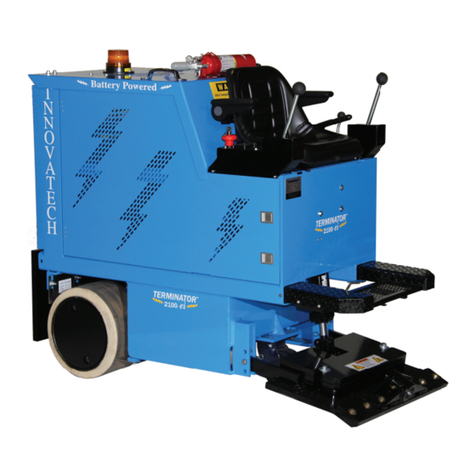

Innovatech Terminator T-2100XME User manual

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR INNOVATECH PURCHASE,

CALL 1-800-267-6682.

IN MOST CASES AN INNOVATECH REPRESENTATIVE CAN RESOLVE YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITAL TO THE SUC-

CESS OF INNOVATECH’S QUALITY IMPROVEMENT PROGRAM.

™

INSTRUCTION MANUAL

Terminator® T-2100XME

Battery Powered Floor Scraper

Manual Version 1.2 Updated 09/08/15

© Copyright 2013 Innovatech Products & Equipment Co., Everett, Washington USA. All rights reserved.

Pat. Num.: 5,641,206

SN: T2100-001-XME forward

Page 2 Innovatech Products & Equipment Co.

Table of Contents

Introduction ................................................................................................................................................ 4

About This Manual .................................................................................................................................... 4

Important Safety Instructions .................................................................................................................. 5

Safety Instructions for All Tools ....................................................................................................................................5

Additional Safety Rules for Riding Floor Scrapers .....................................................................................................6

General Operating Instructions for the Terminator® .......................................................................... 7

Safety Features .......................................................................................................................................... 7

Warning Light and Back-Up Alarm ...............................................................................................................................7

Fire Extinguisher ...........................................................................................................................................................7

Auto-stop ......................................................................................................................................................................7

Emergency Battery Disconnect ....................................................................................................................................7

Safety Instructions .........................................................................................................................................................7

Terminator® Specications ....................................................................................................................... 8

Tools & Supplies .............................................................................................................................................................8

Ventilation Requirements .......................................................................................................................... 9

Guards, Warning Notices & Signs ............................................................................................................ 9

Service Instructions & Personnel ............................................................................................................. 9

Replacement Parts & Materials ............................................................................................................... 9

Uncrating The Terminator® And Preparing It For Operation ................................................................. 10

Loading/Unloading Procedures: .............................................................................................................. 11

Operator Controls ..................................................................................................................................... 11

Drive And Blade Controls And Foot Pedal ...................................................................................................................11

Auto Stop ........................................................................................................................................................................11

Emergency Brake ...........................................................................................................................................................11

Power Limiter .................................................................................................................................................................11

Displays and Indicators ............................................................................................................................ 12

Battery Display And Hour Meter ...................................................................................................................................12

Hydraulic Oil Over Temperature Indicator ...................................................................................................................12

Hydraulic Filter Clog Indicator ......................................................................................................................................12

Manual Disconnect And Lockout .................................................................................................................................12

Electric Motor and Batteries .................................................................................................................... 12

Blade Assembly ......................................................................................................................................... 13

Taking Up Floor Coverings ............................................................................................................................................13

Page 3

Terminator T-2100XME Manual

Ballast ......................................................................................................................................................... 13

Tricycle Or Caster Wheelbase And Tires ................................................................................................. 13

Battery Safety ............................................................................................................................................ 14

Hazardous Elements ......................................................................................................................................................14

Sulfuric acid: ............................................................................................................................................................14

Explosive Gases: .......................................................................................................................................................14

Electricity: ..................................................................................................................................................................14

Weight: ......................................................................................................................................................................14

Lifting Batteries ..............................................................................................................................................................14

Wearing Protective Clothing .........................................................................................................................................15

Setting Up A Charging Area .................................................................................................................... 15

Connecting/Disconnecting Charger .............................................................................................................................15

Basic Charging Facts .....................................................................................................................................................16

The Charging Process ...................................................................................................................................................16

Temporary Storage Of Battery Pack .............................................................................................................................16

First Aid ...................................................................................................................................................... 16

First Aid for Acid Splashes ............................................................................................................................................16

Eye Wash And Emergency Shower Facilities ..............................................................................................................17

Maintenance Schedule ............................................................................................................................. 18

Warranty ..................................................................................................................................................... 20

Parts Diagrams .......................................................................................................................................... 21

Electrical Schematic ......................................................................................................................................................60

Material Safety Data Sheets (MSDS) ....................................................................................................... 62

Batteries ..........................................................................................................................................................................62

Hydraulic Oil ...................................................................................................................................................................67

Page 4 Innovatech Products & Equipment Co.

