Innomax Perfection Series User manual

SETTING UP YOUR FLOTATION SLEEP SYSTEM

1. Unpack the Box

Take all of the components out of the box. You should have the following items:

•Power Edge Support Rail System Includes:

-Attached Head/Foot Rails

-Attached Side Rail Assembly

•The Head Rail Is Marked & Has Exit Slits For

The Power Cords

•Fluid Support Chamber(s) or Tubes

•Low Watt (120 Watts or Less) Waterbed

Temperature Control System

•Vinyl Safety Liner

•Mattress Cover/Pillow Top Enclosure

•Kor Q Split or Single T/F Foundation (Optional)

•9Point Center Support Metal Bed Frame (Optional Purchase)

NOTE: It is extremely important you use the proper structural base for your new

fluid support system. Do not attempt to use a standard bed frame. Using any support

frame that does not have a minimum of 9 points of contact with the floor will result

in damage to your sleep system and can cause personal injury. Only use an

approved 9 Leg metal bed frame, Versaleg™support system or a platform pedestal

with center cross supports.

2. Your entire Fluid Support System can be easily assembled. First step,

determine where your bed will be positioned. If you are

using a headboard, make sure you have enough room

between the wall and the frame before you begin to fill

your mattress. Assemble the support base you intend to

use. This can be a center support metal bed frame, a

platform pedestal or light weight Versaleg™system.

Assemble the metal frame or pedestal in the desired

location and place your foundation in the frame with the

open side down. Many platform pedestals don’t require

the use of a foundation. For VersaLeg™assembly, place

the foundation halves on the floor with the open side up.

Position the Versaleg™plates on all four corners of each foundation half and then

place one plate on each side approximately half way between the head and foot

plates. Use four of the provided screws to attach each plate to the foundation.

Repeat this process for the second foundation piece. Once the plates have been

secured, twist the threaded end of the Versaleg™into each plate. Once all have

been inserted, simply flip the foundation over so the (CONTINUED)

FLUID SUPPORT ASSEMBLY INSTRUCTIONS

WARNING: Do Not Use A Standard Full Watt Heater With A Softsided Mattress. This Can

Result In Severe Damage To Your Sleep System And Void All Warranties.

1

Electric Pump Usage/Draining Instructions: Unplug Heater Before Draining!

If interested in using an electric pump, please ask your dealer for more information.

