Innovate 9500 User manual

496332 Issue 1 1 of 22

9500

Installation and User Guide

Compatible Equipment

9525 Remote Keypad

9505 LIM

9507 LIM + PSU

9508 Shunt LIM (4 zones)

9509 Shunt LIM Controller

9510 EOL LIM (3 Zones)

9585 Engineers Printer (Centronics)

9589 Printer lead (Centronics)

9590 Hardware Mimic System

9597 Computer Mimic System

2 of 22 496332 Issue 1

Introduction

The 9500 Series System is a fully programmable, microprocessor controlled,

electronic intruder alarm system designed to meet the security requirements

of medium to large industrial and commercial premises.

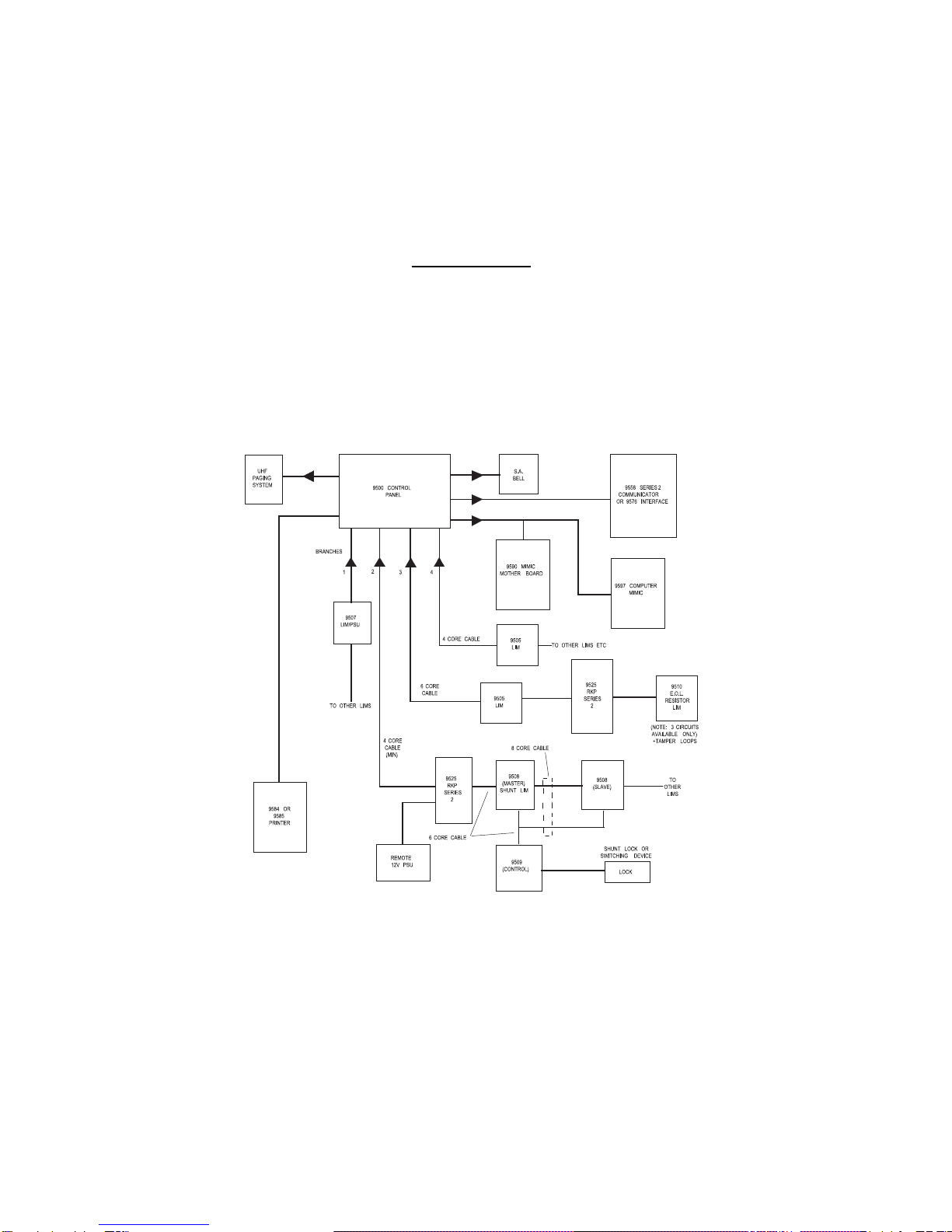

The system operates on the “Multiplex” principle using four main data high-

ways (or branches) from the main control panel. Each branch comprises a

minimum 4-core cable, (6-core where keypads are included in branch), which

may be up to 2km (2000 metres) in length and may accommodate a combi-

nation of up to 16 Line Interface Modules (LIMs), Remote Keypads and

Isolation LIMs.