Introduction

The Terminator® Carpet and Tile Removal Machine is

intended for use on large demolition and asbestos abatement

projects as well as smaller oor covering removal jobs. De-

signed and built by experienced oor covering demolition and

installation experts, the machine incorporates several design

features that are essential for efcient operation:

• Tricycle wheelbase and short turning radius allows for better

turning ability – especially in narrow spaces.

• Blade vertical and tilt position adjustments allow for posi-

tioning the angle of the blade for each application.

• Ballast in front and rear provides extra traction needed for

tile and glue removal.

• Foot control for a very smooth start and stop.

If operated and cared for as instructed in this Manual, the Ter-

minator® provides trouble-free, safe, and efcient performance.

About This Manual

This Manual contains the information and procedures to assist

you to operate and maintain the Terminator® machine safely

and correctly. Read this Manual before you operate or service

the equipment. If you need additional information or assis-

tance, please get in touch with our Customer Service Depart-

ment:

Innovatech Products & Equipment Co.

832 80th ST. SW

Everett, WA 98203 USA

(425) 402-1881 or 800-267-6682

Fax (425) 402-8547

E-mail: [email protected]

NOTE: Throughout this Manual directional instructions (left,

right, up, down, push, pull, etc.) are given from the point of

view of the operator performing the action.

Page 5

Terminator T-2100XME Manual

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions should always be followed to reduce the risk of re, electric

shock, and personal injury, including the following:

READ ALL INSTRUCTIONS

Safety Instructions for All Tools

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING TOOLS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed from the Terminator® before turning on.

• KEEP WORK AREA CLEAN. Cluttered areas invite acci-

dents.

• KEEP CHILDREN AWAY. All visitors should be kept a safe

distance from the work area.

• WEAR PROPER APPAREL. No loose clothing, gloves,

neckties, rings, bracelets or other jewelry to get caught in

moving parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair.

• ALWAYS WEAR SAFETY GLASSES. Also use a face or

dust mask if operating in a dusty environment. All users and

bystanders must wear eye protection that conforms to ANSI

Z87.1. (CAN/CSA Z94.3)

• MAINTAIN EQUIPMENT WITH CARE. Keep equipment

clean for best and safest performance. Follow instructions

for lubrication and changing accessories.

• DISCONNECT BATTERY before servicing.

• REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure handles are centered and foot pedal is not de-

pressed before starting.

• USE RECOMMENDED ACCESSORIES. Consult the in-

struction manual for recommended accessories. The use of

improper accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the

machine is tipped or rocked.

• CHECK DAMAGED PARTS. Before further use of the

equipment, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function—check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting and any other conditions that may affect its op-

eration. A guard or other part that is damaged should be

properly repaired or replaced. Do not use tool if switch does

not turn it on and off.

• NEVER LEAVE EQUIPMENT RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave equipment until it comes

to a complete stop.

• DO NOT OPERATE ELECTRIC TOOLS NEAR FLAM-

MABLE LIQUIDS OR GASSES OR EXPLOSIVE ATMO-

SPHERES. Motors in these tools may spark and ignite

fumes.

Page 6 Innovatech Products & Equipment Co.

Additional Safety Rules for Riding Floor Scrapers

CAUTION: FAILURE TO HEED THESE WARNINGS

MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH

AND SERIOUS DAMAGE TO THE TERMINATOR®.

The Terminator® is to be operated only by qualied, trained per-

sonnel.

DON’T attempt to operate the Terminator® if you are not thor-

oughly familiar with the operation of the Terminator®.

DON’T operate the Terminator® unless every guard, warning

notice or sign is in place.

DON’T use the Terminator® on roofs or oors not designed to

carry the weight of the machine. The Terminator weighs 1,862

lbs.

DON’T attempt to operate on anything but the designated volt-

age.

DON’T operate unless all clamp handles are tight.

DON’T wedge anything against the motor fan to hold motor

shaft.

DON’T operate equipment without guards in place.

DON’T operate the Terminator® near an open flame or smoking

materials.

DON’T operate the Terminator® while under the influence of

drugs, alcohol or medication.

DON’T engage in horseplay on or near the Terminator®

DON’T stand directly behind or in front of the Terminator® when

power is enabled.

DON’T lift the hood, inspect the blade, or otherwise service or

maintain the Terminator® while power is enabled.

DON’T operate the Terminator® if the top cover is open.

DON’T overreach. Keep proper footing and balance at all times.

DON’T run the machine into piles of debris, as this may cause

the machine to become unstable and tip over.

DON’T sit on or stand next to, under or around the Terminator®

when it is being transported in a moving vehicle, whether by

itself or with other equipment.

DON’T attempt to use the Terminator® on a non-horizontal sur-

face or turn the Terminator® around on a ramp or hill.

DON’T put your hands or feet in the blade area when the Termi-

nator® is running.

DO turn the power off when not in use.

DO use personal safety equipment such as steel toe shoes,

safety glasses, gloves, and ear plugs.

