innovAg DVG LH DR40-0080 User manual

DVG LH

Dairy Vacuum

Gauge

USER MANUAL

Part No. DR51-0044-14

2 © 2018 InnovAg

FCC Compliance Statement

This device complies with Part 15 of the FCC rules. Operation is subject

to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including

interference that may cause undesired operation.

Declaration of Conformity

Standards to which Conformity is Declared:

• EN 61000-4-2

• EN 61000-4-3

• EN 61000-6-1

• EN 61000-6-2

• EN 61000-6-4

• IEC 61326-1:2005

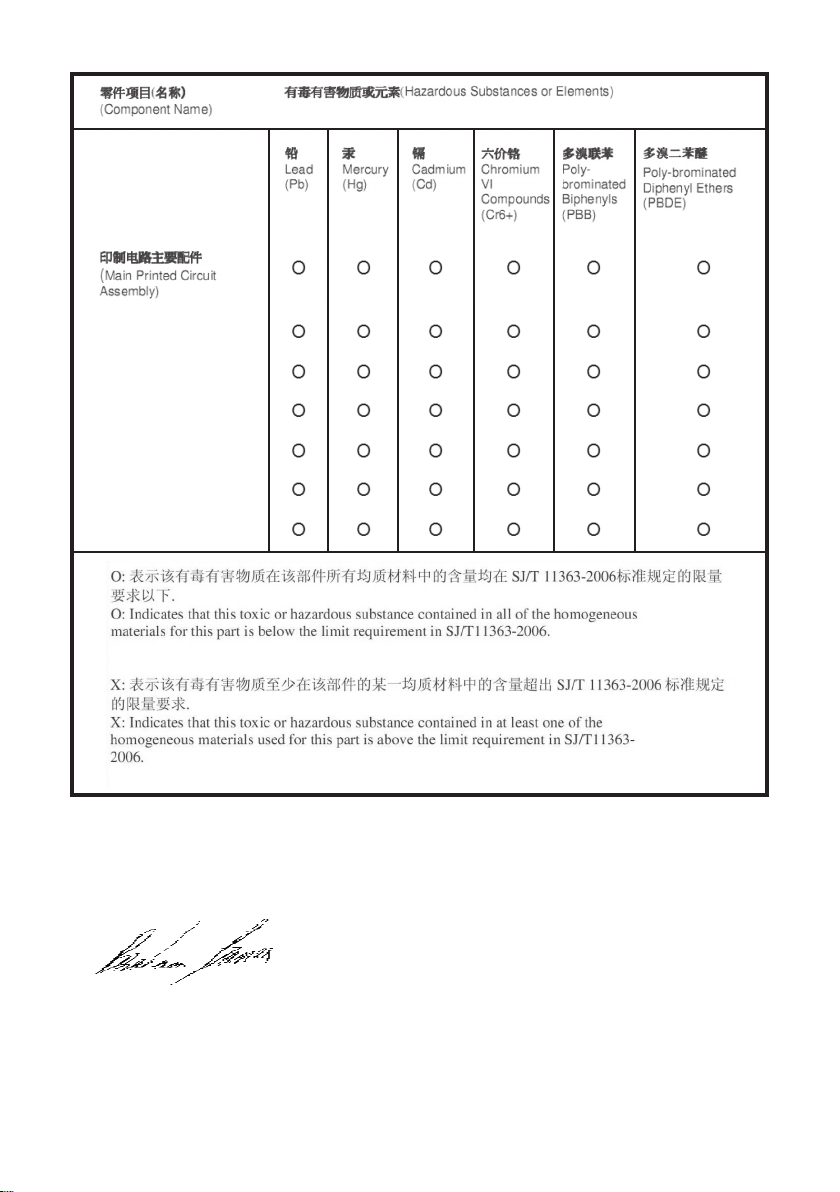

• EU Directive 2002/95/EC

• EU Directive 2004/108/EC

• China RoHS

Manufacturer’s Name: InnovAg Pty. Ltd.