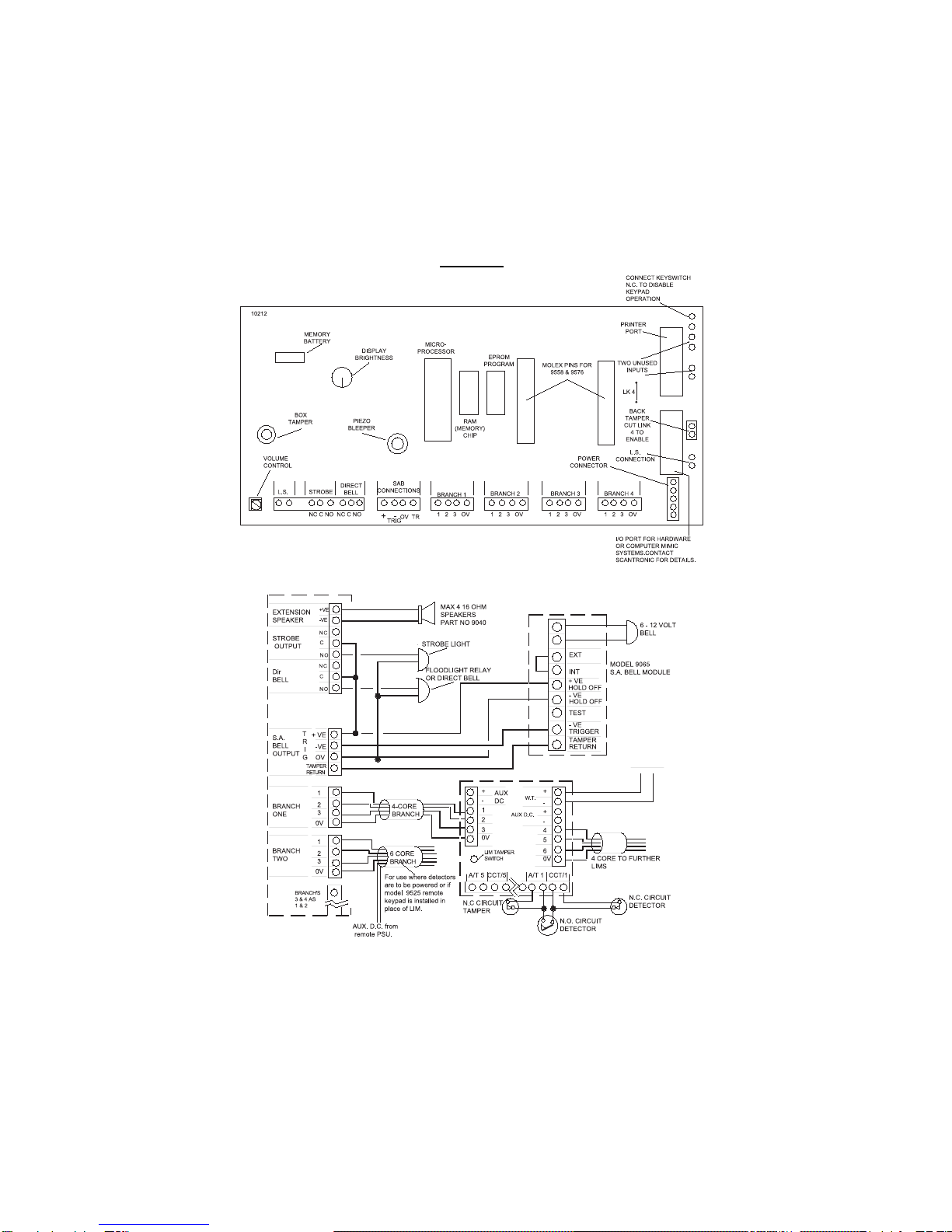

Figure 1. System Configuration

Each Line Interface Module has five double-pole circuits which can individu-

ally be programmed to any one of six circuit types and can feature any or all

9500

496332 Issue 1 3 of 22

of the seven circuit attributes, (Attributes do not apply to P.A., Technical

Alarm or 24 hour circuits).

The main control panel is provided with outputs suitable for connection to a

printer or a completely programmed mimic diagram system. The system will

accept a plug-in digital communicator (fast format only) or a direct-line

interface, which can also be used to connect the Series 9500 to “Red Care”

or “ABC” (Alarms by Carrier).