DO use gloves when changing blades and removal tools. Tools

may be hot and cause burns.

DO familiarize yourself with all safety features and controls be-

fore each use.

DO use the Terminator® only for the purpose for which it was

designed. Attempting to alter the Terminator® will invalidate ap-

plicable warranties and possibly damage the machine.

DO reduce speed next to walls, machinery and other objects.

DO pre-survey the oor for cracks, ditches, trenches, electrical

outlets or bolts, which could catch the blade of the machine.

DO use the seat belt on the machine.

DO operate the Terminator at a safe speed.

Page 7

Terminator T-2100XME Manual

General Operating Instructions for the Terminator®

• The Terminator® is designed to remove carpet, tile and glue

residue from oors.

• When removing product, position removed product so it

rolls to the side of the machine or have someone on the

side of the machine remove the product. NEVER WALK IN

FRONT OF OR BEHIND THE TERMINATOR® WHILE IT IS

RUNNING.

• Sharpen blades or dice material into narrower widths if

machine slows down or seems to be struggling.

• Do not use the Terminator® within one foot of walls or sta-

tionary objects. Damage to objects may occur if the Termi-

nator® strikes them.

• Use safe, OSHA approved tools and methods for sharpen-

ing blades.

• Make sure the Terminator® has a charged re extinguisher,

working back up beacon and strobe light before operating.

Safety Features

The Terminator® is equipped with several features to help en-

sure your safety and the safety of workers around you.

Warning Light and Back-Up Alarm

An amber light is installed on the top rear section of the hood.

When the Terminator’s® ignition is in the ON position, the

warning light will ash. When the drive control is set in RE-

VERSE, the back-up alarm sounds to warn people nearby that

the machine is backing up.

Fire Extinguisher

A re extinguisher with gauge is installed on the hood behind

the operator’s seat, within the operator’s reach. As a safety

measure, regularly inspect the gauge and recharge the re

extinguisher as needed to maintain full capacity. Always re-

charge the extinguisher after each use.

Auto-stop

The Terminator® has two drive levers located to the right and

left of the operator seat and a blade height lever to the left

of the operator seat. The drive levers control the forward,

reverse, left, and right directions of the machine; the blade

height lever raises and lowers the blade. You must push

(forward) or pull (reverse) and hold the levers in position to

drive the machine or move the blade in the direction desired.

When you release a lever, the Terminator® or blade automati-

cally STOPS and will not move again until you push/pull and

hold the levers again. However, these levers are not meant as

brakes. Block wheels with a oor block when stopping on a

ramp and use the emergency brake. Without the emergency

brake the machine may roll forward or backwards on any slop-

ing surface.

Emergency Battery Disconnect

To the right side of the operator seat is a red disconnect

switch with a key. This disconnect will remove power from the

motor and other electronic components. Warning! Removing

power from the Terminator® while on a hill or ramp can lead to

a dangerous roll away situation. Always engage the parking

brake before disconnecting power.

Safety Instructions

The Terminator® is designed for safe operation by trained, des-

ignated personnel. To help ensure your safety as a designated

operator, read these safety instructions before you operate the

equipment. Regardless of your experience with machinery,

the Terminator® has unique features and systems which you

need to know about and understand before you operate or

service the machine.

Page 8 Innovatech Products & Equipment Co.

Terminator® Specications

Element English Metric

Length 53” 135cm

Width 27” 68cm

Height 45” 114cm

Weight* 1862 Lbs 844.6 Kg

Tires 15” OD x 8” W 38.1 cm OD x 20.3 cm W

Motor Voltage 48 VDC

Motor Power 10 HP 7.5 KW

Batteries 12 VDC 115AH (24 VDC 115AH Per Battery Pack)

Motor Operating Speed 0 -3600 RPM

Hydraulic Oil Type ISO 46

Hydraulic Oil Capacity 8 Gal 30.3 L

Hydraulic Relief Valve Pressure 2200 PSI 15.16 MPa

*Weight includes the base machine and 2 Rear Weight, 6 Front Weights and 2 Wheel Weights.

Tools & Supplies

Maintenance tools and supplies are not provided with the machine. You are responsible for purchase of these items. The following

are suggested items to have on the job site.

1. 4” or 7” Grinder

2. 10”-15” Crescent Wrench

3. 16-20 oz. Hammer

4. 3/8” or ½” Socket Set

5. Grease Gun

6. WD 40

7. ¾ Open End and Box Wrench

8. Screw Driver Set

9. Safety Glasses

10. Ear Plugs

Page 9

Terminator T-2100XME Manual

Ventilation Requirements

Charge the batteries only in well-ventilated areas. (See

Battery Safety section)

Guards, Warning Notices & Signs

The guards, warning notices and signs are placed on the

Terminator® for your protection. If one of them becomes dam-

aged or is lost, contact our Customer Service Department to

order a replacement.

Service Instructions & Personnel

Like other machinery, the Terminator® requires regular

inspection and maintenance of the batteries, motor, hydraulic

system and other parts. To prolong the safe and efcient op-

erating life of the machine, clean and service it as instructed in

the Maintenance section of this manual.

Always use trained personnel to service the equipment.

Never allow anyone to service the equipment that has not been

specically trained to do so.

If you need help with a service or maintenance problem, con-

tact our Customer Service Department.

Replacement Parts & Materials

The Terminator® is designed and engineered to operate safely

and efciently with the parts and materials installed on it in our

factory. To ensure the continued safe and efcient operation of

the equipment, use replacement parts and materials that meet

both of the following requirements:

• Innovatech must solely authorize replacement parts and

materials.

• Replacement parts and materials must be identical to the

items originally provided with the machine, except as autho-

rized by Innovatech.

Never use “equivalent” or substitute parts, except as expressly

authorized by Innovatech.

If you fail to adhere to these instructions, you may cause injury

to yourself and/or others, cause damage to the Terminator®,

and invalidate applicable warranties.

If you are in doubt about any replacement parts or materials,

call our Customer Service Department for assistance.

Page 10 Innovatech Products & Equipment Co.

Uncrating The Terminator® And Preparing It For

Operation

When you receive the Terminator®, inspect the outside of the

crate completely, to detect damage to the crate itself. If it is

damaged, notify the carrier immediately and follow his/her

instructions to le a claim.

Carefully uncrate the machine and inspect it for damage that

may have occurred during shipping. If the shipment is dam-

aged, notify the carrier immediately and le a claim in the

normal manner.

Check packing slip for complete shipment. If shipment is

incomplete, notify our Customer Service Department within 24

hours.

Remove the crate debris, set aside the blades and other pack-

ages, and prepare the Terminator® for operation:

Raise the hood. Inspect batteries for damage during shipment.

DO NOT MOVE THE TERMINATOR® MACHINE WITH THE

LID OPEN!

To remove the TERMINATOR® from crate:

1) Plug the battery connectors together.

2) Take 2 x 4’s off the edge of the crate and between the wheels.

3) Place 2 x 4’s behind the crate of the rear of the machine.

4) Make a ramp with the 2 x 4’s and the crate material.

5) To enable power to the TERMINATOR®, turn the key, pull up

on red knob.

6) Depress foot pedal to start motor. Lift front wheel off of the

crate 5 inches by pulling back on the valve handle. (Front blade

holder will be on crate).

7) Pull back the left and right handles evenly and depress the

foot pedal slowly. The machine will start moving slowly back-

wards.

8) Ensure that both rear wheels come off the crate evenly. Fail-

ure to back off evenly could result in the machine tipping over

and harm to the operator.

9) As machine moves back, ensure that the center wheel clears

the crate. If center wheel does not clear the crate, depress

the center handle while pressing the foot pedal until the wheel

clears the crate.

10) Once machine is on the ramp, slide all the way to the bot-

tom, then lift jaw up and set center wheel down to the ground.

11) Whenever mounting or dismounting the TERMINATOR®,

ALWAYS disable the power by pressing down on the red power

knob.

Page 11

Terminator T-2100XME Manual

Loading/Unloading Procedures:

• Do not load or unload the Terminator® on uneven ground.

• Ensure ramps into moving vehicles are stable and square to

the ground.

• Always turn the Terminator® OFF when you transport the

Terminator® by forklift or other vehicle.

• Load and unload the machine with a properly weighted fork-

lift or lift-gate.

• Make sure all safety stops are installed on a lift-gate before

loading or unloading.

• Never position yourself under or around the machine while

moving it with other machinery.

• Park the machine with the blade completely down after

loading.

• Properly secure the machine with chains, tire chocks, and

other necessary tie downs.

• Never ride in a moving vehicle next to a Terminator®. It may

tip, causing severe injury.

Operator Controls

The operator controls consist of the drive and blade height le-

vers, foot pedal, manual disconnect, and a power limiting.

Drive And Blade Controls And Foot Pedal

The drive and blade controls (three levers) are located to the left

and right of the operator seat. The drive levers (left and right)

control the direction of rotation of the rear wheels. The blade

height lever controls the vertical position of the blade. The foot

pedal controls the speed of the hydraulic pump. The levers

only work when the foot pedal is partially depressed and the

pump is running. Operation of the drive levers is as follows.

From the view of the seated operator:

Push the left and right levers forward together and hold them

in position then slowly depress the foot pedal to move the ma-

chine forward.

Pull the left and right levers back together and hold them in po-

sition then slowly depress the foot pedal to move the machine

in reverse. (The alarm sounds.)

Push only the left lever forward to turn the machine to the right.

Push only the right lever forward to turn the machine to the left.

To adjust the blade down, push and hold blade lever forward

and press the foot pedal to move the blade down. To adjust the

blade up, pull and hold the blade lever back and press the foot

pedal to move the blade up.

Auto Stop

When you release the drive or blade lever, the motor continues

to run (with foot control depressed) but the drive or blade mo-

tion automatically stops and will not start again until you push

or pull the levers again.

Emergency Brake

The Terminator® is supplied with an emergency brake to prevent

unintended movement when left unattended. The brake handle

is located to the left of the operator seat. Pull the handle up to

engage the brake, push the handle down to release the brake.

To increase tension on the brake you can rotate the end of the

handle in a clockwise direction. Rotate the end of the handle

counter clockwise to reduce the tension.

Power Limiter

The power limiter allows the top output speed to be set from

70% to 100%. This will allow you to conserve power during

normal operation when top speed is not required. (Increasing

motor power will reduce the run time of the machine)

Page 12 Innovatech Products & Equipment Co.

Manual Disconnect And Lockout

The manual disconnect is located to the right side of the op-

erator seat. To enable operation of the Terminator® unlock the

manual disconnect lock and pull up. In case of emergency push

down to remove power from all electrical components. Always

push down this switch to OFF when the Terminator® is not in

use.

Electric Motor and Batteries

The electric motor and batteries are located under the top

cover. The electric motor provides the power to the hydraulic

pump to drive the Terminator®.

The electric motor requires little maintenance, inspect wire

connections and check for debris to maintain its efciency and

prolong its operating life.

Battery life can be ensured by proper periodic maintenance.

Batteries should be charged before placing the Terminator®

into long term storage. The stored battery should be charged

monthly when not in use to prolong battery life.

Displays and Indicators

Battery Display And Hour Meter

The battery display shows pump use time, key power time and

battery life. (When the last box starts to blink, you have about

15 minutes before battery power is exhausted.)

Hydraulic Oil Over Temperature Indicator

Normal temperatures are below 120°F. Do not allow the hydrau-

lic uid to exceed 200°F because it may damage the hydraulic

system and in turn, damage the Terminator®. If the indicator

light is continually coming on, turn machine off and let it cool

for 45-60 minutes. If the light regularly turns on, call Innovatech

Service Department.

Hydraulic Filter Clog Indicator

The hydraulic oil lter is equipped with a clog indicator which

will illuminate when the hydraulic oil lter is clogged. (Note: The

indicator may also inadvertently come on in cases when the

hydraulic oil is very cold, the light will stop illuminating once the

hydraulic oils has warmed to normal operating temperature.)

Page 13

Terminator T-2100XME Manual

Blade Assembly

Blades are available in different congurations and thickness.

An assortment of blades is included in the purchase price of

the Terminator®. Extra blades are available upon request from

Innovatech Products & Equipment Co., Inc.

Installing a Blade

1.) Raise the blade assembly to maximum up position,

which is ve inches off the oor.

2.) Unwrap the pre-sharpened blades and select the blade

thickness and length you need for the job.

3.) Loosen the 7 holding bolts.

4.) Insert the sharpened blade.

5.) Tighten bolts rmly, starting from the center and working

out. Bolts should be snug but not over tightened.

Taking Up Floor Coverings

1.) Insert blade. (As explained above)

2.) Lower blade to oor. Lift caster wheel off the oor ¼

inch. Use previous procedures to drive forward.

3.) As the Terminator® is removing ooring material, it is

recommended to have another person at the side of the ma-

chine remove all debris.

Ballast

The Terminator® is equipped with weights in front (25 pounds

each) and rear (72 pounds each) to provide traction for tough

jobs. These weights can be removed to reduce traction for

certain jobs, and to transport the Terminator® by forklift or truck

or elevator. Wear gloves when handling these weights. Use

caution to not smash toes and ngers. Use OSHA approved

lifting techniques.

Tricycle Or Caster Wheelbase And Tires

The tricycle wheelbase allows better turning ability. The wheel

bearings on the front caster roller require lubrication with grease

every 30 hours of machine operation. There are three ttings,

two on the wheel and one on the housing. When running over

debris such as carpet, the carpet yarn will get caught between

the wheel and the housing. Clean out wheel and housing regu-

larly.

The rear tires are solid rubber, tubeless, and require no mainte-

nance. Over time, they may wear out and need to be replaced.

Before each job, inspect the rear tires and lug bolts. Tighten the

lug bolts as needed to 70 foot-pounds torque. It is important to

keep the lug bolts tight.

Wheel hub should be tightened from 310 to 350 ft.-lbs. Inspect

and re-torque every 100 hours of operation. Lift machine off of

oor so no weight is on wheel when re-torquing pack nut.

Page 14 Innovatech Products & Equipment Co.

Battery Safety

Receiving the Terminator®

After receiving the Terminator®, examine the covers and battery

catch tray for signs of damage. Attention should be given to

the crate and pallet of the Terminator® when it arrives for any

damage that may have happened during shipment. If you see

any dented or crushed housing parts contact Innovatech for

procedures to repair shipping damage. If you see wet areas, the

batteries may have been damaged during shipping.

Only trained or authorized personnel should change, repair or

charge batteries.

When used properly, a lead-acid motive power battery is a safe,

dependable source of electrical power. However, if proper care

and safety precautions are not exercised when handling a bat-

tery, it can be an extremely dangerous piece of equipment.

There are four hazardous elements in a lead-acid battery.

1. Sulfuric acid

2. Explosive gases

3. Electricity

4. Weight

Hazardous Elements

Sulfuric acid:

Although the T-2100XME is supplied with sealed, absorbed

electrolyte batteries there is a potential for leakage of acid in

catastrophic damage situations. The electrolyte in a lead-acid

storage battery is a diluted solution of water and sulfuric acid.

Although the acid content in the solution is only about 37%, it

is still a strong corrosive agent and can burn skin and eyes as

well as devour many types of fabric. (See Wearing Protective

Clothing.)

Explosive Gases:

When a lead-acid battery is being charged, it produces a small

explosive mixture of hydrogen and oxygen gases. Never

smoke, use an open ame or create an arc or sparks on or near

a battery without rst eliminating explosive gases from the cells

you are working on.

(See Setting Up Charging Area Section Below)

Electricity:

An electrical shock hazard exists for any person who comes in

contact with a battery over 50 volts, this is one of the reasons

that the Terminator 2100XME battery pack has been limited

to 48 volts for maximum power potential as well as maximum

safety. In addition, metallic objects coming in contact with ex-

posed cell connectors will cause a short circuit resulting in the

metallic object heating up to a high temperature. Even shorts

involving a single cell can become hot enough to cause severe

burns. Any tools used on or around the Terminator 2100XME

should be covered with a plastic coating or heat shrink.

Weight:

The Terminator® 2100XME has 2 battery packs weighting up to

180 pounds. It can cause serious injury if it is not handled care-

fully during installation, removal or transport. Use proper lifting

equipment and techniques at all times. It is recommended to

have 2 people remove and install the battery packs.

Lifting Batteries

Always use proper lifting equipment to reduce the risk of battery

damage, shorting and possible injury. An insulated lifting device

used with an overhead hoist is the safest way to move a battery.

Chain hoists used to handle batteries should be equipped with

a non-metallic container or bucket to prevent the chains from

dangling and possibly causing a short by coming in contact

Page 15

Terminator T-2100XME Manual

with exposed cell connectors on the battery top.

Never lift batteries by the inter-cell connecting cables. Con-

nectors on these cables are designed for maximum current

ow and not strength. The connectors will suddenly come

apart while the battery is in midair. Connect lifting device to

negative terminal only if there is not a lifting strap in place.

Lifting by both terminals could cause the negative and positive

terminals to be shorted together.

Wearing Protective Clothing

When working on or near batteries, always wear proper protec-

tive clothes including a face shield, safety glasses, long sleeved

shirt, and acid-resistant gloves. Do not wear any metal jewelry

including rings, as they can short circuit a battery and become

extremely hot if it accidentally contacts exposed inter-cell con-

nectors.

Setting Up A Charging Area

All owners of the Terminator® 2100XME need to designate a

charging area, to charge the battery pack at the end of a work-

day or while storing the Terminator®.

This area should have all the proper battery handling equip-

ment. The area needs to be well ventilated even when the bat-

tery is only being trickle charged.

Ventilation is considered satisfactory if the hydrogen concen-

tration does not exceed 1.5% - 2% in any one location. Con-

centrations of more than 4% are explosive and dangerous.

A prominent NO SMOKING sign should be posted as a remind-

er.

Factors for determining proper ventilation include the number

of Terminator® 2100XME machines or other battery operated

machinery such as forklifts that are stored in the location, as

well as the size, height and air-tightness of the storage location.

A number of instruments, such as combustible gas indicators

and ammable vapor indicators, are available for continuous

and automatic analysis of hydrogen content in the air. A oor

standing fan or box fan will help signicantly to disperse off

gassing.

A source of running water nearby is desirable. A water hose is

recommended at the charging and lling station.

The oor in the battery charging and lling area should have an

acid resistant coating and able to be washed down with clean

water after a spill. The spill should be neutralized with Baking

Soda or Soda Ash before it is cleaned up. While Soda Ash is

relatively safe to handle, being very similar to Bicarbonate of

Soda, both of these chemicals will react with sulfuric acid to

produce Carbon Dioxide, which is a gas that is heavier then air

and tends to collect in low places if not ventilated properly.

Carbon Dioxide is a non-toxic gas normally present in the air,

which can reduce the oxygen content of the air from the normal

21% by dilution or displacement. Air containing 16% or less

oxygen may cause injury or even death to a person breathing

in such an environment. While good ventilation will control the

carbon dioxide hazard in open spaces, extra special care must

be taken when neutralizing signicant quantities of sulfuric acid

in closed areas with the above type of chemical.