Manufacturer’s Address: 37/328 Reserve Road, Cheltenham

Victoria 3192, Australia

Type of Equipment: Vacuum Gauge

Brand Name: DVG

Model Number: DR40-0080

© 2018 InnovAg 3

I, the undersigned, hereby declare that the equipment specied above

conforms to the above Directives and Standards.

Braham Basser Date: 30 July 2010

Director

InnovAg Pty. Ltd

Enclosure

LCD

Silicone tubing

Metal ttings

Front panel label

Rating labels

Contents

1. Features 6

2. Installation 6

3. Initial set up 7

4. Normal operation 9

5. Display indications 11

6. Demonstration mode 12

7. Maintenance & Calibration 13

8. Specications 13

9. Warranty 14

All rights reserved. No part of this manual may be

reproduced, transmitted, stored in a retrieval system, or

translated into any language in any form by any means

without the written permission of InnovAg Pty. Ltd.

6 © 2018 InnovAg

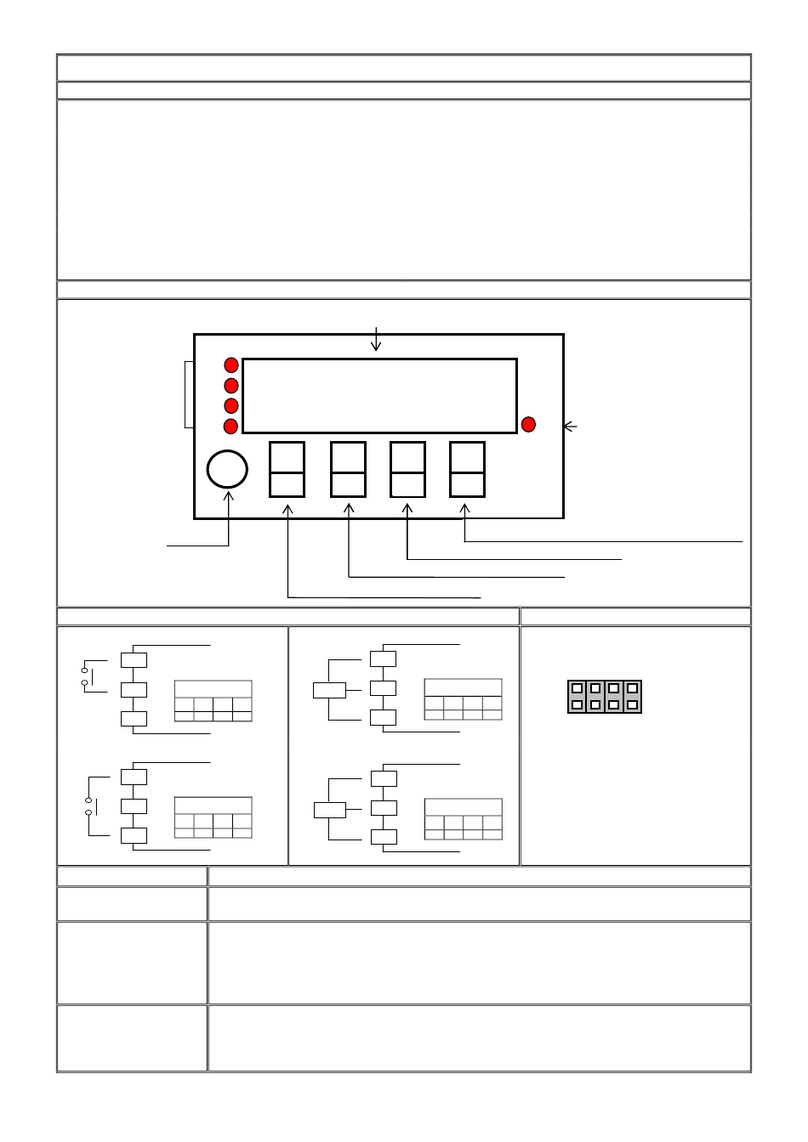

1. Features LED

BUTTON

REMAINING

LINER LIFE

BAR GRAPH

Accurate display of dairy vacuum:

• Damped to prevent display instability common with other digital

gauges.

