Innovate LM-2 User manual

11-0122B

1

LM-2

Digital Air/Fuel Ratio Meter

User Manual

This manual assumes that firmware version 1.18 or later is installed.

Warning!

It is extremely important to avoid hot-plugging sensor connections. Do

not connect or disconnect the sensor connectors while the unit is

powered ON.

The Oxygen Sensor used in this device gets very hot in operation.

Do not touch the hot sensor. Do not let a hot sensor touch a

combustible surface. Do not use the sensor with or near flammable

liquids or gases. Failure to heed these warnings may result in severe

burns, explosions or fires.

When installed in the exhaust, the oxygen sensor MUST be connected

and operating with the LM-2 whenever the car is running. An un-

powered oxygen sensor will be quickly damaged when exposed to hot

exhaust gases.

11-0122B

2

TABLE OF CONTENT

1LM-2.........................................................................................................3

1.1Main Screen.......................................................................................5

1.2Status Bar...........................................................................................5

1.3Configuration Menu Screen ...............................................................7

2Air/Fuel Ratio Setup.................................................................................8

2.1Sensor Placement..............................................................................8

2.2Sensor Calibration..............................................................................9

2.3Calibration Schedule........................................................................10

3OBD-II....................................................................................................11

3.1Selecting OBD-II Channels on the LM-2..........................................11

3.2Check Vehicle Trouble Codes on the LM-2 .....................................12

3.3Clear Vehicle Trouble Codes on the LM-2.......................................12

3.4Selecting Channels with the LM Programmer software...................12

3.5Check and Clear Vehicle Trouble Codes with LM Programmer......13

3.6OBD II connection diagnostic trace..................................................14

4Analog Cable..........................................................................................14

4.1RPM Input ........................................................................................14

4.1.1Enable/Disable RPM.................................................................15

4.1.2Configure RPM..........................................................................15

4.1.3Attenuating a Tach Signal.........................................................16

4.2Analog Inputs ...................................................................................17

4.2.1Enable/Disable Analog Inputs...................................................17

4.2.2Wiring Analog Inputs.................................................................17

4.3Analog Outputs Factory Default Settings.........................................17

4.3.1Programming Analog Outputs..................................................18

4.3.2Advanced output programming.................................................19

4.3.3Wiring Analog Outputs ..............................................................19

5Data Logging..........................................................................................20

5.1Recording.........................................................................................21

5.2Log File Format................................................................................22

5.3Downloading Logs from Memory Card.............................................22

5.4Playback...........................................................................................22

6Software (LogWorks 3 and LM Programmer)........................................23

6.1Download the Logworks 3 software package ..................................23

6.2Installing software.............................................................................23

6.3Driver Instalation ..............................................................................23

6.4Updating Firmware...........................................................................23

6.5Changing Sensor Type ....................................................................25

Appendix A: Specifications............................................................................26

Appendix B: Limited Warranty.......................................................................27

Appendix C: Error Codes and Troubleshooting Tips ....................................28