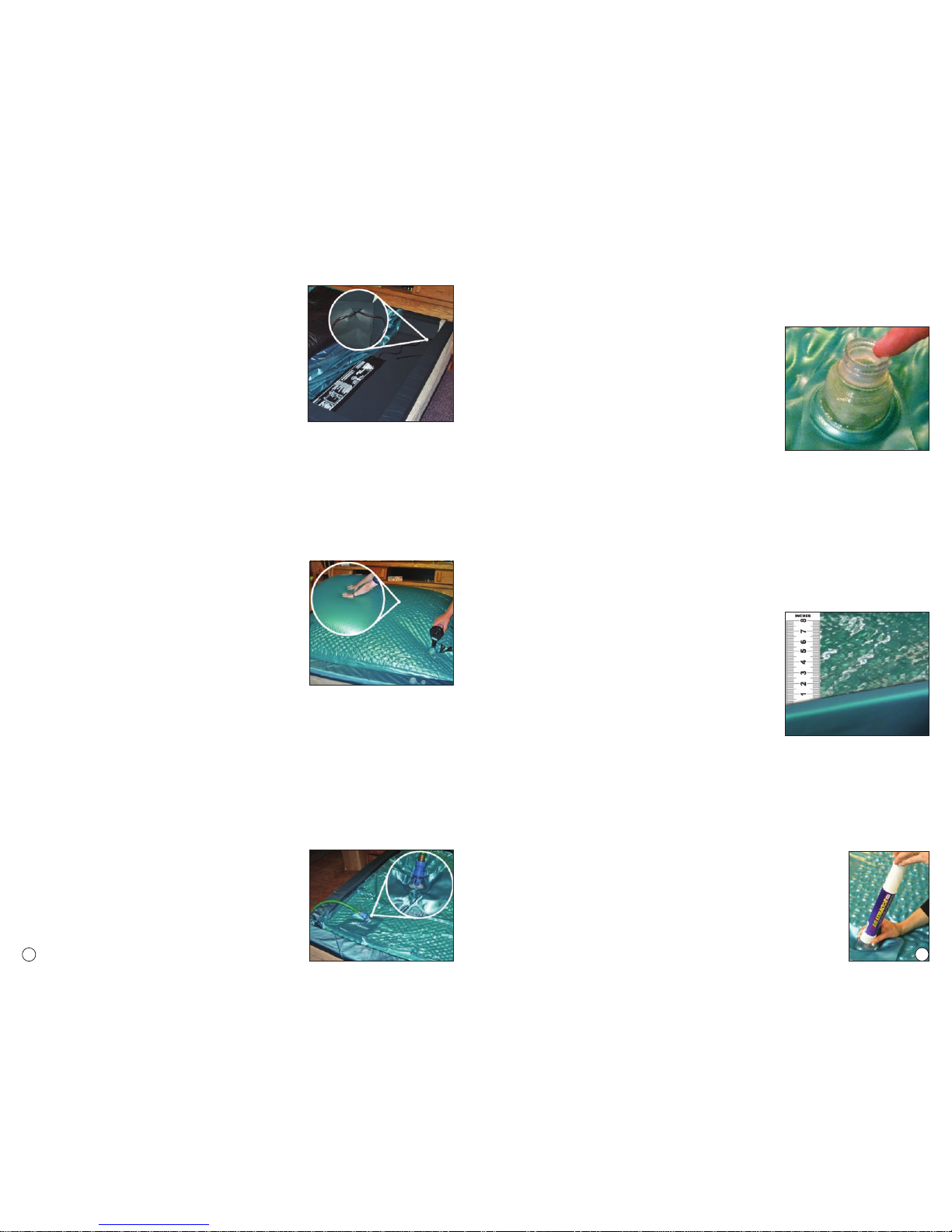

1. Remove all of the air from your mattress.

2. Attach the “perfect union” connector on the

end of the clear hose on the pump to the valve

in your mattress. Make sure all washers are

used and the connections are tight to maintain

proper suction.

3. Connect your exit hose to the discharge port

on the pump. Ensure the exit hose is in the

desired location. The force of the water can

actually cause the hose to flop about and come

out of a normal bathtub. Do not leave the hose

unattended while indoors. Place the pump on

atowel or cardboard piece to prevent possible

damage to the floor or other surface.

4. Plug the pump into a grounded electrical

outlet. Note: There is no on/off switch and

the pump will begin to operate immediately.

5. Allow the pump to run until the water

slows to a trickle. The pump will remove

nearly all of the water & the mattress will

become “vacuum-sealed” to ensure all

internal support features remain in their

proper location. Do not lift the head of the

mattress until the mattress is vacuum

packed, as this could damage the mattress.

6. Immediately unplug the pump. Do not run

the pump without water for an extended period

of time, as this can severely damage the pump.

7. Disconnect the perfect union connector

from the mattress and immediately insert

the cap and seal to ensure the mattress

remains vacuum packed.

If the mattress is still too heavy to move, you can utilize a shop (wet/dry) vacuum to get the remainder of the water out

6

It is strongly recommended that an electric drain pump be utilized to prevent damage

to the internal support structure of your mattress. A typical electric pump will remove

nearly all of the water in a king sized mattress in 45 minutes or less. If no electric pump is

available, the use of a standard fill & drain kit will assist in removing the water from the

mattress. Attach the faucet adapter to the sink, taking care not to cross thread the adapter.

Screw the siphon pump to the adapter and attach the hose to the siphon. Using the hose

adapter, attach the opposite end of the hose to the valve on the mattress. To start the siphon

action, turn on the faucet to a moderate level.

If your siphon is self priming, the pump will

soon begin to remove water. If it is not self

priming, turn the bottom of the pump to the

“fill” setting and allow water to go into the

mattress. Once the hose is free of air, twist

the bottom of the pump to the “drain” setting

to create a siphon to remove water. Continue

this until the mattress is completely vacuum

sealed and is free from water.Firmly grab the

top, internal fiber, and the bottom to prevent

shifting when folding the mattress. Once the

process is complete, remove the hose

adapter and quickly insert the cap & seal to

maintain a vacuum inside the mattress. This

will hold all of the internal components of the mattress in their desired location. When moving

the mattress, do not drag it across the floor as this can cause a friction burn in the vinyl. If the

mattress is to be stored for more than 7 days before reinstalling, it is recommended that a

bottle of Fiber Bed Conditioner be placed inside to prevent odor and bacterial growth. Do not

store the mattress in conditions below 32 degrees Fahrenheit, as this can cause the vinyl to

crack. If it is stored in cold temperatures, gently place mattress in a warm room for up to 24

hrs prior to unfolding & filling with water to minimize the possibility of a cold crack.