• Fast mode (low damping) for technician use during testing.

• Auto zero adjustment.

• Manual zero adjustment.

• Display in either inHg or kPa units.

• Liner wear monitoring:

• Continuous bar-graph display of remaining liner life.

• Display of remaining liner life in %.

• Manual reset of liner life remaining, i.e. liners have been replaced

2. Installation

• Mount DVG as required.

• Connect to a power source 10 – 32VDC, 9 to 24VAC.

• Power wires can be connected in either polarity.

• The display will rst show a test screen, then 0.0

The round black sticker on the side of the DVG is an

expensive waterproof air vent that allows the case to

‘breath’. It should NOT be removed or covered.

© 2018 InnovAg 7

3. Initial Setup

With the power off press and hold the button and turn the power on.

The button must remain pressed to stay in setup mode.

Manual Zero

Keep holding the button down after the calibration year is shown in

setup mode to initiate Manual-zero.

Make sure there is no vacuum on the port.

The software version is

shown eg. v5.0

Calibration month eg. October Calibration year eg. 2018

The display will ash 0.0 ve

times before the zero starts.

When it stops ashing

Manual-zero is completed.

8 © 2018 InnovAg

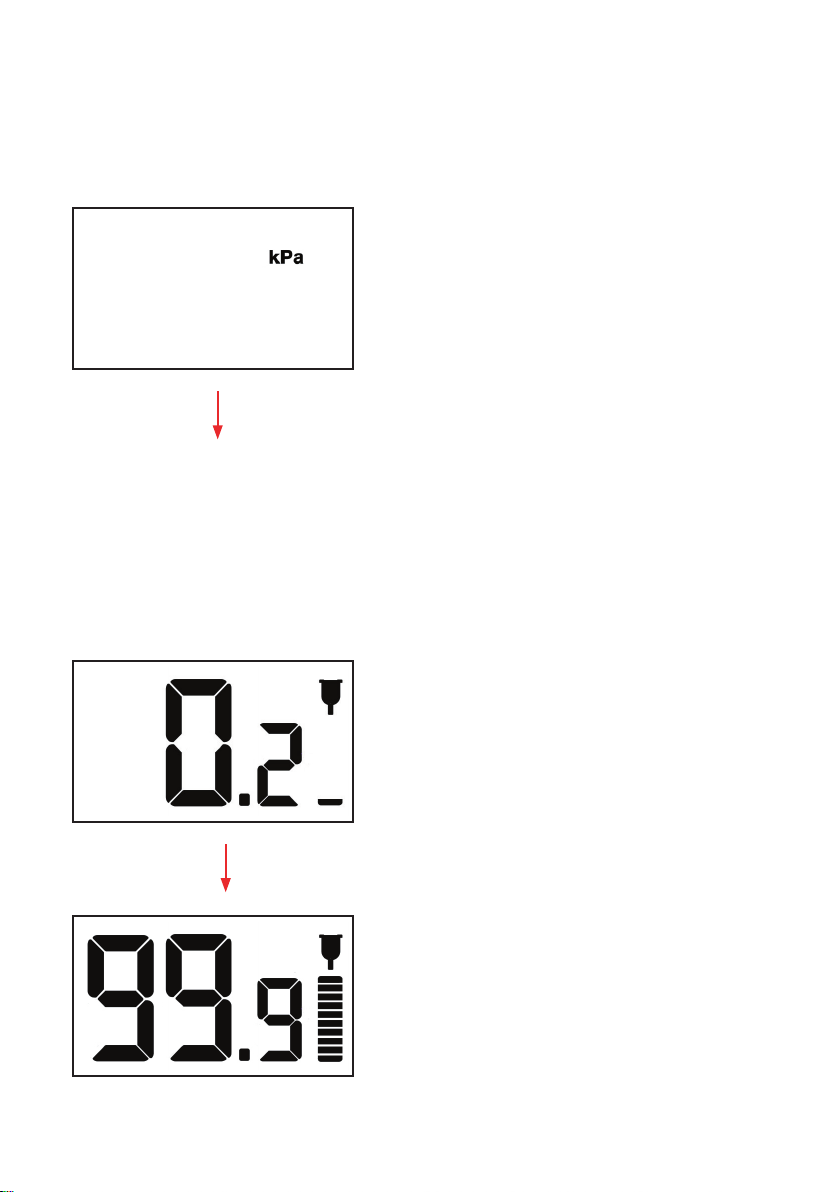

Changing Vacuum Units and Liner Milkings

Keep holding the button down after the Manual-zero is completed

to enter unit and liner setup mode. The screen will cycle through all

combinations continuously.

Release the button when the desired setting combination is shown as

described below.

Units = kPa.

Liner milkings = disabled

Units = kPa.

Liner milkings = 1200

Units = kPa.

Liner milkings = 2500

Units = inHg.

Liner milkings = 2500

Units = inHg.

Liner milkings = 1200

Units = inHg.

Liner milkings = disabled

© 2018 InnovAg 9

4. Normal Operation

Pressing the button will display