11-0122B

3

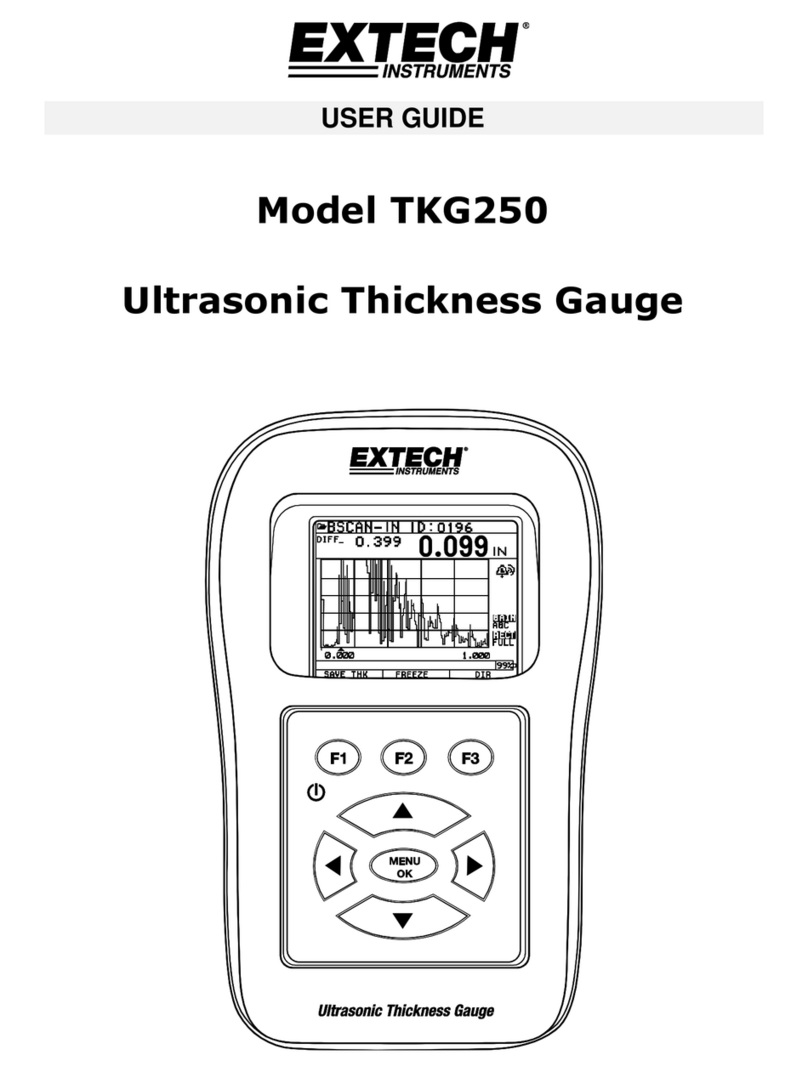

1 LM-2

The LM-2 is a single or dual channel wideband controller with a built-in OBD

II scan tool, RPM input, four analog inputs, MTS serial I/O, SD memory card

recording and two analog outputs.

Front

MODE

Press once to

cycle through

channel display

screens. Press

and HOLD to enter

Setup Menu.

CANCEL

Press to cancel

out of menu or to

stop recording.

RECORD

Press once to

record or a second

time to stop

recording. Press

and HOLD to force

a new log.

UP

Scroll through

available

channels. Move

through menu

ENTER

Accept an entry in

the menu screen.