Contact Your Dealer For Rental Info.

or ToPurchase The Drain Hero™ -

10 Piece Maintenance Kit.

Unplug The Waterbed Heater Before Draining The Mattress

DRAINING INSTRUCTIONS

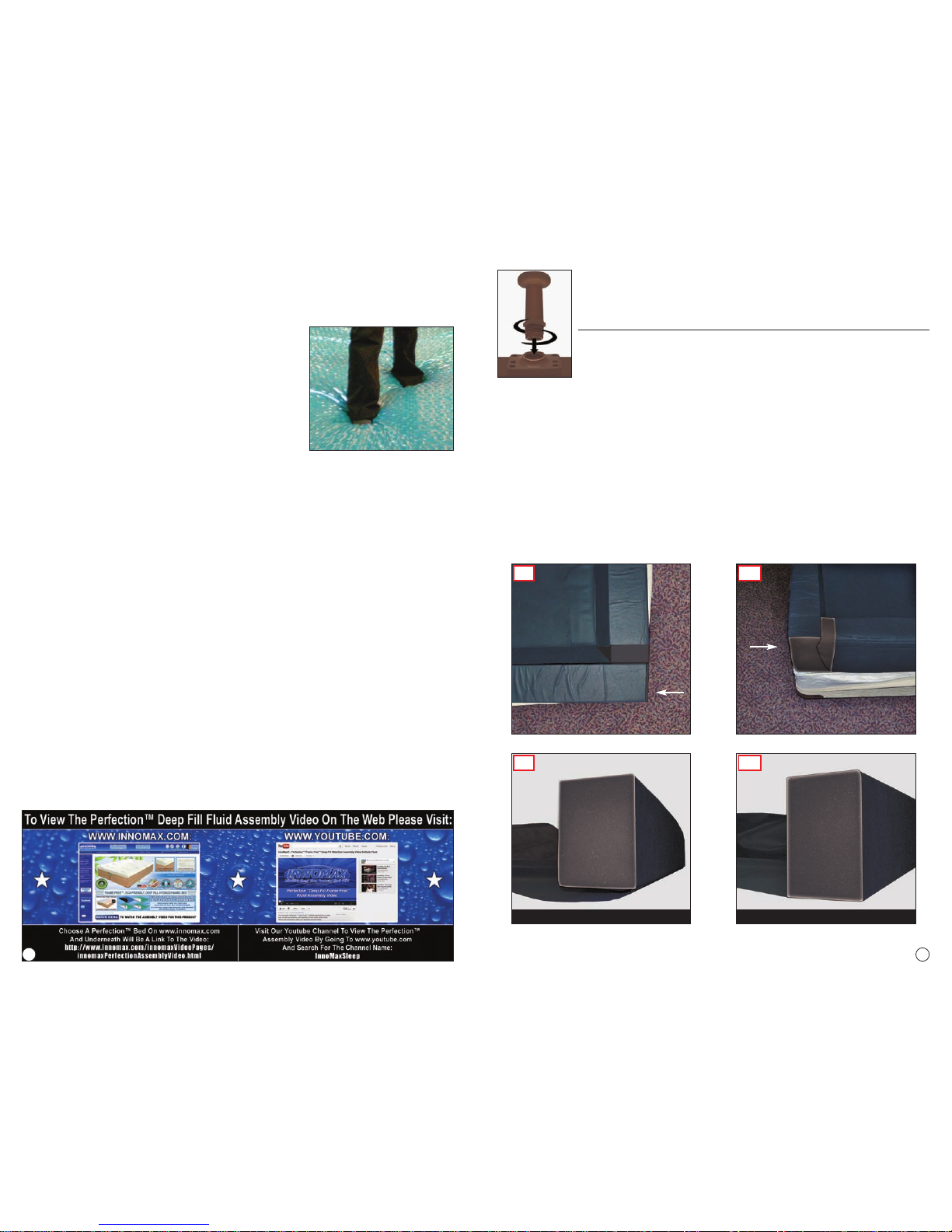

3. Unfold the mattress enclosure and completely unzip the cover. Insert the

head and foot rail inside the cover. The head of the bed should be stamped and

will have two slits in the black webbing material.This is for the exit of your temperature

control sensor and heater pad power cord. The side rails are inserted in between

the head and foot rails with the webbing as smooth as possible. The rails are

correctly installed when the webbing material is completely unrolled and is at the

bottom of the rail (see DIAGRAM B2). The rail should be approximately 6” in

height and 4” in width. Exception: The Perfections®Sponge Bed™is a full depth

flotation style system and is designed with the “M Rail System” which is

approximately 8” in depth and has interlocking slanted rails (see DIAGRAM A2).

The black webbing is also to be at the bottom of the rail (see DIAGRAM B2).

legs rest upon the ground and you have the firm, flat side of the

foundation is facing up. You are now ready to begin the bed

assembly.

For the assembly video of this product please visit: www.innomax.com

or www.youtube.com under the channel name InnoMaxSleep

2

5

B1

INCORRECT

Black Webbing Running Under Rails B2

CORRECT

Black Webbing Running Straight Out

From Rails

A1

Perfection Rails Top View

Foot

Of Bed

A2

Perfection Rails Side View

Foot

Of Bed

4. Install the heater pad(s) directly on the black webbing material in head to

toe position. Ensure that the entire pad is on a solid (CONTINUED)

all of the trapped air. Use the Air Extractor to remove the excess air.

10. Several of InnoMax’s®firmer water chambers feature a high level of fiber,

closed cell and/or sponge support sheets. These layers need to become fully

saturated with water to provide the desired comfort

levels. This process may take several days and may

require you to walk or roll on the mattress many times

during this period to extract as much air as possible.

While this early portion of the mattresses life may be

somewhat inconvenient, you will off set the extra

effort with the enhanced comfort you will enjoy for

years to come. The mattress may not feel as it did in

the showroom until you have finished this process. It

is recommended that you do not adjust fill levels to change firmness levels during

this process. Most sleepers find that following the “break end” period, the initial fill

level is the preferred setting.

11. Plug the heater pad into the heater control. Plug the control into a 110 volt

wall outlet and then set the temperature to the desired level. It is recommended to

be set between 80-87 degrees Fahrenheit depending upon your personal comfort

level. If you have a dual heating system, repeat this step for the other side of the

mattress.

12. Zip up the cover/pillow top. Install the new mattress pad and sheets. Enjoy

agreat night’ssleep on your new fluid support system!

13. Maintenance of your fluid support sleep system. Toreceive the maximum

comfort, enjoyment and longevity from your new fluid system, it is important to

perform periodic maintenance. In addition to the use of quality waterbed conditioner

on an annual basis, it is recommended to use Blue Magic®Vinyl Cleaner on the outside

of your water chamber(s) and vinyl safety liner at least 2-3 times per year to

prevent plasticizer migration which dries vinyl and can cause brittleness, and in

some cases, cracking of the surface. Also, vinyl is a porous surface and over time,

air molecules can pass through into the chamber requiring the use of the Air

Extractor to remove the trapped air bubbles. This small amount of maintenance

will allow you to benefit from the amazing comfort and support of your fluid

system for many years to come.

5. Place the vinyl safety liner over the heater pad(s) and tuck around the

Power Edge Rail System. Making sure the corners of the fitted liner are matching

the corners of the rail system. Smooth the vinyl away from the center of the mattress

area and toward the edge rails.

surface and not over the crack between foundation halves or plywood pieces in a

platform. It is best to place the pad as far down the

bed as possible to avoid constant pressure of sitting

on the pad. Push the pad power cord through the

slits in the black webbing and cover. The temperature

sensor on the control can be pulled through from the

outside. Make sure the sensor is a minimum of 12”

away from the pad and is not tucked under any

portion of the Power Edge Rail System to ensure

proper temperature readings. Repeat the process

on the opposite side if using a dual system.

Note: Do Not Plug In The Heater Until The Flotation Mattress Is Completely Filled With Water!