Technical Specification

Zones 0-320.

Display 32 Character “Supertwist” LCD.

Expansion By line interface modules of up to 5 circuits

per LIM.

BS 4737 Full Specification.

Log 450+ events ( Date andTime ).

Panel Siren No.

Internal Siren 9040 4 max.

Dimensions Panel h x w x d 290 x 400 x 10mm.

Dimensions Keypad h x w x d 180 x 110 x 40mm.

Weight Panel 4.6 Kg, Keypad 500g.

Battery 6 Ah.

Communicator

Output Plug-on STU/ 9058/9056 by using the 9578.

Signalling Conversion Interface.

Plug-on Interface 9576, 9576-01.

Outputs Bell relay contacts,

Strobe relay contacts.

Quiescent Current Ratings

12 Volt Power Quiescent: Panel 165mA, Keypad 50mA.

12 Volt AUX Output Not available unless detector power.

requirement less than 150 mA.

9500 Control Panel 165mA.

9558 Communicator 10mA.

9525 Remote Keypad 50mA.

9505 Standard LIM 10mA.

9506 Bare LIM 10mA.

9510 End Of Line LIM 10mA.

9508 Shunt LIM 10mA.

9509 Controller 12mA.

9500 Technical Specification

4 of 22 496332 Issue 1

Wiring

Figure 2. Main PCB Layout

Figure 3. Main PCB Connections

9500

496332 Issue 1 5 of 22

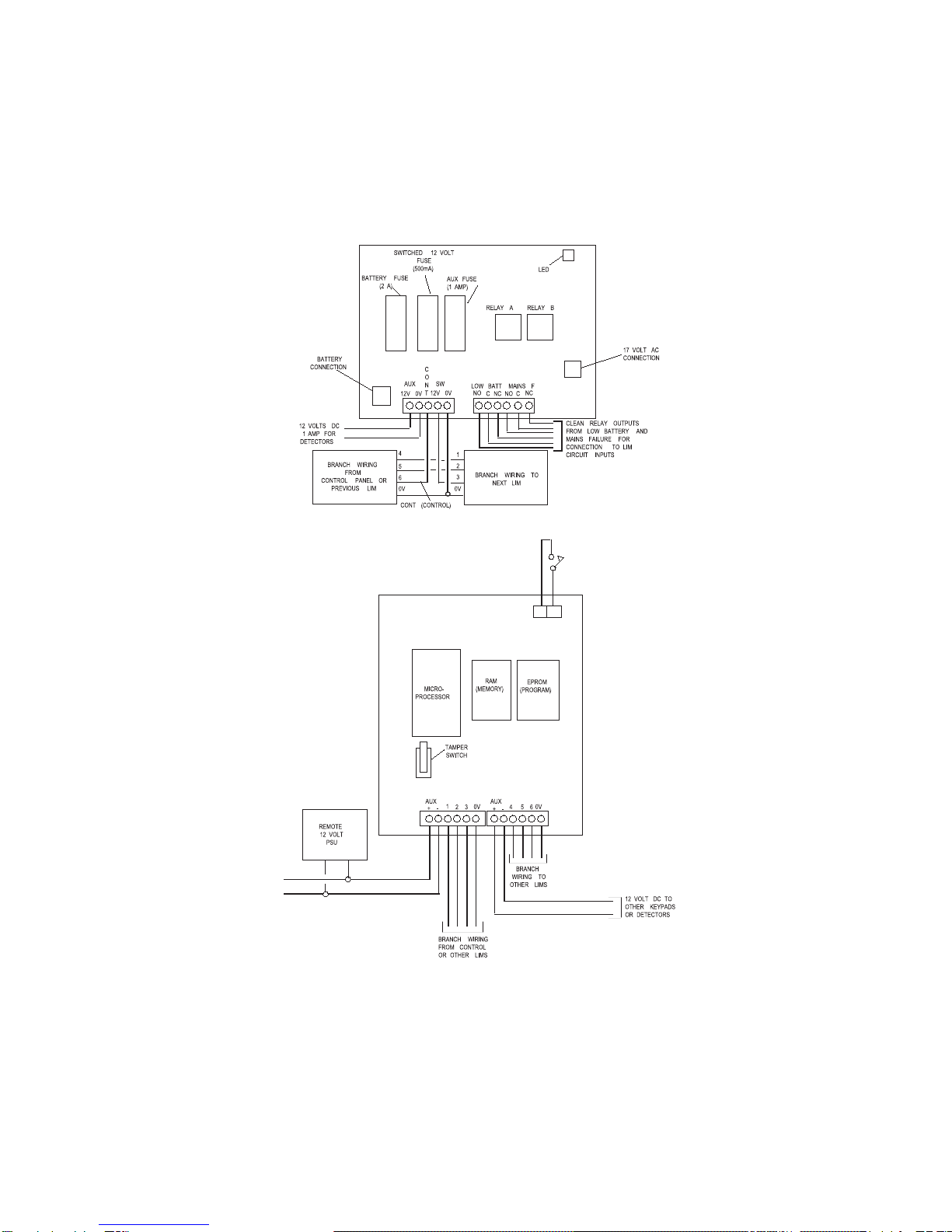

Figure 4. Standard LIM PCB

Figure 5. Connection of Shunt LIM as Single Shunt

9500 Wiring

6 of 22 496332 Issue 1

Figure 6. Connection of Shunt LIM as Multiple Shunt

Figure 7. Connection of End of Line Resistor LIM

Wiring 9500

496332 Issue 1 7 of 22

Figure 8. Remote PSU/LIM Layout and Connections

Figure 9. Remote Keypad Connections

9500 Wiring

8 of 22 496332 Issue 1

Figure 10. Wiring the Remote Keypad(s) to the Branch Loops

Figure 11. 9558 Communicator Layout and Connections