DOWN

Scroll through

available

channels. When in

the Move through

menu

11-0122B

4

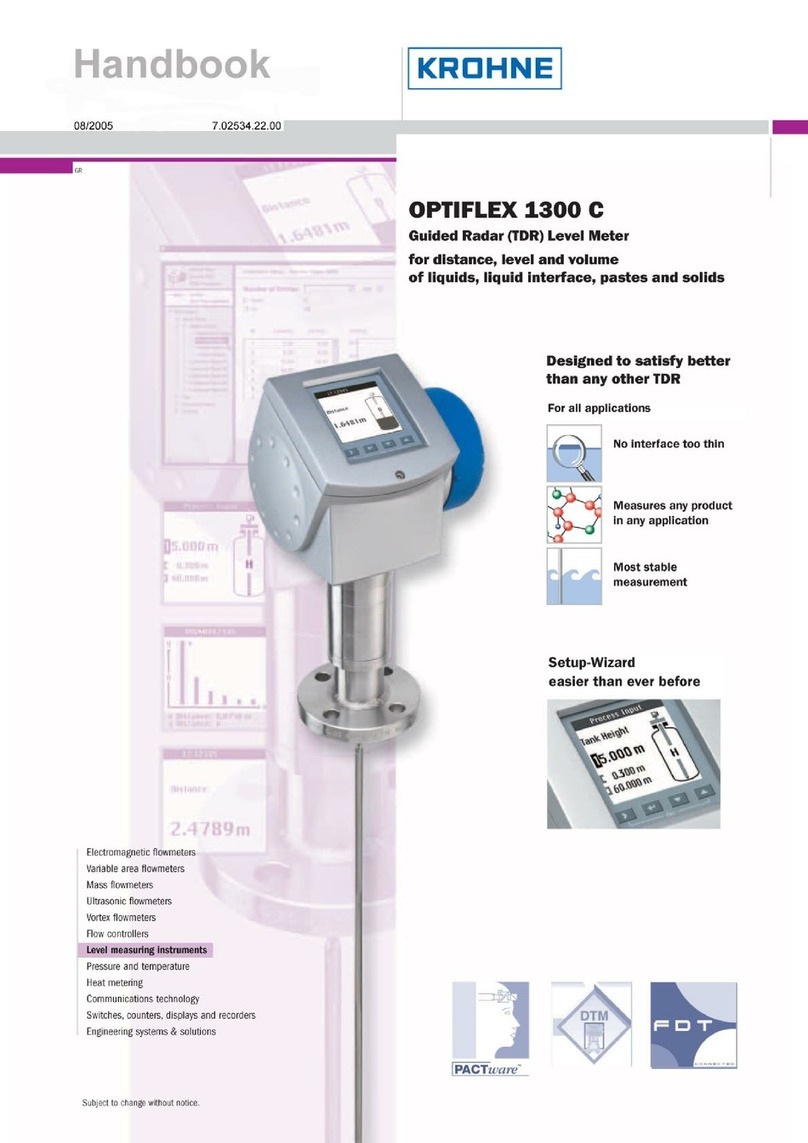

Left

Top

Bottom

Inductive Clamp MTS Serial IN MTS Serial OUT

SD Memory Card

USB Connector

Sensor Port # 2

(Enabled with the

Dual Channel version)

Analog Cable

Sensor Port # 1

OBD-II

Connector

Power

11-0122B

5

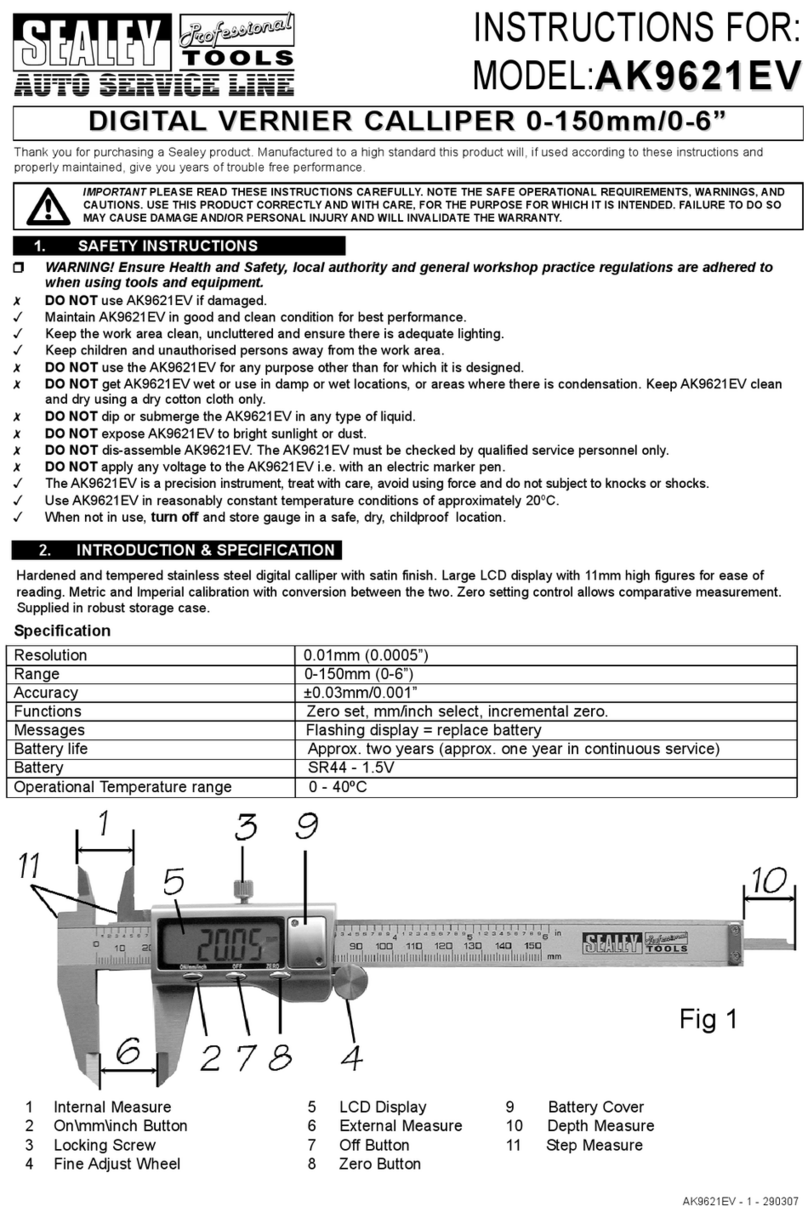

1.1 Main Screen

There are 3 different screen view options: one channel, two channels, and

four channels. These can be cycled by momentarily pressing the MODE

button. The type of channels being displayed can be changed by using the

UP and DOWN arrows.

