the bers

•Splicing

•How to protect the splice

•Moving the ber to the heat oven

•Shrinking

•Resetting the ber movement motors

18

18

18

18

18

19

19

20

21

21

21

22

22

23

24

24

18

Preparing the splicer

Connecting the power supply

•Connect the splicer to the main by inserting the power cable into the socket on

the left side of power supply of the splicer.

Note: If the splicer is powered with a fully charged battery, then the main power

supply is not necessary.

•Press the On / Off button on the side of the splicer unit on the top left of the

front panel. If the LED becomes green, then the power is on. Press and hold the

On / Off button until the LED ashes, then release the button and the splicer will

power off.

Cleaning V-grooves

•Clean V-grooves, if necessary (see chapter 4 “Maintenance”)

Replace electrodes

•Check and make sure there are no ber within the splicer and close the safety

shield.

•From the main menu press:

•In the replace electrodes, press: “Conrm” to replace the electrodes.

Preparing the ber

There are three basic preparatory steps to be completed before the bers can be

placed in the splicer:

•Stripping

•Cleaning

•Cleaving

Chapter 2 Basic operation

19

Note: Always remember to slip a heat-shrinkable sleeve onto either end of the

bers at the beginning of each ber preparations.

Important: Preparing the bers for splicing is one of the most important factors

in the splicing process and must be carried out with the utmost care to minimize

splice loss. Poorly cleaned and cleaved bers will normally result in high splice loss

and low mechanical strength.

How to strip the ber

•Remove at least 50mm of secondary coating (valid for both tight and loose tube

secondary coating) with an appropriate stripper (see A, and B).

•Remove approximately 30mm of primary coating with an appropriate stripper

(see C).

Important: Do not put extra stress on the bers by bending or crimping them. (see

illustrations of different strippers below.)

How to clean the ber

Clean bare bers with a tissue or a pair of cotton swabs soaked in propanol or

ethanol.

Important: From this point, you must be very careful with the bers to ensure

that they do not become dirty again. (for example, avoid putting them down on a

dusty working surface, or even waving them around in the air). Also check if the

V-grooves are clean, if not, wipe them clean.

Loose tube

secondary coating

Tight secondary coating Primary coating coating

1 2 3

Chapter 2 Basic operation

Other manuals for IFS-10

1

Table of contents

Other INNO Instrument Welding System manuals

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual