innovAg MiniTest User manual

MiniTest

Dairy Vacuum

& Pulsation Meter

USER MANUAL

Part No. DR51-0028-10

2 © 2017 InnovAg

FCC Compliance Statement

This device complies with Part 15 of the FCC rules. Operation is subject

to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including

interference that may cause undesired operation.

Declaration of Conformity

Standards to which Conformity is Declared:

• EN 61000-4-2

• EN 61000-4-3

• EN 61000-6-1

• EN 61000-6-2

• EN 61000-6-4

• IEC 61326-1:2005

• EU Directive 2002/95/EC

• EU Directive 2004/108/EC

• China RoHS (See following page)

Manufacturer’s Name: innovAg Pty. Ltd.

Manufacturer’s Address: 37/328 Reserve Road, Cheltenham

Victoria 3192, Australia

Type of Equipment: Pulsation Tester/ Vacuum Gauge

Brand Name: MiniTest II

Model Number: DR40-0080

© 2017 InnovAg 3

I, the undersigned, hereby declare that the equipment specied above

conforms to the above Directives and Standards.

Braham Basser Date: 30 October 2001

Director

InnovAg Pty. Ltd

Enclosure

LCD

Silicone tubing

Metal ttings

Front panel label

Rating labels

© 2017 InnovAg 5

Contents

1. What is MiniTest? 6

2. Safety Precautions 6

3. Maintenance and Calibration 6

4. The Front Panel 7

5. Vacuum – Setting up 8

6. Checking Vacuum 9

7. Pulsators – Setting up 9

8. Checking Pulsation 10

9. Software Version and Calibration Date 11

10. Replacing the batteries 12

11. Repairs 13

12. Troubleshooting your MiniTest 14

13. Specications 15

14. Warranty 16

All rights reserved. No part of this manual may be reproduced,

transmitted, stored in a retrieval system, or translated into any

language in any form by any means without the written permission of

innovAg Pty. Ltd.

6 © 2017 InnovAg

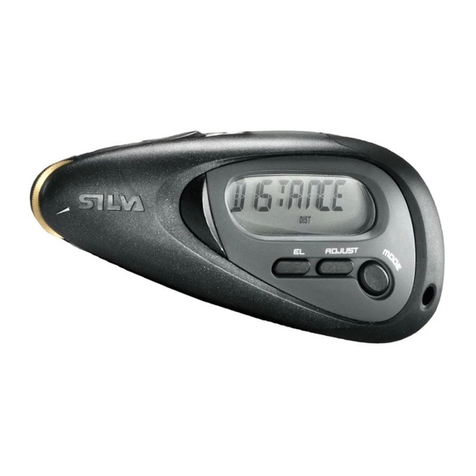

1. What is a MiniTest?

MiniTest is a small, light, handheld instrument for testing vacuum supplies

and pulsators in dairies. It uses the same high-accuracy analysis as its

‘big brother’ DairyTest Professional, but in a smaller, lighter, lower-cost

format. It is intended for use by personnel with technical knowledge of

dairy operation as an accessory to a professional test kit, eg. for bench-

testing of pulsators or a quick check on dairy performance. It has only a

single vacuum port and cannot be connected to a PC or printer.

If you have difculties, we have a Freecall help line within Australia

(1800 061 167). International users should call their local distributor or

2. Safety Precautions

MiniTest is intended to be used in the milking stall – always allow for the

unpredictable nature of animals.

During the measurements, sharp needles may be used – take care they

don’t hurt people or animals.

Always ask the dairy farmer about the behaviour of the animals and

milking method used.

If using MiniTest in wet tests, always keep the unit above the test point

to prevent uid entering. Damage to the unit from uid entering the

sensor is not covered under the warranty.

3. Maintenance and Calibration

Maintenance

Clean the MiniTest with a moist cloth. Do not use cleaning agents.

MiniTest performs a self test when turned on, turning on all segments

of the LCD. If an error message is displayed (E-01 for example), or you

suspect the unit is damaged; contact innovAg or the local distributor for

further information.

Calibration

MiniTest automatically performs a zero calibration when turned on.

Do not turn on your MiniTest with vacuum connected. If the unit

© 2017 InnovAg 7

reads other than zero on start-up, a manual ‘force-zero’ feature can be

used. Refer to Section 12: ‘Troubleshooting your MiniTest’.

A complete calibration should be performed with an approved and

certied calibration test instrument every 24 months. This can be

organised by InnovAg or the local distributor.

4. The Front Panel

In Pulsation Mode, MiniTest can measure six pulsation parameters

(A+B, B, C, D ratios, rate and Max Vacuum) and provide indication of

B-phase drop and pulsation stability. In Vacuum Mode three vacuum

parameters are measured (Minimum, Average and Maximum). The

picture below shows the front panel indicators and controls.

Low-Battery Indication

If the remaining battery capacity is getting low the battery symbol will

ash. Replace/recharge the batteries.

8 © 2017 InnovAg

5. Vacuum – Setting up

MiniTest can display vacuum in either kiloPascals (kPa) or inches-of-

mecury (inHg) units as required. The Units Indicator on the left-hand

side of the display will appear next to those currently set.