One Channel

Two Channels

Four Channels

1.2 Status Bar

The bottom edge of the screen is the status bar and will look something like

this:

The left most portion is the current time (which can be set via menu and is

set automatically by LM Programmer).

11-0122B

6

During Recording, an upper case ‘R’ and a counter will display on the lower

left:

Counting minutes and seconds of recording.

Similarly, during playback a upper case ‘P’ and a counter will display:

Counting elapsed time during playback.

Note: If Recording does not start (see later section), also look here, the word

“Card?” will appear if no SD card is detected when Record is selected. The

word “Full!” will appear if you have either filled the SD card, or exhausted the

available log names (see section on recording).

Moving to the right, the next two indications are O2 sensor status, which can

be one of the following:

HW - Heater Warm-up

Cal - Calibrating

O2 - Reading O2 context (lambda over 8.something)

L - Reading Lambda (or AFR)

Ex - Error, Check Appendix E for error code meanings and trouble

shooting tips

Note: If the LM-2 is a single channel model, the second indication will be

blank, not an error code.

The next indicator, “R”, will appear when a) RPM is selected for logging/use

(see menus) and b) an RPM signal is detected. Note, when RPM is enabled,

but no RPM signal is detected, this symbol will appear in lower case (“r”).

The “A” indicator means that the 4 Analog Inputs are selected for

logging/Use (see menus). It is all or nothing. The display will be blank if

disabled.

The “O” indicates that an OBD-II connection is active. This indicator will blink

at the relative ‘sample rate’, which will vary on the number of channels

selected and the vehicle’s protocol. The display will be blank if the unit is not

connected to an OBD-II port.

11-0122B

7

The blinking “M” indicates that MTS serial data is being generated. This will

blink at the relative MTS packet rate (for comparison with the O indicator). If

the unit is not the “head” unit, then this will only blink when packets are being

received via the Serial In connector.

Last, “H” indicates that the unit is the MTS head unit. If the unit is not head

this indicator will appear as a “-“

1.3 Configuration Menu Screen

To enter the Configuration Menu Screen press and hold the MODE button.

Navigating the Menu:

“ENTER” Accepts

“CANCEL” Returns one menu level

“MODE” Returns to Main Screen

UP and DOWN arrows adjust selection or value

“RECORD” has no effect

When “MODE” is first pressed, the following choices appear:

Display AFR or Lambda. Factory default setting is AFR.

Calibrate Sensors - Free Air Calibrate ALL O2 sensors connected

will be calibrated

Fuel Type Setup – Change the AFR fuel type setting. Factory

default setting is Gasoline (14.7.)

RPM – Enable/Disable RPM and Configure RPM.

OBD-II - Configure Number of Channels (0-16), Channel Use,

Get/Clear DTC codes Display in Metric/Imperial Units, and Start

Trace File.

Playback Log

Reverse/Normal Display

Set Date/Time - Set the current date/time

Wideband Sensor Type Setup – Allows to select from the Bosch

LSU 4.2 or LSU 4.9 sensor. Refer to “Changing Sensor Type”

chapter.

Note: Entering the Configuration Menus will stop recording and suspend

MTS packet output

11-0122B

8

2 Air/Fuel Ratio Setup

2.1 Sensor Placement

Optimum bung placement will vary from application to application, but using

the guideline below will ensure the longest sensor life with the most accurate

readings. Using a bung is the preferred method for mounting the oxygen

sensor in all applications.

Weld the bung at least 24 inches downstream of the exhaust port outlet

(after the collector), or 24 inches after the turbocharger if so equipped.

The bung should be welded before the X or H pipe if so equipped.

Using a clock as reference, mount the bung between the 9:00 o’clock

and 3:00 o’clock position. Welding the bung in the lower section of the

exhaust pipe can result in sensor damage caused by condensation

making contact with the sensor’s internal heating element.

A 1” bung (provided in the kit) will best protect the sensor. When fully

threaded, the sensor’s tip will sit flush with the exhaust pipe, this does

not adversely affect the readings.

The bung should always be welded before the Catalytic Converter.

Welding the bung after the catalytic converter will skew the readings

toward lean. The skew in readings will vary with engine load and the

efficiency of the catalytic converter.

Leaded fuel and two stroke applications will reduce the sensor’s life.

There are many other factors that dictate the sensor’s lifespan so it is

impossible to predict it’s total longevity.

Exhaust leaks, camshaft overlap, and open (shorty) exhausts will cause

false lean readings at light engine loads. Typically, once the engine is

under load and the exhaust gas volume increases, you will see accurate

readings.

When installed in the exhaust, the oxygen sensor must be connected to

a powered, functional LM-2 (no error codes) whenever the engine is

running. An un-powered sensor will be damaged in a short period of time

when exposed to exhaust gas.

Do not pre-warm the sensor before starting the engine, simply start the

engine as normal. Allowing the sensor to pre-warm before starting the

engine will increase the possibility of damaging the sensor from shock-

cooling.

11-0122B

9

The maximum temperature of the sensor at the bung (the sensor

mounting location) should not exceed 500

o

C or 900

o

F. If these

temperatures are exceeded in your application you should install the

Innovate Motorsports HBX-1 heat sink bung extender. (p/n 3729.)

Alternatively you can also use the optional exhaust clamp (p/n 3728) to

sample exhaust gases at the end of the tail pipe. Be aware that this

method of sampling exhaust gas is prone to give false lean readings at

light engine loads.

As the O2 sensor measures the oxygen content of the exhaust

gas to provide an accurate O2 reading, even a small pin-hole

leak in a poorly welded sensor bung will affect the accuracy

and performance of your O2 sensor. Remember, any deviation from

the instructions provided for proper sensor installation will lead to

inaccurate O2 readings.

2.2 Sensor Calibration

Innovate Motorsports’ ‘Direct Digital’ wideband measurement technology

allows you to calibrate the sensor to compensate for sensor wear and

atmospheric pressure variances. This procedure takes just a few moments

and it will ensure the most accurate readings throughout the oxygen sensor’s

life. This procedure is required anytime a NEW oxygen sensor is

installed.

It is extremely important to avoid hot-plugging sensor

connections. Do not connect or disconnect the sensor

connectors while the unit is powered ON.

The calibration procedure requires that the oxygen sensor be in free air, this

means removed from the exhaust system completely.

1. With the LM-2 powered off, connect the oxygen sensor to the sensor

cable and the other end to the sensor input on the LM-2.

Single Channel: The active sensor port is #1 which is parallel to the

power connection.

Dual Channel: Both oxygen sensors may be connected to the unit

at the same time or one at a time.

2. Connect the LM-2 to the cigarette power plug with the provided

cigarette power adapter.

11-0122B

10

3. The sensor(s) will start warming up. The LM-2 will display WXX,

where XX is the percentage of temperature reached. Notice the

status bar displaying a ‘W’.

4. Once the unit stops indicating the sensor is warming up, it is time to

trigger the calibration. Press and hold the MODE button until the

Configuration Menu appears. Select ‘Calibrate Sensors’ and press

the Enter button.

5. Confirm by selecting ‘Start Sensor Calibration’ and press the ENTER

button.

6. The display will momentarily display ‘Cal’ and then it will switch to

reading a percentage of oxygen. If the oxygen content now differs

from 20.9% by more than 0.4%, repeat the calibration.

7. The LM-2 is calibrated and ready for use.

The LM-2 must be powered by the cigarette adapter (12 volts) in

order to properly heat the Oxygen sensor and measure Air/Fuel. If

the unit is only connected to the OBDII port it will properly function

as a scan tool, but not warm up the sensor.

2.3 Calibration Schedule

Normally aspirated (daily driver)

- Calibrate before installation of new sensor

- Calibrate new sensor again after 3 month of use

- Thereafter calibrate once a year or every 20,000 miles, whichever comes

first

Turbo Application, daily driver (tuned rich)

- Calibrate before installation of new sensor

- Calibrate new sensor again after 3 month of use

- Thereafter calibrate twice a year or every 10,000 miles, whichever comes

first

Race Application

- Calibrate before first installation of new sensor

- Calibrate once per race weekend

11-0122B

11

Dyno use:

- Calibrate a new sensor

- Calibrate every 2-3 days, depending on usage

3 OBD-II

Before setting up your OBD-II channels it is important to understand that the

number and type of channels selected have a dramatic effect on response

speed and ECU connectivity. For example, older vehicles running the

ISO9141 protocol will not deliver as many channels as newer vehicles

running the CAN protocol. It is important to start with one channel, establish

the connection with the ECU, then incrementally increase the channel count.

The common symptoms for too many active channels can be seen as

channel drop outs and/or disconnections. The channel selection can be

optimized by designating certain channels as “Low Priority.” Channels

designated as “Low Priority” will be queried less often which will allow more

bandwidth for the high priority channels.

When the LM-2 first establishes the connection to the vehicle’s ECU it will

query the list of available channels, the LM-2 will then only allow a selection

from this list.

When moving the LM-2 from vehicle to vehicle is it important to reset the

channel count to 1 and set the protocol to ‘Automatic’. This will allow the LM-

2 to reestablish the available channel list and give a starting point to which

response speed can be evaluated.

3.1 Selecting OBD-II Channels on the LM-2

1. Connect the OBD-II cable to vehicle’s OBD-II port and the other end

to the LM-2

2. Start the engine.

3. Press and hold the MODE button to go into the Configuration Menu

Screen. Select OBD-II and press the ENTER button.

4. Select Configure OBD-II.

5. You will now be given the option to select a particular OBD II

protocol or you can leave it on ‘Automatic’ which will scan all

available protocol until it connects. Press ENTER.

6. Select the number of OBD II channels to read It is recommended to

start off with 1 channel and slowly increase the number, evaluating

the speed at which the ECU delivers data. Press ENTER.

7. You will now be able to scroll through all available channels and

make your selection. Note: If you are connected the unit will filter and

11-0122B

12

only display the available channels available by the ECU, otherwise

the unit will display all OBD-II channels. Press ENTER.

8. Chose if the channel is Low or High Priority. Press ENTER to move

to the next channel.

9. After all channels have been selected the unit will return to the main

screen.

It cannot be stressed enough, the number and type of channels

selected will have a dramatic affect in response speed and ECU

connectivity.

3.2 Check Vehicle Trouble Codes on the LM-2

1. Connect the OBD-II cable to vehicle’s OBD-II port and the other end to

the LM-2

2. Do not start the engine, put the key in the accessory position.

3. To view your vehicle trouble codes press and hold the MODE button to

go into the Configuration Menu Screen.

4. Select OBD-II and press the ENTER button.

5. Select “Get DTC’s”. A list (if any) of error codes will be displayed on the

screen. You may scroll up and down the list using the arrows.

6. To see the specific meaning of the error code, select it and click ENTER.

Click ENTER again to return to the list.

7. Press MODE or CANCEL to exit.

3.3 Clear Vehicle Trouble Codes on the LM-2

1. Connect the OBD-II cable to vehicle’s OBD-II port and the other end to

the LM-2

2. Do not start the engine, put the key in the accessory position.

3. To clear your vehicle trouble codes press and hold the MODE button to

go into the Configuration Menu Screen.

4. Select OBD-II and press the ENTER button.

5. Select Clear DTC Codes and press the ENTER button.

3.4 Selecting Channels with the LM Programmer software

1. Connect the LM-2 to your computer with the provided USB cable.

Connect the OBD-II cable to vehicle’s OBD-II port and the other end to the

LM-2.

2. Start the engine.

3. The LM Programmer application can be launched from Start->Programs-

>LogWorks3->LM Programmer from the Windows task bar.

11-0122B

13

4. The Inputs tab allows you to set the number of MTS channels to

generate.

5. Click the Inputs tab. Only the number of channels selected on the

Protocol/Channels page can be edited. The available values for logging

on the connected ECU are listed in the drop list for each Input. Some

vehicles will support larger lists than others.

6. Hit the ‘Program’ button to send the configuration.

3.5 Check and Clear Vehicle Trouble Codes with LM Programmer

1. Connect the LM-2 to your computer with the provided USB cable.

2. Connect the OBD-II cable to vehicle’s OBD-II port and the other end to

the LM-2.

3. Do not start the engine, put the key in the accessory position.

4. The LM Programmer application can be launched from Start-

>Programs->LogWorks3->LM Programmer from the Windows task bar.

5. Click the tab labeled “Trouble Codes.”

Standard Trouble Codes are listed both with a number and a description.

Manufacturer specific codes will generally just appear as a number, though

sometimes, the general category can be identified.

You can request that the ECU clear the pending codes using the Clear and

Refresh button at the bottom right corner of the page.

11-0122B

14

3.6 OBD II connection diagnostic trace

In the rare situation where the LM-2 is not able to connect to the vehicle’s

OBD-II protocol creating a trace file will greatly aid in diagnosing the

problem.

1. Press and hold the MODE button to go into the Configuration Menu

Screen.

2. Select OBD-II and press the ENTER button.

3. Use the ARROW buttons to scroll down to Start Trace File and press

the ENTER button. A 't' will alternate (or stay steady) in the "O" spot

on the status bar.