Wiring 9500

496332 Issue 1 9 of 22

Figure 12. 9576 Interface Layout

Figure 13. 9576-01 Interface Board Layout

9500 Wiring

10 of 22 496332 Issue 1

Programming

Initial Start Up

Check that all LIM box tampers are closed. Make sure that the Bell and

Strobe is not connected to the main 9500 PCB. Link out any circuits that are

nnot used.

When powering up the panel for the first time:

1. Close the control panel lid and connect the mains supply.

The display shows: <SYSTEM RESET>

12:00 16 OCT 90

Alternatingwith: 12:00 16 OCT 90

Status : Alarm

2. Key in 4567 + Enter.

The display shows: Display

customer log?

3. Press No.

The display shows: <SYSTEM RESET>

12:00 16 OCT 90

Alternatingwith: 16 OCT 12:00:00

CALL ENGINEER

4. Key in 7890 + Enter.

The display shows: Ver 4.20

14 FEB 1991

Followedby: Do you want

engineer reset?

Note: Whenever you enter engineer mode, the software version number and its date

will be displayed. Make a note of this number, as it will be useful when contact-

ing the Scantronic Product Support Department with any queries.

5. Press No.

The display shows: Do you want

test functions?

6. Press No.

The display shows: Do you want

reports?

7. Press No.

The display shows: Do you want to

program the system?

8. Open the control panel lid.

9500

496332 Issue 1 11 of 22

9. Press Yes.

You are now in Engineering Mode.

Defaults

The default Manager 1 Code is 4567 followed by ‘Enter’.

The default Engineer Code is 7890 followed by ‘Enter’.

All circuits are set to Normal Alarm, and not allocated any specific function.

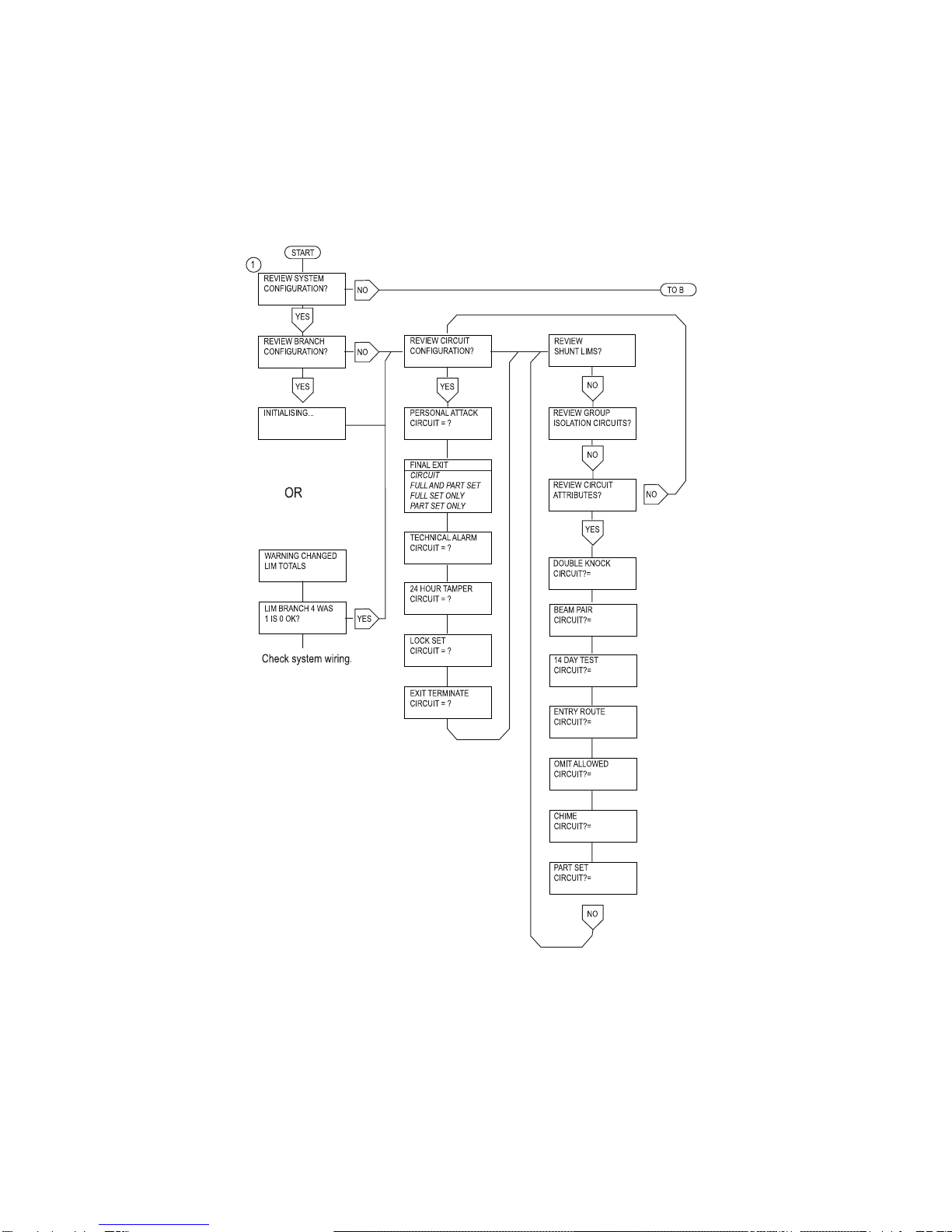

Engineering Program Commands

While programming the system, the control unit shows a series of questions

on the keypad display. Answer the questions by pressing Yes or No on the

keypad. When you respond to a question the control unit will display further

questions in order to lead you through the programming sequence.

In the first stages of programming the system there are a set of numbered

entry points that let you go directly to a specific area of programming. These

numbers are shown in the following table:

Command Keypaddisplay

1 Review system configuration?

2 Review panel controls?

3 Change engineer access code?

4 Review communications?

5 Change site location number?

6 Do you want to set the clock?

7 Do you want test functions?

8 Do you want reports?

9 Do you want engineer reset?

When programming the system for the first time, no circuits are allocated to

specific functions. On entering a function the system asks for a circuit

number. Each circuit has a unique four-digit identification number, made up

of the branch, LIM and circuit number as follows:

1st digit Branch number (1, 2, 3 or 4).

2nd and 3rd digit LIM number (01 to 16). LIMs are numbered in sequence

for each branch. The first LIM on the branch is 01.

4th digit Circuit number (1 to 5).

If you return to a function the display shows the first circuit number of those

you have already programmed. To keep that circuit press “Yes”.

If you want to return a circuit to default programming, call it to the display, key

in “0000”. The system removes that circuit from the display.

The next four pages show the programming commands in more detail.

9500 Engineering Program Commands

12 of 22 496332 Issue 1

Engineering Program Commands 9500

496332 Issue 1 13 of 22

9500 Engineering Program Commands

14 of 22 496332 Issue 1

Engineering Program Commands 9500

496332 Issue 1 15 of 22

Leaving Engineering Mode

Before leaving Engineering Mode, check that the Bell, Strobe, all detectors,

tampers etc., are connected. Also check that the 6.Ah standby battery is

connected and all lids are closed on LIMs, keypads and main control panel.

If your system is fitted with remote signalling, check that it is programmed for

‘Engineer Reset’, and proceed as follows:

The display shows: Do you want to

engineer reset?

1. Press Yes

The display shows: Branch 1

No of LIMs=5

Followedby: Branch 2

No of LIMs=7

Followedby: Branch 3

No of Lims=8

9500 Leaving Engineering Mode

16 of 22 496332 Issue 1

Followedby: Branch 4

No of LIMs=6

Followedby: Total LIMs=26

confirm: yes/no

2. EITHER Press No

The display shows: Review system

configuration

Check for system wiring faults, LIM failures etc.

See "Branch Configuration"

3. OR Press Yes

The display shows: Please wait...

testing system

Followedby: Engineer reset

all circuits OK

Followedby: 26 July 07:46:37

Status:day

You are now in customer day mode.

Re-entering Engineering Mode

1. Key in 7890 + Enter.

The display shows: Ver 4.20

14 FEB 1991

Followedby: Do you want

engineer reset?

2. Press No.

The display shows: Do you want

test functions?

3. Press No.

The display shows: Do you want

reports?

4. Press No.

The display shows: Do you want to

program the system?

5. Open the control panel lid.

6. Press Yes.

You are now in Engineering Mode.

Note: 1. If the system is in operation and has to be powered down (battery & mains)

for servicing, when powering up, the battery must be connected first.This will

Re-entering Engineering Mode 9500

496332 Issue 1 17 of 22

prevent any problems of high current being drawn which could damage the

control panel.

2. The Engineer Reset, Test Functions and Reports can be selected without

opening the control panel lid.

Refreshing The System

If the system requires all the programmed information to be deleted and

returned to the factory de-faults, it is possible to refresh the system in the

followingway.

1. Completely power down the control panel.

2. Remove the RAM chip, which is located on the main PCB and is the

centre of the three large chips.

3. Replace the chip and Power up the control panel. Reset the system and

continue to re-programme as required.

9500 LOG EVENTS

Access engineer

Tamp. panel keys Excess key presses

Fault tel line Telephone line fault (line missing)

Fault tel comm Telephone communication failure

(e.g., no reply)

Fault mains A.C. Power failure

Faultbattery

Fault aux supply Aux. 12v DC fuse blown

Fault all power Total power failure

Engineer reset

Customer reset

Set proc started Set procedure started

Walk test System walk test

Viewed ENG log Viewed engineers log

MGR 24-hr omit Manager omitted 24-hour circuits

(list follows)

-R-tamper-panel- Restore panel tamper

-R-tamper-bell- Restore bell tamper

—R-tel-line— Restore telephone line

-Mains- restored-

9500 Refreshing the System

18 of 22 496332 Issue 1

Aux-pwr-restored AUX DC Power power restored

Entry bykeypad Entry initiated at panel keypad

CUST WALK TEST

ENG WALK TEST

Changed location Site location code changed

Online print off

Fault direct line Direct line fault input tripped

Set proc aborted Setting procedure terminated

Snd/bll/strb tst Sounder bell and strobe tested

Printed ENG log

No option selctd

Reset branches

Viewed CST log

Tamper panel

Tamper bell

Printed codes

Access codes Manager modified or printed access codes

Groups isolated Always followed by a list of groups isolated

Exit fault

Date/time change (date/time is old time)

New Date/time (date/time is new time)

Personal attack

Tamp. alarm #### #### represents a circuit number

24-hr-alarm ####

Alarm PA ####

Tech alarm ####

Tamp. FE ####

Omit ####

24-hr tamp. ####

Tamper LIM ####

Omit 24-hr ####

WT tamper panel Walk test panel tamper (engineer walk test only,

printeronly)

WT tamper bell Walk test bell tamper (engineer walk test only,

printeronly)

9500 Log Events 9500

496332 Issue 1 19 of 22

WT tamper #### Walk test (engineer walk test only, printer only)

WT PA cct #### Walk test (engineer walk test only, printer only)

WT PA tamp #### Walk test (engineer walk test only, printer only)

WT FE cct #### Walk test (engineer walk test only, printer only)

WT FE tamp #### Walk test (engineer walk test only, printer only)

Wt tech cct #### Walk test (engineer walk test only, printer only)

WT tech tamp #### Walk test (engineer walk test only, printer only)

Wt 24hr cct #### Walk test (engineer walk test only, printer only)

WT 24hr tmp #### Walk test (engineer walk test only, printer only)

WT Ex Tr cct #### Walk test (engineer walk test only, printer only)

WT Ex Tr tmp #### Walk test (engineer walk test only, printer only)

WT LkSt #### Walk test (engineer walk test only, printer only)

WT LIM tmp #### Walk test (engineer walk test only, printer only)