Lime, caustic soda and ammonia or ammonium hydroxide do

not release carbon dioxide when neutralizing sulfuric acid but

are very strong chemicals themselves and should ONLY be

used by qualied, chemically trained individuals.

Connecting/Disconnecting Charger

Always turn the charger off at the charging unit before con-

necting or disconnecting the battery charger leads. The Battery

Connectors in the battery compartment are shipped in a dis-

connected state; this connector will have to be plugged in order

Page 16 Innovatech Products & Equipment Co.

to operate the Terminator® 2100XME.

It is also good practice to leave this main power connector un-

plugged during storage.

Live leads can cause arcing and sparks which could cause an

explosion if battery gases are present, please check that the

main contactor/disconnector is not in the on position when you

connect or disconnect the battery terminal plug. In addition, the

battery connector terminals will became pitted over time result-

ing in poor connections and increased heat generation in the

battery leads and connectors.

Basic Charging Facts

• Proper charging is essential for maximum battery life.

• In general, the proper charging rate is any rate that does not

produce a battery temperature higher than 115F or 46C, and

or does not produce excessive gassing.

* The Terminator® 2100XME is supplied with a QuiQ 18 Amp

charging unit, which has been sized to give optimum charging

time without causing excessive heating or off gassing.

* Do not use a 12v battery charger on the Terminator® 2100XME

battery pack this will cause damage to the charger as well as

the battery pack.

* When a discharged battery is initially placed on charge, it will

draw a current equal to or close to the chargers maximum out-

put. As the battery voltage rises back to its rated voltage the

chargers output will adjust down automatically to assure a safe,

efcient charging rate during all stages of the charge

* The QuiQ Charger is designed to start and stop so as not

to under or over charge the battery pack. The “smart” charger

has a computerized control unit, which can determine when the

battery is fully charged and then automatically end the charge

cycle.

Standard Re-charge: After a battery has undergone a normal full

shift and has been fully or partially discharged, it must undergo

a standard charge. Normally a standard recharge is based on

an 8-hour charging cycle.

The Charging Process

During the charging process, the sulfate (from the sulfuric acid)

in the battery lead plates, which is accumulated during the dis-

charge and use process, is driven back into the electrolyte. This

increases the specic gravity and brings the on-charge volt-

ages up to 2.50-2.75V per cell depending on the battery age.

Temporary Storage Of Battery Pack

When the battery pack is fully charged the Terminator® 2100XME

can be stored for up to a year. It should be stored in a cool dry,

well-ventilated area away from direct sunlight. If a battery pack

needs to be stored for several months or longer, a refreshing

charge should be performed prior to its stored. If the average

storage temperature is below 68°F (20°C), check the batteries

at least once every two months. If the average temperature is

above 68°F (20°C) check it every month

To obtain maximum service life from your battery pack, care

should be taken to not operate the battery pack over 115° F

(46°C) as well as not to run the battery pack below 80% of nom-

inal voltage. (The controller onboard the Terminator® 2100XME

will shut the power down if this limit is reached).

First Aid

First Aid for Acid Splashes

Eyes: Flush immediately with gently running water for at least

15 minutes, then see a doctor as quickly as possible. For con-

tact lens wearers, remove the lens before the eyes are ushed.

A buffering or neutralizing agent should not be used in the eyes

Page 17

Terminator T-2100XME Manual

without the approval of medical or safety personnel.

Skin: Wash affected areas under running water and apply a

chemical burn treatment.

Severe burns require immediate medical attention.

Clothing: If large areas of clothing have been splashed or

soaked, the clothing must be removed and the acid must be

neutralized with a baking soda or soda ash solution, and then

rinsed under running water. If the clothing is rinsed quickly

enough, the chances of damage to the material are lessened.

Acid-resistant boots should always be checked before wearing,

for any acid puddles that may have formed inside the boot.

Eye Wash And Emergency Shower Facilities

Emergency eyewash and acid neutralization facilities should be

located in the immediate work area for easy access. The three

most popular types of eyewash and acid neutralizing equip-

ment are the chemical burn stations, deluge shower and eye

wash fountains.

1. A chemical burn station is the most commonly used type

in small battery charging and repair areas. The station consists

of a wall mounted plastic squeeze bottle that contains a buffer-

ing solution for treating acid burns on skin, eyes and clothing.

This inexpensive equipment is practical for personnel protec-

tion while working on the Terminator® 2100XME battery pack.

2. A Deluge Shower should be used where high specic

gravity acid (above 1.400) is handled. The Terminator® 2100XME

does not use this high of a specic gravity concentration. This

type of wash station is only really needed at a battery repair

center.

3. An eye wash fountain is permanently hooked up to a wa-

ter supply and is usually wall mounted. This is recommended

equipment if possible.

Page 18 Innovatech Products & Equipment Co.