the remaining liner life as

percentage, eg. 75.3%.

Display Liner Life in %.

Holding the button down will display the software version, calibration

month and calibration year.

The software version is

shown eg. v5.0

Calibration month eg. October Calibration year eg. 2018

10 © 2018 InnovAg

Fast (Technician) Mode

Keep holding down the button after showing the calibration year to

toggle FAST mode on or off. For example, if it was off it will turn on

before entry.

Reset Remaining Liner Life

When new liners have been tted the Remaining Liner Life counter

should be reset to 100% (99.9%).

Keep holding the Button down after FAST mode to initiate Liner reset

mode.

Slow response to vacuum changes can

be inconvenient when performing an

equipment test.

FAST Mode temporarily makes the unit

respond faster to vacuum changes.

FAST mode automatically cancels after

20 minutes

The display will ash 10 times before

resetting.

Continue holding the button down until

the display stops ashing and shows

99.9%

© 2018 InnovAg 11

5. Display Indications

MEANING DIGITS LED UNITS

IDLE 0.0 off on on life

MILKING vacuum ashing on on life

REMAINING vacuum ashing on ashing one bar

LINER LIFE

LOW

REMAINING ashing ashing ashing ashing empty

LINER LIFE vacuum

ZERO

FAST MODE vacuum as above ashing on life

REMAINING life in % as above both on on life

LINER LIFE

% DISPLAY

LINER

ICON

LINER LIFE

BAR GRAPH

Milking - Vacuum has been higher than 20kPa (5.9inHg) for at least 20 mins.

Liner Life – Remaining life based on 1200 or 2500 milkings of 15 min each.

Unstable Vacuum Indicator

DVG will detect if the vacuum is unstable (drops by more than 4kPa

from the average) and will ash the decimal point for 5s each time a

drop is detected. The displayed reading is not affected by the drop. The

Unstable indicator is not shown in Fast Mode.