Changing/checking the setting.

1. Make sure the unit is turned ON and in Vacuum mode.

(Min, Avg or Max displayed).

2. Press and hold the Forward/Setup key for about 3

seconds to enter setup mode. The display wil show

unt (Units).

3. Press either the Power/Up or Mode/Down

keys to change between kPa and inHg.

4. Press the Forward/Setup key to save the changes and

return to normal operation.

Auto Exit

MiniTest will automatically exit Setup mode after 1 minute if you don’t

press any keys.

Startup Mode

Vacuum mode defaults to Average (AVG) on startup. The setting is kept

when the mode is changed to Pulsation but is reset when the unit is

turned off or the batteries run at.

© 2017 InnovAg 9

6. Checking Vacuum

When set to Vacuum mode, MiniTest will display the minimum (Min),

average (Avg) or maximum (Max) vacuum level on the digital display.

Press the Forward/Setup key until the required parameter is selected.

Auto-power OFF

If there is no vacuum on the port and you don’t push any keys the unit

will automatically turn OFF after 10 minutes to save battery life.

What is it measuring?

All vacuum measurements are taken over a rolling 1.6 second period,

sampled 1000 times per second.

7. Pulsators – Setting up

MiniTest can display Pulsation Ratios (A+B, B, C and D) as either

percentage (%) of the total cycle, or in milliseconds (ms). The selected

method applies to all ratio parameters (A+B, B, C and D). Rate

measurement is xed in Cycles-per-minute (CPM).

Changing/checking the setting.

1. Make sure MiniTest is turned ON and in Pulsation mode.

2. Press and hold the Forward/Setup key for about 3

seconds to enter setup mode. The display will show

rAt (Ratio).

3. Press either the Power/Up or Mode/Down

key to set the required Ratio display method;

percentage (%) or milliseconds (ms).

4. Press the Forward/Setup key to save the changes and

return to normal operation.

10 © 2017 InnovAg

Auto Exit

The tester will automatically exit Setup mode after 1 minute if you don’t

press any keys.

Saved Settings

Settings are kept until changed by you. They do not reset when the unit

is turned off or the batteries run at.

8. Checking Pulsation

MiniTest can display Pulsation Ratios A+B, B, C and D as well as Rate

(in CPM).

Press the Forward/Setup key until the required parameter is selected.

Note: Use Vacuum Mode to measure Maximum Vacuum of the pulsation

waveform.

Stability Indication

If the current reading varies from the average by more than 5%, then the

pulsation being measured is not stable. Avg will ash to warn the user

to wait until the readings settle. If Avg does not stop ashing, there is a

problem with the pulsation being measured.

B-Phase Drop Indication

If a vacuum drop of more than 4kPa is detected within the B Phase then

the pulsation is not within ISO specication and ‘B’ will ash to warn the

user.

Auto-power OFF

If there is no vacuum on the port and you don’t push any keys, MiniTest

will automatically turn OFF after 10 minutes to save battery life.

© 2017 InnovAg 11

What is it measuring?

All Pulsation measurements are taken using 4kPa thresholds, sampled

1000 times per second. Readings conform to ISO standards by averaging

over 5 cycles. A ‘rolling’ system is used where measurements from the

current cycle and the four previous ones are averaged together, which

means ISO requirements are met while the screen is still continuously

updated.

9. Software Version and Calibration Date

To display both MiniTest ‘s software version number and last calibration

date use the following sequence:

1. With MiniTest turned off, press and hold all three buttons. After

3 seconds the display will show the version number, e.g. P03

means Program version 03.

2. Release the buttons.

3. The last calibration date will then be shown in 4 steps:

CAL Calibration date follows.

23- Calibration day, eg. 23rd

-11 Calibration month, eg. November

-14 Calibration year, eg. 2014

12 © 2017 InnovAg

10. Replacing the batteries

When it is time to replace MiniTest’s batteries, the battery symbol will

start to ash.

We recommend the batteries be replaced as soon as possible once the

low battery indicator starts, to prevent unreliable readings or operation.

Batteries should not be left in the unit for extended periods in case of

leakage. Use quality Alkaline or NiMH ‘AA’ rechargeable cells.

© 2017 InnovAg 13

11. Repairs

DO NOT OPEN THE CASE

THERE ARE NO USER SERVICABLE PARTS INSIDE

YOU MAY VOID YOUR WARRANTY.

Defective units should always be sent to innovAg or your nearest

distributor.

Smaller repairs that can be performed by your distributor are:

• Changing parts of the housing.

• Replacing hoses

• Calibration (only if a certied original calibrator is used)

For other defects, please contact the manufacturer for further instructions:

InnovAg

37/328 Reserve Rd

Cheltenham VIC 3192 Australia

Ph. +613 9583 2832

email: [email protected]

14 © 2017 InnovAg

12. Troubleshooting with your MiniTest

Before returning your MiniTest for repair, check the following:

• The unit does not turn on or won’t stay on – replace batteries.