Maintenance Schedule

Procedure / Hours 50 100 150 200 250 300 350 400 450 500 600

Check Hydraulic Oil Level • • • • • • • • • • •

Change Hydraulic Oil Filter • • • • • •

Change Hydraulic Oil • •

Check Brake Pad Wear • • • • • •

Adjust Emergency Brake as needed • • • • • •

Replace Brake Pads •

Re-torque Wheel Lugs • • • • • •

Re-torque Pack Nuts • • • • • •

Adjust Wheel Scrapers • • • • • •

Grease Caster Wheel • • • • • •

Replace Motor Brushes •

Page 19

Terminator T-2100XME Manual

Page 20 Innovatech Products & Equipment Co.

Warranty

Innovatech warrants to the original buyer, for a period of one (1) year or 300 operating hours (whichever comes rst) from the date of delivery,

that Equipment is free from defects in materials and workmanship and that the Equipment conforms to the operating specications supplied

with the Equipment. The foregoing warranty is subject to proper operation and maintenance of the Equipment in accordance with the operat-

ing instruction and manual supplied to Buyer with the Equipment.

Warranty claims shall be made by Buyer in writing. Innovatech’s sole obligation under the foregoing warranty, where it appears to Innovatech’s

satisfaction that the defect was present at the time of delivery, is at Innovatech’s sole option, to repair, replace or correct any such defect.

EXCEPT AS STATED ABOVE THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED. INNOVATECH EXPRESSLY DISCLAIMS ANY WARRAN-

TY, EXPRESS OR IMPLIED, THAT EQUIPMENT SOLD HEREUNDER IS OF MERCHANTABLE QUALITY OR THAT IT CAN BE USED FOR OR IS

FIT FOR ANY PARTICULAR PURPOSE. ANY DESCRIPTION OF THE EQUIPMENT IN THIS AGREEMENT OR IN MANUALS, BROCHURES OR

LITERATURE AND ANY USE OF ANY SAMPLE, MODEL OR PROTOTYPE OF THE EQUIPMENT IS FOR THE SOLE PURPOSE OF IDENTIFY-

ING OR ILLUSTRATING THE EQUIPMENT, IS NOT PART OF THE BASIS OF THE AGREEMENT BETWEEN INNOVATECH AND BUYER, AND

DOES NOT CONSTITUTE A WARRANTY THAT THE EQUIPMENT, AS SUPPLIED, WILL CONFORM TO ANY DESCRIPTION OR TO ANY SAM-

PLE, MODEL OR PROTOTYPE. INNOVATECH DISCLAIMS ANY WARRANTY RESPECTING OPERATING CAPACITY OR CAPABILITY OF THE

EQUIPMENT OR THE ABILITY OF THE EQUIPMENT TO MEET ANY PARTICULAR NEEDS OF THE BUYER. THE EQUIPMENT IS POWERED

TO OPERATE AS STATED IN THE OPERATING SPECIFICATIONS SUPPLIED WITH THE EQUIPMENT BUT IT IS UNDERSTOOD AND AGREED

TO BUY BUYER THAT ACTUAL OPERATING CAPABILITIES VARY UNDER DIFFERENT OPERATING CONDITIONS FOR WHICH INNOVATECH

CAN ASSUME NO RESPONSIBILITY.

BUYER’S EXCLUSIVE REMEDY FOR CLAIMS ARISING UNDER THIS AGREEMENT SHALL BE FOR REPAIR OR, AT INNOVATECH’S SOLE

OPTION, REPLACEMENT OF ANY ITEM OF DEFECTIVE EQUIPMENT. INNOVATECH’S LIABILITY FOR ANY LOSSES OR DAMAGE, WHETH-

ER ON ACCOUNT OF NEGLIGENCE, BREACH, WARRANTY OR OTHERWISE SHALL IN NO EVENT EXCEED THE PURCHASE PRICE OF

THE PARTICULAR ITEM OF EQUIPMENT WITH RESPECT TO WHICH SUCH LOSSES OR DAMAGE OCCURRED. IN NO EVENT WILL IN-

NOVATECH BE LIABLE FOR ANY DAMAGES CAUSED BY BUYER’S FAILURE TO PERFORM BUYER’S RESPONSIBILITIES, OR FOR ANY

LOST PROFITS, LOST PRODUCTION, LOSS OF ANTICIPATED PROFITS OF OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN

IF INNOVATECH HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO EVENT WILL INNOVATECH BE LIABLE FOR ANY

DAMAGES RESULTING FROM ANY CLAIM AGAINST BUYER BY ANY OTHER PARTY.

FACTORY SERVICE

A warranty will not be valid unless a written claim authorization comes with returned parts. Innovatech will not provide for any shipping

costs for items returned for repair. To obtain warranty repairs, buyer must prepay shipment and return all warranty parts to Innovatech. Dam-

age occurring during shipment is deemed the responsibility of the carrier and claims should be made directly with such carrier.

It will be the customer’s responsibility to pay for any non-warranty replacement parts plus the current hourly labor rates for any work

done on any machine or part. Service is available upon request; call Innovatech for current labor rates.

Table of contents

Other Innovatech Power Tools manuals