4. Connect the LM-2 to the vehicle’s OBD-II port. Wait one minute.

5. Wait one minute, then either press RECORD to stop, or select "Stop

Trace File" from OBD-II menu.

6. A file named OBDIIxx.TXT will be saved on the SD card (xx counts

up to 99).

7. E-mail this file along with the year, make, and model of the vehicle to

the support staff at Innovate Motorsports

4 Analog Cable

The provided analog cable has 14 stripped ends. The wire assignments are

as follows:

Analog Out 1 + (Lime Green)

Analog Out 1 – (Yellow) Analog Out 2 + (Brown/White)

Analog Out 2 – (Dark green)

Analog In 1 + (Purple)

Analog In 1 – (Black) Analog In 2 + (Grey)

Analog In 2 – (Brown)

Analog In 3 + (White)

Analog In 3 – (Red) Analog In 4 + (Peach)

Analog In 4 – (Orange)

RPM + (Black/White)

RPM – (Blue)

4.1 RPM Input

The LM-2 has a direct tach signal input signal. This input can be used to feed

a signal from the negative lead of a coil, ECU, negative lead of an injector,

or ignition box (i.e. MSD 6AL). This tach signal can be feed to the RPM +

(Black/White) wire. The negative wire (Blue) can be connected to ground if a

tach signal is not being registered.

Note: Ignitions running a multi-spark setup (i.e. MSD 6AL) must use the

provided tach signal from the ignition box.

11-0122B

15

4.1.1 Enable/Disable RPM

Enabling the RPM channel will allow you to display the channel on the

LM-2 and log it on the SD memory card. Disabling the channel will do the

exact opposite.

1. Press and hold the MODE button to go into the Configuration Menu

Screen.

2. Select RPM and press the ENTER button.

3. You will now have the option to Enable/Disable RPM.

4.1.2 Configure RPM

1. Press and hold the MODE button to go into the Configuration Menu

Screen

2. Select RPM and press the ENTER button.

3. Select Configure RPM and press the ENTER button.

4. You will now have the option of selecting the Tach input source, use

the arrows to change the selection. 0 is the input from the Analog

Cable, 1 is the input from the Inductive Clamp. Press ENTER.

5. You will now have the option to select the ‘Polarity.’ Rising Edge is

the most common way to measure a tach signal. If you find that your

readings are very erratic you should change this setting to Falling

Edge. Press ENTER.

6. Select the RPM range. Options are 10230 RPM or 20460 RPM.

Press ENTER.

7. Select Pulses per Rotation. Below are two tables to aid in your

selection:

Cylinder number and RPM calibrate number 4 Cyl engine

Cylinder

Count Pulses/Crank-

Rotation Calibrate

Number Comment

1 1/2 1 Use also when using inductive

clamp on spark wire or power wire

of COP system of 1 cylinder only

for all cylinder numbers

2 1 2 Use also when using inductive

clamp on spark wire or power wire

of Waste spark coil of 1 cylinder

only.

Waste spark system:

1 coil for every 2 cylinders.

3 1-1/2 3

4 2 4

5 2-1/2 5

6 3 6

8 4 7

10 10 8

11-0122B

16

12 12 9

Cylinder number and RPM calibrate number 2 Cycle and Rotary Engine

Cylinder

Count Pulses/Crank-

Rotation Calibrate

# Comment

1 1 2 Use also when using inductive

clamp on spark wire or power wire

of COP system of 1 cylinder only

for all cylinder numbers

Also use for rotary engine.

2 2 4 Use also when using inductive

clamp on spark wire or power wire

of Waste spark coil of 1 cylinder

only.

Waste spark system:

1 coil for every 2 cylinders.

3 3 6

4 4 8

5 5 8

6 6 9

8. Once the selection is made press ENTER. You will be brought back

to the main screen.

4.1.3 Attenuating a Tach Signal

The problem of an erratic tach signal happens if there is a lot of ringing at

high voltages. To counteract this, it is sometimes necessary to attenuate the

tach signal by about 30dB or so. This is accomplished with a 100k variable

potentiometer which can be purchased at Radio Shack or any electronics

store.

Wiring

1. Connect the tach signal to terminal A.

2. Connect terminal B to the tach signal input of the LM-2’s analog

cable which is the Black wire with a White stripe.

3. Connect the terminal C to Ground. (Do not connect this to the Blue

tach signal ground on the LM-2’s analog cable.)