• The battery symbol is ashing – batteries are getting low.

• MiniTest reads vacuum with no vacuum connected – disconnect

from the vacuum supply and turn it off and on again to reset the

zero. If it still does not display zero, the button sequence below will

manually force the unit to accept the pressure value on the port as

zero:-

1. Turn the unit on. Select VAC mode.

2. Press and hold the Mode/Down key.

3. Then press and hold both the Power/Up

and Forward/Setup keys.

4. After a few seconds the digists should go off

and the screen should show ‘. .’ indicating the manual zero has

been accepted. Release all keys and check the display shows

0.0.

• Damaged MiniTests should be returned for repair. There are no

user serviceable parts inside the case and opening it may void your

warranty.

• If you have a question or problem you cannot solve, contact innovAg

or your local distributor.

© 2017 InnovAg 15

13. Specications

Display:

3 digit x 7 segment LCD

Vacuum

Maximum, average or minimum.

Pulsation

Ratios – A+B, B, C, D in % or ms

Rate – CPM

MaxVac

B-Phase drop – B ashes if more than 4kPa drop in B-phase

Stability – Avg ashes until values settle to ISO requirements

Pulsation:

Rate range: 40 to 500 CPM.

Rate accuracy: ± 2%.

Ratio accuracy: ± 2% of calculated value.

Time (ms) accuracy: ± 2%.

Vacuum:

Range: +10 to -80 kPa at 1 atm.

Accuracy: ± 0.5 kPa

Repeatability: ± 0.3 kPa

Resolution: 0.1 kPa

General:

Sample rate: 1000 samples/sec.

Operating temperature: 5 to 40°C

Storage temperature: 0 to 60°C

16 © 2017 InnovAg

Automatic turn-off time: 10 minutes after last key press

if no vacuum on port.

Batteries: two ‘AA’ Alkaline or NiCd/NiMH rechargeable cells.

ALL InnovAg testers include:

• Digital calibration with certicate supplied.

• Re-calibration service available.

• Selectable units: Vacuum – kPa & inHg, Pulsation ratios (where

included) – % and ms.

• Pulsation measurements (where included) conform to ISO standard

with stability indication.

• Auto power off and low battery indication.

• Automatic vacuum zero (with manual zero if required).

*Specications are subject to change without notice.

14. Warranty

InnovAg Pty. Ltd. provides the following limited two-year warranty

warranty to the original purchaser of MT (“product”). This warranty

cannot be assigned or transferred to subsequent purchasers. The

registration form must be completed and returned to innovAg in order to

be able to claim under this Warranty.

WHAT WE WILL DO

If the product fails under normal use and service because of a

manufacturing defect in materials or workmanship within the warranty

period, innovAg will, at its option either repair or replace the product

with an equivalent product. The repaired or replacement product will

be warranted under the terms of this warranty for the remainder of the

applicable warranty period. Repair may include the replacement of

parts or components with functionally equivalent reconditioned parts

or components with functionally equivalent reconditioned parts or

components.

© 2017 InnovAg 17

WARRANTY PERIOD

The term of this warranty is two (2) years from the date of purchase.

WHAT IS NOT COVERED

This warranty does not cover any failures of equipment not supplied by

innovAg, nor does it cover any failures of or damage to the product due

to:

(i) improper handling, misuse, neglect, accident, improper installation ,

non-compliance with the directions for use;

(ii) any internal or external alteration or modication of any kind which

in the opinion of innovAg will affect the ability to service the product; or

(iii) repair by anyone other than an authorised innovAg Service Centre.

RIGHTS UNDER THE TRADE PRACTICES ACT

Under applicable State, Territory and Commonwealth law, certain

conditions and warranties may be implied in this contract and rights

and remedies conferred upon you as user in relation to the product

which cannot be excluded, restricted or modied by agreement (“Non-

excludable Rights”). Any rights conferred upon you by this warranty are

in addition to and do not detract from those Non-excludable Rights.

innovAg disclaims all express or implied conditions and warranties in

relation to the product other than the express terms of this warranty

and any Non-excludable Rights. With respect to Non-excludable Rights,

innovAg’s responsibility to the purchaser, where permitted, is limited to

the undertakings as stated in the clause headed ‘WHAT WE WILL DO’.

Subject to the above, in no event shall innovAg be liable (whether before

or after discharge of the contract for supply of the product or otherwise)

for any loss or damage suffered by you as the user arising from or

caused or contributed to by the negligence of innovAg, its servants or

agents, nor shall innovAg be liable for special, incidental, indirect or

consequential loss or damages suffered by you as user as a result of

breach by innovAg of this warranty or otherwise including but not limited

to economic or moral loss, loss of prots or revenue or costs arising

from the loss of use of the product or the cost of substitute products.

18 © 2017 InnovAg

InnovAg Pty Ltd

37/328 Reserve Road

Cheltenham Victoria 3192, Australia

FreeCall (within Australia) 1800 061 167

www.innovag.com

A.C.N. 073 191 376

© 2017 InnovAg

Table of contents

Other innovAg Measuring Instrument manuals