WT circuit #### Walk test

-R-circuit #### Restore circuit ####

-R-tamper- #### Restore tamper ####

-R-PA-cct- #### Restore personal attack circuit ####

-R-PA-tmp- #### Restore personal attack tamper ####

-R-FE-cct- #### Restore final exit circuit ####

-R-FE-tamp- #### Restore final exit tamper ####

-R-Tech-cct- #### Restore technical alarm circuit ####

-R-Tech-tamp- #### Restore technical alarm tamper ####

-R-24hr-cct #### Restore 24 hour circuit ####

-R-24hr-tamp #### Restore 24 hour tamper ####

-R-ExTr-cct- #### Restore exit terminate circuit ####

-R-ExTr-tamp- #### Restore exit terminate tamper ####

-R-LkSt-cct- #### Restore lock set circuit ####

-R-LkSt-tamp- #### Restore lock set tamper ####

-R-LIM-tamper #### Restore LIM tamper ####

—FE —cct—#### Violation of final exit circuit ####

-R-DKnk-cct- #### Restore double knock circuit ####

-Tech tamper #### Violation of technical alarm tamper ####

-ExTr tamper #### Violation exit terminate tamper ####

9500 9500 Log Events

20 of 22 496332 Issue 1

-LkSt tamper #### Violation of lock set tamper ####

Entry by FE #### Entry via final exit door ####

Entry by RKP #### Entry at RKP

DKnock cct -#### Violation of double knock circuit #### (not an alarm

event)

Tamper RKP #### Violation of rkp ### back tamper, or excess

presses at RKP

Alarm ####

Tamper ####

Alarm #### (test) Circuit violation of circuit #### currently under test

-R-RKP-tamper-#### Restore RKP ### back tamper

OPR ## deleted Operator deleted from system

Duress deleted Duress code deleted from system

MGR ## deleted Manager deleted from system (not applicable to

Manager 1)

Specific LIM ### Walk test of a LIM ### (engineer walk test)

Entry alarm keys Entry alarm following entry initiated at panel keypad

Part Set System part set

Omit 24hr grp ## Omission of 24 hour groups

Access manager ##

Tamper branch # Failure of branch communications or branch

wiring fault

Alarm entry #### Entry alarm following entry at final entry circuit ####

Invalid log code Invalid entry found in log

Open Return from full set status

Day Return from part set status

Close System set

B#L=$$ B$ L=$$ Log of LIMs found on each branch (eg B1 L=10 B2

L=7)