12 © 2018 InnovAg

6. Demonstration Mode

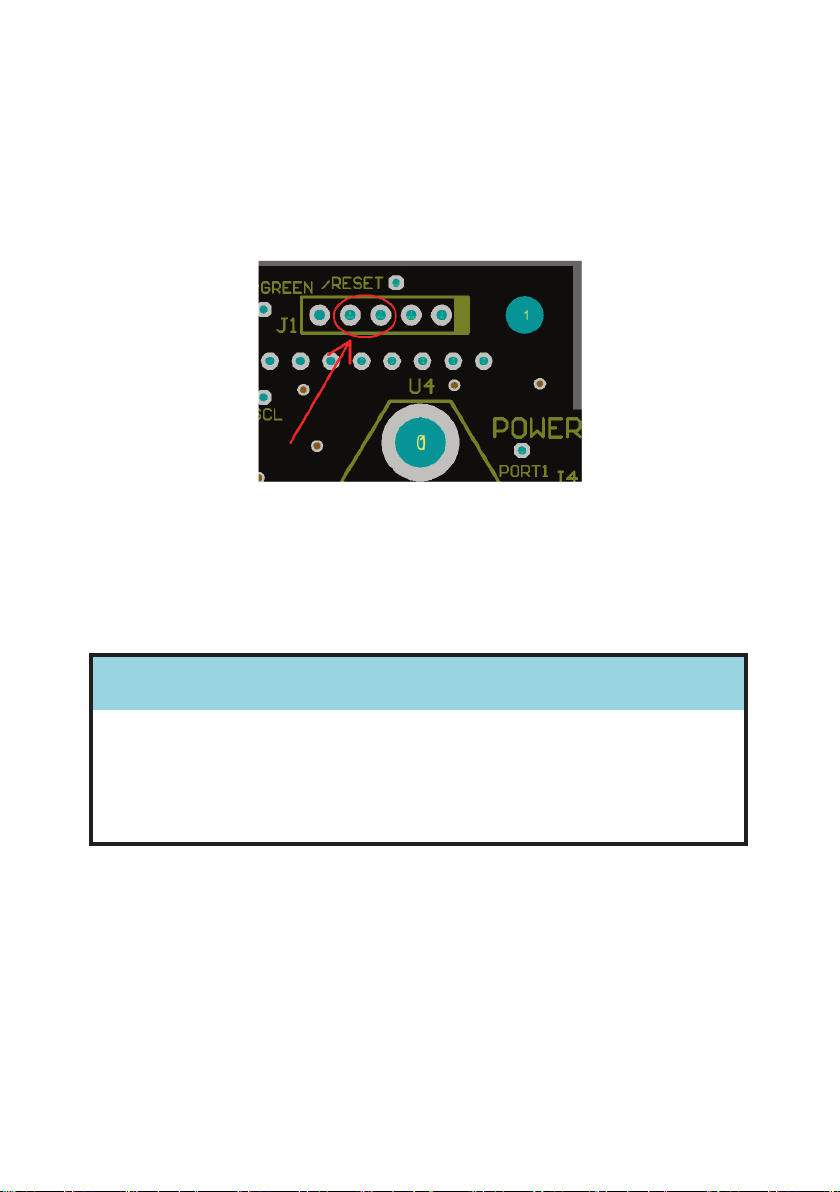

If pins 3 and 4 of J1 are shorted when DVG is powered on it will go into

Demonstration

Mode, indicated by the Liner icon ashing continuously.

This mode is useful to show how the DVG works without waiting the

long times normally required for events to occur. The following times

change:

ITEM NORMAL DEMO

Wait for vacuum to stabilise at start of milking 20 min 1 min

Liner wear bars drop one by one at 1200 30h 10.8s

Liner wear bars drop one by one at 2500 62.5h 22.5s

Exit Demonstration Mode by removing the short and power cycling DVG.

© 2018 InnovAg 13

7. Maintenance & Calibration

DVG requires little maintenance for years of accurate operation. If the

vacuum readings appear to be incorrect replace the small dust lter in

the silicone tube connected to the vacuum sensor.

DVG is factory-calibrated with a traceable Swiss reference vacuum

gauge (±0.05kPa). To ensure highest accuracy the calibration should be

checked every two years. Many vacuum gauges (both dial AND digital)

can have an error of 2kPa or more. Even a wellmaintained mercury

manometer can easily have an error of ±0.5kPa. If checking DVG be

careful that the other meter you are using is reliably accurate and the

vacuum is perfectly stable.