3

6. Please note that if the chambers have been in very cold conditions, you

must allow them to attain room temperature before handling the chamber to

avoid cracking the vinyl. Unfold the fluid support

chamber(s) and place on top of vinyl safety liner. The

valves on the water chamber(s) should be located at

the foot of the bed. Open both valves on the chamber(s)

to allow the vacuum sealed water mattress(es) to

begin to expand. Square the corners of the mattress(es)

with the inside corners of the Power Edge Support

Rail System. This is CRITICAL and must be done

before filling the chamber(s) with water. To assist in

the process you may fill the chamber(s) with air using a shop vac or a hair dryer

with a cool setting. Inflate the mattress(es) until it is approximately 18”-24” above

the foam rails. Place the caps back on the valves and push down on the center of

the mattress(es). This will pop out the corners so they can be easily adjusted to

align with the rail system. Once the mattress is centered, open the valves to

release the air.The shop vac can be used to expedite this step. If you are using a

dual support chamber system, place the “T” shaped thermal divider between the

two fluid chambers, with the “T” in an inverted position so that the flaps are slightly

under each chamber and the “leg” of the “T” is standing vertically between the chambers.

7. Begin the filling process. The first step is to pour one 8 ounce bottle of

Multipurpose Fiber Bed conditioner into the water

chamber (or 4 ounces into each half of a dual system)

to provide proper water treatment and to prevent

algae growth. This should be done every 12-18

months. Next, open both valves on the mattress and

screw the blue Perfect Union™adaptor onto the male

end of the hose. This adaptor is then attached to

either fill valve. Applying a (CONTINUED)

small amount of petroleum jelly to the rim of the valve will ensure a tight seal and

lessen the amount of air going into the mattress. This is also helpful after the entire

mattress is filled when the cap & seal on both valves are closed for the final time.

The second valve remains open during the filling process to allow air to escape.

The female end of the garden hose is attached to

your water supply. For best results, the mattress

should be filled using lukewarm water. The use of a

faucet adaptor will generally allow you to use the

bathroom sink, shower head or kitchen sink to fill the

water mattresses. This method of filling will offer the

proper temperature for better sleep and can control the

flow more easily. Generally, most household water

heaters will run out of hot water during the fill process.

Monitor the water temperature for this drop. Turn off both hot and cold valves and

wait for the tank to replenish the supply of hot water (Approximately 1 hour) and

then restart the lukewarm fill. While this method may require a longer filling time,

the end result is a more comfortable sleeping environment from the first night on.

Using an outside faucet to fill the bed results in a cold fill and can require up to 7-

10 days for the bed to attain optimal sleeping temperature. The normal operation

of the heater will raise the bed temperature approximately 1/4 to 1/2 degree

Fahrenheit per hour. The time required to heat a cold water filled mattress does

not indicate a problem with your heater.

8. Proper Fill Depth is approximately 1/2” to 1” below the top edge of the

support rail. For a firmer feel, lower the water level

slightly. For a softer feel, add a small amount of water.

Never fill the mattress so that it is above the side rail.

All of the InnoMax®water chambers, both mid-fill and

deep fill are manufactured using overcut vinyl allowing

the sleepers to rest gently in the bed instead of on top

of it. This creates positive spinal alignment and

improves overall comfort. Do not attempt to take the

wrinkles out of the vinyl by overfilling the mattress!

Overfilling the mattress will result in the bowing of the side rails and will greatly

reduce the comfort level of the bed. Remove the Perfect Union™adaptor and the

hose from the fill valve. Attach the Air Extractor to the fill valve and close the Ez

Burp Air Release (secondary valve) by inserting the seal and twisting the cap in

place. Adding the small amount of petroleum jelly to this air release valve will help

to create a more air tight seal.

9. Carefully use the Air Extractor to remove as much surplus air as possible.

Some air will be trapped under the closed cell float layers or in the

fiber layers inside the mattress. This air can only be removed

when it is pushed to the outer edges of the mattress. Before starting

this step, please make sure the heater is still unplugged. Remove

your shoes and stand in the middle of the mattress and walk to

any edge pushing trapped air out of the support layers and letting

it rise to the top of the mattress. Repeat this step, walking in a

different part of the mattress to release (CONTINUED) 4

Other Innomax Medical Equipment manuals