OPR ## changed Operator code changed

Duress changed Duress code changed

MGR ## changed Manager code changed

ENG code changed Engineer code changed

LIM ### No reply LIM failed to make a valid response on three

attempts

9500 Log Events 9500

Table of contents

Popular Security System manuals by other brands

SkyLink

SkyLink FS-101 operating instructions

ERA

ERA Protect Replica Siren Installation and operating manual

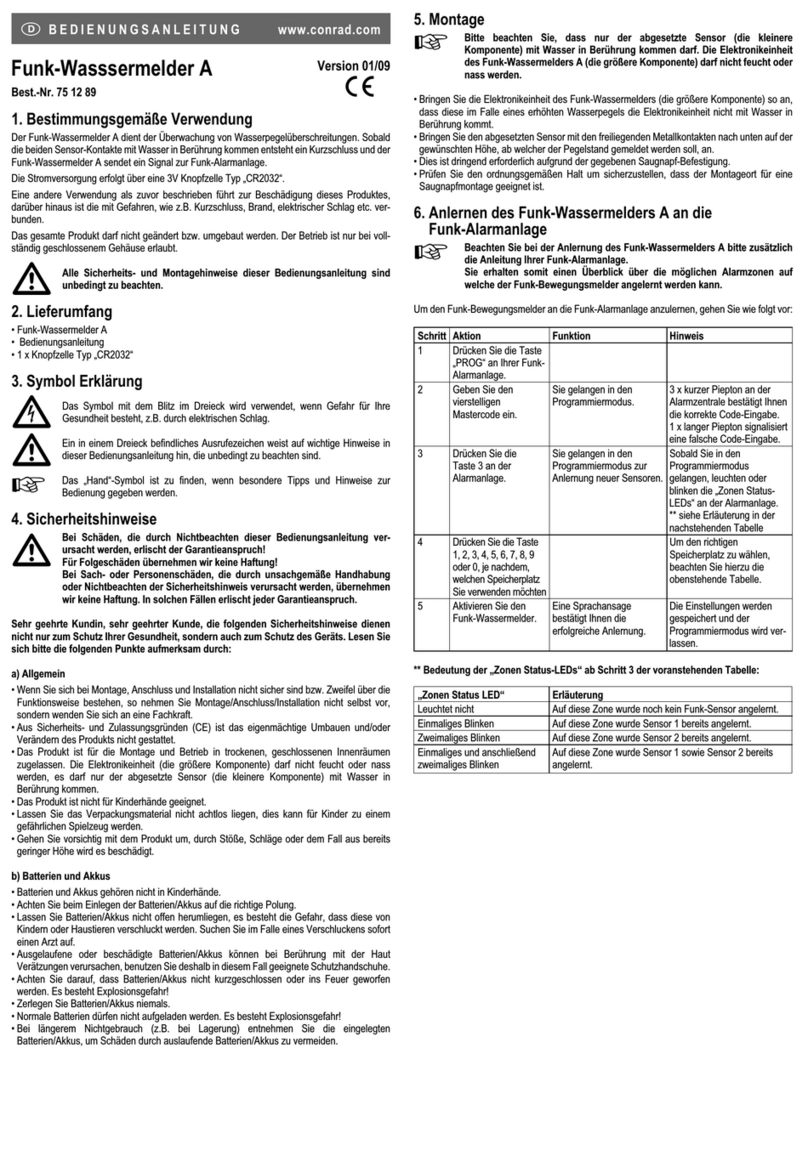

GE Security

GE Security Simon user guide

Chore-Time

Chore-Time Chore-Tronics Broadcaster Installation and Operators Instruction Manual

TeleCare24

TeleCare24 Pendant Alarm Plan user guide

GeoVision

GeoVision GV-Compact V3 user manual

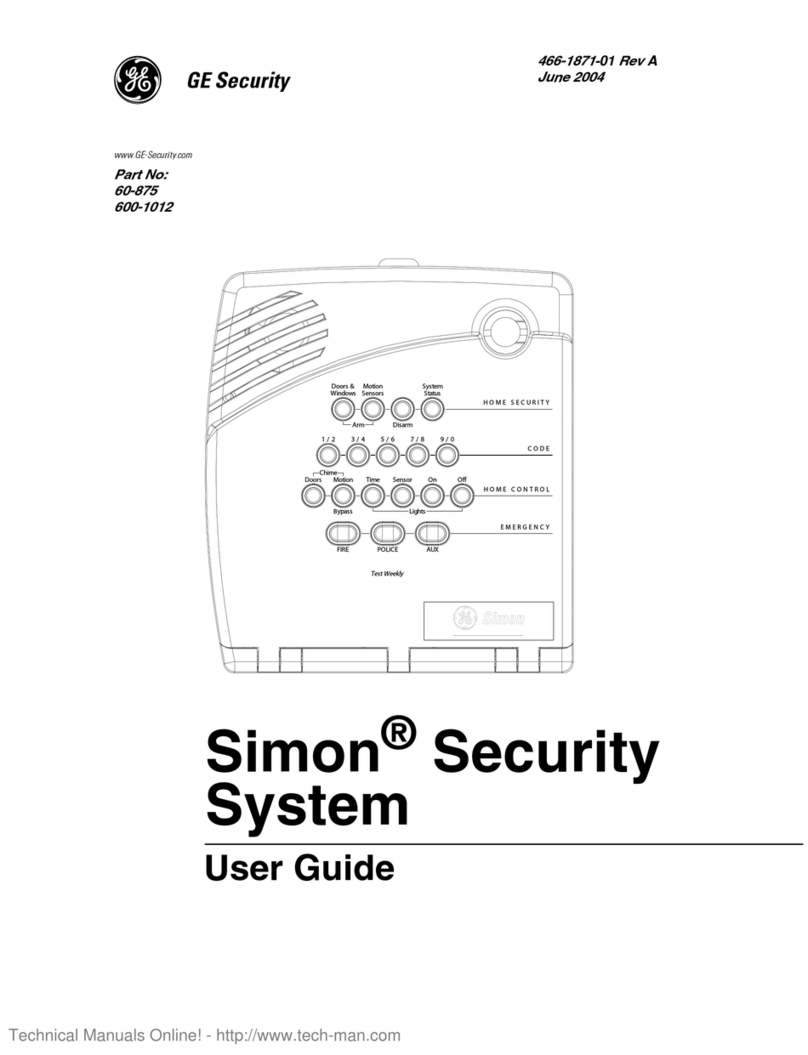

Pima Wireless

Pima Wireless alarmview+ quick start guide

Bay Alarm Medical

Bay Alarm Medical SOS Mobile user guide

DSC

DSC Power832PC5010 CP-01 installation manual

Whelen Engineering Company

Whelen Engineering Company RB6T installation guide

Scientific Atlanta

Scientific Atlanta Explorer 8300 Getting started

EPIC SAFETY

EPIC SAFETY Surf-km installation guide