DVG can be returned to InnovAg for recalibration. Contact InnovAg or

your local distributor for the latest calibration prices.

8. Specications

Input Voltage: 10V to 32V DC, 9V to 24V AC

Pressure Range: 0 to 80 kPa Vacuum

Accuracy: ± 0.3 kPa typical, ± 0.6 kPa max

Repeatability: ± 0.3 kPa

Resolution: 0.1 kPa

Response time: 30s (Normal), 3s (Fast)

Operating Temperature: -5 to 40°C

Storage Temperature: -20 to 80°C

Liner Replace Limit: 1200 or 2500 milkings of 15min each.

*Specications are subject to change without notice.

14 © 2018 InnovAg

14. Warranty

InnovAg Pty. Ltd. provides the following limited two-year Warranty to the

original purchaser of the product). This Warranty cannot be assigned or

transferred to subsequent purchasers. The registration form must be

completed and returned to innovAg in order to be able to claim under

this Warranty.

WHAT WE WILL DO

If the product fails under normal use and service because of a

manufacturing defect in materials or workmanship within the Warranty

period, innovAg will, at its option either repair or replace the product

with an equivalent product. The repaired or replacement product will

be warranted under the terms of this Warranty for the remainder of the

applicable Warranty period. Repair may include the replacement of

parts or components with functionally equivalent reconditioned parts or

components.

WARRANTY PERIOD

The term of this Warranty is two (2) years from the date of purchase.

WHAT IS NOT COVERED

This Warranty does not cover any failures of equipment not supplied

by innovAg, nor does it cover any failures of or damage to the product

due to:

(i) improper handling, misuse, neglect, accident, improper installation ,

non-compliance with the directions for use;

(ii) any internal or external alteration or modication of any kind which

in the opinion of innovAg will affect the ability to service the product; or

(iii) repair by anyone other than an authorised innovAg Service Centre.

© 2018 InnovAg 15

RIGHTS UNDER THE TRADE PRACTICES ACT

Under applicable State, Territory and Commonwealth law, certain

conditions and warranties may be implied in this contract and rights

and remedies conferred upon you as user in relation to the product

which cannot be excluded, restricted or modied by agreement (“Non-

excludable Rights”). Any rights conferred upon you by this Warranty are

in addition to and do not detract from those Non-excludable Rights.

innovAg disclaims all express or implied conditions and warranties in

relation to the product other than the express terms of this Warranty

and any Non-excludable Rights. With respect to Non-excludable Rights,

innovAg’s responsibility to the Purchaser, where permitted, is limited to

the undertakings as stated in the clause headed ‘WHAT WE WILL DO’.

Subject to the above, in no event shall innovAg be liable (whether before

or after discharge of the contract for supply of the product or otherwise)

for any loss or damage suffered by you as the user arising from or

caused or contributed to by the negligence of innovAg, its servants or

agents, nor shall innovAg be liable for special, incidental, indirect or

consequential loss or damages suffered by you as user as a result of

breach by innovAg of this Warranty or otherwise including but not limited

to economic or moral loss, loss of prots or revenue or costs arising

from the loss of use of the product or the cost of substitute products.

16 © 2018 InnovAg

InnovAg Pty Ltd

37/328 Reserve Road

Cheltenham Victoria 3192, Australia

FreeCall (within Australia) 1800 061 167

www.innovag.com

A.C.N. 073 191 376

© 2018 InnovAg

Table of contents

Other innovAg Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

GLI International

GLI International C53 Operating instructions manual

ABB

ABB MagMaster Quick reference guide

Ametek

Ametek DTI 1000 Reference manual

PCB Piezotronics

PCB Piezotronics HT356A02 Installation and operating manual

Keysight Technologies

Keysight Technologies B1505A Configuration guide

Lutz

Lutz ST operating instructions