Tuning RPM

1. Turn the pot all the way to the right (until no RPM is registered).

11-0122B

17

2. Start turning the pot to the left and stop when you start registering a

tach signal and the LM-2 displays an 'R' on the status bar.

4.2 Analog Inputs

The LM-2 has 4 analog inputs for external 0-5V sensors. Each input has a

corresponding positive lead (+) for the signal and a negative lead (–) for the

ground signal source. It is important to wire both of these leads to get

accurate measurements.

4.2.1

Enable/Disable Analog Inputs

1. Press and hold the MODE button to go into the Configuration Menu

Screen.

2. Select Analog Inputs and press the ENTER button.

3. You will not have the option to Enable/Disable the Analog Inputs.

4.2.2

Wiring Analog Inputs

The LM-2’s inputs are differential. A differential input does not measure a

signal relative to electrical ground. Instead it measures the relative voltage

between two signals. That is, it does not measure the '+' signal in

relationship to ground, but in relationship to the '-' signal. It measures the

'difference' between them. The following diagrams better illustrate the

correct way to wire in external sensors. Please note that the + lead is signal

positive, NOT power.

4.3 Analog Outputs Factory Default Settings

Single Channel A/F units: Analog Output 1 is programmed to output

between 0 V for an AFR of 7.35 (gasoline) and 5.0V for an AFR of 22.39.

Analog Output 2 is configured as 1.1 V for an AFR of 14 and .1 V for an AFR

of 15.

11-0122B

18

Dual Channel A/F units: Analog Output 1 and Analog Output 2 are

programmed to output between 0 V for an AFR of 7.35 and 5.0V for an AFR

of 22.39. They represent sensor 1 and sensor 2, respectively.

4.3.1 Programming Analog Outputs

1. Connect the LM-2 to your computer with the provided USB cable.

2. Power up the LM-2.

3. Launch LM Programmer. The LM Programmer application can be

launched from Start->Programs->LogWorks3->LM Programmer from

the Windows task bar.

4. Select one of the Analog output tabs. The Analog output page looks

like this:

This shows the analog output voltages versus Lambda for one of the two

analog outputs. The graph display is automatically scaled to the selected

voltages. For each output you can specify a minimum and maximum lambda

value and the associated voltages. Below the minimum and above the

maximum lambda values the output voltages stay constant at the associated

programmed voltage.

11-0122B

19

By selecting the ‘use Air-Fuel-Ratio’ button you can program the curve by

AFR instead of Lambda. This does not change the programming, only the

representation of the data. When programming by AFR the LM Programmer

converts the number to Lambda before programming the LM-2.

Click the ‘Program’ button to download the new data into the LM-2. Once the

unit is programmed the ‘Program’ button will grey out.

Note for Dual A/F channel units: You can program each analog output to

represent the data from sensor 1 or 2 by selecting the appropriate radio box.

4.3.2 Advanced output programming

The ‘Advanced’ button allows programming to set the analog out update

speed and the voltage output during sensor Warm-up and Error Condition.

The factory defaults of the analog outputs is to update the outputs 1/12 of a

second. The factory default voltage output is set for 0 volts for both the

Warm-up and Error Condition.

When setting the LM-2 to the slower response speed settings the measured

mixture data will be averaged over the response time setting before being

output.

4.3.3 Wiring Analog Outputs

The analog outputs on the LM-2 are differential. As with the analog inputs,

the negative lead (-) must be connected to ground for the readings to be

accurate. Below are the three different ways the analog outputs of the LM-2

can be wired. If you are unsure whether your analog input is differential or

not you may wire the analog output as shown in diagram 1.

11-0122B

20

5 Data Logging

The LM-2 can record up to 32 channels of information at 12 times per

second. Data can originate from the internal analog inputs, OBD-II port, or

the built-in wideband channel(s). The LM-2 can also accept other Innovate

Motorsports’ MTS (Modular Tuning System) devices through the serial IN

Other manuals for LM-2

1

Table of contents

Other Innovate Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Oval

Oval Flowpet-5G Series instruction manual

Shodex

Shodex RSpak DE-213 Operation manual

WURM

WURM HVI-G4 quick start guide

Tuthill

Tuthill FILL-RITE TN700 Series Owners installation, operation, and safety manual

Eastron

Eastron SDM230-Modbus user manual

Worldcast Systems

Worldcast Systems audemat GOLDENEAGLE ATSC user manual